TSI Quest EVM-7 User manual

ENVIRONMENTAL MONITOR

EVM SERIES

USER MANUAL

Dangers, Warnings, & Cautions

EVM Series User Manual

iii

ENVIRONMENTAL MONITOR

EVM SERIES

Dangers, Warnings, & Cautions

DANGER!

Failure to observe the following procedures may result in serious personal injury:

Not for use in Explosive or Hazardous locations. This product is NOT Intrinsically Safe.

Contains built-in lithium ion battery pack. DO NOT incinerate or dispose of in fire.

DO NOT disassemble, alter, or re-construct the li-ion battery.

Contains Class 3B visible laser radiation source (658 nm, nominal 5 mW). DO NOT look

directly into beam or view with telescopic devices.

This instrument will NOT detect natural gas.

WARNING!

Read the manual before operation.

DO NOT store in temperatures exceeding 60°C (140°F) and in direct sunlight.

DO NOT immerse in liquids.

The Sensors and batteries in this instrument have limited shelf-life, even if never used.

DO NOT disassemble, service, or clean the optical engine internal components while power is

applied. The laser source can hurt you.

Caution!

General

Condensation may damage your instrument and its sensors.

A non-condensing environment is required for proper measurements.

DO NOT charge batteries outside the range of 0°C to 40°C (32°F to 104°F).

Battery run-time may be somewhat reduced at lower than 20°C (68°F) temperatures.

Caution!

Temp/RH/Dew Point

The internal Temp/RH sensor in this instrument is not designed for use in bright sunlight or in the

presence of a strong radiant heat sources. It is intended primarily for indoor use. It is not equivalent

to a protected dry-bulb thermometer.

Dangers, Warnings, & Cautions

EVM Series User Manual

iv

Caution!

PM/dust

Clean the optical engine mirror with a soft cloth, if it is dirty. Scratches will affect performance.

Avoid measuring wet particles, fogs, and liquid mists that will tend to cling to the impactor,

optical engine, tubing, and pump surfaces.

Avoid oily mists as found near some machining operations.

This monitor is designed to measure dry particulates, not filaments.

DO NOT attempt to measure Asbestos with this instrument.

Keep a "Pump Protection Filter" or other gravimetric filter in place to help prolong the life of the

pump.

You must check and calibrate the flow rate, when using this device as a (gravimetric) sampling

pump.

Caution!

CO2

Avoid exposure to condensation, fogs, and liquid mists that can contaminate the optical path inside

the CO2sensor.

Caution!

PID

This instrument cannot detect methane gas.

For best sensor life, avoid acidic condensing gases.

The presence of moisture can affect performance of the PID.

Caution!

Toxic

Beware of certain cross-sensitivities when measuring toxic gas levels. Readings can be

nonspecific in the presence of certain cross-contaminant gases.

Caution!

ir velocity

The tip of the Air velocity probe is very fragile.

Dangers, Warnings, & Cautions

EVM Series User Manual

v

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial or residential

environment. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. If harmful interference occurs, the user will be required to correct the

interference at his or her expense.

Table of Contents

EVM Series User Manual

vii

Table of Contents

Dangers, Warnings, & Cautions.......................................iii

Table of Contents..............................................................vii

Introduction......................................................................... 1

Particulate Sampling (Aerosols/Dust Vapors) ................. 2

Particulate Path ...............................................................2

Particulate Sizes..............................................................3

Particulates and Cut-Point...............................................4

Collecting/Sensing the Particulates.................................4

Gravimetric Sampling ......................................................4

Pump ...............................................................................4

Gas Sensors Sampling....................................................... 4

Gas Sensors and Path ....................................................5

Volatile Organic Compounds (VOCs) Sampling.............. 6

Temperature, Relative Humidity, Dew Point .................... 6

What the Standards Say..................................................... 6

Resources .......................................................................7

EVM Series .......................................................................... 8

Applications .....................................................................8

Models Explained ............................................................9

Getting Started..................................................................11

Checking the Equipment..................................................11

Display and Keypad..........................................................12

Diagram.........................................................................12

Keypad description........................................................12

Turning on .........................................................................13

Start Screen Explanation...............................................13

Navigating......................................................................14

Indicators/Icons on the display......................................14

Turning Off ........................................................................ 15

Instrument Information ....................................................15

Unit Information Screen.................................................15

TSI Detection Management Software DMS .................... 17

Communicating................................................................. 17

Powering and Outputs on the EVM ...............................17

Battery......................................................................17

Charging...................................................................18

Outputs.....................................................................18

Setting up the Environmental Monitor............................ 19

Setting up Parameters via the Keypad ...........................19

Time and Date Setting...................................................19

Checking Battery Power................................................20

Display: Language, Contrast, and Key Click.................22

Setting Logging and Viewing Run Time ........................23

PID Sensor Setup..........................................................25

Changing Units (Temperature, Particulates, PID,

and Air Velocity) .........................................................27

Setting up Particulate Settings ......................................27

Setting Profiles (Particulate Correction Factors) ...........28

How Particulate Factors are Adjusted and Calculated..28

Dust Correction Factors (Profiles)............................28

Particulate Pump: Enable or Disable.............................30

Resetting the Gravimetric Filter.....................................30

Auxiliary Input/Output ....................................................31

Digital Output ...........................................................31

Air Velocity.....................................................................33

Analog-out .....................................................................33

Restoring Default Factory Settings................................34

Backlight Setting............................................................36

Resetting the EVM.........................................................36

Lock/Secure Run and/or Setup .....................................36

Unlock run and/or setup ................................................38

Auto-run.........................................................................38

Auto-run and timed-run mode ..................................38

Auto-Run with Date Mode........................................39

Auto-Run with Day of Week (DOW) Mode...............40

Calibrate Sensors .............................................................43

Placement and Calibration of Sensors...........................43

Calibrating sensors include: ..........................................43

Inserting and Removing Sensors ..................................43

Calibrating Particulates..................................................44

Impactor and use...........................................................45

Adjusting the Impactor/Turret Setting............................46

Particulates Calibration (Zero Cal) ................................47

Particulate Advanced Calibration (Gravimetric) ............51

Gravimetric Calibration Overview ............................52

Performing a Gravimetric Calibration ............................52

Pump Flow Rate Calibration..........................................53

Toxic Gas Sensors ........................................................54

Cross Sensitivity ............................................................55

How Sensors Operate..............................................55

Quality Calibrations .......................................................55

About Sensors and Cal Storage....................................55

Calibration History and Sensor Serial Numbers............55

Applying a Gas Sensor..................................................56

Calibrating Toxic Gas Sensors......................................56

Toxic Gas Zero Calibration ......................................57

Ozone Calibration for Zero and Span ......................57

Toxic Gas Span Calibration .....................................59

Calibrating CO2 AND O2................................................60

O2 Accuracy..............................................................60

Table of Contents

Table of Contents

EVM Series User Manual

viii

Calibrating Photo-Ionization Detector (PID) Sensor......63

PID parts per million (ppm) zero calibration.............63

PID parts per billion (ppb) zero calibration...............63

PID Span Calibration ...............................................64

Calibrating Relative Humidity and Temperature ...........66

Calibration History .........................................................67

Verify Calibration and Drifting Analysis .........................68

Measuring and Viewing.................................................... 71

Overview of Running a Session......................................71

Quick Help.....................................................................71

Measuring..........................................................................71

Understanding What Data is Stored..............................72

Summary Data .........................................................72

Logged Data/Time History.............................................72

Running and Stopping...................................................73

Measurement Screens and Navigation........................... 74

Unit defined ...................................................................74

About the Measurement Soft Keys................................75

Particulate Measurement Screen ....................................76

Impactors and Particulate Measuring............................76

Extending Run-Time for PM Measurements .................76

Changing Particulate Measurements ............................77

Relative Humidity and Temperature Measurements ..... 78

Relative Humidity and Temperature Screen .................78

Gas Measurements........................................................... 79

Gas Screen....................................................................79

Composite Measurement .................................................80

Composite Screens .......................................................80

Air Velocity Meaursurement Screen ...............................81

Summary Data................................................................... 82

Viewing Details in the Measurement Screen ................82

Trend Data .........................................................................83

Viewing trend data in the measurement screen............83

Past Session...................................................................... 84

Summary Data Screen ..................................................84

File System Menu ............................................................. 86

Deleting Sessions Individually.......................................86

Delete All Sessions .......................................................87

Memory Remaining and File Properties........................88

Estimated Run Time......................................................89

Detection Management Software ....................................91

Environmental Monitor Communication ........................91

Downloading Data with the EVM ..................................... 93

EVM: Viewing Data ...........................................................93

Selecting a session/study..............................................93

EVM Panel Layout View (PLV) Page ............................94

EVM Reports and Printing................................................96

Customizing Reports .....................................................97

EVM Setup ....................................................................98

Saving and Sending Configurations.........................98

General EVM Setup.......................................................99

EVM General Parameters Table..............................99

EVM and Logging Settings..........................................100

EVM Logging Parameters Table............................101

EVM and Auto-Run Setting .........................................101

Timed-Run and Auto-Run Setting..........................102

Date and Auto-Run Setting ....................................102

Day of Week and Auto-Run Setting .......................103

EVM and Security Settings..........................................104

EVM and Triggering Settings.......................................104

EVM and Particulate Settings......................................106

EVM and Particulates Setup ..................................106

EVM Firmware Update ................................................107

Maintenance and Cleaning.............................................109

Overview ..........................................................................109

PID Sensor ..................................................................109

Removing and Installing PID Sensor...........................110

Maintenance and Cleaning Overview of PID...............111

Cleaning PID Sensor...................................................111

Optical Engine: Maintenance and Cleaning................113

Impactor Care..................................................................116

Impactors and When To Clean....................................117

Gravimetric Cassette and Filter Paper..........................117

Specifications..................................................................119

Particulate Sensor ..........................................................119

Volatile Organic Compounds (VOCs) Gas

Detector (PID Sensor).....................................................119

Carbon Dioxide Sensor ..................................................120

Relative Humidity Sensor...............................................120

Temperature Sensor.......................................................120

Toxic Gas Sensors..........................................................121

Air Velocity Accessory (Optional –Air Probe 10)........121

Displayed Data ................................................................121

Electrical Characteristics...............................................122

Environmental effects ....................................................122

Physical characteristics.................................................122

Measurements units .......................................................122

Operating Modes.............................................................123

Time Constants ...............................................................123

Special Functions ...........................................................123

Table of Contents

EVM Series User Manual

ix

Estimated Logged Run Times ....................................... 124

Standard EVM-7 (Memory and logged time)...............124

Standard EVM-4 (Memory and logged time)...............125

Standard EVM-3 (Memory and logged time)...............127

Accessories: Replacement and Optional Parts........... 128

Customer Service ...........................................................131

Technical Support Contacts ..........................................131

Service Contact Information.......................................... 131

Returning for Service .....................................................132

Calibration .......................................................................132

Warranty ..........................................................................133

Glossary of Terms .......................................................... 135

Appendix C......................................................................141

PID sensor and correction factors tables ....................141

Appendix D......................................................................151

Frequently Asked Questions (FAQs)............................151

Particulate Measurements...........................................151

Gravimetric Sample (optional for particulate

calibration)................................................................153

Toxic Sensor Measurements.......................................154

Pump/Airflow Measurements.......................................155

Digital Output (using stereo plug & diagram) ..............156

PID Questions (for Volatile organic compound

measurements) ........................................................157

Power...........................................................................158

Alarm Outputs..............................................................158

General: Mechanical....................................................159

CO2Sensor and how to reorder ..................................159

CO2Sensor and how to reorder (continued) ...............160

Calibrating Sensors .....................................................160

Appendix E ......................................................................163

System Errors Displayed on the EVM Series...............163

INDEX ...............................................................................165

List of Figures

Figure 1-1: Particulate path diagram .................................... 2

Figure 1-2: Particulates and diameter size ........................... 3

Figure 2-1: Identifying your equipment ............................... 11

Figure 2-2: EVM keypad and display explained ................. 12

Figure 2-3: Start screen defined ......................................... 13

Figure 2-4: Unit Information screen .................................... 15

Figure 2-5: Selecting Unit Info. Sensors.............................16

Figure 2-6: Viewing installed sensors.................................16

Figure 2-7: Communicating with DMS via USB cable ........ 17

Figure 2-8: USB, power jack and digital output port ........... 18

Figure 3-1: Time-Date screen parameters ......................... 20

Figure 3-2: Start screen ...................................................... 21

Figure 3-3: Battery screen .................................................. 21

Figure 3-4: Screen display settings .................................... 22

Figure 3-5: Logging screen................................................. 24

Figure 3-6: Estimated run time for logging screen.............. 25

Figure 3-7: PID correction factor......................................... 26

Figure 3-8: PID correction factor displayed on

measurement screens.................................................... 26

Figure 3-9: Units screen ..................................................... 27

Figure 3-10: Edit profiles for dust calibration ...................... 29

Figure 3-11: Entering a profile for particulate calibration.... 29

Figure 3-12: Particulate setup screen................................. 30

Figure 3-13: Configuring digital output................................ 32

Figure 3-14: Air Velocity setting.......................................... 33

Figure 3-15: Analog out results with temperature

as output......................................................................... 33

Figure 3-16: Analog-Out screen ......................................... 34

Figure 3-17: Defaults screen (restoring factory settings).... 34

Figure 3-18: Restoring default calibrations .........................35

Figure 3-19: Backlight key ..................................................36

Figure 3-20: Lock Soft key..................................................37

Figure 3-21: Setting lock/secure .........................................37

Figure 3-22: Selecting auto-run with timed-run mode.........38

Figure 3-23: Setting timed-run and duration .......................39

Figure 3-24: Selecting auto-run with date mode.................39

Figure 3-25: Setting auto-run date mode............................40

Figure 3-26: Setting auto-run DOW mode ..........................41

Figure 4-1: Sensor housing and manifold...........................43

Figure 4-2: Sensors’ locations ............................................44

Figure 4-3: How the impactor functions ..............................45

Figure 4-4: PM2.5 impactor setting example......................46

Figure 4-5: Adjusting impactor/turret setting.......................47

Figure 4-6: Particulate zero cal with HEPA filter.................48

Figure 4-7: Selecting calibration screen .............................48

Figure 4-8: Particulate cal screen .......................................49

Figure 4-9: Particulate calibration and ready screen ..........49

Figure 4-10: Particulate calibration and waiting screen......50

Figure 4-11: Particulate calibration pause screen ..............50

Figure 4-12: Zero Cal set for Particulates...........................51

Figure 4-13: Reset gravimetric setting................................52

Figure 4-14: Pump flow rate calibration ..............................53

Figure 4-15: Flow Rate Calibration .....................................54

Figure 4-16: Calibration history for EVM.............................55

Figure 4-17: Applying a gas sensor ....................................56

Figure 4-18: Selecting sensor for calibration process.........57

Figure 4-19: Calibration zero screen ..................................58

Figure 4-20: Calibration zero pause screen........................58

Table of Contents

EVM Series User Manual

x

Figure 4-21: Span Calibration............................................. 59

Figure 4-22: Saved Calibration screen ............................... 60

Figure 4-23: Selecting a calibration sensor ........................61

Figure 4-24: Calibration CO2 ready screen........................61

Figure 4-25: Setting CO2Span Cal screen......................... 62

Figure 4-26: Saved Calibration ........................................... 62

Figure 4-27: Selecting PID sensor for

calibration process .........................................................63

Figure 4-28: Calibration mode screen ................................ 64

Figure 4-29: PID Calibration Span soft key ........................ 65

Figure 4-30: Saved Calibration screen ............................... 66

Figure 4-31: Temperature calibration .................................67

Figure 4-32: Calibration History screen .............................. 67

Figure 4-33: Calibrate offset verify screen for

PID sensor...................................................................... 68

Figure 4-34: Calibrating PID ............................................... 68

Figure 5-1: Quick help list for running a study .................... 71

Figure 5-2: Sample summary data from DMS reporting..... 72

Figure 5-3: Sample time history data (or logged data)

chart................................................................................ 73

Figure 5-4: Composite measurement screen in

run mode ........................................................................73

Figure 5-5: Example of measurement soft key menus....... 75

Figure 5-6: Particulate Measurement screen .....................76

Figure 5-7: Selecting a measurement calculation ..............77

Figure 5-8: RH and temperature measurement screen...... 78

Figure 5-9: Gas measurement screen................................79

Figure 5-10: Composite measurement screen ................... 80

Figure 5-11: Attaching Air Probe and measuring

Air velocity......................................................................81

Figure 5-12: Details of the composite measurement

screen............................................................................. 82

Figure 5-13: Selecting Trend soft key................................. 83

Figure 5-14: Trend Screen for PM (Dust) ........................... 84

Figure 5-15: Past session screen ....................................... 84

Figure 5-16: Past Session with Files selected....................85

Figure 5-17: Summary screen of a past session ................86

Figure 5-18: Delete session message ................................87

Figure 5-19: Delete all sessions message..........................87

Figure 5-20: File Systems properties screen......................88

Figure 5-21: Viewing estimated run time ............................89

Figure 6: Communicating with the EVM and DMS .............91

Figure 6-1: DMS Start page and Setup/Download

options ............................................................................92

Figure 6-2: EVM and downloading .....................................93

Figure 6-3: Data finder page...............................................94

Figure 6-4: Charts and Graphs (panels) .............................95

Figure 6-5: EVM data in a report format .............................96

Figure 6-6: Customizing DMS reports ................................97

Figure 6-7: Saving and sending EVM setups .....................98

Figure 6-8: General EVM setups ........................................99

Figure 6-9: Logging EVM setups ......................................101

Figure 6-10: EVM Timed-Run Auto-Run setting ...............102

Figure 6-11: EVM Auto-Run with Date setting..................103

Figure 6-12: EVM Auto-Run with Day of Week setting.....103

Figure 6-13: EVM Auto-Run with Day of Week setting.....104

Figure 6-14: EVM Triggering setup...................................105

Figure 6-15: EVM Auto-Run with Day of Week ................106

Figure 7-1: Removing and inserting PID sensor...............110

Figure 7-2: Removing intelligent-sensor casing

with PID ........................................................................111

Figure 7-3: Removing the lamp with removal tool ............112

Figure 7-4: Remove/insert PID sensor with lamp

& pellet..........................................................................112

Figure 7-5: PID sensor cleaning kit...................................112

Figure 7-6: Fitting/Inserting the lamp and pellet ...............113

Figure 7-7: Optical engine and cleaning ...........................114

Figure 7-8: Cleaning the optical engine ............................115

Figure 7-9: When to clean impactors................................117

Figure 7-10: Gravimetric cassette and filter paper

maintenance .................................................................117

List of Tables

Table 2-1: Keypad/user interface explained ....................... 13

Table 2-2: Indicators (i.e., run, stop, battery, Altf ...............14

Table 3-1: Display settings explained.................................22

Table 3-2: Logged intervals and selecting logged

measurements................................................................ 23

Table 3-3: Digital out/Logic settings.................................... 31

Table 4-1: Cross-sensitivity table of interfering gas............55

Table 4-2: Gas calibration soft keys explained...................58

Table 5-1: Unit abbreviations..............................................74

Table 5-2: Measurement soft keys explained.....................75

Table 5-3: Measurement values explained.........................78

Table 5-4: Past session files soft keys explained ...............85

Introduction

Table of Contents

EVM Series User Manual

1

Introduction

The EPA (Environmental Protection Agency) conducted a study over the last 25 years (1975-2000) and

determined that 107 measurable air pollutants, specifically carcinogens, exist in working environments.

Combined with the advent of closed windows, modern office buildings and various cleaning solvents,

the outcome has been energy efficient buildings and homes which contain levels of carcinogens. At high

levels, this is known as “Sick Building syndrome” and can cause acute effects such as headaches,

eye/nose/throat irritation, dry cough or itchy skin, fatigue, and trouble concentrating just to name a few.

Area monitoring or spot checking for high levels of pollutants, such as particulates, VOCs, and toxics,

should be a common practice to ensure good indoor air quality exists in your environment. If poor air

quality is determined, engineering controls such as proper air ventilation and the removal of toxic gases,

would be put into place in order to provide an adequate working/living environment.

The EVM is equipped to measure several different airborne containments or air pollutant applications

including:

Particulate matter sampling (dust monitoring)

Gas sampling

Temperature sampling

Relative Humidity and Dew Point sampling

To get you started quickly with the EVM, the first chapter is dedicated to introducing basic particulate

matter and toxic gas information. The subsequent chapters will guide you through setting up the EVM,

running studies, and assessing your results with easy to follow steps and illustrations.

Caution

The EVM is intended to measure gases that are potentially dangerous to human health. To help

ensure worker safety through the proper use of your unit, it is important that you not only read but

also understand the contents of this manual. Familiarize yourself with the unit before using it in a

potentially hazardous situation.

.

CHAPTER

1

Introduction

Particulate Sampling (Aerosols/Dust Vapors)

EVM Series User Manual

2

Particulate Sampling (Aerosols/Dust Vapors)

The EVM is a portable-area monitoring instrument with a laser-photometer that measures and stores

concentration levels of airborne-dust over time. It is designed to measure and help you identify the air

pollutants, existing as matter (gases and aerosols) in the environment. The methodology used entails a

handful of components including: an air inlet, the impactor (which is the particle size selector), the

collection of particulates, gravimetric sampling, and the pump which are addressed in the upcoming

sections.

Particulate Path

Figure 1-1: Particulate path diagram

(1) TURRET

Air travels though the impactor and the

larger, heavier particulates will stick to

the greased plates within the impactor.

(2) OPTICAL ENGINE

While the pump maintains the flow rate,

the smaller lighter particulates will pass

through the optical engine.

(4) PUMP

The remaining clean/filtered air passes

through the pump.

(3) GRAVIMETRIC CASSETTE

The particulates will collect/trap in the

gravimetric filter/cassettes.

(5) FLOW SENSOR

The clean/filtered air passes through

flow sensor (flow-control orifice hole).

(6) OUTLET

Lastly, it passes through to the Outlet on

the back of the instrument.

❶

❷

❸

❹

❺

❻

Introduction

Particulate Sampling (Aerosols/Dust Vapors)

EVM Series User Manual

3

Particulate Sizes

Aerosols and gases are experienced in industrial processes, workplaces, and in everyday life. Keeping

in mind that inhalable dust is 100 microns and smaller, this dust is usually filtered through the hairs and

membranes in your sinuses. 10 microns and smaller is considered “thoracic”, 4-10 microns is “inhalable”

reaching into your windpipe and other regions, and 4 microns and smaller is “respirable”. These

particulate sizes will represent what you will be measuring.

The figure below identifies different types and sizes of particulates and how it affects the human body.

Gases

and

Aerosols

Defined

-----Liquid: Mist--------------►

-----Solid: Fume---►

◄--------Spray----------------

◄-------Particulates----------

Aerosols and

Particles

Medical

implications

◄---Oil smokes---►

◄-------------

◄---------------

Cement dust-----------►

---Fly ash----------------------

----Tobacco smoke--►

◄--------------

--- Coal dust---------------►

◄---Pollens-------------►

◄--Atmosphere/Airborne--►

inhalable particulates

◄--Wood.►

Dust

◄--Textiles--►

Dust

---------Respirable pm---------►

(inhaled & penetrates the lungs)

---Thoracic pm------------------------►

(inhaled & penetrates the larynx/throat)

----------------------------Inhalable pm------------------►

(inhaled via the nose and /or mouth)

.01 0.1 1 10 100 1000

Particle matter (pm) diameter μm

Figure 1-2: Particulates and diameter size

Gas Sensors Sampling

Particulates and Cut-Point

EVM Series User Manual

4

Particulates and Cut-Point

In consideration of how the size of particulates affect the human body, it is important to select a

particulate size cut-point. Essentially, the particle size selector on the EVM is a top-mounted rotary

impactor. Based on your setting, it will filter out all particulates at or above the selected size. The

instrument has four settings which include 2.5 μm, 4 μm, 10 μm, or none (100 μm). (This is explained in

more detail in Chapter 4.)

Collecting/Sensing the Particulates

Once the impactor setting is selected, the EVM collects (or measures) real-time aerosol/dust

concentration using a 90º optical light scattering photometer to determine the total mass concentration

(in units of mg / m3) of particulate matter. Additionally, gravimetric sampling, a more accurate method, is

also used to determine the mass of particulates.

Gravimetric Sampling

Gravimetric sampling is a type of filtering process in which the

particulates are collected and filtered into the gravimetric

cassette after the dust passes through the optical engine of the

EVM. A user supplied sealed gravimetric cassette can be used

in place of the cassette provided by TSI. The sealed cassette

can be sent to a laboratory for analysis. This testing is typically

used to measure personal exposure to inhalable dust

concentrations.

Pump

The pump is used in the particulate sampling process as a source of air movement so the particulates

are aspirated (or suctioned out) and collected for measurement. The flow rate is 1.67 Liter per minute.

The pump is typically calibrated before each gravimetric sampling.

Gas Sensors Sampling

The EVM uses a unique smart sensor technology includes automatic sensor recognition and measures

up to three gases simultaneously: a selection of optional nine toxic gases, Carbon Dioxide, combustible

gases, and VOCs.

Gas Sensors Sampling

Gas Sensors and Path

EVM Series User Manual

5

Gas Sensors and Path

TSI’s unique smart sensor technology includes automatic sensor recognition, calibration levels,

temperature compensation information and other valuable data that travels with the sensor from one

unit to another.

The following diagram illustrates the gas sensor path for Toxic, CO2, and PID sensors. It also identifies

the temperature sensor for additional analysis/measurements.

Figure 1-3: Gas sensor path illustration

(1) AIR INLET COVER

The path begins with the air pulling

through the air inlet cover.

(2) GAS SENSOR CHAMBERS

The air continues through the gas

sensor bar passing the Toxic, PID, and

CO2sensor chambers.

(3) Fan

It is continuously ventilated by the fan.

(NOTE: When the pump is off, the fan

can be heard near the louvers on the

back cover.)

(4) Temperature sensor

Measures the ambient air temperature.

❹

Temperature sensor

Gas sensor(s) path

❷

❶

Air inlet cover

❸

Fan

Very quiet!

Introduction

Volatile Organic Compounds (VOCs) Sampling

EVM Series User Manual

6

Volatile Organic Compounds (VOCs) Sampling

According to the American Lung Association, Volatile Organic Compounds (also referred to as VOCs)

are one of the top Indoor Air Quality (IAQ) pollutants. These include:

Biological agents (mold, dust, mites, etc.)

Formaldehyde

Second-hand tobacco smoke

Volatile organic compounds (measured with a PID detector)

Serious, long-term exposure could lead to health affects including leukemia, cancer, eye and respiratory

irritations and short term effects such as dizziness, memory loss, and visual impairments.

With the EVM you have the following parameters:

Range 0 to 2,000 ppm Isobutylene.

Calibrated with Sensitivity 1.0, using Isobutylene. Response varies with each VOC.

Units selection: ppm, ppb, mg/m3(for ppm PID sensor) or µg/m3(for ppb PID sensor).

Temperature, Relative Humidity, Dew Point

It is important to monitor temperature, control moisture, relative humidity, and monitor dew point levels

in occupied spaces such as office buildings, schools, and hospitals, to name a few. With the presence of

too much moisture mixed with dirt/dust particles, this can contaminate the environment and enable mold

to thrive. High levels of relative humidity (RH) is a contributor of spreading and growing biological

pollutants such as molds, mildew, viruses, mites, building dust, and pollen. Failure to control water

leakage from humidifiers, refrigerators, and ventilation equipment can also lead to high levels of RH and

high Dew Point. For appropriate air quality control, RH levels should be maintained between 30 to

50 percent in a home/office environment. Some of the common side effects include nausea, headaches,

running nose, coughing, and difficulty breathing to name a few.

What the Standards Say

Many organizations have studied and analyzed the effects of toxic gas and particulate exposures. As a

result, standards were developed to regulate exposure. In the United States, the Occupational Safety

and Health Administration (OSHA), the Mine and Safety and Health Administration (MSHA), and the

American Conference of Governmental Industrial Hygienists (ACGIH), NFPA (National Fire and

Protection Agency), National Institute and Technology (NIST), and American Society of Heating,

Refrigeration, and Air-Conditioning (ASHRAE) have all created regulations and limitations on total

permissible exposure levels.

International standards are specified by the health and safety regulations such as the European Union

(EU) and the European Committee of Air Handling and Refrigeration Equipment Manufacturers

(EUROVENT-CEDOMAF). For Canadian standards, the Canadian Standards Association (CSA)

specifies air quality guidelines/regulations.

What the Standards Say

Resources

EVM Series User Manual

7

Resources

To access some of these copyrighted standards, refer to the following:

OSHA

http://www.osha.gov

NFPA-654

http:///www.nfpa.org

MSHA

http://www.msha.gov

NIOSH

http://www.cdc.gov/niosh

ACGIH

http://www.cdc.gov/niosh

ASHRAE

http://www.ashrae.org

NIST

http://www.nist.gov

IEC

http://www.iec.ch

CSA

http://www.csa.ca

EVM Series

Applications

EVM Series User Manual

8

EVM Series

Applications

A real-time, direct reading dust monitor is used in many different applications such as walk-through

surveys in manufacturing, wood making plants and/or bakery shops, background sampling, site dust

measurements, assessment of the effectiveness of dust control systems, and measurement of indoor air

quality (IAQ). It is also used to analyze work-place exposure and help identify dust control techniques

such as training or implementing engineering controls.

Industrial setting - Used to monitor and ensure health

and safety in settings where toxic fumes are released

(such as testing levels at a paper mill or a foundry). This

information can be used to identify the source and

particle concentrations.

Sick Building syndrome –Used to evaluate air toxins

and ensure building standards maintain a comfortable

work setting.

Work site assessments.

Military applications.

Outdoor monitoring applications include construction

sites/dust outside of mines.

Regulatory compliance (i.e., OSHA, MSHA, IEC,

ACGIH).

As a mapping device- Layout a grid of high contaminant

areas, and quickly collect sample data at multiple

locations to help identify paths and sources, by relative

readings.

As a survey monitor

Specific area in a plant/facility –used to maintain a

quality work environment and conduct area

monitoring samples throughout an entire facility.

Specific areas in a plant/facility- used to identify

key areas that may be toxic or unsafe and implement

acceptable practices such as changes in the

ventilation.

Time history: manufacturing

EVM Series

Models Explained

EVM Series User Manual

9

Models Explained

The EVM Series simultaneously measures and data logs specific sensors/parameters that were ordered

with your instrument. The models, sensors, and accessories are explained in detail below. Refer to the

part’s listing for further details (such as calibration accessories).

Models and Sensors

Optional Sensor Accessories

EVM-7 includes:

Particulates

Carbon monoxide (CO) or (1) selectable toxic gas

Selectable toxic gas sensors include:

1. Carbon Monoxide (CO) 2. Chlorine (CL2)

3. Ethylene Oxide (ETO) 4. Hydrogen Cyanide (HCN)

5. Hydrogen Sulfide (H2S) 6. Nitric Oxide (NO)

7. Nitrogen Dioxide (NO2)8. Oxygen (O2)

9. Sulphur Dioxide (SO2)

Volatile Organic Compounds with PID ppm or PID ppb sensor

ppm –parts per million (0 –2,000 ppm)

ppb –parts per billion (0 –50,0000 ppb)

Relative Humidity

Temperature

Carbon Dioxide (CO2)

Air Probe-10

EVM-4 includes:

Carbon monoxide (CO) or selectable toxic gas

Relative Humidity

Temperature

Carbon Dioxide (CO2)

Air Probe-10

Toxic sensor/CO sensor

CO2sensor

PID sensor

Particulates

EVM-3 includes:

Particulates

Relative Humidity

Temperature

Air Probe-10

Toxic sensor/CO sensor

CO2sensor

PID sensor

EVM Series

Models Explained

EVM Series User Manual

10

(This page intentionally left blank)

This manual suits for next models

2

Table of contents

Other TSI Quest Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

CyberVisuell

CyberVisuell LDW-6092K Operation manual

Taxitronic

Taxitronic TX52 installation manual

YOKOGAWA

YOKOGAWA Power Series Plus instruction manual

MEWOI

MEWOI MEWOI-JY218 user manual

Camlogic

Camlogic CLC40 Installation and Maintenance

Dwyer Instruments

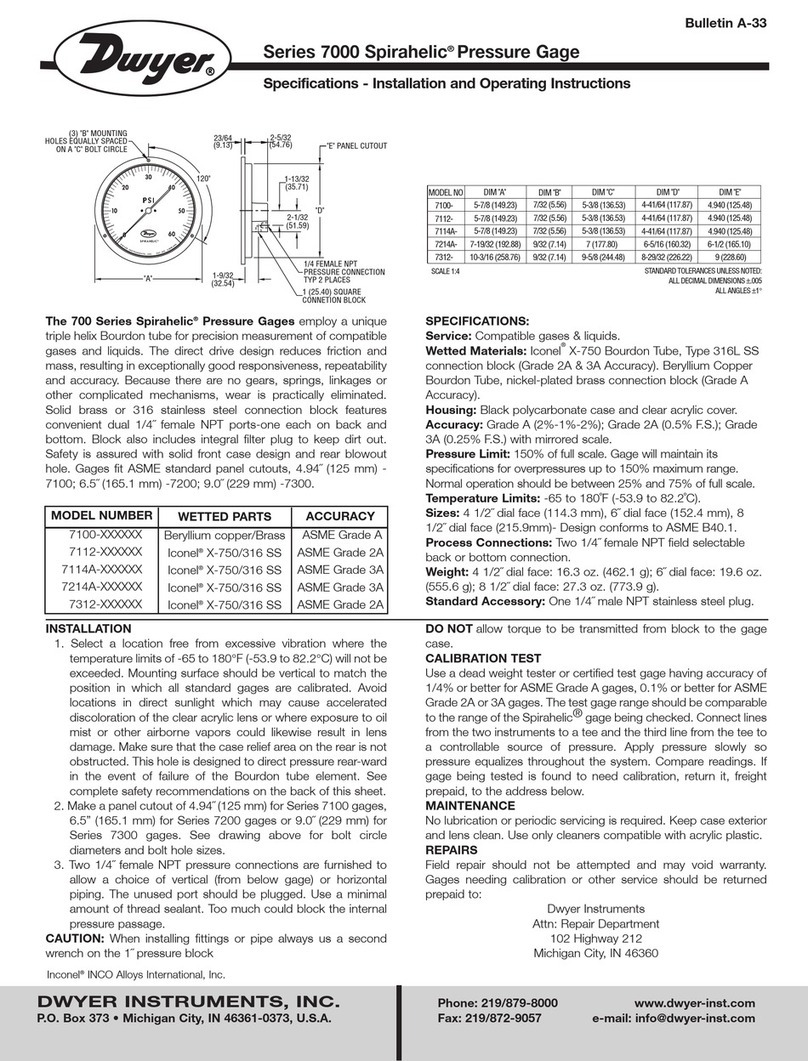

Dwyer Instruments Spirahelic 7000 Series Specifications-installation and operating instructions