truflo TKB Series Instruction manual

Battery Operated Flow Meter

TKB SERIES

Quick Start Operating Manual

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

360°

TKB Series Battery LCD Flow Meter

SET

8

8

8

8

8

8

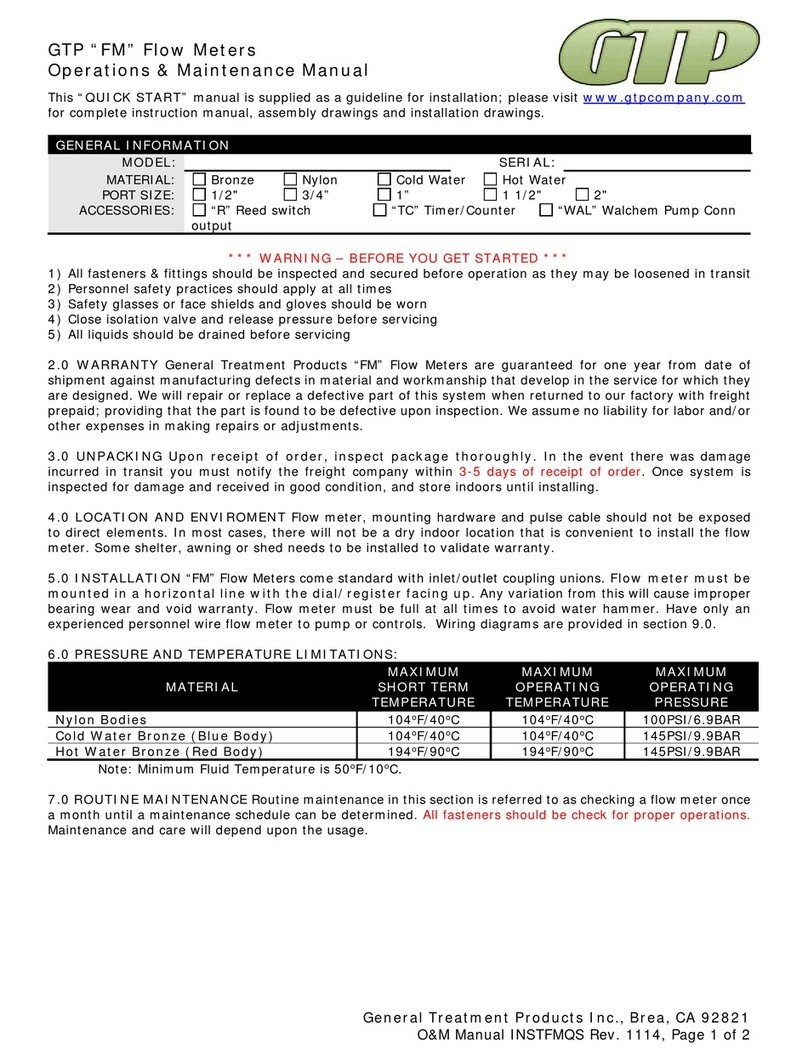

Safety Information

Technical Specifications

Model Selection

Exploded View

Programming

Flow Totalizer

Alarm Limit of Flow Rate Meter

Low Battery Notification

Displaying Flow Rate | Flow Totalizer

K-Factors for TK

Flow Rates

Pressure vs. Temperature Psi H2O | Non-Shock

Dimensions

Battery Replacement

Procedure to Rotate Display

Installation Positions

Warranty, Returns and Limitations

03

04

05

05

06

07

07

07

07

08

08

08

08

09

09

10

11

Table of Contents

02

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

1. De-pressurize and Vent System Prior to Installation or Removal.

2. Confirm Chemical Compatibility Before Use.

3. DO NOT exceed Maximum Temperature or Pressure Specifications.

4. ALWAYS Wear Safety Goggles or Face-shield During Installation and/or Service.

5. DO NOTAlter Product Construction.

If leaking is observed from the retaining cap, it indicates

defective or worn o-rings on the sensor. Do not attempt to

correct by further tightening.

WARNING!

Indicates a potential hazard. Failure to follow all

warnings may lead to equipment damage, injury, or

death

Warning | Caution | Danger

Overtightening may permanently damage product

threads and lead to failure of the retaining nut.

Hand Tighten Only

Failure to follow these instructions may result in

the sensor being ejected from the pipe!

Use of tool(s) may damage product beyond repair

and potentially void product warranty.

Do Not Use Tools

Highlights additional information or detailed

procedure.

Note | Technical Notes

Safety Information

Do Not Remove Under Pressure

Please ensure that the Instruments are not to be subject to water hammer or pressure spikes!

Always Pressure Test System with H2O Prior to Initial Start-Up

Before Before installation be certain the appropriate instrument has been selected considering operating pressure, full scale

pressure, wetted material requirements, media compatibility, operating temperature, vibration, pulsation, desired accuracy and

any other instrument component related to the service application including the potential need for protective attachments and/or

special installation requirements. Failure to do so could result in equipment damage, failure and/or personal injury. Ensure only

qualified personnel personnel are permitted to install and maintain this instrument.

Sensor may be under pressure, take caution to vent system prior to installation or removal.

Failure to do so may result in equipment damage and/or serious injury

Pressurize System Warning

TK Series can be installed in a horizontal or vertical direction. Please ensure enough length of straight pipe to avoid turbulence

that can effect readings.

A Bag Filter or Y Strainer Filtering Device upstream toAvoid the Paddle Wheel from being damaged by the solids or fibers

- max 10% Particle Size - Not to Exceed .5mm Cross Section or Length.

Please do not flush the pipe after the Flow Meter is installed with Compressed Air this may damage the ceramic shaft and will

Void Warranty

Please Ensure Full Pipe

Min 10x Pipe Diameters Upstream 3x Pipe Diameters Downstream.

Always utilize the most appropriate PPE during installation and service of Truflo products.

Personal Protective Equipmet (PPE)

03

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

04

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

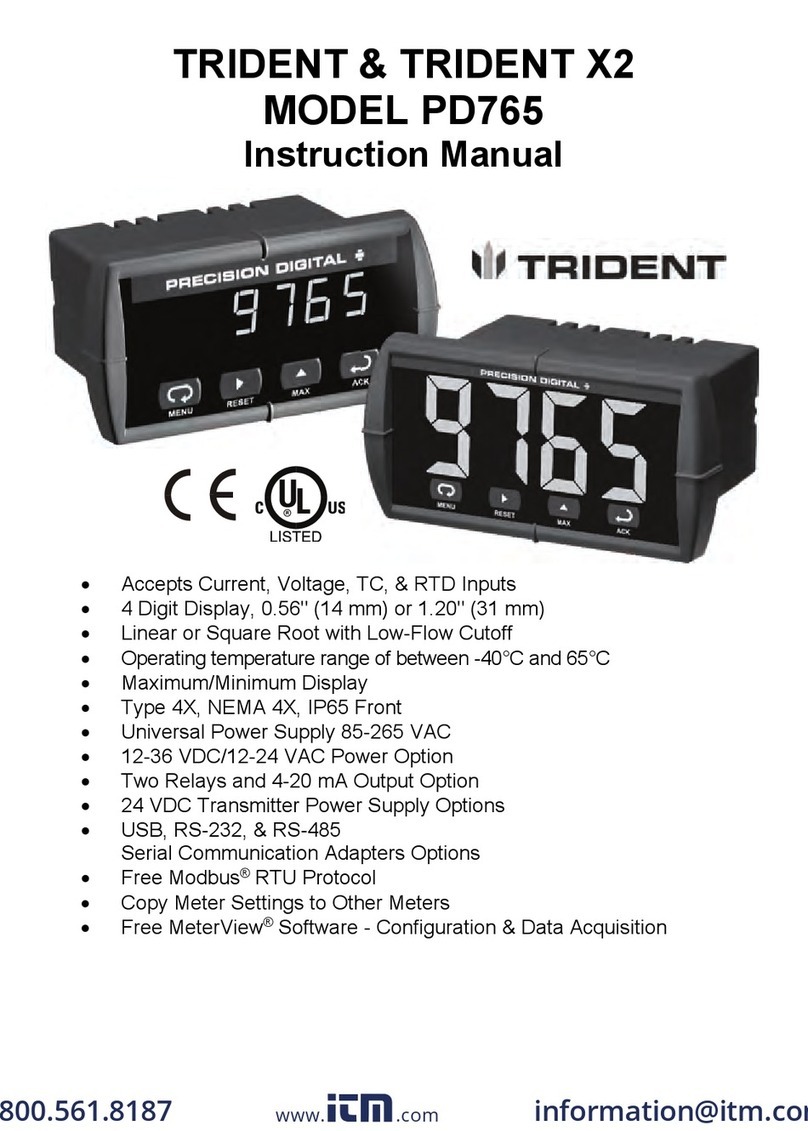

Technical Specifications

General

Operating Range 0.3 to 33 ft/s

Pipe Size Range ½ to 4"

0.1 to 10 m/s

DN15 to DN100

Linearity ±0.5% of F.S @ 25°C | 77°F

Repeatability ±0.5% of F.S @ 25°C | 77°F

Fluid Water or Chemical Liquid-Viscosity Range: .5-20 centistokes

Flow velocity 10 m / s max

Low cut 0.3 m / s min.

Operating press. 150 PSI (10 Bar) @ Ambient Temp-Non Shock

Range ability 10 : 1

Response time Real Time

Flow total meter Range = 0~999999 ; Unit = Gallon or Liter or Ton (KL) Selectable

Repeatability Range = 0.0~999.9 ; Unit = GPM or LPM or TPM Selectable

Accuracy ± 0.5% of F.S. @ 25°C

Electrical

Operating voltage Battery 3.0 VDC

Battery Lithium Battery (CR2477T)

Life of battery >1 Year Normal >2 Years Eco Mode

Wetted Materials

Sensor Body PVC (Dark) | PP (Pigmented) | PVDF (Natural)

O-Rings FKM | EPDM* | FFKM*

Rotor Pin | Bushings Zirconium Ceramic | ZrO2

Paddle | Rotor ETFE Tefzel®

Max. Temperature/Pressure Rating - Standard and Integral Sensor | Non-Shock

PVC 180 psi @ 68°F

180 psi @ 68°F

12.5 bar @ 20°C

12.5 bar @ 20°C

PP

200 psi @ 68°F 14 bar @ 20°C

40 psi @ 140°F

40 psi @ 190°F

2.7 bar @ 60°C

2.7 bar @ 88°C

40 psi @ 240°F 2.7 bar @ 115°C

PVDF

Operating Temperature

PVC 32°F to 140°F

PP -4°F to 190°F

0°C to 60°C

-20°C to 88°C

PVDF -40°F to 240°F -40°C to 115°C

Standards and Approvals

CE | FCC | RoHS Compliant

Outputs

TKB Series Flow | Frequency Pulse - Total

Exploded View

Model Selection

6

5

7

Same Controller | Rotor Assembly for All Sizes

4" ½"

05

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

Removable Cover

(No Tools Required)

Removable Cover

LPM | GPM | KL

Waterproof Battery

Holder Standard

"C" Type Battery

Screen Backlight

Battery Life

Indication

1. Polycarbonate Cover

2. Flow Controller

3. Hall Pickup Sensor

4. Redesigned Rotor Assembly

5. Body | PVC | PP | PVDF *

6. Re-inforced Inserts

7. Shearpro Contoured Rotor

Zirconium Rotor Pin & Bearings

1

2

3

4

TKB

-- - -

15 PF V S

Pipe Size Body Material

PVC = PVC

PP = PP

PF = PVDF

ST = SUS 316

O-Rings Seals

V = Viton***

E = EPDM

End Connections

08 = DN08 (¼")*

10 = DN10 (3/8")*

15 = DN15 (½")

20 = DN20 (¾")

25 = DN25 (1")

* SST Version Only | Note : Sanitary and Flanged Connections Size ½"- 4" Only

** Plastic Versions Only *** Viton is Standard

40 = DN40 (1 ½")

50 = DN50 (2")

65 = DN65 (2 ½"

80 = DN80 (3")**

100 = DN100 (4")**

(PVC) T = NPT | S = SOC | F = Flanged

(PP | PVDF)T = NPT | B = Butt | F = Flanged

(316SS) T = NPT | S = Sanitary | F = Flanged

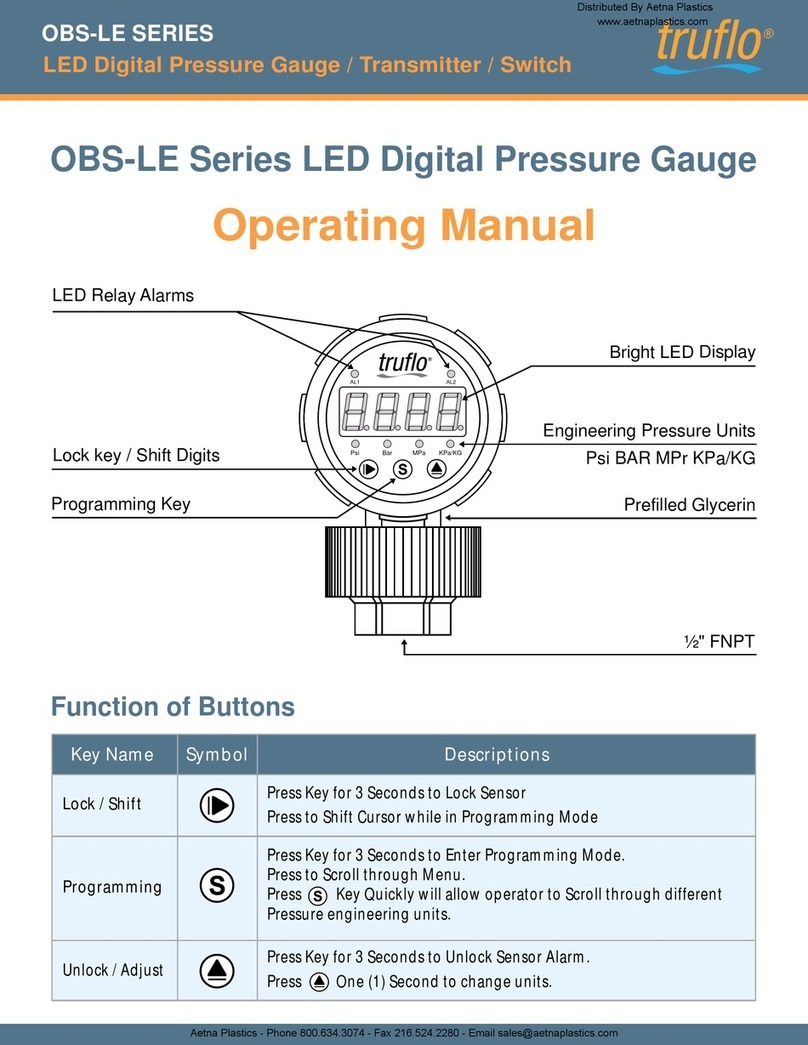

0~999999

or

0.1~9999.9

SELECTION DESCRIPTION

Battery Installed | LCD Display On r = Flow Rate | Default Setting

Programmable

0~9

Selectable

Programming

Backlight 'ON'

Time

Programming

Alarm Delay

time | sec

Factory Unlock Number is 8 Enter ANY Number from 0 - 9 to Set

Press SET & FF Key for 5 sec Password #

Flow Rate or Flow Total Display Flashing

Set Password Enter #

Factory Preset 1. Flow Coefficient = Input pulses x 1/k *

Changing K Factor K = #

Press Key for 3 sec (Hold)

Press

& Hold

3 Sec

Press to Scroll Between

Flow Rate and Flow Total Totalizer

or

Press & Key for 5 sec

dSP-Eco

dSP-non

1. dSP-non | Press any key to turn on the LED back light | Default

is set to 6 seconds

2. dSP-Eco | Backlight LED function is not active

Display Mode dSP.non

1~9999

In dSP-non mode Backlight default is t-0006 | Set Duration Time

(sec) of Backlight to remain On.

Press any key to turn on the display to turn on LED light

(> Time = < Reduced Battery Life)

Light -On t-5

1~9999

Delay Time ensures Alarm Setting only becomes

active after the flow remains constant for xx seconds

Programming the High | Low Alarm

Press + 3 Sec to Display High Alarm Setting

Press or to EnterAlarm Value.

Press to Display Low Alarm Setting. Press or to Enter

Alarm Value. The Press to Confirm

Flow Alarm Delay dt-10

SETUP

Programming

Totalizer

Password

1. To Prevent Totalizer reset - Enter Password Number 0-9

(excluding # 5 ) Flow Totalizer Reset Protection Active

2. rESEt.= 5 Default = Flow Totalizer Reset Enabled

Reset Totalizer rESEt.0

Only required if changing displays from one size to another

i.e. 1" to 2" pipe size

SET

SET

SET

Press to Scroll Between Flow

Rate and FlowTotal (Totalizer)

SET

Selection of the Engineering Units for Flow Rate | Flow Total

Press Key for Hold 3 Seconds, then press or to select Flow Rate Units Flow Total | Totalizer Units

GPM LPM TPM GAL LTR KL

06

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

Programming

Press key

Press key

Press key

Press key

Press key

Press to Select

or

Press to Select

or

Press to Select

or

Press to Select

or

Press to Select

or

Press to Select

or

F

07

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

Flow Totalizer

1. Please press the key for 3 seconds hold to show current value of the 7th ~ 8th digits

2. After releasing the key the current value of the 1st ~ 6th digits will be displayed

Display the Current Value of Flow Totalizer : Range 0~99,999,999

Alarm Limit of Flow Rate Meter

Low Battery Notification

Displaying Flow Rate |Flow Totalizer

How to Set the Alarm Limit of Flow Rate Meter?

The Flow Total | Totalizer can be Protected from an Accidental Reset. To set lockout program any number from 0-9 excluding | # 5 | The

Unlock Number = 5 = Factory Default

Totalizer Reset Press Both & Keys Together for 3 Seconds

Full Scale

Mild Scale

Low Scale (Pilot BAT flashing)

3.0V

< 3.0V

< 2.8V

< 2.6V

Low Voltage (Pilot BAT & Display flashing)

Voltage of Battery Symbol of Battery Status

ECO GAL KL GPM LPM TPM

LTR

TKB Series Battery LCD Flow Meter

SET

F

ECO GAL KL GPM LPM TPM

LTR

Flow RateFlow Rate

Battery Life

Mode of Operation

(Eco) = Extended Battery Life

Press and Hold Set

for 3 Sec to Change

from Flow Rate to

Flow Total

r indicates Default

Flow Rate Mode

Press & Hold for 3 Sec

to view 8 + 9 digits while

in Totalizer Screen

Highlighted to Indicated

Programmed Unit of Measurement

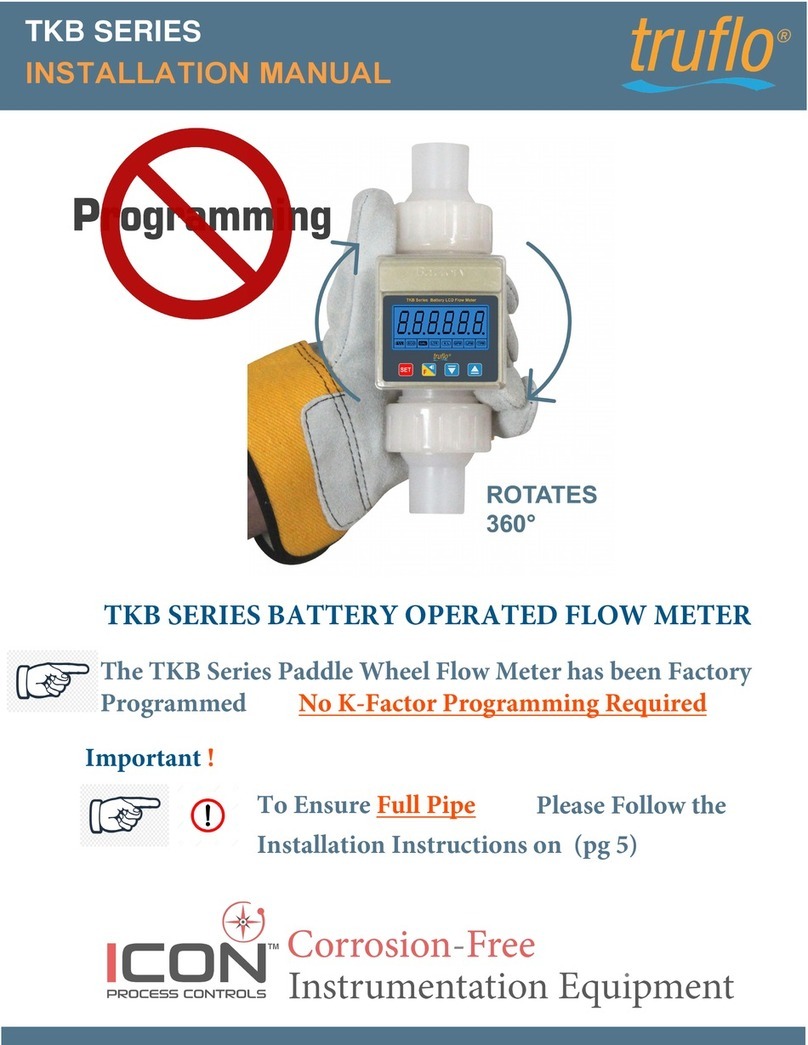

K-Factors for TK

Dimensions

Pressure vs. Temperature Psi H2O |Non-Shock

Flow Rates

72

124

19

54

4.7

10.3

2.1

LPM

¾"

½"

1 ½"

1"

3"

2"

4"

Size

274

471

72

171

18

39

8

GPM

K-Factor is Pre-Programmed

Pipe Size (O.D.) LPM |GPM LPM |GPM

0.3m/s min. 10m/s max.

DN15 (½")

DN20 (3/4")

DN25 (1")

DN40 (1 ½")

DN50 (2")

2 ½

DN80 (3")

DN100 (4")

3.5 | 1.0

5.0 | 1.5

9.0 | 2.5

25.0 | 6.5

40.0 | 10.5

60.0 | 16

90.0 | 24

125.0 | 33

120 | 32

170 | 45

300 | 79

850 | 225

1350 | 357

1850 | 357

2800 | 739

4350 | 1149

INCHES mm

NOMINAL SIZE PVC

30° F

70° F 71° F

105° F 106° F

120° F 121° F

140° F - 5° F

85° F 86° F

120° F 121° F

140° F 141° F

175° F - 5° F

70° F 71° F

105° F 106° F

140° F 141° F

175° F 176° F

210° F

PP PVDF

½-2

2-½

3

4

15-50

65

80

100

150

150

150

150

120

120

120

120

100

100

100

100

30

NA

NA

NA

150

150

150

150

110

95

95

95

90

70

70

70

55

40

40

40

150

150

150

150

125

125

125

125

100

100

100

100

85

85

85

85

55

55

60

60

67.0

ECO GAL K L GPM LPM TPM

LTR

TKB Series Battery LCD Flow Meter

SET

F

65.0

49.0

Pipe Size 1/2" FactorK 116

Body PVDF O-Rings Viton

Rate Min. 1.0 GPM Rate Max. 32 GPM

Lot No, 1710

ECO GAL K L GPM LPM TPM

LTR

TKB Series Battery LCD Flow Meter

SET

F

V

E

R

T

I

C

A

L

ECO GAL K L GPM LPM TPM

LTR

TKB Series Battery LCD Flow Meter

SET

F

HORIZONTAL

08

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

Pipe Size 1/2" FactorK 116

Body PVDF O-Rings Viton

Rate Min. 1.0 GPM Rate Max. 32 GPM

Lot No, 1710

Pipe Size 1/2" FactorK 116

Body PVDF O-Rings Viton

Rate Min. 1.0 GPM Rate Max. 32 GPM

Lot No, 1710

Pipe Size 1/2" FactorK 116

Body PVDF O-Rings Viton

Rate Min. 1.0 GPM Rate Max. 32 GPM

Lot No, 1710

Pipe Size 1/2" FactorK 116

Body PVDF O-Rings Viton

Rate Min. 1.0 GPM Rate Max. 32 GPM

Lot No, 1710

GPM

SET

F

+

TKB Series Battery LCD Flow Meter

GPM

SET

F

+

TKB Series Battery LCD Flow Meter

SET

TKB Series Battery LCD Flow Meter

GPM

F

GPM

SET

F

Lightly Press on

Both Sides Battery

Cover

Remove the Battery

Cover Remove the Battery Insert the New Battery

Ensure (+ -) orientation is

correct

1 2 3 4

1 2 Lift the display

Rotate Display Reposition the Display Tighten (Snug) the Allen Screws

Both Sides

3

4 5 6

Lightly pull on the screws in

an outwards direction Screws

are Captive - Do Not

Completely Remove

Use an Allen key and loosen

the screws located on both

side of the display

09

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

Battery Replacement

Procedure to Rotate Display

Please Ensure Full Pipe

TK Series can be installed in a horizontal or vertical direction.

Please ensure enough length of straight pipe to avoid turbulence that can effect readings.

Note: Min 10x Pipe Diameters Upstream 3x Pipe Diameters Downstream.

A Plastic Basket Strainer, Bag Filter or Y Strainer Filtering Device upstream to Avoid the Paddle Wheel from being damaged by the solids

or fibers - max 10% Particle Size - Not to Exceed .5mm Cross Section or Length.

Please do not flush the pipe after the Flow Meter is installed with Compressed Air this may damage the ceramic shaft and will Void Warranty

10x 3x

CORRECT INCORRECT

10x 3x

CORRECT

INCORRECT

10x 3x

CORRECT

INCORRECT

10x 3x

CORRECT INCORRECT

Installation Positions

10

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

Warranty, Returns and Limitations

Icon Process Controls Ltd warrants to the original purchaser of its products that such products will be free from defects in

material and workmanship under normal use and service in accordance with instructions furnished by Icon Process Controls Ltd

for a period of one years from the date of sale of such products. Icon Process Controls Ltd obligation under this warranty is

solely and exclusively limited to the repair or replacement, at Icon Process Controls Ltd option, of the products or components,

which Icon Process Controls Ltd examination determines to its satisfaction to be defective in material or workmanship within the

warranty period. Icon Process Controls Ltd must be notified pursuant to the instructions below of any claim under this warranty

within thirty (30) days of any claimed lack of conformity of the product. Any product repaired under this warranty will be warranted

only for the remainder of the original warranty period. Any product provided as a replacement under this warranty will be warranted

for the one year from the date of replacement.

Warranty

Products cannot be returned to Icon Process Controls Ltd without prior authorization. To return a product that is thought to be

defective, go to www.iconprocon.com, and submit a customer return (MRA) request form and follow the instructions therein. All

warranty and non-warranty product returns to Icon Process Controls Ltd must be shipped prepaid and insured. Icon Process

Controls Ltd will not be responsible for any products lost or damaged in shipment.

Returns

This warranty does not apply to products which: 1) are beyond the warranty period or are products for which the original purchaser

does not follow the warranty procedures outlined above; 2) have been subjected to electrical, mechanical or chemical damage due

to improper, accidental or negligent use; 3) have been modified or altered; 4) anyone other than service personnel authorized by

Icon Process Controls Ltd have attempted to repair; 5) have been involved in accidents or natural disasters; or 6) are damaged

during return shipment to Icon Process Controls Ltd reserves the right to unilaterally waive this warranty and dispose of any

product returned to Icon Process Controls Ltd where: 1) there is evidence of a potentially hazardous material present with the

product; or 2) the product has remained unclaimed at Icon Process Controls Ltd for more than 30 days after Icon Process Controls

Ltd has dutifully requested disposition. This warranty contains the sole express warranty made by Icon Process Controls Ltd in

connection with its products. ALL IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. The remedies of repair

or replacement as stated above are the exclusive remedies for the breach of this warranty. IN NO EVENT SHALL Icon Process

Controls Ltd BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND INCLUDING PERSONAL

OR REAL PROPERTY OR FOR INJURY TO ANY PERSON. THIS WARRANTY CONSTITUTES THE FINAL, COMPLETE AND

EXCLUSIVE STATEMENT OF WARRANTY TERMS AND NO PERSON IS AUTHORIZED TO MAKE ANY OTHER

WARRANTIES OR REPRESENTATIONS ON BEHALF OF Icon Process Controls Ltd. This warranty will be interpreted pursuant

to the laws of the province of Ontario, Canada.

If any portion of this warranty is held to be invalid or unenforceable for any reason, such finding will not invalidate any other

provision of this warranty

For additional product documentation and technical support visit www.iconprocon.com | e-mail: [email protected]

Limitations

11

In-Line Paddle Wheel Flow Meter

TKB SERIES Battery Operated

Other manuals for TKB Series

2

Table of contents

Other truflo Measuring Instrument manuals

truflo

truflo TKB Series Instruction manual

truflo

truflo TIB Series User manual

truflo

truflo TKS Series Instruction manual

truflo

truflo ICON TIR Series User manual

truflo

truflo ULTRAFLO 5000 User manual

truflo

truflo TIM Series Instruction manual

truflo

truflo OBS-LE Series User manual

truflo

truflo TIP Series User manual

truflo

truflo TKB Series User manual

truflo

truflo UltraFlo 500 Series User manual