7

5.3 Maintenance

WARNING-Beforeundertaking maintenance

operationsoradjustmentsswitchoff machine

and unplug from the electricitysupply.

Toreceivereliableservicefromthisequipment,

regulardailymaintenanceisarequirement.

Fabriccleaning,bothcarpet andupholstery,isa

verydirtyenvironment foranyequipment.

The following recommendationsare offered.

•Keepthe equipment clean,both inside and

out.

•Supplycord -Regularlyinspectsheath, plug

and cordanchoragefordamage orloose

connection.

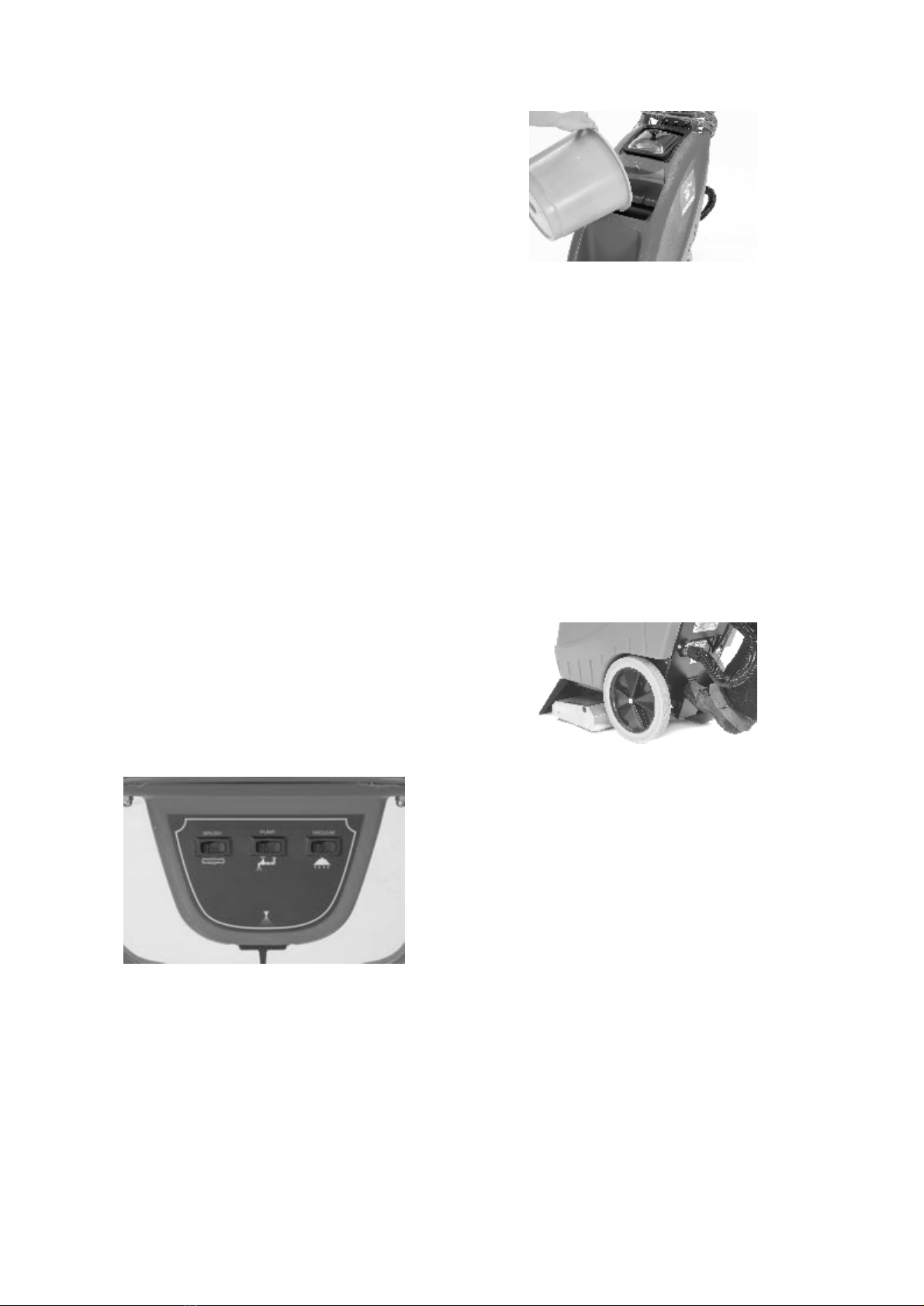

•Solution tank –checkfilterisclean and

undamaged. Adamagedfiltermustbe

replacedordamage to pumphead and spray

jet couldoccur.

•Vacuum head –Checkand removeany

debrisorlint build-up fromthe head.

•Sprayjet –Checkjet forblockage andfull

spraypattern. Blowthroughjet to clean. Do

not use a pin, asthiscoulddamage the jet.

•Lubricatebrass quickdisconnectsand drain

valveswith aqualitylubricant suchasWD-

40.

•Flushsolutionsystemsafterusewithclear,

clean water.(Awhite vinegarsolution may

alsobe used).Thiswillcounter-acthard

waterand alkalinedepositsand aidin

keeping orrificaesclean.

•Do not allowfluideitherinsolution orwaste

tankto sitovernight.The unitshouldbe

emptied and cleaned daily/ aftereveryuse.

•Cleanthe strainerinthe solution tank,the

filters on the vacuumstackinvacuumtank

and alllintfilters intheinletorvacuumtanks

daily/ afteruse.

•Do not usethesamebucket to fillsolution

tankthat isused toremovewaste fromthe

recoverytank.

•When the unitisnotinuse, leavethe

recoverytanklid open.

•Afteruse/beforestorage,run the vacuum

for2 minuteswith lid open and filteroff.

IMPORTANT –Allotherservicingand repairs

shouldonlybeperformed byaTruvoxengineer

orAuthorised Service Agent.

IMPORTANT –Shouldthe machinefailto

operatepleasereferto the faultdiagnosissection

inthebackofthe instruction manual.Ifthe

problem/remedyisnotlistedpleasecontact

TruvoxCustomerServiceDepartment forrapid

attention.

6AfterSales Service

Shouldyourequireaftersalesserviceplease

contactthesupplierfromwhomyou purchased

the machine, who willarrange service.Repairs

and servicing ofTruvoxproductsshouldonlybe

performed bytrained staff.Improperrepairs can

cause considerabledangersto the user.

Enquireabout the Truvoxlowcostand efficient

MaintenanceContract.

7 Guarantee

Yourproductisguaranteed for one yearfromthe

date oforiginalpurchase, orhirepurchase,

againstdefectsinmaterialsorworkmanship

duringmanufacture. Withinthe guarantee period

we undertakeat ourdiscretion, torepairor

replacefree ofcharge to the purchaser,anypart

found to be defective,subjectto thefollowing

conditions.

CONDITIONS

1. Claimsmade underthetermsof the

guarantee mustbe supported bythe original

invoice/bill ofsaleissued at the timeof sale,

orthe machine SerialNumber.

2. Forclaimsunderthisguaranteecontactthe

supplierfromwhomyoupurchased the

productwho willarrangetheappropriate

action.Do not initiallyreturnthe productas

thiscould resultin transitdamage.

3. NeitherTruvoxnoritsdistributors shallbe

liable foranyincidentalorconsequentialloss.

4. Thisguaranteeisgoverned bythelawsof

England.

5. Thisguarantee doesnotcoveranyofthe

following:

•Periodicmaintenance, and repairor

replacement ofpartsdue to normalwear

and tear.

•Damage caused byaccident, misuseor

neglect, orthefittingofotherthan genuine

Truvoxparts.

•Defectsinotherthangenuine Truvox

parts,orrepairs,modificationsor

adjustmentsperformed byotherthan a

Truvoxserviceengineerorauthorised

service agent.

•Costsand risksoftransportrelating

directlyorindirectlyto the guarantee of this

product.

•Consumableitemsand wearpartssuchas

drive belts.

Thisguarantee doesnotaffectyourstatutory

rights,noryourrightsagainstthe supplierarising

fromtheirsalesorpurchase contract.

8 WasteElectrical & Electronic Equipment

Do not dispose ofthisdevicewith unsorted

waste. Improperdisposalmaybe harmfulto the

environment and human health.

Please referto yourlocalwaste authorityfor

information on return and collection systemsin

yourarea.