3

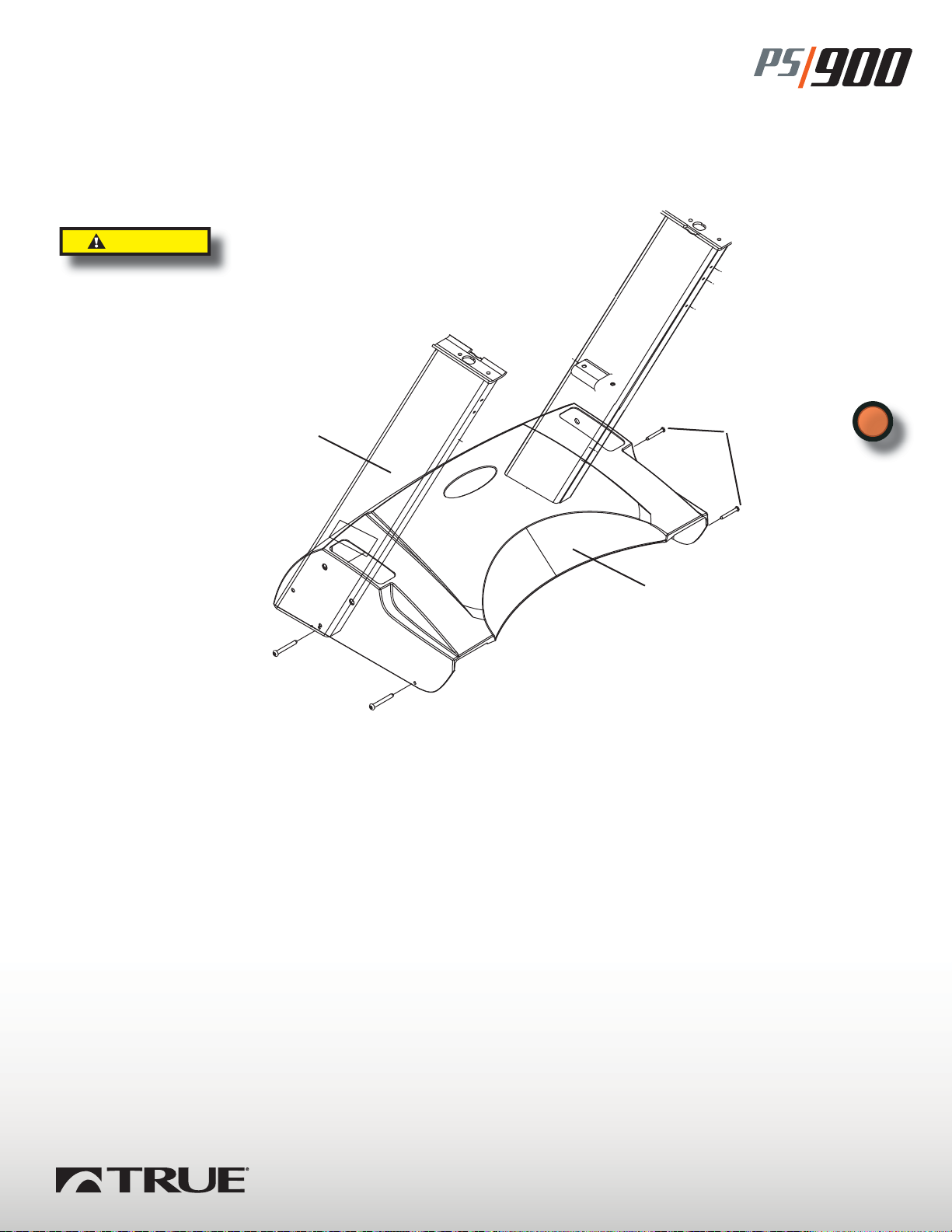

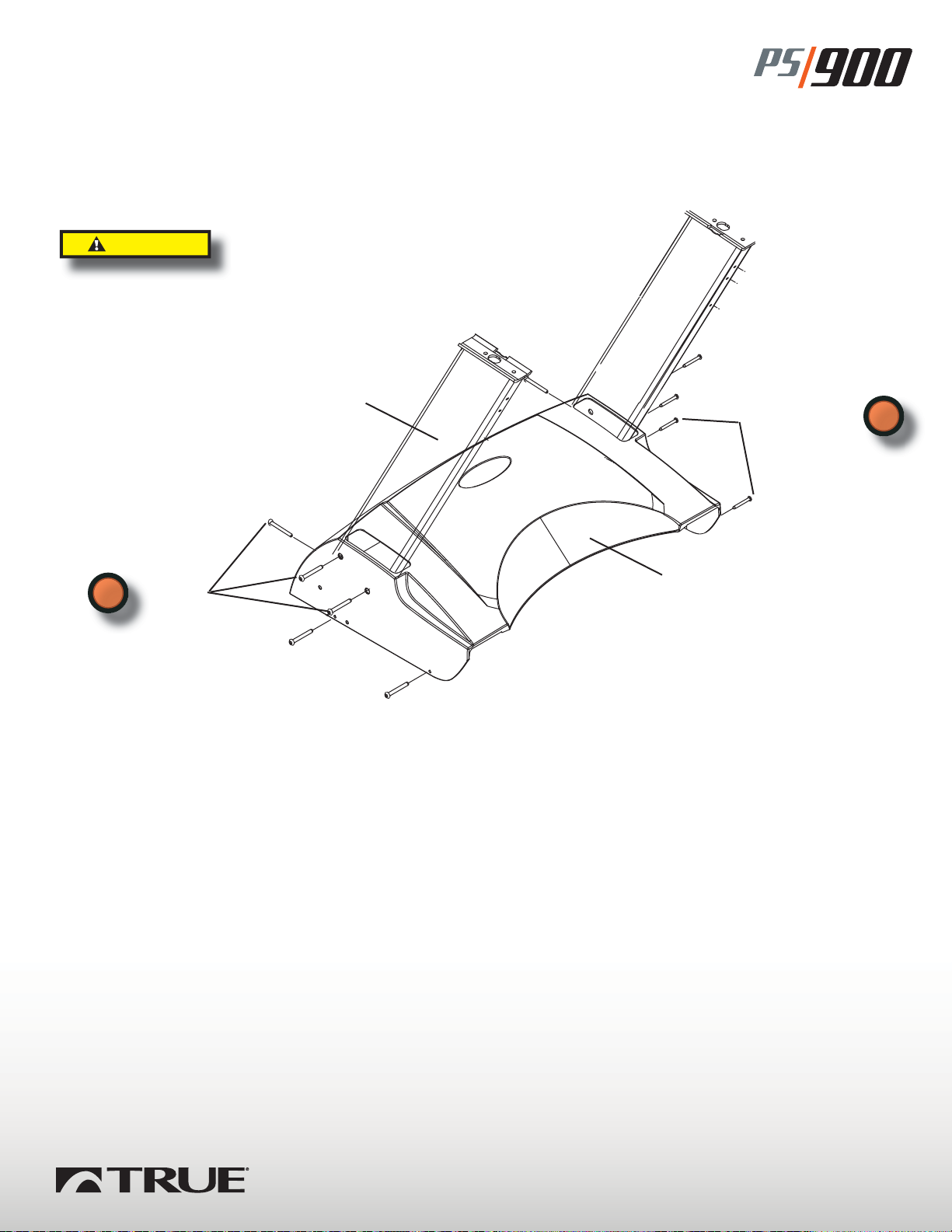

SAFETY INFORMATION

This TRUE Fitness Technology Inc. equipment contains hazardous voltages and high speed moving parts.

Contact with these hazards may damage equipment and could potentially cause serious injury or even

death.

Only qualified personnel, (as outlined below), should install, operate and maintain this equipment.

Always properly ground equipment and lock out electric power (de-energize) before maintenance (unless

instructed to power equipment as part of a test procedure or an electrical check). TRUE recommends the

use of safety glasses when servicing equipment.

Using non-specified / unauthorized parts or components to repair equipment, or tampering with safety

devices/systems will result in dangerous conditions which can potentially cause damage to equipment,

severe personal injury or even death. Take note of and follow all safety instructions contained in this

manual.

This service manual does not claim to cover all detail or variations in TRUE Fitness equipment, nor

does it provide for all possible conditions encountered while installing, operating or maintaining this

equipment. If further information is desired or needed to address any particular installation, operation

or maintenance problem not covered in this document, contact your authorized factory representative at

800-883-8783.

(Exercise good judgment in selecting the appropriate tools for each repair application).

NOTE: It is the policy of TRUE Fitness Technology Inc. to continuously work toward product improvement.

We reserve the right to change product design and specifications without notice. Specifications within

this manual are subject to change without notice.