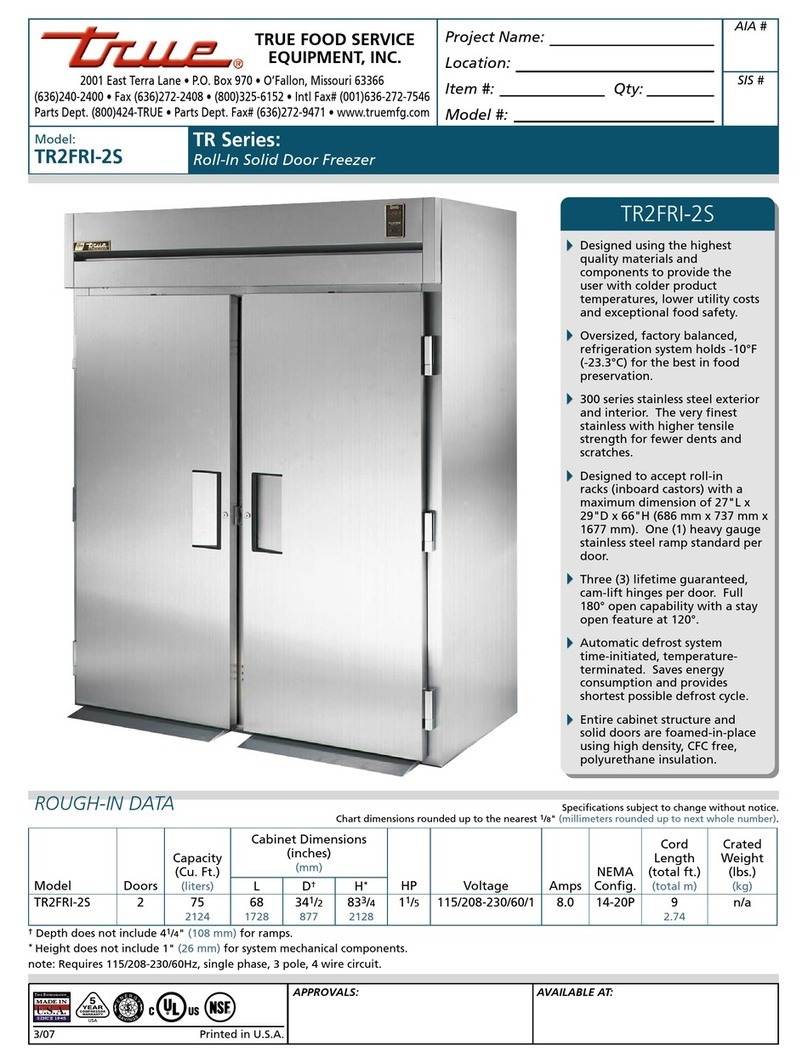

STANDARD FEATURES

Model:

TRUE FOOD SERVICE EQUIPMENT

2001 East Terra Lane • P.O. Box 970 • O’Fallon, Missouri 63366 • (636)240-2400 • Fax (636)272-2408 • (800)325-6152 • Intl. Fax# (001)636-272-7546 • www.truemfg.com

WARRANTY

One year warranty on all parts

and labor and an additional 4

year warranty on compressor.

(U.S.A. only)

METRIC DIMENSIONS ROUNDED UP TO THE

NEAREST WHOLE MILLIMETER

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

Model Elevation Right Plan 3D

PLAN VIEW

KCL

TG1FRI-1S TFQY51E TFQY64S TFQY51P TFQY643

TG1FRI-1S

DESIGN

• True’s solid door roll-in’s are designed

with enduring quality that protects your

long term investment.

• Designed using the highest quality

materials and components to provide the

user with colder product temperatures,

lower utility costs and exceptional food

safety.

REFRIGERATION SYSTEM

• Factory engineered, self-contained,

capillary tube system using

environmentally friendly (CFC free) 404A

refrigerant.

• Extra large evaporator coil balanced

with higher horsepower compressor and

large condenser maintains -10°F (-23.3°C)

cabinet temperature.

• Sealed, cast iron, self-lubricating

evaporator fan motor(s) and larger fan

blades give True roll-in’s a more efficient

low velocity, high volume airflow

design. This unique design ensures

faster temperature recovery and shorter

run times in the busiest of foodservice

environments.

• Top mounted refrigeration system with

evaporator positioned out of food zone

to maximize capacity.

• Automatic defrost system time-initiated,

temperature-terminated. Saves energy

consumption and provides shortest

possible defrost cycle.

• Automatic evaporator fan motor delay

during defrost cycle.

CABINET CONSTRUCTION

• Exterior - 300 series stainless steel

door and rainshield. Anodized quality

aluminum sides, back and bottom.

• Interior - NSF approved white aluminum

sides walls and back liner. 300 series

stainless floor with coved corners.

• Insulation - entire cabinet structure and

solid door are foamed-in-place using

high density, CFC free, polyurethane

insulation.

• One (1) heavy gauge stainless steel ramp.

• Designed to accept roll-in racks (inboard

castors) with maximum dimensions of

27"L x 29"D x 66"H (686 mm x 737 mm x

1677 mm).

DOOR

• 300 series stainless steel. Door opens

within cabinet dimension.

• Door lock standard.

• Lifetime guaranteed recessed door

handle. Door fitted with 12" (305 mm)

long recessed handle that is foamed-

in-place with a sheet metal interlock to

ensure permanent attachment.

• Wiper gaskets for positive seal, reversible.

• Three (3) lifetime guaranteed, cam-lift

hinges. Full 180° open capability with a

stay open feature at 120°.

• Magnetic door gasket of one piece

construction, removable without tools for

ease of cleaning.

• Door is field reversible.

LIGHTING

• Incandescent interior lighting, safety

shielded.

MODEL FEATURES

• Exterior digital temperature display,

available with either °F or °C display.

• Evaporator epoxy coated to eliminate the

potential of corrosion.

• Backguard improves airflow.

• Minimum wattage heater in cabinet

frame.

• Interior bumpers protect cabinet walls

from abuse caused by roll-in carts.

• NSF-7 compliant for open food product.

ELECTRICAL

• Unit completely pre-wired at factory and

ready for final connection to a 115/60/1

phase - 15 amp dedicated outlet. Cord

and plug set included.

OPTIONAL FEATURES/ACCESSORIES

Upcharge and lead times may apply.

❒ Metal door handle (factory installed).

❒ Electronic temperature control (factory

installed).

❒ Correctional facilities options.

❒ Remote cabinets (condensing unit

supplied by others; system comes

standard with 404A expansion valve and

requires R404A refrigerant). Consult

factory technical service department for

BTU information.

TG Series:

Roll-In Solid Door Freezer

ELEVATION PLAN VIEW

833/4"

(2128 mm)

843/4"

(2153 mm)

347/16"

(875 mm)

30"

(762 mm)

647/16"

(1637 mm)

35"

(889 mm)

1"

(26 mm)

RIGHT VIEW

3811/16"

(983 mm)

41/4"

(108 mm)

115/60/1

NEMA-5-15R