STANDARD FEATURES

Model:

WARRANTY

One year warranty on all parts

and labor and an additional 4

year warranty on compressor.

(U.S.A. only)

METRIC DIMENSIONS ROUNDED UP TO THE

NEAREST WHOLE MILLIMETER

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

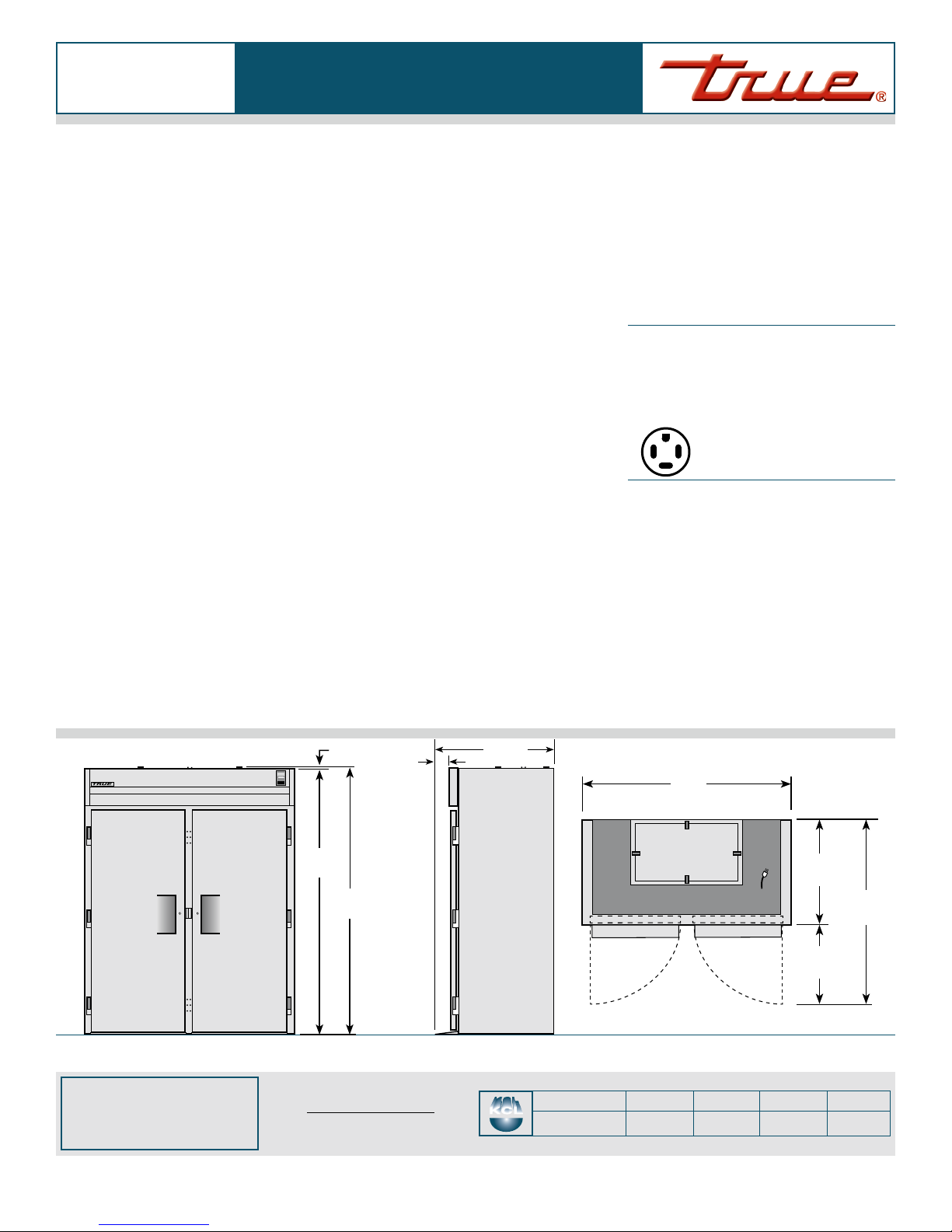

Model Elevation Right Plan 3D

PLAN VIEW

KCL

TRUE FOOD SERVICE EQUIPMENT

2001 East Terra Lane • P.O. Box 970 • O’Fallon, Missouri 63366 • (636)240-2400 • Fax (636)272-2408 • (800)325-6152 • Intl. Fax# (001)636-272-7546 • www.truemfg.com

TR2FRI-2S

TR2FRI-2S

DESIGN

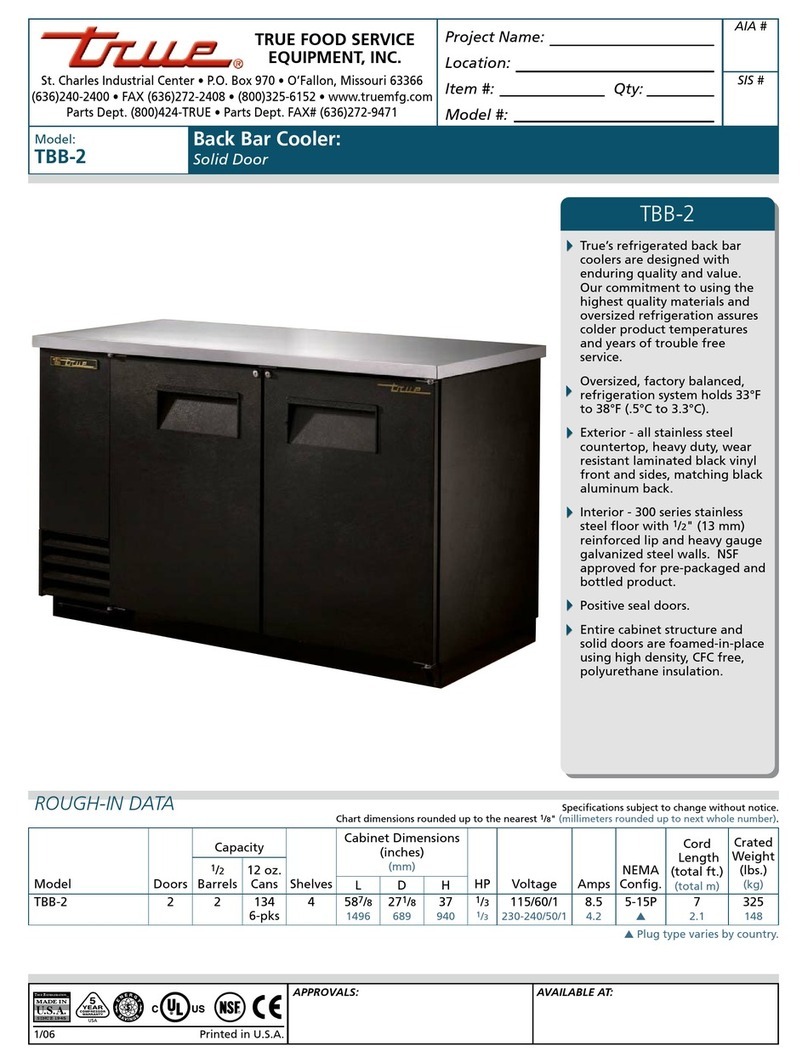

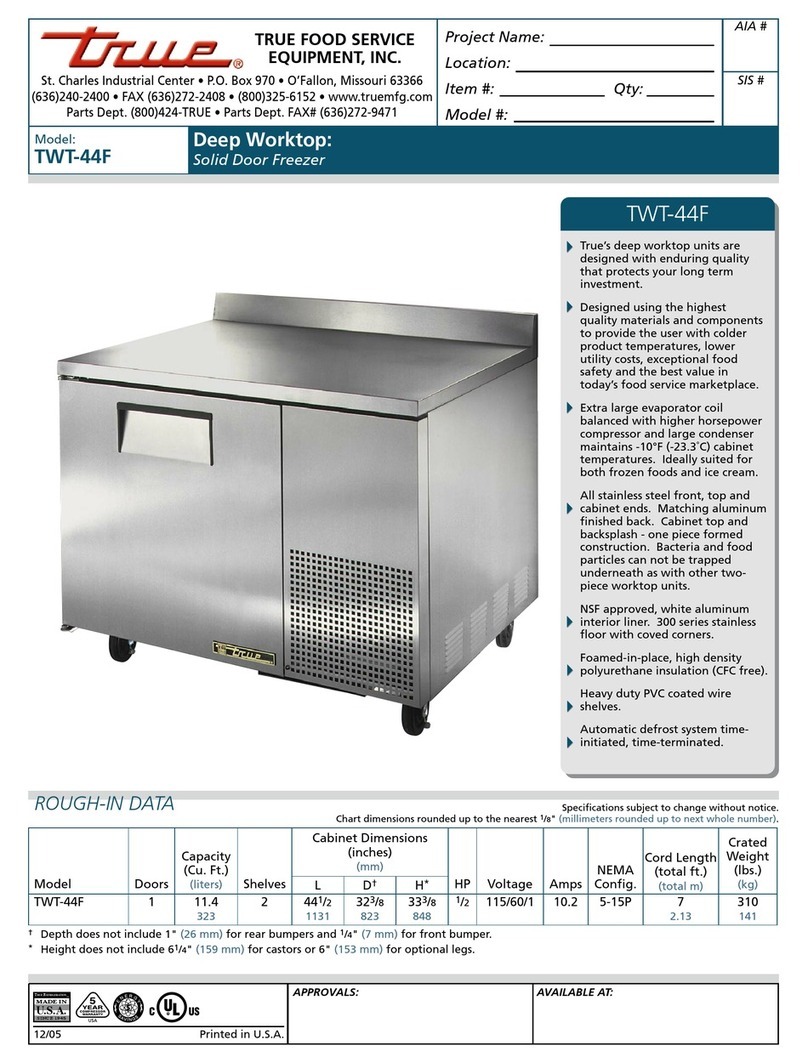

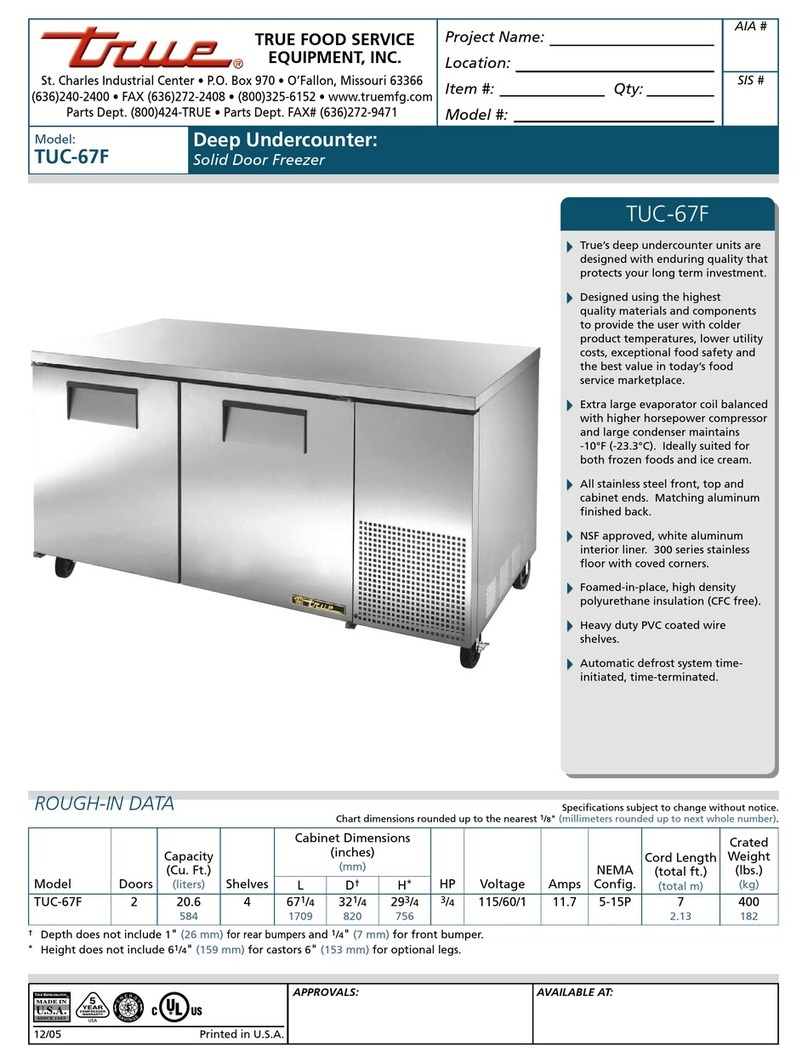

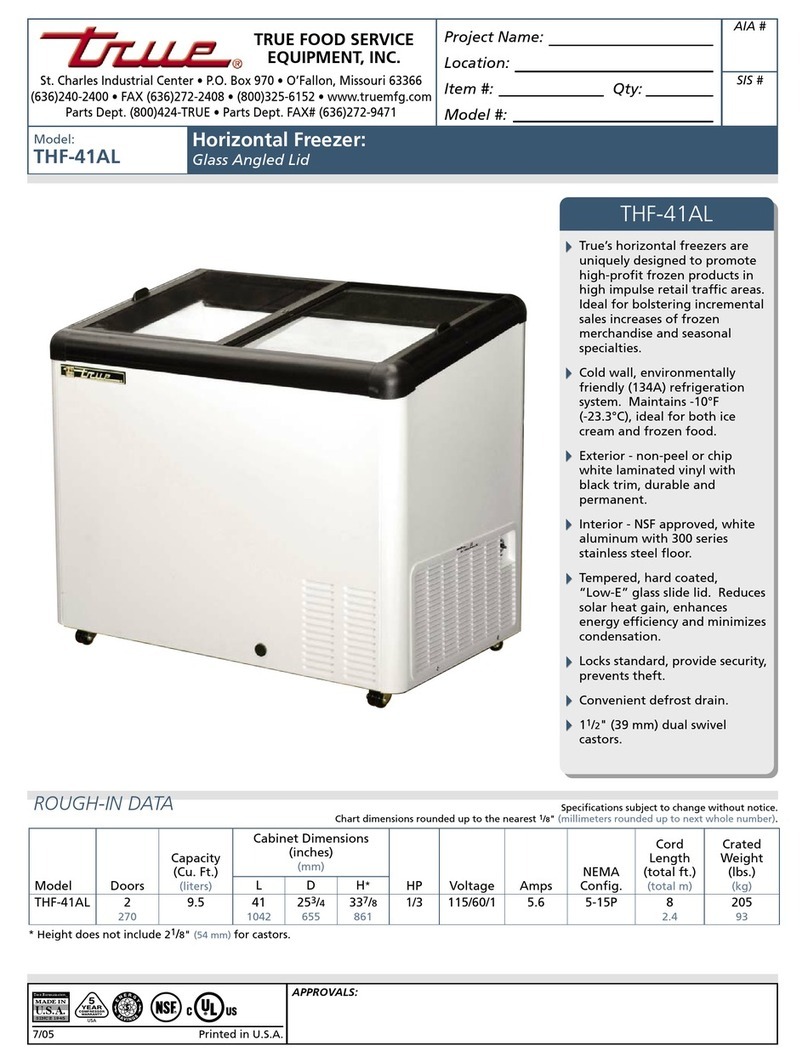

• True’s solid door roll-in’s are designed

with enduring quality that protects

your long term investment.

• Designed using the highest quality

materials and components to

provide the user with colder product

temperatures, lower utility costs and

exceptional food safety.

REFRIGERATION SYSTEM

• Factory engineered, self-contained,

capillary tube system using

environmentally friendly (CFC free)

404A refrigerant.

• Extra large evaporator coil balanced

with higher horsepower compressor

and large condenser maintains -10°F

(-23.3°C) cabinet temperature.

• Sealed, cast iron, self-lubricating

evaporator fan motor(s) and larger

fan blades give True roll-in’s a more

efficient low velocity, high volume

airflow design. This unique design

ensures faster temperature recovery

and shorter run times in the busiest of

foodservice environments.

• Top mounted refrigeration system

with evaporator positioned out of

food zone to maximize capacity.

• Automatic defrost system time-

initiated, temperature-terminated.

Saves energy consumption and

provides shortest possible defrost

cycle.

• Automatic evaporator fan motor delay

during defrost cycle.

CABINET CONSTRUCTION

• Exterior - 300 series stainless steel

doors, front, sides, back and bottom.

• Interior- 300 series stainless steel liner

and floor.

• Insulation - entire cabinet structure

and solid doors are foamed-in-

place using high density, CFC free,

polyurethane insulation.

• One (1) heavy gauge stainless steel

ramp per door.

• Designed to accept roll-in racks

(inboard castors) with a maximum

dimension of 27"L x 29"D x 66"H

(686 mm x 737 mm x 1677 mm).

DOORS

• 300 series stainless steel. Doors opens

within cabinet dimension.

• Door locks standard.

• Lifetime guaranteed recessed door

handles. Each door fitted with 12"

(305 mm) long recessed handle that

is foamed-in-place with a sheet

metal interlock to ensure permanent

attachment.

• Wiper gaskets for postitive seal,

reversible.

• Three (3) lifetime guaranteed,

cam-lift hinges per door. Full 180°

open capability with a stay open

feature at 120°.

• Doors are field reversible.

LIGHTING

• Incandescent interior lighting, safety

shielded.

MODEL FEATURES

• Exterior digital temperature display,

available with either °F or °C .

• Evaporator epoxy coated to eliminate

the potential of corrosion.

• Minimum wattage heater in cabinet

frame.

• Interior bumpers protect cabinet walls

from abuse caused by roll-in carts.

• NSF-7 compliant for open food

product.

ELECTRICAL

• Unit completely pre-wired at factory

and ready for final connection to a

115/208-230/60Hz single phase, 3 pole,

4 wire - 20 amp dedicated outlet.

Cord and plug set included.

OPTIONAL FEATURES/ACCESSORIES

Upcharge and lead times may apply.

❒Metal door handle (factory installed).

❒Electronic temperature control

(factory installed).

❒Correctional facilities options.

❒Remote cabinets (condensing unit

supplied by others; system comes

standard with 404A expansion valve

and requires R404A refrigerant),

consult factory technical service

department for BTU information.

115/208-230/1

NEMA-14-20R

TR Series:

Roll-In Solid Door Freezer

ELEVATION PLAN VIEW

833/4"

(2128 mm)

843/4"

(2153 mm)

347/16"

(875 mm)

30"

(762 mm)

647/16"

(1637 mm)

68"

(1728 mm)

1"

(26 mm)

RIGHT VIEW

3811/16"

(983 mm)

41/4"

(108 mm)