TRUE RESIDENTIAL®TEC_TM_151 | REV. A | EN07/28/2021Page 6 of 48

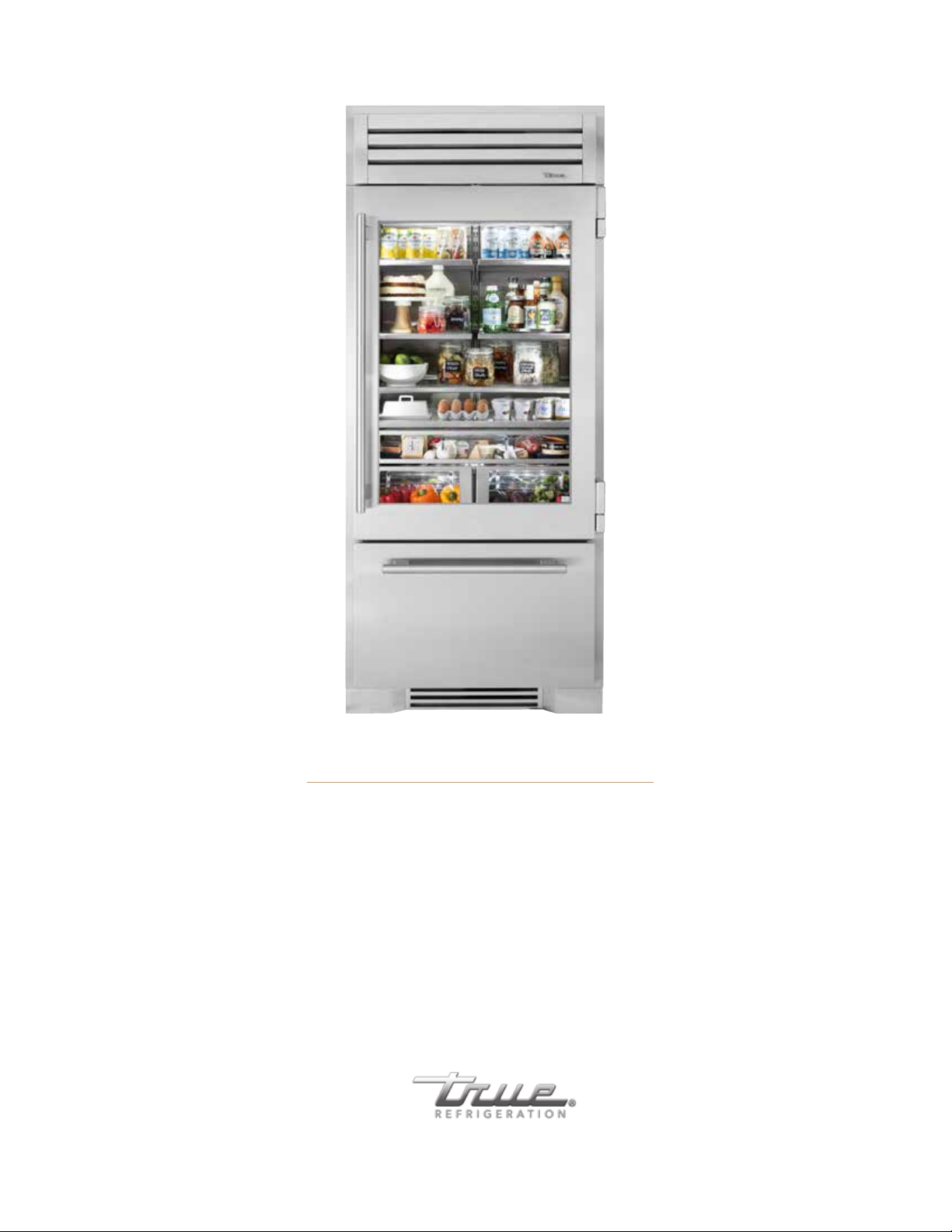

You have selected one of the finest commercial

refrigeration units made. It is manufactured under

strict quality controls with only the best quality

materials available. Your TRUE cooler, when properly

maintained, will give you many years of trouble-free

service.

WARNING – Use this appliance for its intended

purpose as described in this Installation Manual.

REFRIGERANT SAFETY & WARNING

INFORMATION

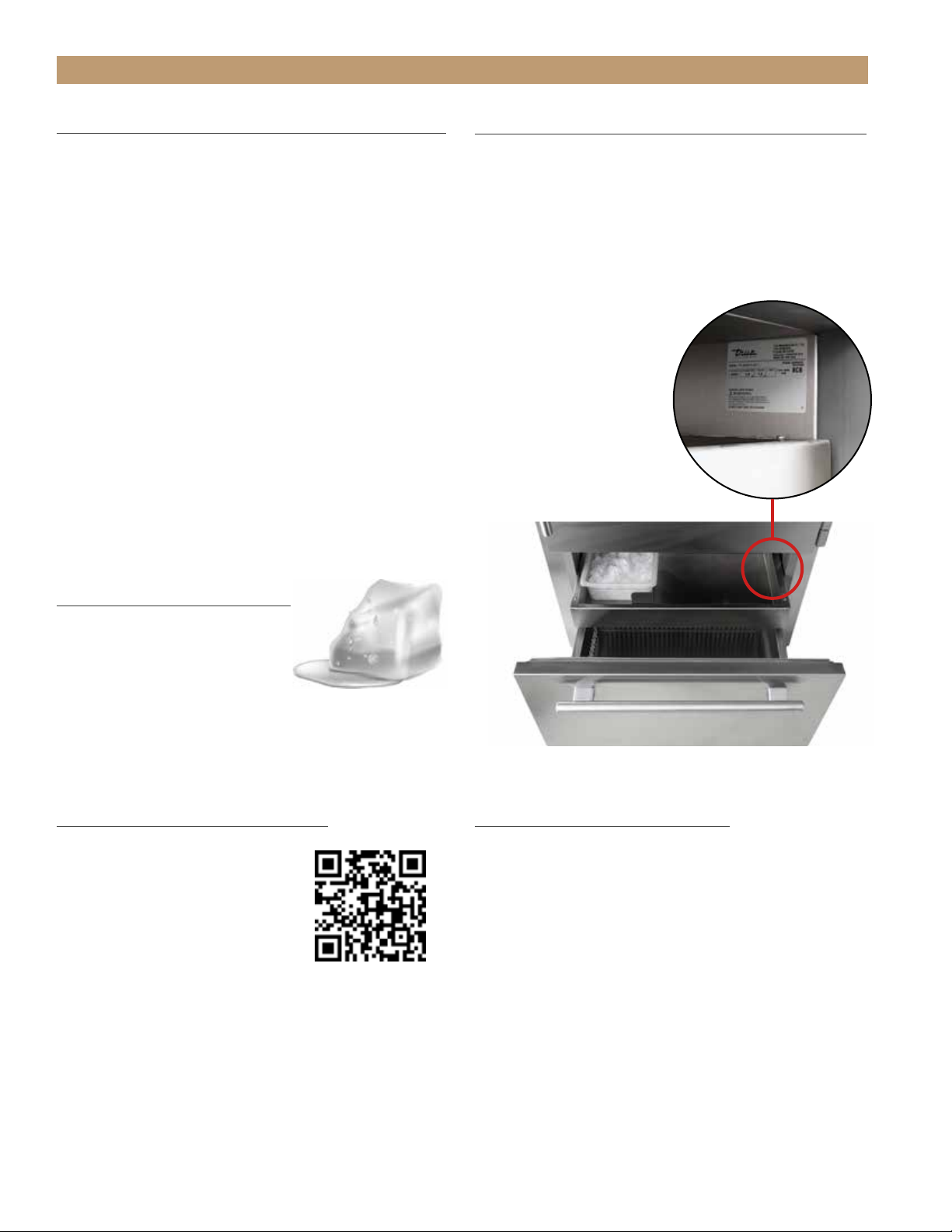

See the serial label inside the cabinet for the units

refrigeration type. For Hydrocarbon Refrigeration

(R290 only), see below:

DANGER – Risk of fire or explosion.

Flammable refrigerant used. DO NOT

use mechanical devices to defrost

refrigerator. DO NOT puncture refrigerant

tubing; follow handling instructions

carefully. To be repaired only by trained

service personnel.

DANGER – Risk of fire or explosion

(flammable refrigerant used), consult

repair manual/owner’s guide before

attempting to service this product. All

safety precautions must be followed.

Dispose of properly in accordance with

local and federal regulations. Follow all

safety precautions.

CAUTION – Keep all ventilation openings

clear of obstruction in the appliance

enclosure or in the structure housing the

appliance.

BASIC SAFETY & WARNING

PRECAUTIONS

• Take care during operation, maintenance or

repairs to avoid cuts or pinching from any part/

component of the cabinet.

• Units may pose a tipping hazard while uncrating,

during installation, or when moving the unit.

• Ensure the unit is properly installed and located

in accordance with the Installation Instructions

before use.

• This appliance is not to be used, cleaned or

maintained by persons (including children) with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge, unless they

have been given supervision or instruction.

• DO NOT allow children to play with the appliance

or climb, stand, or hang on the unit’s shelves to

prevent damage to the refrigerator and personal

injury.

• DO NOT touch the cold surfaces in the freezer

compartment when hands are damp or wet. Skin

may stick to these extremely cold surfaces.

• Unplug the refrigerator before cleaning and

making repairs.

• Setting temperature controls to the 0 position or

powering off an electronic control may not remove

power from all components (e.g., light circuits,

perimeter heaters, and evaporator fans).

• DO NOT store or use gasoline, or other flammable

vapors and liquids, in the vicinity of this or any

other appliance.

• DO NOT store explosive substances such as aerosol

cans with a flammable propellant in this appliance.

• Keep fingers out of the "pinch point" areas;

clearances between the doors and cabinet are

necessarily small; be careful closing doors when

children are in the area.

• DO NOT use electrical appliances inside the food

storage compartments of the units unless the

appliances are of the type recommended by the

manufacturer.

NOTE: ALL SERVICING MUST BE PERFORMED BY A

QUALIFIED TECHNICIAN.

HOW TO MAINTAIN YOUR TRUE REFRIGERATOR TO RECEIVE THE MOST

EFFICIENT AND SUCCESSFUL OPERATION

SAFETY INFORMATION AND OWNERSHIP