truflo UltraFlo 500 Series User manual

Clamp-On Ultrasonic Flow Meter

Read the user's manual carefully before starting to use the unit.

Producer reserves the right to implement changes without prior notice.

UltraFlo®500 Series

Operating Manual

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Safety Information

Product Description

Features

Exploded View

Working Principle

Technical Specifications

Components

Installation and Connection

Panel Function

Keypad Functions

Powering ON

Display Description

Setup Menu

Pipe Parameter Setup Menu

System Setting Setup Menu

Calibration Setup Menu

Output Setting Setup Menu

Data Logging Setup Menu

Dimensions

Warranty, Returns & Limitations

03

03

04

04

05

05

06

06

07

07

07

08

08

09

09

11

12

14

14

15

2

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Table of Contents

Notice : Is used to lead users to helpful information not related to personal injury.

Indicates a potential hazard. Failure to follow all

warnings may lead to equipment damage, injury,

or death.

Warning | Caution | Danger

Use of tool(s) may damage produced beyond

repair and potentially void product warranty.

Do Not Use Tools

Please always observe the following safety instructions!

Please pay attention to the safety instructions with the following pictograms and signal words in these operating instructions :

The Truflo®UF-500 Series clamp-on ultrasonic flow meters are easy to install with exceptional long life performance and they

require no alteration to current piping configurations.

The sensor sends over 50 pulses/sec in order to provide accurate measurement of liquid flow rates in full pipes and can be used

in low pressure systems.

The Flow Meter UltraFlo®should only be used for measuring the flow of pure, homogeneous liquids.

The UltraFlo®is not intended for use in medical applications.

The volume flow meter UltraFlo®is built in accordance with industry standard EN 61010 regulations (corresponds to VDE

0411 "Safety specifications for electrical measurement, control and laboratory devices").

The manufacturer is not liable for any injury, damage or harm due to inappropriate or unintended use or modifications of

the flow meter. Conversions and/or changes to the flow meter may only be made, if they are expressly performed in

accordance with the operating instructions in this operating manual.

Intended Use

Assembly, electrical installation, commissioning and maintenance of the flow meter must be carried out by

qualified, trained personnel. The qualified personnel must have read and understood the operating

instructions in this operating manual and must follow the operating instructions in this manual.

The installer has to ensure that the flow meter is correctly connected according to the electrical connection

diagrams in this operating manual.

Serious injury or death from electric shock may occur if wiring, installation, disassembly or removal of wires

is performed while electrical power is energized

Personnel for Installation, Commissioning and Operation

The manufacturer reserves the right to revise, alter, or modify the flow meter to the most current technology without special

prior notice. Further information about the latest updates and potential additions to these operating instructions are available

from Truflo.

Technological Progress

Wide Dynamic Flow Range 0.3 to 15 ft/s | 0.1 to 5 m/s

Light weight

Excellent External Corrosion Resistance

Convenience, Accuracy and Value in an Ultrasonic Flow Meter

3

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Safety Information

Product Description

4

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Features

Under 2 Minute Installation Time

No Contact with Liquid

No Moving Parts

Simple to Install-No Cutting of Pipe

4-20mA | RS485 Output

Flow Rate + Totalizer | Resettable

Simple Programming

Large Blue OLED Low Light Display

Wide Dynamic Flow Range

of 0.3 to 15 ft/s | 0.1 to 5 m/s

High Accuracy | ± 2.0% of Full Scale

Pipe Sizes ½ - 4"

Lightweight

Excellent External Corrosion Resistance

Data Logging

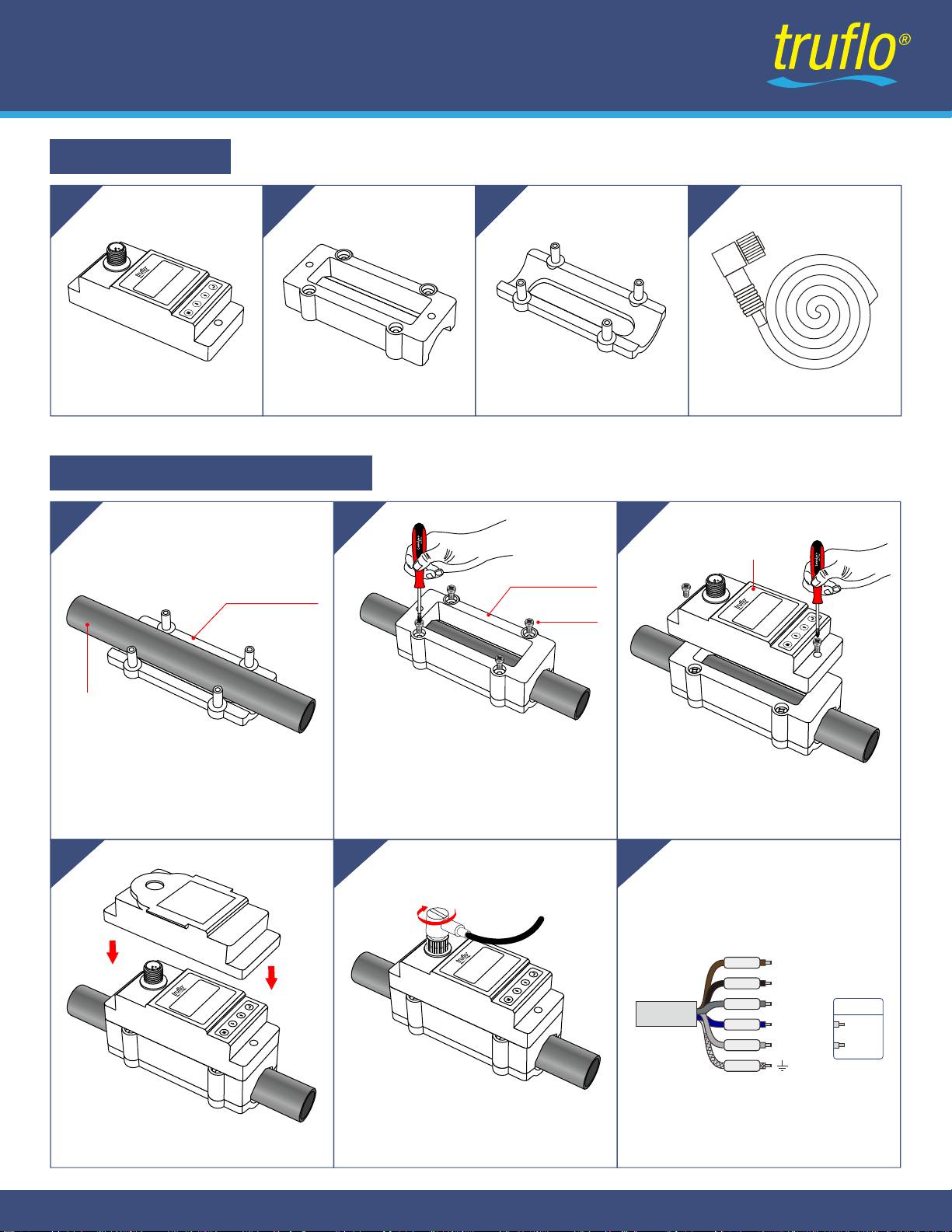

Exploded View

Chemical Resistant,

High Impact

Polycarbonate Cover

M12 Quick

Connection

Flow Rate and Total

Magnetic Connection

(for easier installation)

Bright LCD Display

Teflon®Epoxy

Coated Aluminum

Pipe Sizes ½ to 4"

5

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

General

Accuracy 2.0%

Repeatability 0.8%

Data Storage

Day, Month and Year Flow Totalizer

Response Time 2s

Analog Output

4 ~20mA

Alarm Output

OCT, High and Low Flow Alarm Function (option)

Communication

RS485, Power Waste: 3W

Power Supply 24 VDC

Cable Length 2m

Keypad

Four Light Touch Buttons

Screen OLED 128* 64 Display Screen

Units

Metric and Imperial units are available.

Cubic Meters(m3), Liters(L), US Gallons(GAL), /hour,/ min

Default Unit Setting : GPM

Totalizer

Six Bit Digit

Liquid Water, Sea water, Oil...

Pipe Material

Carbon Steel | Stainless Steel | PVC | Copper | PVDF | PFA | PTFE | PU | Aluminum

Case Material Teflon® Epoxy Coated Aluminum | Aluminum

Environment Temp. 0°C - 50°C

Liquid Temp. 0°C - 50° C

Environment Humidity

0-95% Relative Humidity Without Condensation

IP Grade IP54

Technical Specifications

Working Principle

Signal B Signal A

Lower Bracket

Sensor Body

M12 Quick Connection

Upper Bracket

Flow Flow

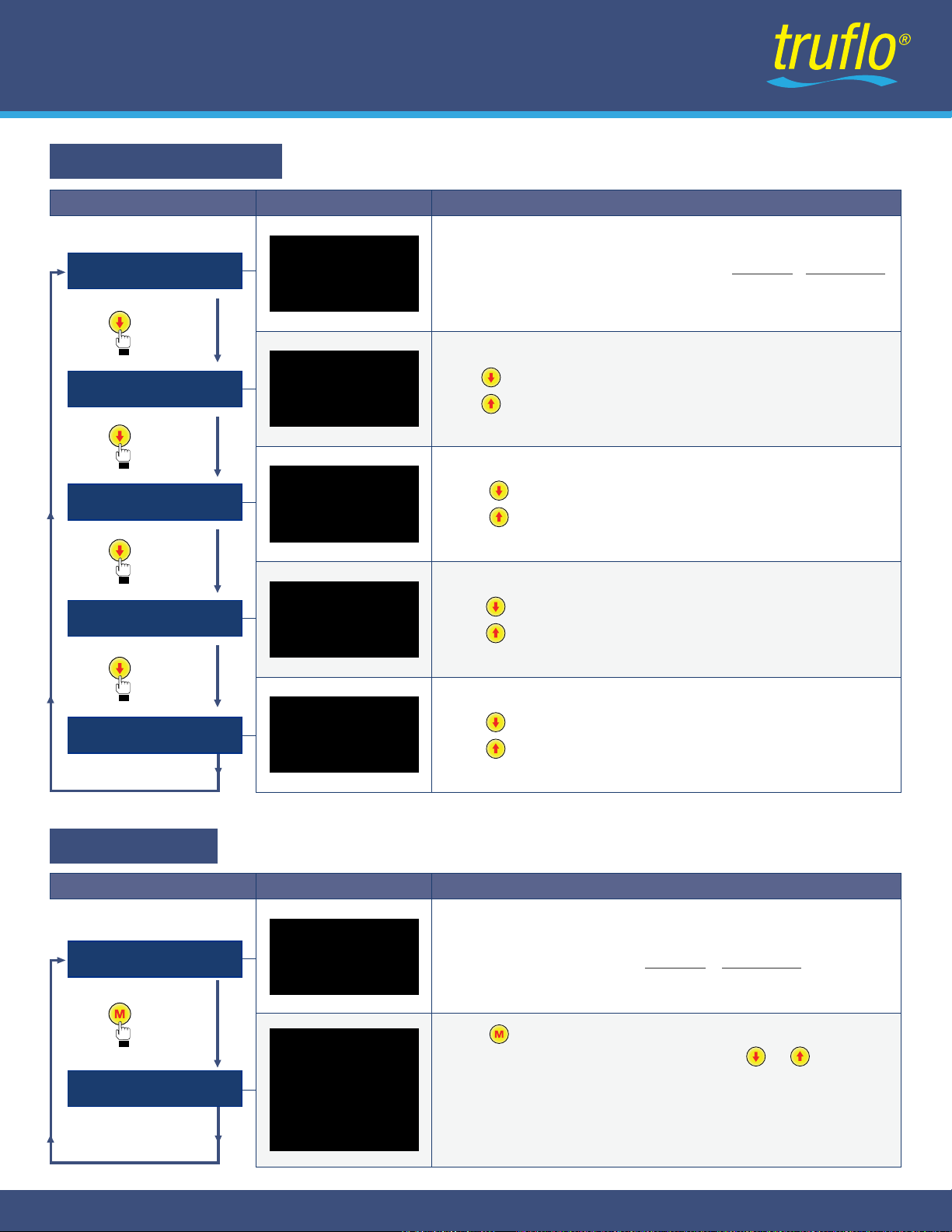

01 02 03

01 02 03 04

04 05 06

Sensor Body

Make sure no dirt, paint, or other

stains on the surface of the tube. Then

position the Lower Bracket on the pipe.

Align the Upper Bracket to the pipe position.

Magnets will hold brackets in place.

Using the mounting screws connect the

Upper and the Lower Brackets together.

Ensure that the parts are snug,

but DO NOT over-tighten.

Upper Bracket Lower Bracket M12 Cable

Position the display over the Upper

Bracket and connect using the mounting

screws. DO NOT over-tighten.

Install Polycarbonate Cover Connect M12 Cable

Wiring Diagram

Pipe

Lower Bracket

Display

6

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Components

Installation and Connection

Screw

Upper Bracket

UltraFlo-500

www.iconprocon.com

UltraFlo-500

www.iconprocon.com

UltraFlo-500

www.iconprocon.com

DC+

Brown

Black

Gray

Blue

White

Shield

4-20mA+

RS485 A

RS485 B OCT+

OCT-

Option

DC-/4-20mA-

UltraFlo-500

www.iconprocon.com

SQ 0

23:22:18

GPM

8.635

Net 723.58 GAL

UltraFlo-500

www.iconprocon.com

Mounting Screw

Mounting Screw

M12 Connector

Flow Rate

Net Totalizer

Bright LCD Display

Keypad

When connected to a VDC Power Supply the Ultrapro 500 will begin to run self-diagnosis program

Follow these Guide Lines when using the Flow Meter Keypad:

SQ value is short for Signal Quality. It indicates the level of the signal detected. SQ value is indicated by

numbers from 0~99. 00 is the minimum signal could be detected and 99 represents the maximum.

Normally, the transducer position should be adjusted repeatedly and coupling compound should be

checked frequently until the signal quality detected is as strong as possible.

Press to Enter the Programming Mode or to return to the previous menu during programming.

Press to Scroll Up or Down

Press to move to the Next Digit

Press to Select Digits (0-9)

Press to Confirm Selection.

SQ 99

Net 723.58

GAL

GPM

01:58

3.368

7

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Panel Function

Keypad Functions

Powering ON

Signal Quality (SQ value)

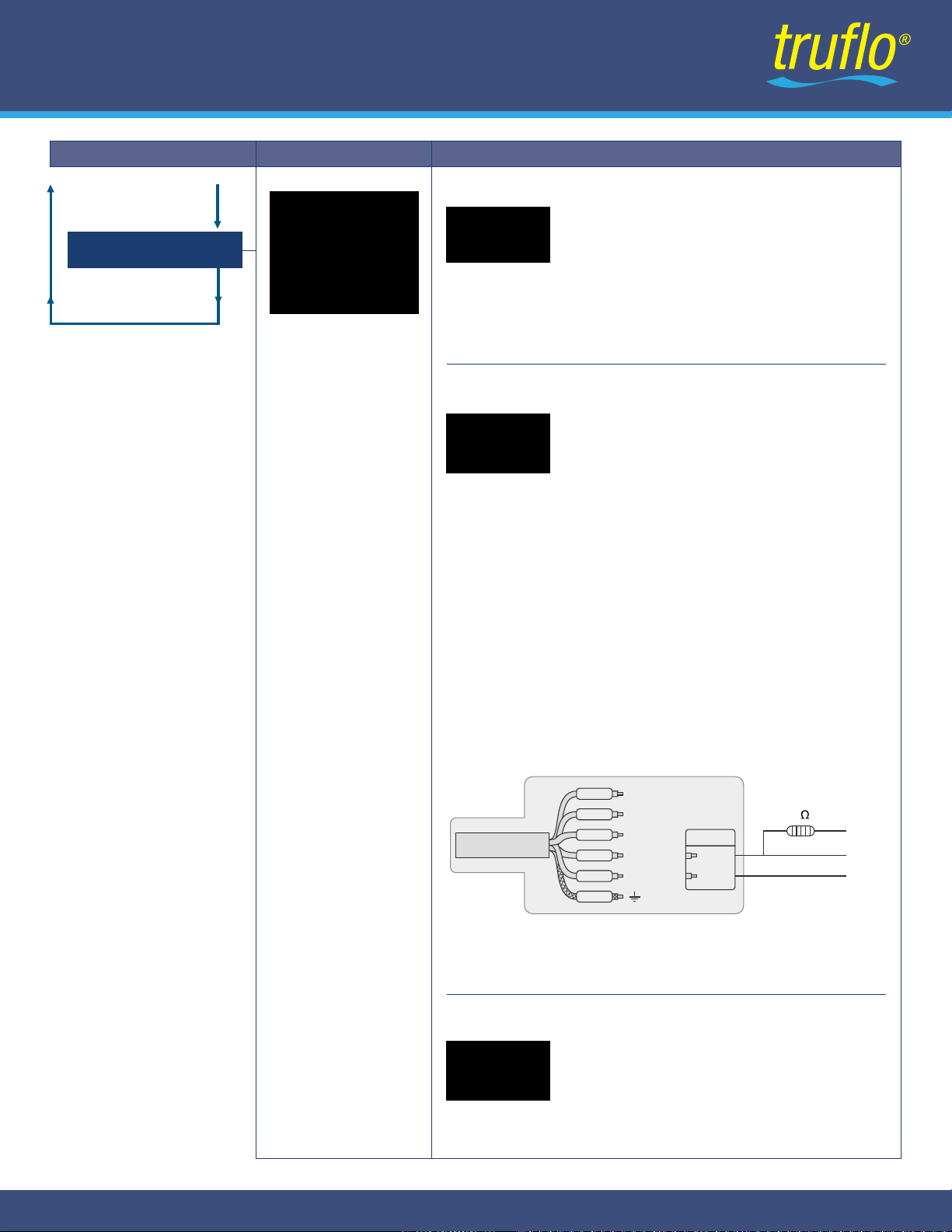

When power is on, the flow meter will display Flow Rate / Net Totalize

r

.

Signal quality & Time.

OPERATIONDISPLAY

STEPS

Main Display

Press Key

Totalizer

SQ 99

Net 768.89GAL

GPM

12:30:18

3.368

SQ 99

S.ToT

23.89

GAL

GPM

12:30:18

3.368

Press to Display Run time / Day Totalizer / Month Totalizer / Year Totalizer

Press to Return to Previous Menu.

Press Key

Press Key

Flow Rate / S.TOT Totalizer

Press Key

Flow Rate / Velocity / Net Totalizer

Press to Display Flow Rate / S.TOT Totalizer

Press to Return to Previous Menu.

Velocity / Net Totalizer

Press to Display Velocity / Flow Rate / Net Totalizer

Press to Return to Previous Menu.

Runtime

Year

GAL

Day GAL

Mth. GAL

216h

79.068

3839.8

3768

SQ 99

Net GAL

f/s

GPM

Vel

Flow

12:30:18

1.068

3.339

768.89

Press to Display Velocity / Net Totalizer,

Press to Return to Previous Menu.

8

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Display Description

Power on Main Display shows

Flow Rate & Net Totalize

r

OPERATIONDISPLAY

STEPS

Main Display

Press Key

Setup Menu

Press to Display Setup Menu.

The following options are available (using the or Buttons)

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

4. History data

Setup menu

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

4. History data

Setup Menu

20-03-18

Net

768.89

GAL

f/s

12:30

1.868

SQ 99

Net 768.89GAL

GPM

12:30:18

3.368

OPERATIONDISPLAY

STEPS

Setup menu

Press to Key

Pipe Parameter

Press to display Setup menu.

The following options are available (using the or buttons)

0. Pipe Parameter

1. System Setting

2. Calibration

3. Output Setting

Setup menu

Press , Select 0.Pipe parameter, then to Display :

The following options are available (using the or buttons)

0. Outer diameter

1. Wall thickness

2. Material :

Press or can option PVC, Carbon steel, Steel,

Copper, PVDF, PFA, PTFE, PU, Aluminum.

3. Fluid type :

Press

or

to choose between Water, Sea Water, Oil...other.

Pipe Setting

0. Outer diameter

1. Wall thickness

2. Material

3. Fluid type

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

4. History Data

OPERATIONDISPLAY

STEPS

Setup Menu

Press to Key

System Setting

Press to display Setup menu.

The following options are available (using the or buttons)

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

Setup menu

Press , Select 1. System setting then to display:

The following options are available (using the or buttons)

0. System Unit : Press or to choose between Metric, English.

1. Flow Rate Unit :

Press or

to choose between m3/h, LPM, GPM, LPH.

2. Total Unit : Press or to choose between m3, L, GAL.

3. Total Reset : Press then Parameters will be reset.

4. Time Set :

When modifying, the default is 30 seconds.

Generally, it is unnecessary to modify date &

time as the system is equipped with a highly

reliable perpetual calendar chip.

Next Page

System setting

0. System Unit

1. Flow Rate Unit

2. Total Unit

3. Total Reset

4. Time Set

5. System Lock

6. System INFO

7. Display dir

8. Damping

9. Display format

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

yy-mm-dd hh:mm

19-06-20 12:30

9

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Pipe Parameter Setup Menu

System Setting Setup Menu

OPERATIONDISPLAY

STEPS

System Setting

5. System lock

System setting

0. System Unit

1. Flow Rate Unit

2. Total Unit

3.Totalizer Reset

4. Time Set

5. System Lock

6. System INFO

7. Display dir

8. Damping

9. Display format

System lock

System Unlocked

System Unlocked

ENT to lock

ENT key word

0000

System lock

System locked OK

System lock

System locked

System lock

ENT to unlock

ENT key word

0000

System lock

System Unlocked OK

Once the system is locked, any modifications to the system are

prohibited, but the parameter is readable. "Unlock" using your

designated password. The password is composed of 1 to 4 numbers.

7. Display dir

Display dir

0. Normal

1. Inversion

Select the display direction of the screen,

which can be rotated by 180 degrees.

Display Inversion (180 degree rotation) to be

mentioned as a key feature

Previous Page

8 . Damping

Damping

003

When the flow regime is unstable and the display value changes

greatly, damping can be set to adjust the measurement response

speed of the product. The unit is in seconds.

9. Display format

Display format

0. x 0.001

1.x 0.01

2.x 0.1

The display digit of the measured value can be set through the zoom

function. It is displayed after the decimal point by default 3 digits.

You can choose to display 2 digits after the decimal point, 1 digit after

the decimal point and 0 digit after the decimal point.

10

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

6. System INFO

System INFO

Flowmete

SN:30001399 V1.00

Manual Totalizer

ENT To Start

Manual Totalizer

ENT To Stop

1.239 m3/h

SQ99 1.056L

Display serial number (SN) of the meter. This SN is the only one

assigned to each flow meter ready to leave the factory.

The factory uses it for files setup and for management by the user.

Press 5 times to enter Manual Totalizer; The manual totalizer is

a separate totalizer. Press to start, and press to stop it.

It is used for flow measurement and calculation.

Manual Totalizer

ENT To Restart

1.239 m3/h

SQ99 1.056L

Next Page

11

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

OPERATIONDISPLAY

STEPS

Setup Menu

Press to Key

Calibration

Press to display Setup Menu.

The following options are available (using the or buttons)

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

Setup menu

Press , Select 2. Calibration, then to display:

The following options are available (using the or buttons)

0. Scale factor

Calibration

0. Scale factor

1. 4-20mA CAL

2. Set Zero

3. Low flow Cut

4 . Manual zero

5 . HiAGC

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

Refers to the ratio between the “actual value” and “

reading value”. For example, when the measurement

is 2.00, and it is indicated at 1.98 on the instrument,

the scale factor reading is 2/1.98.

This means that the best scale factor constant is 1.01.

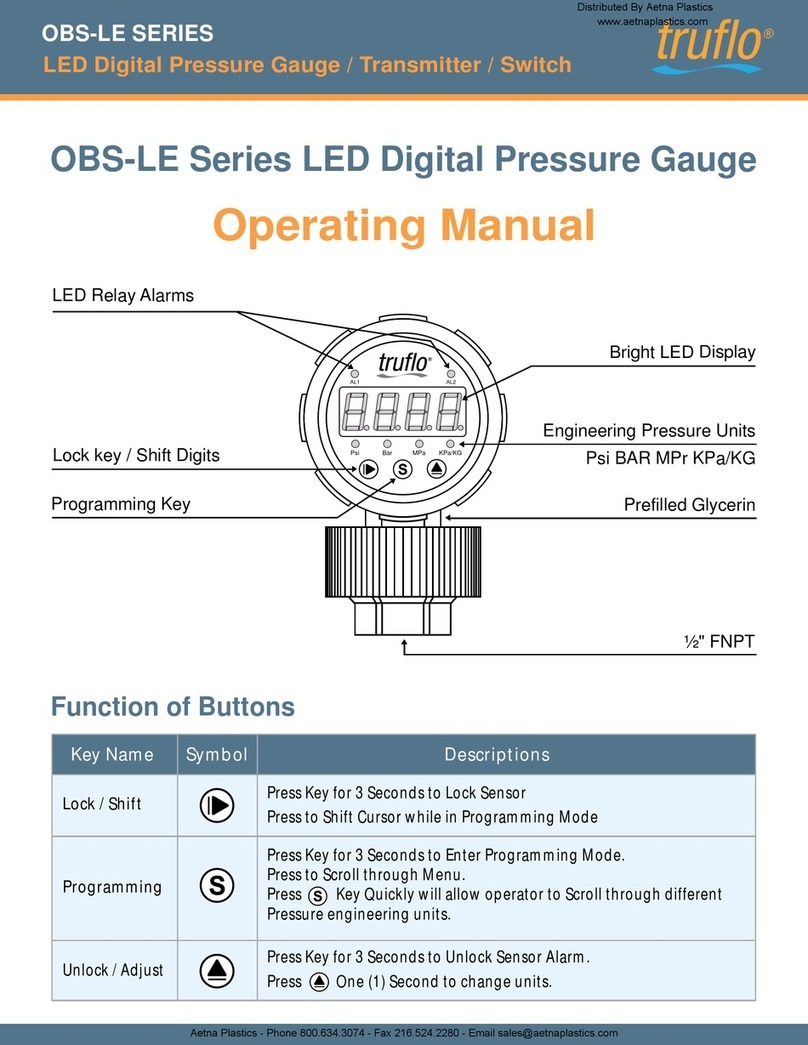

Calibration Setup Menu

4mA Calibrate

25492

Scale factor

1.000

20mA Calibrate

4555

Set zero

Ent to set zero

Reset zero

Set zero

SQ 88

Vel 0.035 f/s

Waitting...

This function can prevent that when the pump stops working and the

liquid flows at a low speed in the pipe, data accumulation error

caused by continuous reading of flow meter. Input is generally

recommended 0.05f/s as the low flow cut-off point. The low flow

cut-off value is independent of the measurement results.

After setting, return to the main interface and the flow is "0".

If you return to the main interface, the flow is not "0", the setting is

unsuccessful. Check whether the installation is correct or not.

1. 4-20mA CAL

2. Set Zero : Press ; reset “Zero Point” which was set by the user.

Check if the current loop has been calibrated before leaving the

factory. Press move to display 4mA or 20mA , and at the

same time, check with an ammeter to verify that Current Loop

output displayed values. It is necessary to re-calibrate the current

loop, if over the permitted tolerance.

The displayed value has no meaning, but is only used for internal

records. Correct only by up and down Key operation, check the

displayed value of ammeter (multimeter).

Low flow cut

0.0500 f/s

3. Low flow cut : Flow rate falls below the low flow cutoff value.

Calibration

Calibration

0. Scale factor

1. 4 & 20mA CAL

2. Set Zero

3. Low flow Cut

4. Manual zero

5. HiAGC

6. Negative Flow

Previous Page

OPERATIONDISPLAY

STEPS

Setup Menu

Press to Key

Output Setting

Press to display Setup menu.

The following options are available (using the or buttons)

0. Pipe parameter

1. System setting 2. Calibration

3. Output setting

Press , Select 3. Output setting, then to display:

The following options are available (using the or buttons)

0. RS 485 Setup

Output setting

0. RS485 Setup

1. 4-20mA range

2. Alarm value

3. OCT output

4. OCT multiplier

Setup menu

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

4. History data

Then select : None. Data length : 8 Stop bit is fixed length.

Factory default value for serial port parameter is ''9600, 8, None,1''

Next Page

12

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Output Setting Setup Menu

4mA value

0.00

20mA value

15.00GPM GPM

Generally, pipes made of SS304 or SS316 are with wall thickness of

more than 2mm. In practical use, it will receive false signals due to

the interference of pipe wall signals, It is recommended that the low

flow rate should be cut off at 0.08m/s or above.

4. Manual zero

Manual zero

0.0000 m3/h

High gain switch do not needs to be set generally,

could try to switch on for special pipes with weak

signal detected.

This method is not commonly used and is only

suitable for experienced operators. It is not suitable

for other parties. Manually input the value and add

it to the measured value to obtain the actual value.

This window is used to set RS 485 serial port. It must

match the equipment's connected parameters.

First select baud rate: 2400, 4800, 9600, 19200

are selectable

5. Hi AGC

Hi AGC

0. OFF

RS485 Setup

0.Network addr

1.RS485 Baudrate

2.RS485 Parity

3.RS485 Stopbits

1. 4-20mA range

Set the Current Loop output value according to the flow value at

4mA, and 20mA. The flow unit is GPM.

OPERATIONDISPLAY

STEPS

Output Setting

Output setting

0. RS485 Setup

1. 4-20mA range

2. Alarm value

3. OCT output

4. OCT multiplier

Previous Page

Enter the low alarm value; any measured flow lower than the low value,

will activate the alarm in the OCT hardware or relay output signal.

Enter the high alarm value; any measured flow higher than the high

value, will activate the alarm in the OCT hardware or relay output signal.

Alarm value

0. Low value

1. High value

2. Alarm Value (Optional)

The OCT output in the flow meter is a kind of isolated collector open

circuit output with programmable open and close qualifications.

The user can program the open and close functions under the

following conditions: the system alarm signals are being activated or

the totalizer pulse is being transmitted.

Pulses are cumulative output, and the equivalent of each pulse is

0.01L~ 100m3, It can be set through the menu.

The maximum number of pulses output per second is 40.

To select OCT output, an external 5-10K pull-up resistor shall be

connected at the OCT + end; Add a 5-24vcd power supply at VCC

and com ends, as shown in the figure:

OCT Wiring Diagram:

OCT output

0.Total Pulse

1.Alarm output

2.No Signal

3. OCT output (Applicable to OCT output model)

Select OCT pulse output multiple

OCT multiplier

0. x0.001

1. x0.01

2. x0.1

4. OCT multiplier (Applicable to OCT output model)

13

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

DC+

Brown

Black

Gray

Blue

White

Shield

Resistance

5-10k 1/4W Vcc

Signal

Com

4-20mA+

RS485 A

RS485 B OCT+

OCT-

Option

DC-/4-20mA-

OPERATIONDISPLAY

STEPS

Setup Menu

Press to Key

History Data

Press to display Setup menu.

The following options are available (using the or buttons)

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

4. History data

Setup menu

Press , Select

4. History data

, then to display:

0. By Day : Display Totalizer flow for days.

1. By Month : Display Totalizer flow for months.

2. By Year : Display Totalizer flow for years.

History data

0.By Day

1.By Month

2.By Year

0. Pipe parameter

1. System setting

2. Calibration

3. Output setting

4. History data

14

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Data Logging Setup Menu

Model Pipe OD OD Range A (mm) Max C(mm)

UF500-15 16.5 - 23 86 106

UF500-25 30-35 91 106

UF500-40 48-54 110 106

UF500-50 58-68 126 130

UF500-50 88-96 154 150

UF500-100

½"

1"

1-½"

2"

3"

4" 108-116 177 174

B(mm)

52

58

78

91

119

143

Dimensions

A

C

A

B

42

Icon Process Controls

warrants to the original purchaser of its products that such products will be free from defects in materials

and workmanship under normal use and service in accordance with instructions furnished by

Icon Process Controls

for a period

of one years from the date of sale of such products.

Icon Process Controls

obligation under this warranty is solely and exclusively

limited to the repair or replacement, at Icon's option, of the products or components, which Icon examination determines to its

satisfaction to be defective in material or workmanship within the warranty period.

Icon Process Controls

must be notified

within thirty (30) days pursuant to the instructions below of any claims of lack of conformity under this warranty. Any product

repaired under this warranty will be warranted only for the remainder of the original warranty period. Any product provided as a

replacement under this warranty will be warranted for the full 1 year from the data of sale.

Warranty

Products cannot be returned to

Icon Process Controls

without Icon's prior authorization. To return a product that is thought to

be defective please submit a customer return (MRA) request form and follow the instructions therein. All warranty and non-

warranty product returns to

Icon Process Controls

must be shipped prepaid and insured. Icon will not be responsible for any

products lost or damaged in shipment.

Returns

This warranty does not apply to products which:

1)

Are beyond the warranty period or are products for which the original purchaser does not follow the warranty procedures outlined above;

2) Have been subjected to electrical, mechanical or chemical damage due to improper, accidental or negligent use;

3) Have been modified or altered;

4) Anyone other than service personnel authorized by Icon have attempted to repair;

5) have been involved in accidents or natural disasters;

6) Are damaged during return shipment to Icon Process Controls.

Icon Process Controls reserves the right to unilaterally waive this warranty and dispose of any product returned to Icon where :

1) There is evidence of a potentially hazardous material present with the product;

2)

The product has remained unclaimed at Truflo for more than 30 days after Icon Process Controls has dutifully requested disposition.

This warranty contains the sole express warranty made by

Truflo

in connection with its products. ALL IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULARPURPOSE, ARE

EXPRESSLY DISCLAIMED. The remedies of repair or replacement as stated above are the exclusive remedies forthe breach of this

warranty. IN NO EVENT SHALL LEVELPRO BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGESOF ANY KIND

INCLUDING PERSONAL OR REAL PROPERTY OF FOR INJURY TO ANY PERSON. THIS WARRANTYCONSTITURES THE FINAL,

COMPLETE AND EXCLUSIVE STATEMENT OFWARRANTY TERMS AND NO PERSON IS AUTHORIZED TO MAKE ANY OTHER

WARRANTIES OR REPRESENTATIONS ONBEHALF OF Icon Process Controls.

If any portion of this warranty is held to be invalid or unenforceable for any reason, such finding will not invalidate any other provision of this

warranty

For additional product documentation and technical support visit www.iconprocon.com | e-mail: sales@iconprocon.com

Limitations

15

23-0166 © Icon Process Controls Ltd.

Clamp-On Ultrasonic Flow Meter

UltraFlo®500 Series

Warranty, Returns & Limitations

This manual suits for next models

5

Table of contents

Other truflo Measuring Instrument manuals

truflo

truflo TKS Series Instruction manual

truflo

truflo TK Series User manual

truflo

truflo TIB Series User manual

truflo

truflo TKB Series Instruction manual

truflo

truflo ULTRAFLO 5000 User manual

truflo

truflo TKB Series Instruction manual

truflo

truflo OBS-LE Series User manual

truflo

truflo TIP Series User manual

truflo

truflo ICON TIR Series User manual

truflo

truflo TKB Series User manual