4

IMPORTANT

BEFOREUSEREADTHESEINSTRUCTIONSAND RETAINFORFUTUREREFERENCE

1. Generalinformation

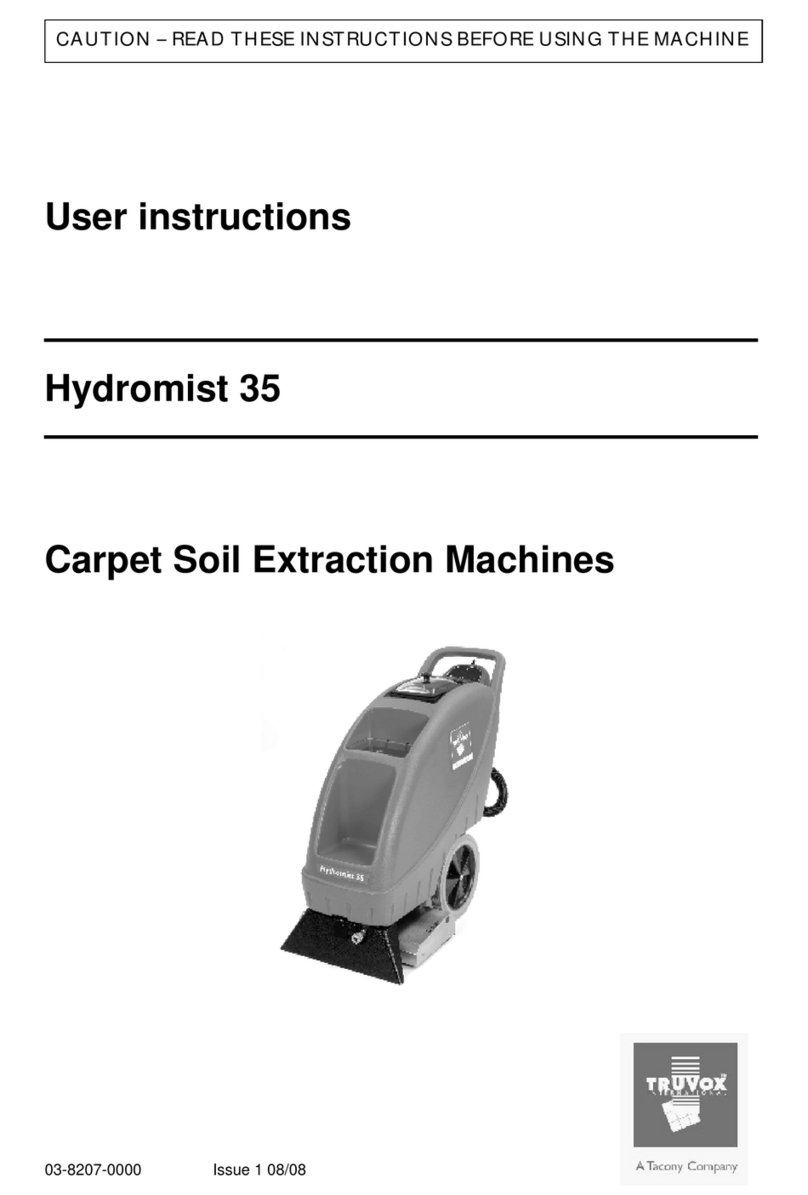

The HM 10 and 20 carpet soilextraction

machinesaredesigned forthe efficientcleaning

of carpetsand upholstery. Theyhavebeen

designed forthe professionalusertoensurelong

servicelifeand safeoperation.

Theseinstructionsonlycoverthe operation of the

machinesand do not include information on the

basicsofcarpetcleaning.Anyusernotfamiliar

withbasiccarpet cleaning shouldcontacttheir

supervisororTruvoxInternational before

proceeding.

Thesemachinesmust onlybe used forthe

manufacturer’sapproved application.Theyare

designed forthe cleaning and removalof normal

carpet soil. Donotuse the machineswhereitis

suspected that the carpetorupholstery contains

healthendangering dust ordebrissuchas

asbestosorchemicalwaste. If thisissuspected

donotproceed, contact yoursupervisoror

TruvoxInternationalforadvice.

The following instructionscontainimportant

information aboutthe machinesand safety

adviceforthe operator.

Equipmentmust be operated,serviced and

maintained inaccordancewiththe

manufacturer’sinstructions. Ifindoubtcontact

thesupplier ofyourmachine.

Theseinstructionsarevalidforthe following

models:

HM10,HM20 andallvariants

1.1ImportantSafetyAdvice

Whenusing electricalequipment basicsafety

precautionsshouldbe followed including the

following.

•Read allinstructionscarefullybeforeuse.

•Keep children and unauthorised persons

awayfromthe machine when inuse.

•Do not leavethe machine connected tothe

electricitysupplywhen not inuse; always

removethe plug fromthe socket-outlet.

•Switchoff the machine beforeremovingthe

plug.

•Whenunplugging pullthe plug, notthe supply

cord.

•Do not operateswitchesortouchthe mains

plug withwet handsasthismaycauseelectric

shock.

•Do not operatethe machine withadamaged

supplycordorplug,orafterthe machine

malfunctionsorisdamaged inanyway.

Contact an authorised ServiceAgentfor

repairoradjustment.

•The plug of the powersupplycordmust be

removed fromthe socket-outlet before

commencing cleaning ofthe machine or

undertaking maintenanceoperations.

•The powersupplycordmust be regularly

inspected forsignsof damage. Ifthe power

supplycordisdamaged,itmust be replaced.

•Do not usewherehazardousdust ispresent.

•Do not useinan explosiveatmosphere.

•Do not pickup oilorotherflammablematerial

withthe machine

•Takecarewhen using amachine nearthe top

of stairstoavoidoverbalancing.

1.2Guidelines fortheoperator

•Operatorsmust be fullytrained inthe useof

the machine inaccordancewiththese

instructions, abletoperformuser

maintenanceand the correct selection of

accessories.

•Operatorsshouldbe physicallycapableto

manoeuvre,transport and operatethe

machine.

•Operatorsshouldbe abletorecognise

unusualoperation of the machine and report

anyproblems.

•Wearsuitablefootweartoavoidslipping.

•Wearsuitableclothingtokeep dryand warm.

•Wherepossibleimplementjob rotation and

adequaterest periodstoavoidcontinuoususe

of the samemuscles.

•Do not leavethe machine running unattended

•Do not allowchildren tocrawlon carpetsuntil

thoroughlydry

•Keep cleaning solutionsawayfromchildren

and petsat alltimes

•Do not smokewhen using the machine.

•CAUTION -Thismachine isforindooruse

onlyand shouldnot be used orstored

outdoorsorinwet conditions.

•WARNING –Shouldwateremitfromthe

machine exhaust switchoff immediately and

refertoinstructionsfor UsingtheMachine

1.3Transportingthemachine

Whentransporting amachine ensurethat all

components, tanksand removablepartsare

securelyfastened, and thatthe supplycordand

plug arenottrailing.Detachhoseand wand from

machine foreaseof carriage.

Do not lift ortransport the machine whilst

containing liquidasthiswilladd considerablyto

the weight.

Takeextremecarewhen moving the machineup

ordownstepsorstairs.