truflo TIB Series User manual

TIB SERIES

INSTRUCTION MANUAL

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

Read the User's Manual Carefully.

Manufacturer Reserves the Right to Implement Changes Without Prior Notice.

General Data

02

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

Specification Description

Battery Lithium Battery | 3 VDC

Life of Battery 3 Years | Sleep Mode

Current Consumption 60mA max.

Flow Totalizer GAL | LTR 0 -999999

Flow Rate GPM | LPM 0.0 -999.9 GPM

Fluid Water | Liquid Chemicals

Accuracy ± 0.5% of F.S. @ 25°C

Response frequency 5K Hz

Max Flow Rate 10m/s | 33ft/s

Min Flow Rate 0.1m/s | 0.3ft/s

Materialsof Construction Paddle | ETFE Tefzel®

Rotor | Bushings | Zirconium Ceramic

Sensor Body | PVC | PP | PVDF

O-Ring Material Viton (std) | EPDM*

Operating Temperature PVC < 60°C | PP < 80°C | PF < 100°C

Protection Class IP-65 | General Purpose

Approval CE | RoHS

*Optional

1. De-pressurize and Vent System Prior to Installation or Removal.

2. Confirm Chemical Compatibility Before Use.

3. DO NOT Exceed Maximum Temperature or Pressure Specifications.

4. ALWAYS Wear Safety Goggles or Face-Shield During Installation and/or Service.

5. DO NOTAlter Product Construction.

Safety Information

WARNING!

Indicates a potential hazard. Failure to follow all

warnings may lead to equipment damage, injury, or

death

Warning | Caution | Danger

Overtightening may permanently damage product

threads and lead to failure of the retaining nut.

Hand Tighten Only

Use of tool(s) may damage product beyond repair

and potentially void product warranty.

Do Not Use Tools

Always utilize the most appropriate PPE during

installation and service of Truflo products.

Personal Protective Equipment (PPE)

Sensor may be under pressure, take caution to vent

system prior to installation or removal. Failure to do so

may result in equipment damage and/or serious injury.

Pressurized System Warning

Highlights additional information or detailed

procedure.

Note | Technical Notes

03

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

TIB Series

OP1 FTM OP2 GPM

Very Important

Lubricate O-rings with a Viscous Lubricant Compatible

with the Materials of Construction.

Using an Alternating | Twisting Motion Carefully Lower

the Sensor into the Fitting. | Do Not Force | Fig 5

Ensure Tab | Notch are Parallel to Flow Direction | Fig-2

Ensure Amble Silicon Grease

(Supplied) is Applied Prior to Insertion Ensure Location Tabs

Are Parallel to Direction of Flow

Fig-3

Screw Down

Retention Cap

Ensure O-Rings

are well Greased

Lubricate (Grease)

Inside of Insertion

Fitting

Positioning Tab

Notch

1¼" NPT

Fig-5

Hand Tighten the Sensor Cap. DO NOT use any tools on the sensor cap

or the cap threads or fitting threads may be damaged. | Fig-5

Process Pipe

(Top View)

Flow

Sensor Blade

Ensure Tab

is Parallel to

Flow Direction

Fig-4

TIB Series

OP1 FTM OP2 GPM

01 02 03

Engage one Thread of the Sensor Cap

then turn the Sensor until the Alignment

Tab is Seated in the Fitting Notch,

Ensure Tab is Parallel to Flow Direction.

Flow Meter Positioning Tab and

Clamp Saddle

Notch

Hand Tighten the Screw Cap.

DO NOT use any Tools, Threads

may be Damaged.

Ensure Meter is Firmly in Place

Notch

Flow Meter

Very Important

Lubricate O-rings

with a Viscous

Lubricant

Compatible

with the System

Correct Sensor Installation

Tab

Notch

Fig-1 Fig-2

Installation

Retention Cap

Flow

04

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

* Maximum % Solids: 10% with particle size not exceeding 0.5 mm cross section or length.

Reducer

90° Elbow | Flow Upward

Flange

Outlet Outlet

2 X 90° Elbow

Inlet OutletInlet

OutletInlet

10xID 5xID 25xID 5xID 15xID 5xID

25xID 5xID 20xID 5xID

Good if NO

Sediment Present Good if NO Air

Bubbles Present Preferred Installation if Sediment* or Air

Bubbles may be Present

Installation Positions

Figure 1 Figure 2 Figure 3

Developed Turbulent Flow

Velocity

Profile

Flow

Ball Valve

OutletInlet

20xID 5xID

Correct Sensor Positioning

TIB

and

Series Flow Meters measure liquids only. No air bubbles should be present

the pipe must always be full. The sensors are not effective in laminar or

transitional flow applications. Minimum Reynolds number required is 4500.

For accurate flow measurement there must be a developed turbulent velocity

profile at the sensor location. This requires a straight run pipe with a minimum

number of pipe diameters distance upstream and downstream of the flow

sensor. These distances depend on the type of piping element (i.e. valves,

elbows, reducers etc.) causing the disturbance. To ensure maximum accuracy,

the following guidelines need to be observed when installing.

90° Elbow | Flow Downward

Inlet Outlet

Inlet

05

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

Long Service Life

Maximum Pressure | Temperature

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

.7

1.4

2.1

2.8

3.4

4.1

4.8

5.5

6.2

6.9

7.6

8.3

9.0

9.7

10.3

11.0

11.7

12.4

13.1

13.8

14.5

(psi) (bar)

0-20 020 40 60 80 100

°F

°C -4 32 68 104 140 176 212

PVDF

Polypropylene

PVC

Note: During system design the specifications of

all components must be considered. | Non-Shock

The TIB Series is equipped with a Zirconium Ceramic Rotor Pin

and 2 Bushings. The TIB Series also incorporates a contoured,

'Low Drag' Paddle Wheel leading to reduced drag, longer wear

and a higher accuracy.

Dimensions | Display

36.5

9.0

Ø84.0

98.0

TIB

Series TKT

Series

OP

1FT

MOP

2GP

M

ECO GAL KL GPM LPM TPM

LTR

Flow Rate

Flow Total

Battery Life

(Eco) = Extended Battery Life

Highlighted to Indicated

Programmed Unit of

Measurement

4Blade ETFE (Tefzel®) Rotor

•Open Channel Design Avoids Cavitation

•Re-Designed Contoured Paddle

Integrated Solid State Electronics

•Encapsulated in Epoxy

Sensor Body

•Available in PVC | PP | PVDF

•2 Sensor Lengths to Measure 2" to 24" Pipes

Ceramic Rotor |Bushings

Rotor

Contoured

Paddle

High Chemical Resistance

Long Life - 40 years/m/s

Self Cleaning Design

•

•

•

06

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

Current Flow Rate | Total

0-1

Programming

OPERATION

RANGE

DISPLAY

STEPS

Home Screen

Press & (HOLD)

Step-1

Screen Lock

Step-2 Programming Lock Out Feature

LCK= '0' Unlocked : Factory Default

LCK= '1' Locked

3 sec

Press Key

0.1-9999

K Factor

Step-3

Programming Display Units

OPERATION

RANGE

DISPLAY

STEPS

Display Units

Press (HOLD)

Step-1 Press to Select & Press To Confirm

Press

non | Eco

Display Mode

Step-4

dSP.non - LED Back Light | Default is set to 5 secs.

dSP-Eco - Back Light Function is not Active | Extended Battery Life

Press

Back Light Timer

Step-5

Time on for Back Light (Secs)

*Longer Time = Shorter Battery Life

Press

Flow Alarm Delay

Step-6

Press

Reset Totalizer

Step-7

rESEt.0 -Flow Totalizer Reset Disabled

rESEt.1(Default) -Flow Totalizer Reset Enabled

Press

Flow Rate - GPM | LPM | TPM

Flow Total - GAL | LTR | KL

1. Totalizer Reset Press Both Together for 3 Seconds

2. Sleep Mode Press for 3 Seconds to Reduce Power Consumption

3. Alarm Setup Press Both Together for 3 Seconds

Time Delay for Visual Alarm

3 sec

Press for Increase Value & Press for Decrease Value

Press to Save Value Press to Change Digit

1-9999

1-9999

Enter K Factor Value

See Chart on Page 9

0-1

07

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

Battery Replacement Procedure

08

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

04 05 06

01 02 03

08 0907

GENTLY tap pin with

Mallet or Hammer

GENTLY tap Rotor Pin

with Mallet or Hammer

Tap until Rotor is 50% out

Pull out Rotor Pin

Push in Rotor Pin

approx. 50%

Congratulations!

Replacement Procedure

Complete!

Pull Out Rotor Pin

entire way until

Paddle Wheel is loose

Paddle

Rotor Pin | Paddle Replacement Procedure

Insert New

Paddle in

Flow Meter

Rotor Hole

Line up Pin with Rotor Hole

Small Pin

Ensure Holes

are Aligned

1-¼"

1-¼"

CPVC Flange x 2

150 LB ANSI Flange

12. CPVC TEE FITTING (SCH80)

Socket Weld

CPVC Tee Style

Notch On Fitting

Ensure Notches

are Parallel to

Direction of Flow

Remember to Grease

Flowmeter & Fitting

09

Battery Operated Paddle Wheel Flow Meter

TIB SERIES

Pipe Size (O.D.) ANSI (ID) (Inches)

Sch (40) Sch (80)

DIN (ID)

(mm)

Flow Rate (LPM) / USGPM

0.3m/s min. 10m/s max.

1/2" | DN15 Ø20 3.5 | 1.0 120 | 32

3/4" | DN20 Ø25 5 | 1.5 170 | 45

1" | DN25 Ø32 9 | 2.5 300 | 79

1 ½" | DN40 Ø50 25 | 6.5 850 | 225

2" | DN50 Ø63 40 | 10.5 1350 | 357

2 ½ Ø75 60 | 16 1850 | 357

3" | DN80 90 | 24 2800 | 739

4" | DN100 125 | 33 4350 | 1149

0.55

0.74

0.96

1.50

1.90

2.30

2.90

3.80

0.62

0.82

1.00

1.40

2.00

2.50

3.10

4.00

Ø78

Ø96.50

Min | Max | Flow Rates

6" | DN150 Ø150 230 | 60 7590 | 1997

8" | DN200Ø200 315 | 82 10395 | 2735

5.70

7.56

6.06

7.94

K )DFWRU7DEOHV

Tee Fitting (Unit:inch)

Size DN Id

½"

¾"

1"

1-¼"

1-½"

2"

2-½"

3"

4"

15

20

25

32

40

50

65

80

100

0.55

0.74

0.96

1.30

1.50

1.90

2.30

2.90

3.83

1013.04

604.80

408.24

250.40

139.86

81.65

54.43

34.96

19.80

S

S

S

S

S

S

S

S

S

K-Factor

Sensor

Length

CPVC | SCH80

Clamp Saddles

Size DN Id

2"

3"

4"

6"

8"

50

65

80

100

150

1.9

2.3

2.9

3.8

5.7

81.65

34.96

19.80

9.18

5.21

S

S

S

L

L

K-Factor

Sensor

Length

CPVC | SCH80

Tee Fitting (Unit:inch)

Size DN Id

2"

2-½"

3"

4"

6"

8"

10"

12"

14"

16"

20"

24"

50

65

80

100

150

200

250

300

350

400

500

600

1.9

2.3

2.9

3.8

5.7

7.0

9.5

11.3

12.4

15.1

19.0

21.0

81.65

54.43

34.96

19.80

9.18

5.21

3.43

2.45

1.77

1.36

0.86

0.60

S

S

S

S

L

L

L

L

L

L

L

L

K-Factor

Sensor

Length

CPVC | SCH80

TEE FITTINGS CLAMP-ON SADDLES CPVC SOCKET WELD-ON

ADAPTERS

4

"

Warranty Information

All warranty and non-warranty repairs being returned must include The RGA number and a fully completed Service

Form and Flow Meter. must be returned to Icon Process Controls directly or to the authorized distributor. Product

returned without a RGA number and Service Form will not be warranty replaced or repaired. Truflo Flow Meters are

warranted out of box but not against any damage, due to Process or Misapplication Failures e.g. High Temperature,

Chemical Attack or Physical Mishandling of Product.

TIB SERIES

Battery Operated Paddle Wheel Flow Meter

TIW

Flow Transmitter

Frequency Pulse Output

TIP

Flow Rate + Flow Total

Pulse | RS485

TIR

Pulse + 4-20mA

TIM

Flow Rate + Total Pulse | 4-20mA

TI Series Products

•Industry's Highest Accuracy: ±0.50%

•PVC | PP | PVDF

•Retrofits into Signet® Fittings

•Size Range - ½" - 24"

•Low Pressure Drop

•Password Protected Security

•Lifetime Warranty on Paddle Wheel Assembly

10

FLOW + PRESSURE + LEVEL + TEMP

for more information visit www.iconprocon.com

for more information visit www.iconprocon.com

Table of contents

Other truflo Measuring Instrument manuals

truflo

truflo ULTRAFLO 5000 User manual

truflo

truflo UltraFlo 500 Series User manual

truflo

truflo TIM Series Instruction manual

truflo

truflo TK Series User manual

truflo

truflo TKS Series Instruction manual

truflo

truflo TIP Series User manual

truflo

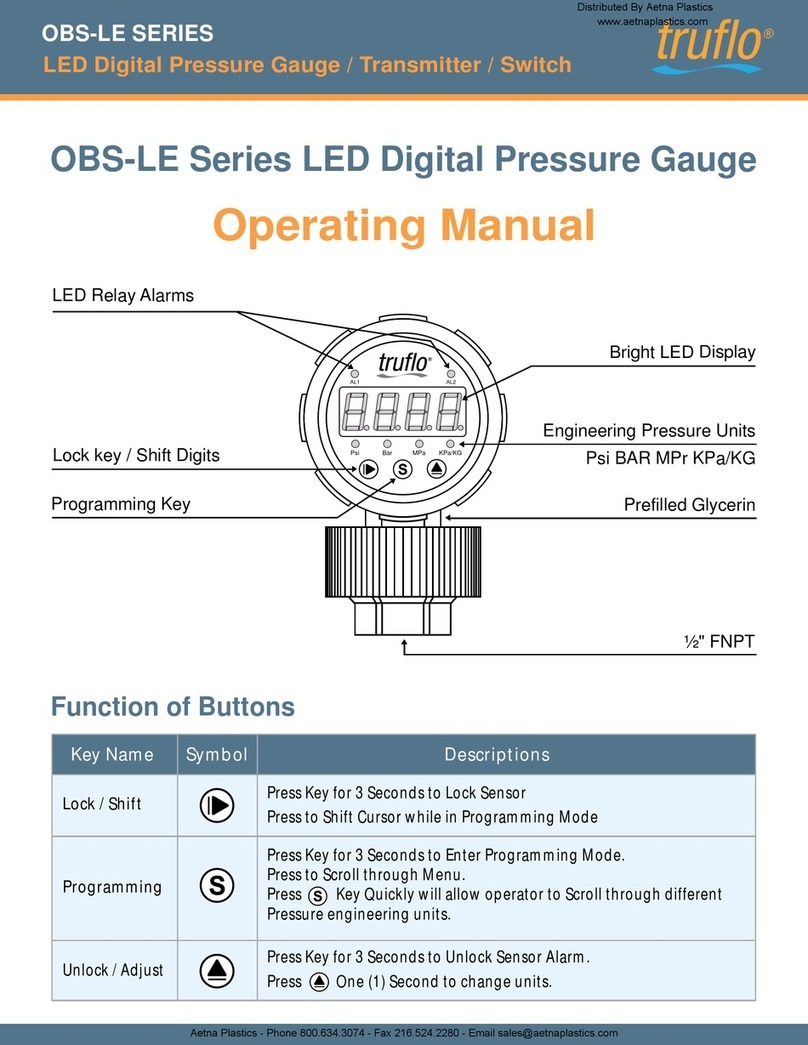

truflo OBS-LE Series User manual

truflo

truflo ICON TIR Series User manual

truflo

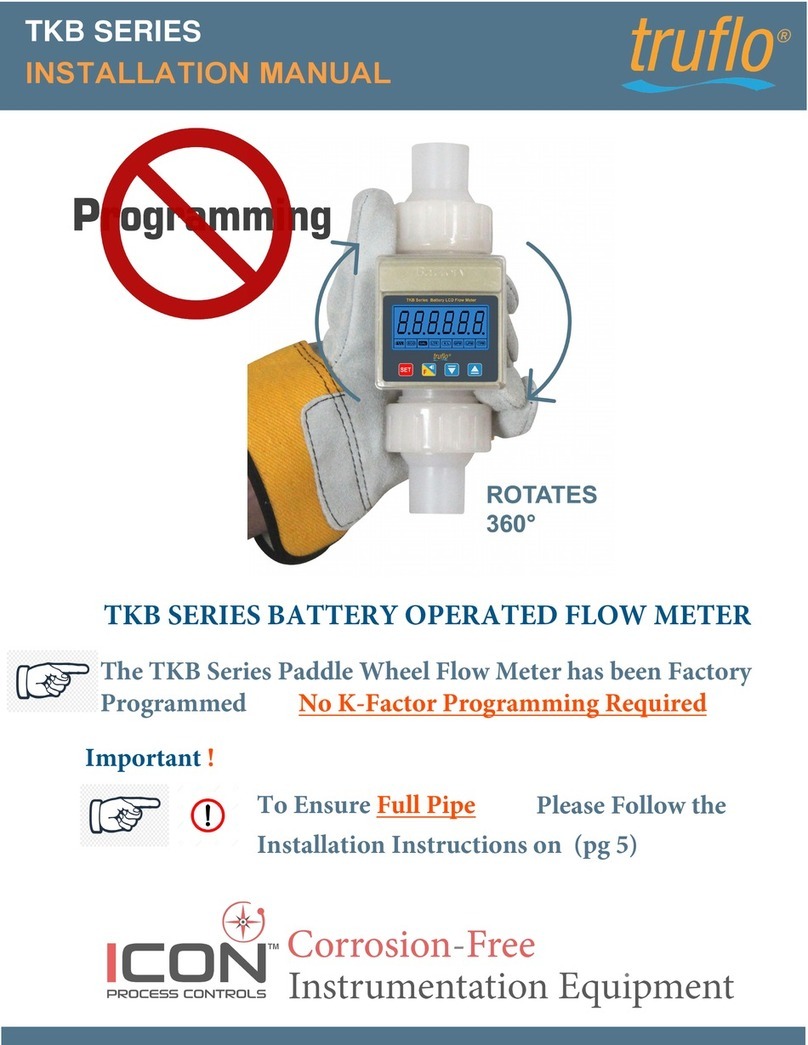

truflo TKB Series Instruction manual

truflo

truflo TKB Series User manual