Truweld TWE-SC900 User manual

TRU‐WELDEQUIPMENTCOMPANY

6400N.HoneytownRoad

Smithville,Ohio44677

(330)725‐7744Phone

(330)669‐2473Fax

http://truweldstudwelding.com

Operations Manual

TheSC900isafullyintegratedstudweldingsystemforferrule‐

shieldedandgas‐shieldeddrawnarcstudwelding.TheSC900con‐

tainsdigitalcontrolsforweldtime,weldcurrent,andgaspurgetime.

Thesystemwasdesignedtobeaperfectfitforshopuse,weldingup

through1/2”studs.Thisisallcontainedinacompact,portablepack‐

age.

TWE - SC900

Drawn Arc Gas Short Cycle

Stud Welding System

Version2.103/24/2014

2

TRU‐WELDEQUIPMENTLIMITEDWARRANTY

AllgoodsproducedbyTruweldEquipmentshallbewarrantedagainstdefectsincludingworkmanshipandcomponents.Nootherwar‐

rantieswhetherexpressed,verbal,orimpliedwillapply.Warrantiesonlyapplytotheoriginalequipmentpurchaser.

WarrantyclaimswillbelimitedtoeitherrepairorreplacementofthedefectivematerialsbyTruweldEquipment.AttheoptionofTru‐

weldEquipmentthelocationofwherethewarrantyevaluationandrepairsaremadewillbedetermined.Allwarrantyclaimitemsre‐

turnedtoTruweldEquipmentwillbeatthecustomer’sexpense.AttheoptionofTruweldEquipmentthedefectwilleitherberepaired

orreplaced.NoticemustbeprovidedtoTruweldEquipmentofawarrantydefectwithin30daysthatthedefectorfailureisincurred.

Warrantiesarenottransferable.

Thiswarrantydoesnotapplyforequipmentwhichisusedimproperlyinanyfashionincludingbutnotexclusivetothefollowing:

Equipmentwhichhasbeenmodified

Equipmentwhichhasnotbeeninstalledproperly

Equipmentwhichhasbeenusedforpurposesotherthanwhichithadbeendesigned

Equipmentwhichhasnotbeenproperlymaintained

Equipmentwhichwascontinuedtobeusedafteradefecthadbeenfound

Equipmentwhichwasdamagedinanyway

TruweldEquipmentwillneverbeliableforconsequentialdamages,loss,orexpenseoccurringdirectlyorindirectlyfromtheuseofthe

equipmentcoveredinthiswarranty.

Allcables,cablesetsandconnectorsarenotwarranted.

Two(2)yearwarrantyperiodfromdateofpurchase

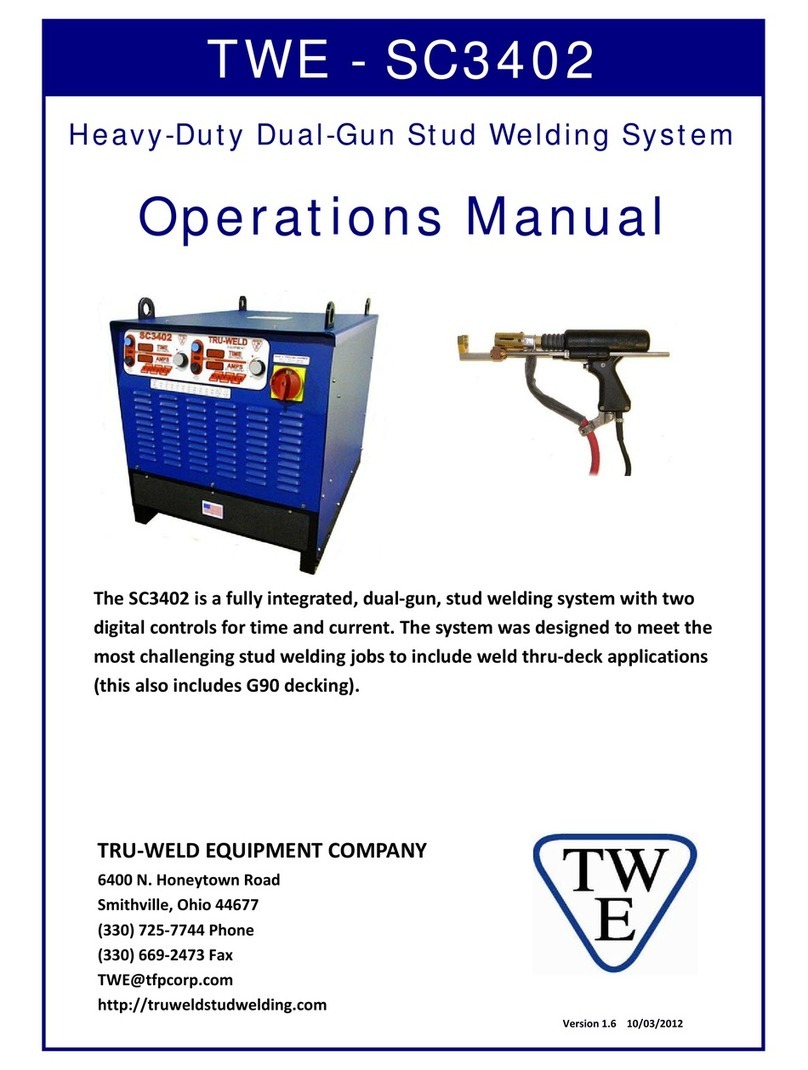

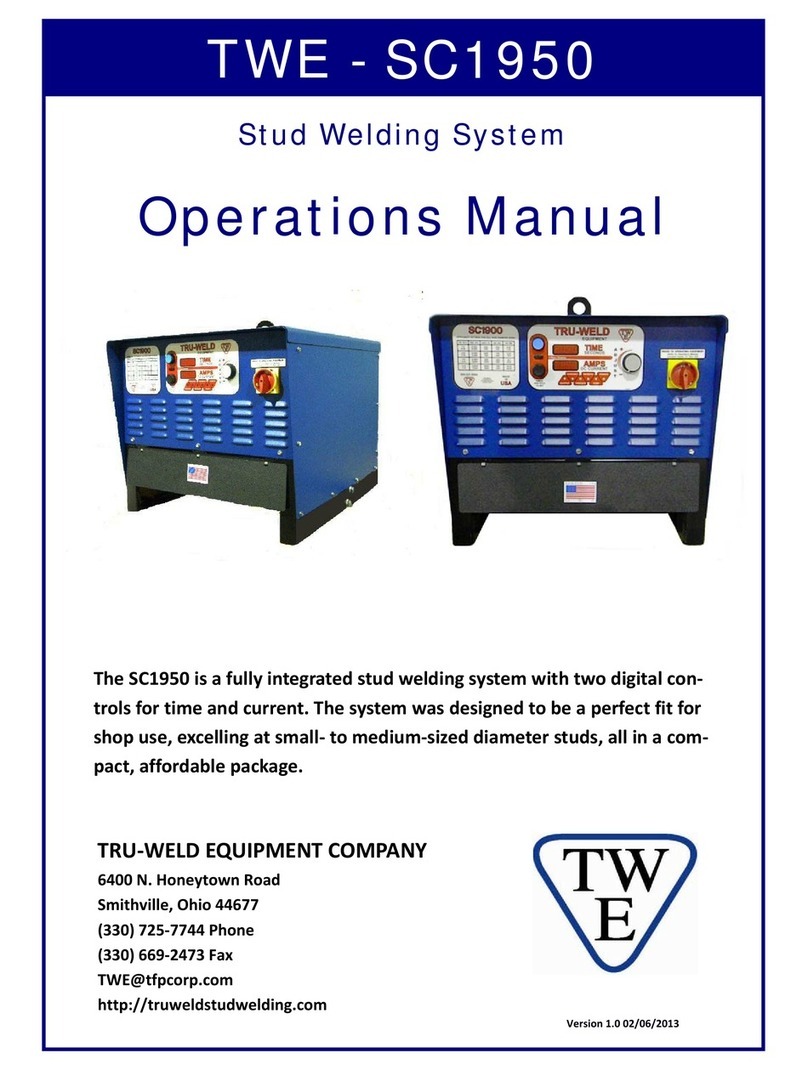

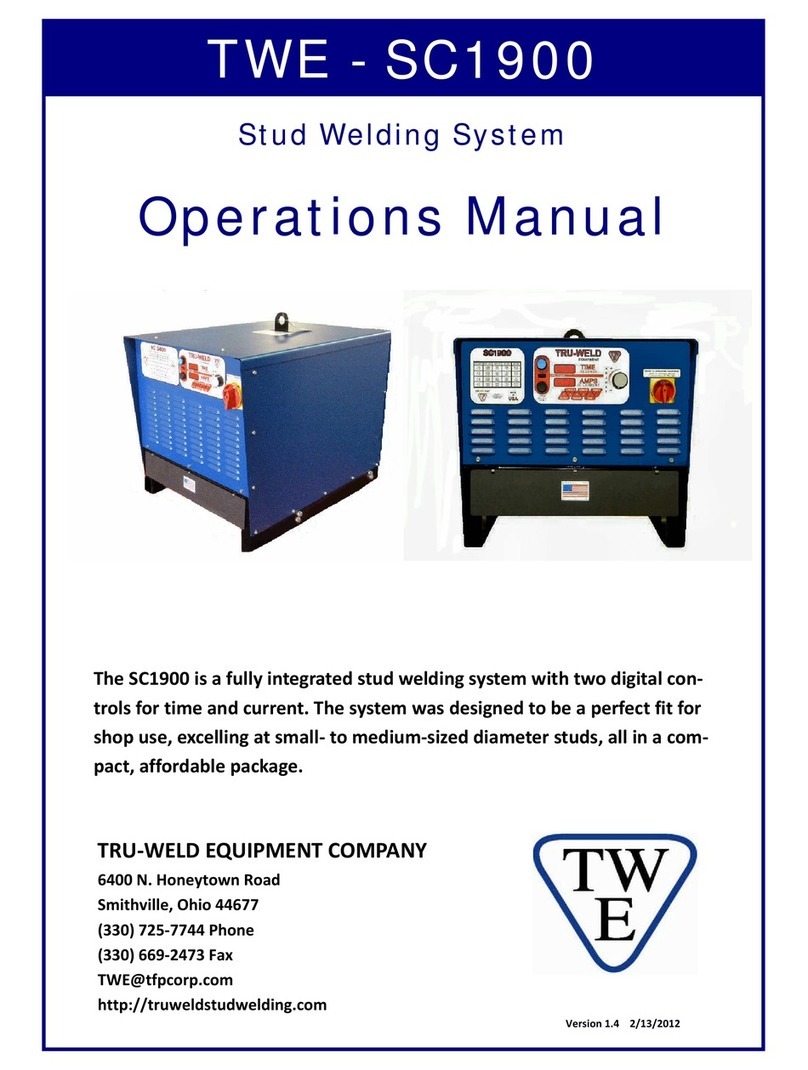

TWE250PowerSupply SC1900PowerSupply

TWE321PowerSupply SC1950PowerSupply

TWE375PowerSupply SC2400PowerSupply

SC900PowerSupply SC2402PowerSupply

SC1400PowerSupply SC2420PowerSupply

SC1450PowerSupply SC3400PowerSupply

SC1600PowerSupply SC3402PowerSupply

SC1650PowerSupply

One(1)yearwarrantyperiodfromdateofpurchase

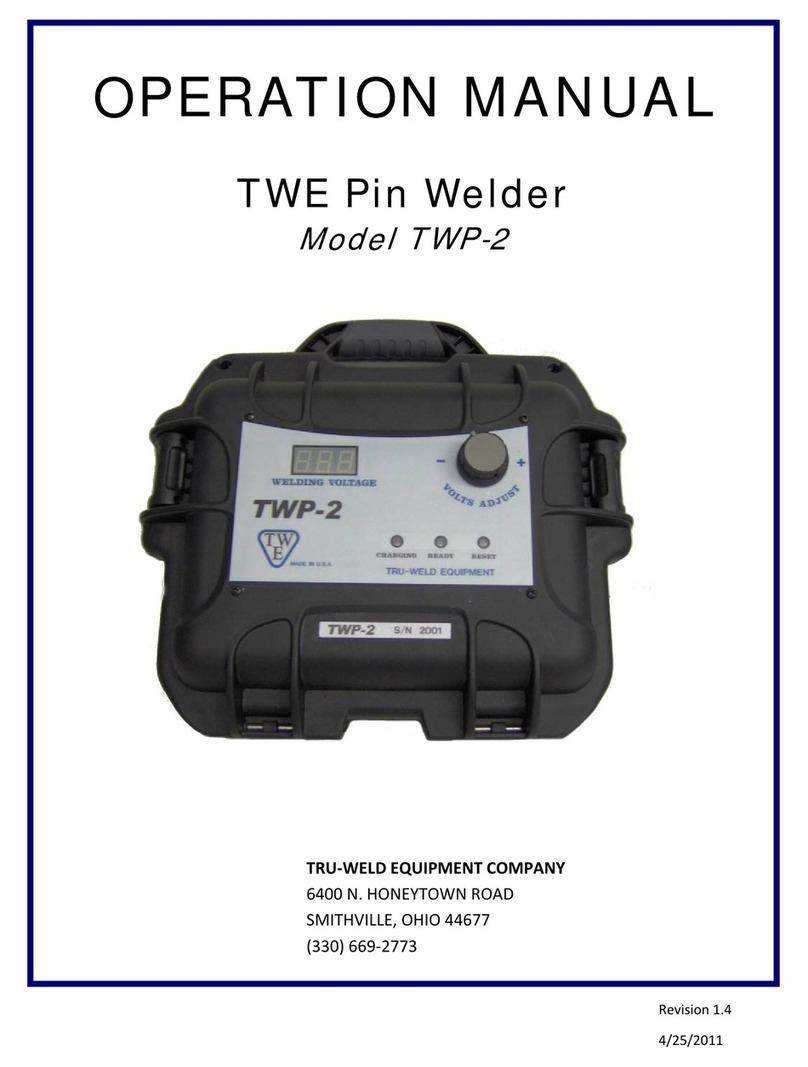

TWESPCPowerSupplies

TWP‐2PowerSupply

NinetyDay(90)warrantyperiodfromdateofpurchase

(Excludingcablesandconnectors)

TWE70000HDArcstudgun

TWE18500MDArcstudgun

TWE19000LDArcstudgun

TWEGCDstudgun

TWEHDGHeavyDutyCDstudgun

3

CompanyandProductInformation

CompanyProfile

Tru‐WeldStudWeldinghasbeenmakingweldstudssince1959,andsince1970wehavebeenpro‐

ducingourownlineofhigh‐qualitystudweldingequipment.Tru‐WeldislocatedinMedina,Ohioand

hasproductandequipmentdistributorsacrossthenation.Tru‐WeldEquipmentCompany(TWE)of‐

fersafulllineofDrawn‐ArcandCapacitorDischarge(CD)studweldingequipment,replacementparts,

andaccessories.

OurexperiencedManagementandStaffiscommittedtoprovidetheutmostinqualityandservicein

everystepofourproduction,whileremainingcompetitiveinthemarketplace.Itisourgoaltomeet

ourcustomer'sneedsmoreeffectivelythanourcompetitorsthroughaprocessofcontinuousquality

improvement.Ourlong‐standingrelationshipwithourcustomers'andsuppliers'isourkeytocontin‐

uedsuccessandgrowth.Ifwecanbeofanyfurtherassistancetoyouandyourcompany,pleasedonot

hesitatetocontactus.

ProductInformation

TheSC900isafullyintegratedstudweldingsystemforferrule‐shieldedandgas‐shieldeddrawnarc

studwelding.TheSC900containsdigitalcontrolsforweldtime,weldcurrent,andgaspurgetime.The

systemwasdesignedtobeaperfectfitforshopuse,weldingupthrough1/2”studs.Thisisallcon‐

tainedinacompact,portablepackage.

Features:

♦ Smootharccurvetargetedforsmalltomediumsizeddiameterstuds

♦ EnhancedDutyCycleproductionrequirements

♦ Capableofupto100feetof2/0weldingcableaccommodatesalargevarietyofworkstation

layouts

♦ Steplesstimeandcurrentcontrolallowforinfinitesettingsforfine‐tuningtheweldingoutput

♦ StudJobCounterthatcanberesetforeveryjob

♦ On‐DemandFanthatcyclesonandoffwhenneeded.

CompletesystemIncludes:

800AmpPowerSupplyController,TWE19000LightDutystudgun,25feetof#1AWGcombocable,

and15feetof#1AWGgroundcablewithclamp.

4

Safetyiseveryone’sresponsibility.TRU‐WELDdesignseverymachinewithsafetyinmind,anda

safeworkenvironmentdependslargelyonyou.

Donotinstall,operate,orrepairthisequipmentwithoutcarefullyreadingthismanualandobserv‐

ingallofthesafetyprecautionsmentioned.Ifthereisaquestion,askyoursupervisor!

SafetySymbols

Everyefforthasbeenmadetoprotecttrainedoperatorsfrominjuryorunnecessaryrisk.Certain

symbolsareusedthroughoutthismanualtocallattentiontosafety‐relatedinformationandin‐

struction.Thesafetysymbolsinthismanualhavethesemeanings:

ThissymbolindicatesDangerousSituations.Whenthissymbolisusedinthismanual,

deathorseriousbodilyharmispossibleorprobableifthecorrespondingpreventative

measuresarenottaken.Operatorsmusttakecautioninthemethodandmannerof

handlingorusingthemachinewhenthissymbolisdisplayed.

SafetyPrecautions

Donotinstall,operate,orrepairtheSC900weldingequipmentwithoutreadingthismanualandall

safetyprecautionsstatedwithin!

Thismachinewasdesignedandbuiltwithoperatorsafetyinmind,butsafetybeginswithyou!

Everyefforthasbeenmadetoprotectthetrainedoperatorfrominjury.Pleasebecomefamiliar

withtheinformationinthismanualtominimizetheriskofshockorinjury.

STUDWELDINGCANBEHAZARDOUS.ALWAYSPROTECTYOURSELFANDOTHERS

FROMPOSSIBLEINJURYORDEATH.KEEPCHILDRENAWAY.

Operatorswhohaveapacemakershouldconsultwiththeirphysicianbeforeoperatingstudweld‐

ingequipment.

FUMESandOXYGENDEPLETION

♦ Onlyweldinareasorroomswhereadequateventilationofweldgasesispossibleandwhere

thereisnotfire,smokeorexplosionhazards.

♦ Whenworkinginaconfinedspacealwayshavetrainedsupportpersonnelnearby.

♦ Weldingfumesandgasescandisplaceairandlowertheoxygenlevelcausinginjuryordeath.Be

surethebreathingairissafe.

♦ Donotweldinlocationsneardegreasing,cleaning,orsprayingoperations.Theheatandraysof

thearcscanreactwithvaporstoformhighlytoxicandirritatinggases.

♦ Donotweldoncoatedmetals,suchasgalvanized,lead,orcadmiumplatedsteel.Thecoating

mustberemovedfromtheareatobewelded.Coatingsandmetalscontainingaboveelements

cangeneratetoxicfumeswhenheatedtoweldingtemperature.

StudWeldingSafetyPrecautions

5

ELECTRICSHOCK

Electricshockcaninjureorkill!

Precautionarymeasuresmustbetakentoprovidemaximumprotectionagainstelectri‐

calshock.

♦ Donottouchliveorenergizedelectricalpartsorstoremetallicobjectsnearpower.

♦ Groundtheworkormetaltobeweldedtoagoodelectrical(earth)ground.

♦ Donotleaveanenergizedmachineunattended.

♦ Neverworkinwetclothing,glovesorfootwear.

♦ Insulateyourselffromworkandgroundusingdryinsulation.Makecertaintheinsulationis

largeenoughtocoveryourfullareaofphysicalcontactwithworkandground.

♦ Inspectallsystemcomponents,protectiveequipment,cables,connectorsandgaslinesprior

tooperatingequipment.Neverusecablesthatarelongerthannecessary.

♦ Whentestingaliveunit,usetheone‐handmethod.Donotputbothhandsinsideoftheunit.

Keeponehandfree.

♦ Disconnectinputpowerconductorsfromde‐energizedsupplylinebeforemovingawelding

powersource.

♦ Alwaysbesuretheworkcablemakesagoodelectricalconnectionwiththemetalbeing

welded.Theconnectionshouldbeascloseaspossibletotheareabeingwelded.

♦ TurnOFFweldingpowersourcebeforeservicingunlesstheprocedurespecificallyrequiresan

energizedunit.

♦ Nevertouchtheenergizedstudorgunbeforedischargingthestudtoground.

♦ Neverusethepowersourcetoprovideheatforthawingfrozenpipes.

ARCRAYSandEYEPROTECTION

Arcrayscaninjureeyesandburnskin.

Arcflashesarepainful.

♦ Useashieldwiththeproperfilterandcoverplatestoprotectyoureyesfromsparksandthe

raysofthearcwhenweldingorwhileobservingopenarcwelding.

♦ Useprotectiveclothingspecificallyintendedforworkwithweldingequipment.Itshouldbe

madeofdurableflame‐resistantmaterialtoprovideampleprotectionfromthearcrays.

♦ Protectothernearbyworkerswithsuitable,non‐flammablescreening.Cautionotherworkers

nottowatchthearcnorexposethemselvestothearcraysortohotspatterormetal.

StudWeldingSafetyPrecautions

6

StudWeldingSafetyPrecautions

WELDINGSPARKS

Heatfromflamesandarcscanstartfires.Hotslagorsparkscanalsocausefiresand

explosions.

Removeallcombustiblematerialsfromtheworkareaorcoverthesematerialswithaprotectivenon‐flammabletarp.

Combustiblematerialsincludewood,fabrics,sawdust,liquidandgasfuels,solvents,paintsandcoatings,paper,etc.

Hotsparksorhotmetalcanfallthroughcracksorcrevicesinfloorsorwallopeningsandcauseahiddensmoldering

fire.Makecertainthatsuchopeningsareprotectedfromhotsparksandmetal.

ELECTRICandMAGNETICFIELDS

ElectriccurrentflowingthroughanyconductorcauseslocalizedElectro‐MagneticFields(EMF).Weldingandcutting

currentcreatesEMFaroundweldingcablesandweldingmachines.

♦ Operatorshavingpacemakersshouldconsulttheirphysicianbeforewelding.EMFmayinterferewithsometype

ofpacemakers.

♦ ExposuretoEMFmayhaveotherhealtheffects,whichareunknown.

♦ OperatorsshouldusethefollowingprocedurestominimizeexposuretoEMF:

♦ Routetheworkcablestogether.Securethemwithelectricaltapewhenpossible.

♦ Nevercoiltheworkcablearoundanypartofyourbody.

♦ Donotplaceyourbodybetweentheworkcables.Routecablesonthesamesideofyourbody.

♦ Connecttheworkcabletotheworkpieceascloseaspossibletotheareabeingwelded.

♦ Keepweldingpowersourceandcablesasfarawayfromyourbodyaspossible.

♦ Electromagneticfieldscanirrevocableerasemagneticdatacarriers(computermemory,creditcards,securityID

cardsordatastoragediskettes).

♦ Electromagneticfieldsmaymagnetizeanddamagewatchesorsimilardigitaldevices.

PROTECTYOURSELFandOTHERS!

Somewelding,cutting,andgougingprocessesarenoisyandrequireearprotection.Thearc,likethesun,

emitsultraviolet(UV)andotherradiationandmayinjureskinandeyes.Hotmetalcancauseburns.

Trainingintheproperuseofweldingprocessesandequipmentisessentialtopreventaccidents.

♦ Alwayswearsafetyglasseswithsideshieldsinanyworkarea.Inconjunctionwitheyeprotection,weldinghel‐

metsorfaceshieldsarealsorequired.

♦ Useafaceshieldfittedwiththecorrectfiltercoverplatestoprotectyoureyes,face,neck,andearsfromsparks

andraysofthearcwhenoperatingorobservingoperations.Warnbystandersnottowatchthearcandnotto

exposethemselvestotheraysoftheelectricarcorhotmetal.

♦ Wearflameprooftypegloves,heavylong‐sleeveshirt,cufflesstrousers,andaweldinghelmetorcapforhairpro‐

tection,toprotectagainstarcraysandhotsparksorhotmetal.Aflameproofapronmayalsobedesirableaspro‐

tectionagainstradiatedheatandsparks.

♦ Hotsparksormetalcanlodgeinrolledupsleeves,trousercuffs,orpockets.Sleevesandcollarsshouldbekept

buttoned,andopenpocketseliminatedfromthefrontofclothing.

7

Features

SmoothArcCurveallowsforawiderangeofwelding.

EnhancedDutyCycleforproductionrequirements.

Powerfuloutputforeventhelargestdiameterweldingprojects.

Timeandcurrentcontrolallowforinfinitesettingsforfine‐tuningtheweldingoutput.

Safetyweldinginterlockkeepssystemfromdouble‐triggering.

SC900ProductSpecifications

**Specificationsaresubjecttochangewithoutpriornotification.

WeldRange14gato1/2”Consistentweldingregardlessofstuddiameter.

DutyCycle14gathru1/4”

3/8”

1/2”

Unlimited

5‐6perminute

2‐3perminute

DimensionsHeight

Width

Length

Weight

12.6”(320mm)

11”(280mm)

22.4”(570mm)

106Lbs.(48kg)

InputVoltages230/460VAC3Phase60Hz

FusingRequirements(Slowacting)230/70Amps

460/35Amps

8

SC900SetupandInstallation

InitialSteps

Onlyqualifiedpersonnelshouldperformthisinstallation.

♦Turntheinputpoweroffatthedisconnectswitchorfuseboxbeforeworkingonthewelder.

♦Donottouchelectricallyhotparts.

ThissectionprovidesdetailedinstructionsfortheproperinstallationoftheTWESC900.Itis

recommendedthattheseinstructionsbefollowedcarefullytoallowforthebestpossibleoperat‐

ingenvironment.

HandlingandUnpackingtheWelder

Immediatelyuponreceiptofthewelder,inspecttheshipmentforanydamageandnotifythe

carrierofsuchdamagebeforeacceptingdelivery.Theninspectwelderfordamagewhichmay

haveoccurredintransit.Afterremovingthecomponentsfromtheshippingcontainer(s),check

thecontainerforanylooseparts.Removeallpackingmaterials.Visuallycheckallairpassagesof

powersourceforanypackingmaterialsthatmayobstructairflowthroughthewelder.Ifthe

equipmentisnotbeinginstalledimmediately,storeitinaclean,dry,well‐ventilatedareauntilin‐

stallation.

SelectingaLocation

Thelocationofthepowersourceshouldbecarefullyselectedtoensuresatisfactoryanddepend‐

ableservice.Choosealocationrelativelyclosetoaproperlyfusedsourceofelectricalpower.Use

careagainsttopplingoverifthemachineisplacedonatiltedsurfaceorplane.Itisimportantthat

themachinebelocatedinanopenareawhereaircancirculatefreelythroughthefrontandrear

openings.Ifspaceisatapremium,leaveatleast1foot(300mm)ofclearancebetweentherear

ofthepowersourceandwallorotherobstruction.

ElectricalInputRequirement

Theweldingpowersourceisdesignedtobeoperatedfromthree‐phase,60Hertz,ACpowersup‐

ply.Consultyourlocalelectricalutilityifyouhaveanyquestionsontheelectricalsystematthe

presentinstallationsite.TheSC900shouldbeoperatedfromaseparate,fusedorcircuit‐breaker

protectedcircuit.

9

SC900SetupandInstallation

PreparingtheUnitforPrimaryPower

Onlyqualifiedpersonnelshouldperformthisinstallation.

♦Turntheinputpoweroffatthedisconnectswitchorfuseboxbeforeworkingonthewelder.

♦Donottouchelectricallyhotparts.

RemovethetopcoveroftheSC900.Alloftheconnectionsthatwillneedtobemadeareaccessi‐

blewiththetopcoverremoved.

PrimaryPowerCable

RoutethePrimaryPowerCablethroughthePowerInletHoleinthecenterconnectorontheback‐

sideofthewelder.

Connectthepowerleads(Black,White,Red)totheL1,L2,andL3connectorsasshowninphoto

Firmlytightenscrewsthatholdthepowerleadsinplace.

Attachthegroundwire(Green)tothegroundlugofasshowninabove.

OncethePrimaryPowerCableisconnected,tightenPowerCableClamponthebackofthe

welder,holdingthepowercablefirmlyinplace.

10

SC900SetupandInstallation

Power/GroundConnections

ElectricalInputRequirement

TheSC900isequippedwithanInputVoltageJumperBlocksoyoucanoperatetheunitfromdif‐

ferentlinevoltagesdependingonyourrequirements.Simplyplugintheappropriatevoltagecon‐

nectorforeither230VAC(redwiredconnector)or460VAC(blackwiredconnector)3Phaseopera‐

tion.

GroundCableConnection

TheSC900isequippedwithonegroundcableconnectionlocatedonthefrontofthewelder

Securethegroundcabletowelderandconnectthegroundclamptotheworksurfacethe.

11

SC900SetupandInstallation

Cable/GasConnections

WeldCableConnection

TheSC900weldcableconnectionislocatedonthefrontofthewelder

ConnectstudguncableassemblydirectlytotheSC900.

Plugstudguncontrolcableplugintotheconnectoronthefrontofwelder.

Gaslineconnection

When“gasshield”weldingconnectthegaslinefromthefootpieceofthestudgunintothegas

fittingonthefrontoftheSC900byeasyquickconnectfitting.

12

StudGunSetup

StudGunSetup

Eachstudweldingapplicationrequiresthatthestudgunbesetupproperlyforthecorrectstud

andferrulearrangement.

♦ Selectthecorrectstyleandsizeofchuckforthestudtobeweldedandattachittothestud

gun.

♦ Selecttheproperlengthlegassembliesforthelengthofthestud.

♦ Selecttheproperfootpiecebestsuitedforyourapplication.

♦ Selectthegriptofittheferrulewhichisprovidedwiththestudtobewelded.

Afteralloftheproperaccessorieshavebeenmountedonthestudgunplacethestudinthechuck

andbeginthealignmentoftheaccessories.

♦ Makecertainthatasufficientamountofthestudisinsertedinthechucksothatthestudis

heldfirmly.

♦ Attachtheferruletotheferrulegrip.

♦ Plungesetting;movetheleg,footandferruleassemblysothatthestudprotrudesbeyondthe

ferrule(1/8”forstuds1/2"andunderindiameter3/16”forstudsupthrough7/8”and1/4”

for1”and1‐1/4”diameterstuds).

♦ Positionthisassemblysothatthestudmovesfreelythroughtheferrulewhenyouslidethe

shaftofthestudgunbackandforth.

13

StudGunSetup

Lift

Settheliftwhenalloftheaccessoriesandstudhavebeenproperlysetonthestudgun,priorto

welding.Plugthecontrolconnectorofthestudgundirectlyintothestudwelder(donotattachthe

weldcable).Turnonthestudwelderandactuatethetriggerofthestudgunwiththestudandfer‐

ruleinplace.Notetheretractionoftheshaftofthestudgun.ThisisdesignatedastheLift.

Theliftsettingshouldbeabout3/32”forgeneralweldingapplicationsandstudsrangingindiameter

through3/4"thisadjustmentshouldbesuitable.Forlargerdiameterstudsandselectapplications

theliftshouldbeadjustedtoapproximately1/8”.

Adjustingthelift:

♦ Removethebackcapofthestudgun.

♦ Loosenthetwosocketsetscrewsaroundtheperipheryoftheliftadjustmentscrew.

♦ Toincreaseliftrotatetheliftadjustmentscrewcounterclockwiseandtodecreaseliftrotate

clockwise.

♦ Witheachturnchecktheliftbyactuatingthestudgununtilthedesiredliftisachieved.

♦ Tightenthesocketsetscrewstoholdtheliftadjustmentscrewinplacetosecuretheselected

setting.

♦ Replacethebackcapofthestudgun.

RearCoilYoke

SetScrew

LiftAdjustingScrew

GunBody

14

StudGunSetup

FreeTravelAdjustment

Thisadjustmentcanbeusedtocontroltheforcewithwhichthestudisplungedintothemolten

weldpoolbymovingtheengagementpointofwhentheshaftofthestudgunengagesthedamp‐

ener.

Rotatingthedampenercovercounterclockwiseincreasestheamountoffreetravel.

15

StudGunSetup

Attachingthestudguntostartwelding

♦ Selectthegun,controlcable,andweldcablethatisrecommendedforthespecifictypeof

welderandthejob.

♦ Attachstudguntoweldandcontrolcableextension.

♦ Actuatethestudgunwithoutplacingitonthesurfacetobeweldedtoassurethatthecon‐

nectionthroughthecontrolcableiscorrecttocompletethecircuitandactuatethestudgun.

♦ Makesurewelderissetupproperlytobegintheweldingprocess.

♦ Placetheselectedstudintothechuckandattachtheferruletotheferrulegrip.

♦ Placestudontosurfacetobeweldedandpressstudgundownuntilferruleisflushwiththe

weldingsurface.

♦ Triggerthegunandholdinplaceuntilcycleiscompleted.

♦ Pullgunassemblystraightupoffoftheweldedstud.

♦ Donotdepresstriggerwhenremovinggunfromstud.

♦ Removetheferrulebybreakingitoffandinspecttheweld.

♦ Makeproperadjustmentsasneeded.

16

SC900PowerSwitch/PowerOn

ThepowerswitchfortheSC900islocatedontheleftfrontofthe

frontcontrolpanel.Turnthereddialclockwisetothehorizontal

position(I)indicatortoturntheunitON.Turnthedialtothever‐

ticalposition(O)indicatortoturntheunitOFF.

Whenthewelderisturnedon,thedigitaldisplaywillgothrougha

self‐diagnosticcheck.Thistakesapproximately3to5seconds,and

thenthedigitaldisplaywillshowthelasttimeandcurrentto

whichtheunitwasset.Thisdenotesthattheunitisreadytogo.

Whenconnectedtothewelder,thestudgunwillactuate3times,

indicatingthatthereisagoodconnection.

SC900DiagnosticLights

OntheControlPanel,locatedbelowthedigitaldisplay,isarowofdiagnosticlightsforthewelder.

OUTPUT‐Whenthestudgunistriggered,thislightcomesontoindicatethattheOCVispresent

attheoutputterminals.

TRIGGER‐Whenthestudgunistriggered,thislightcomesontoindicatethatthetriggercircuitis

functioningproperly,andthattheweldingunitisreceivingfeedbackfromthestudgun.

POWER‐Whenthislightislit,itindicatesthatthereisanerror.

TEMP‐Whenthislightislit,itindicatesthateitherthemaintransformerorweldbridgehas

reachedmaximumtemperatureandthattheunitwillnotfunctionuntilitiscooled.

REMOTE‐Thisfunctionisnotcurrentlyinuse.

SC900Operations‐Settings

17

SC900Operations‐Settings

SettingWeldingControls‐TimeandCurrent

Thetimeandcurrentcontrolsarelocatedonthefrontofthewelder.Thecontrolsconsistofa

TimeButton,CurrentButton,AdjustmentDial,andaFine/CoarseSwitch.Thedigitaldisplaywill

indicatethesettingschosenduringsetup.

Whensettingtimeorcurrent,depressandholddownappropriatebutton,andturnAdjustment

Dialclockwiseorcounter‐clockwisetothecorrectsettingonthedigitaldisplay.

UsetheFine/CoarseSwitchforsettingtheappropriatetimeorcurrent‐thiswilltogglebetween

10’sor100’sofampsand10th’sand100th’sofasecond.

Toadjustgaspurgetime,holdboththeTIMEandAMPSbuttonsandturnAdjustmentDial.The

settingissavedwhenthebuttonsarereleased.

18

SC900Operations‐Settings

Thereisachartofapproximatesettingsforfull‐basediameterstudslocatedonthetopcoverof

theSC900.

WeldCounterandWeldCounterReset

TheSC900isequippedwithdifferentcounterstodisplaythenumberoftimestheunithasdrawn

anarcorthestudgunhasbeenactuated.

PerpetualWeldCounter(Non‐resettable)‐Thisisarunningtotalofeverytimeanarcisdrawnon

themachine.Thisisprogrammedfromthefactoryandcannotbereset.

PerpetualGunCounter(Non‐resettable)‐Thisisarunningtotalofeverytimethestudgunis

actuatedwhetheranarcwasdrawnornot.

JobCounter(Resettable)‐Thisisarunningtotalofthenumberofweldssincethecounterwas

lastreset.Toviewthejobcounter,settheFine/CoarseSwitchtotheFineposition.Eachweldwill

berecordedontheCurrentdigitaldisplay.IftheswitchisintheCoarseposition,theweldwillstill

becounted,butwillnotbedisplayed.YoucanalsoviewtheJobCountertotalbydepressingthe

AdjustmentDialwhiletheswitchisintheCoarseposition.

ToResettheJobCounter;

1. Turnoffunit.

2. DepressandholddownTimeandCurrentbuttons.

3. Turnonmachine.

4. KeepholdingdownbuttonsuntilOUTPUTlightflashesthenreleasethebuttons.

5. JobCounterwillnowbesetat0.

6. WeldcountwillnowregisteronCurrentdigitaldisplay.

SC900approximatetimeandcurrentsettings

19

SC900Operations‐Settings

SC900SupervisorLock

Thesupervisorlockpreventsthesettingsfrombeingadjusted.Thepurposeistoallowameas‐

ureofprocesscontrol.Allsettingsandthecountermaybeviewedwhenthelockisactivated.

Toactivatethelock,turnclockwisetowardthe3o’clockposition.Todeactivatethelock,turn

counter‐clockwisetowardthe12o’clockposition.

20

SC900Operations‐Welding

StudWelding‐StepbyStep

Theweldgunispositionedoverthebasematerialandthemaingunspring

ispartiallycompressed.Holdgunperpendiculartoworksurfaceandhold

ferrulefirmlyagainstthesurface.

Thetriggerispressedandthestudliftsoffthebase,drawinganarc.Thearc

meltstheendoftheweldstudandthebasematerialbelow.Thearcshield

(ferrule)concentratestheheatbelowtheweldstudandcontainsthemol‐

tenmetalwithintheweldzone.Donotmoveweldgunduringweld.

Themainspringplungestheweldstuddownintothemoltenpoolofmetal

inthebasematerial.Thecycleiscompletedinlessthanasecondandthe

resultingweldbonddevelopsthefullstrengthofthefastenerintheweld

zone.Allowmetaltocoolandwithdrawgunfromthestud,pullingthegun

straightupoffofthestud.

Theweldguniswithdrawnfromtheweldstudleavingandtheferrule.The

ferruleisbrokenawayanddiscarded.Visuallyinspectweld.

***Note‐whendeterminingfinishedlengthrequiredfortheparticularapplication,keepinmind

thereductioninlength(burn‐off)fromstudweldingoperations.TRU‐WELDstudlengthsareal‐

waysgivenbeforeweld.

DiameterofStud ReductioninLength

1/4”thru1/2” 1/8”

Table of contents

Other Truweld Welding System manuals

Truweld

Truweld TWP-2 User manual

Truweld

Truweld TW5600 User manual

Truweld

Truweld TWP-1 User manual

Truweld

Truweld TW4300 User manual

Truweld

Truweld TW-i Series User manual

Truweld

Truweld TW55000 User manual

Truweld

Truweld TW6922 User manual

Truweld

Truweld ARWSC900 User manual

Truweld

Truweld TW6802 User manual

Truweld

Truweld TWE - 19000 User manual

Popular Welding System manuals by other brands

LOKERMANN

LOKERMANN GRAND PIPE 270 MULTI user manual

STAYER WELDING

STAYER WELDING POTENZA TIG170 HF operating instructions

ims PRO

ims PRO SPOT EXPERT 400 manual

ESAB

ESAB Aristo Mig 5000i instruction manual

Chicago Electric

Chicago Electric 93793 Set up and operating instructions

Pro-Weld

Pro-Weld CD-212P Operation manual