TTBIO Tiger 300 Series User manual

1. Product Description

Tiger 300 Design

●Compatible to KaVo® MULTIflex®

W&H® Roto Quick®

NSK® QD-J®

●Head size (T: torque, M: mini)

●Spray hole (single, triple)

●Press chucking

2797 www.ttbio.com

Tiger 300 Series

High - Speed Handpiece Operation Manual

4. Installation

1. Please follow the specification and properly use KaVo® MULTIflex®, W&H® Roto

Quick® and NSK® QD-J® coupling.

2. Please follow original manufacturers' operation manuals when use the above coupling.

※KaVo®& MULTIflex®are the registered trademarks of Kaltenbach & Voigt GmbH CO. ,Germany。

※W & H®& Roto Quick®are the registered trademarks of W&H Dentalwerk Burmoos GmbH S.A. Austria。

※NSK®& QD-J®are the registered trademarks of NAKANISHI INC. Japan。

1. Information in this operation manual were carefully reviewed. We cannot assume any

liability for any damage arising from improper use of the handpiece or from use of this

manual.

2. Products are subject to change without notice.

3. Indications for Use: Tiger 300 Series High Speed Handpieces are intended for removing

carious parts of tooth, proceeding cavity and crown preparations.

4. Please refer to the bar code on the packing box for manufacturing and expiration date.

10. Disclaimer

CAUTION: U.S. Federal law resticts the use of this device to licensed professionals. (Rx Only)

3. Safety Notes

1. Once handpiece is damage (ie deformed caused by hit) or improperly use (ie sterilized

above suggested temperature), be sure not to continue using it.

2. Before operation, always make sure the product and its accessories meet the specified

requirements (ie drive air pressure. lubrication...etc).

3. Please contact our dealer or us with proof of purchase, whenever you have problems such

as abnormal vibration, exceeding temperature or unusual noise...etc.

4. Avoid contact between the instrument head and soft tissue (risk of burning due to the

press button heating up).

6. Replacement of Rotor

1. Please contact local dealers and let the technicians replace the rotor.

2. Do not use unsuitable rotors or spare parts, otherwise could damage the handpiece and

result in severe consequence during treatment.

5. Changing Bur

1. Follow the arrowhead direction show in Fig. to take off or install the

bur.

2. Put on protective gloves to reduce the risk of interactive inflection,

especially not to touch the used burs without proper protection.

3. Make sure bur is tightly secured before operation, otherwise risks of

injury to doctors, patients or the third party could occur.

4. Bur must be complied with ISO requirement. Burs not in good

conditions such as being bent and damaged, or are deviated from

ISO standards and in improper length may decrease the lifetime of

the handpiece or even cause severe consequence such as injury to people.

5. Do not press the button while bur is rotating, otherwise it could harm internal parts.

7. Cleaning

1. Put on protective gloves to detach the handpiece from the coupling.

2. Use clean cloth with mild cleaning solution to clean the handpiece

surface carefully, especially handpiece groove, and remove the

residues.

3. Do not immerse handpiece or cartridges/rotor in disinfectant

solution or water, not to be cleaned by ultrasonic process.

4. Cleaning solution must be non-erosive and harmless to human. Solution with 80%

ethyl alcohol is recommended. Please also follow recommendation of the cleaning

solution manufacturer for suggested usage.

5. Clean the spray nozzle with the nozzle cleaner needle when it is blocked (see above

figure)

8. Lubrication and Maintenance

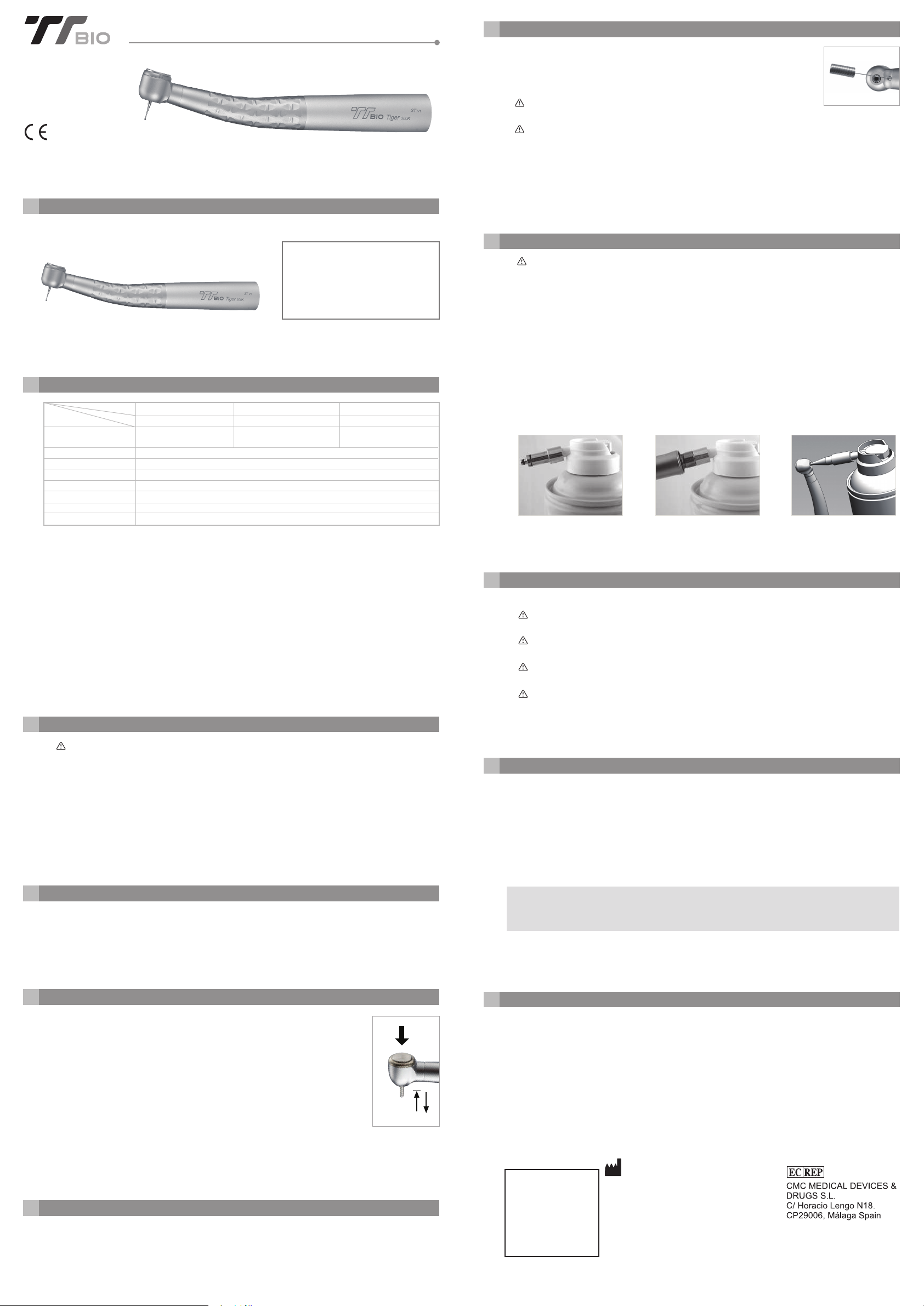

Fig. 1 Fig. 2 Fig. 3

1. Use dental handpiece lubrication oil for maintenance, any unspecified oil not intended

for lubricating handpieces could shorten the lifetime and harm human body.

2. To lubricate 300 series handpiece, put Spray Nozzle into nozzle of the lubrication oil can

(Fig. 1).Connect handpiece with the nozzle (Fig. 2) and inject lubrication oil for 2~3

seconds.

3. Be sure to lubricate the handpieces prior to sterilization and run the handpieces for 20~30

seconds to emit residual oil and dirt.

4. To lubricate handpiece chucks, put Shaft Spray Nozzle into nozzle of the lubrication oil

can and inject lubrication oil into the chuck (Fig. 3) for 1 second. It’s recommended to

lubricate chuck at least once a week and then proceeds step 2.

5. After unpacking and prior to first use, be sure to lubricate with oil and run the handpieces

in low rotation speed for 30 seconds and in full speed for 20~30 seconds to emit residual

oil.

9. Sterilization

TTBIO suggested sterilization in accordance with EN13060

1. Place handpiece in single-use sterile bag and proceed steam prevacuum sterilization.

Do not open the sterile bag before use in order to avoid contact infection.

2. Use qualified sterilization equipment specified by the authority/government for

sterilization procedures.

3. Do not use chemical steam nor immerse handpiece or cartridge/rotor in disinfectant

solution, otherwise could damage the handpiece and cause severe consequences.

4. Sterilization holding time a minimum of 4 minutes at 134℃. (drying time is 15

minutes)

11. Quality and Service

All of our products have passed strict QC procedures before delivery. Please note that

improper use or not using the recommended parts and accessories or modifying our

products without our approval may shorten the lifetime of the product or cause damage.

Please contact us or dealers with proof of purchase for consultation whenever you have

any questions.

2. Specifications

Parameter

※Air pressure must be higher than water pressure. ※ T: torque head M: mini head

※ Pressure values are measured by multi gauge.

Connection

Rotating speed (rpm)

Bur size-diameter / length (mm)

Drive air pressure (bar)

Suggested drive air pressure (bar)

Water flow rate (ml/min)

Water pressure (bar)

Air pressure (bar)

Single

300K T/300K M

300K 3T/300K 3M

KaVo®

MULTIflex®

T:300,000~ 360,000 M:360,000~440,000

Ø1.59 ~ Ø1.60 / T(19-25) ; M(16-21)

2.7~3.3

3

>

50

0.8~2.0

1.0~3.0

W&H®

Roto Quick®

300W T/300W M

300W 3T/300W 3M

NSK®

QD-J®

300N T/300N M

300N 3T/300N 3M

Triple

Air compressor and other devices used by the handpiece must be in accordance with ISO

requirement. (MUST set air pressure higher than water pressure before operation.)

1. Using contaminated water and compressed air containing moisture, impurity or oil to

drive air could shorten the lifetime of the cartridge/rotor, and block the spray nozzle.

2. If NOT follow the required configuration, the risks of damaging the devices and injury to

people could occur.

3. Handpiece is reusable. After unpacking from package or before operating, please

proceed the sterilization from step 7 to 9 by following the procedures: cleaning>lubrica-

tion>sterilization.

Dealer

Manufactured by

TTBIO CORP.

2F.,NO.7, 6TH ROAD INDUSTRY PARK

TAICHUNG. TAIWAN 40755

TEL:886-4-23595958

E-mail:[email protected]

Website:www.ttbio.com

一.產品描述

二. 規格

三. 安全事項

四. 安裝操作

五. 更換鑽針

六. 更換轉子

牙科高速手機使用說明書

●適用KaVo® MULTIflex®

W & H® Roto Quick®

NSK® QD-J®

●頭部尺寸 (T: 大頭, M: 小頭)

●噴水孔 (單孔, 3孔)

●按壓夾持

Tiger 300 設計

參數

※ 冷卻氣壓需大於水壓 ※ T:大頭 M:小頭 ※ 使用快接式壓力計量測壓力值

接頭型式

轉速 (rpm)

鑽針規格 / 長度 (mm)

驅動壓力 (bar)

建議驅動壓力 (bar)

冷卻水流量 (ml/min)

冷卻水壓要求 (bar)

冷卻氣壓要求 (bar)

單孔噴水

300K T/300K M

300K 3T/300K 3M

KaVo®

MULTIflex®

Ø1.59~Ø1.60 / T(19-25) ; M(16-21)

2.7~3.3

3

>

50

0.8~2.0

1.0~3.0

W&H®

Roto Quick®

300W T/300W M

300W 3T/300W 3M

NSK®

QD-J®

300N T/300N M

300N 3T/300N 3M

3孔噴水

本產品為高精密設備,請選擇符合ISO規範之治療台或驅動手機設備,並按照上述規格自

行設定使用環境,或由連接手機該設備所屬技師來設定(設定冷卻氣壓需大於冷卻水壓)

1. 使用不乾燥或含雜質、機油的壓縮氣源和不清潔的水來驅動手機,會縮短手機及轉子的

使用壽命以及阻塞冷卻水氣噴孔之可能。

2. 凡未依使用環境來操作者,有發生危險或產生故障的可能性。

3. 手機為重覆使用之產品。每次在使用前,請依下列七、八、九程序進行完整的消毒及保

養步驟:清洗>潤滑>滅菌。

1. 本產品一旦發生結構上的破壞或不正常使用過後(如受到撞擊產生變形或超過建議

溫度、壓力消毒...等)切勿繼續使用本產品,否則有發生危險的可能性。

2. 使用本產品前,必須檢查所有主、配件及功能是否符合正常條件規范(如進氣壓力、冷

卻水霧、潤滑....等),確認正常後才可使用。

3. 例如震動過大、溫度過高、異常聲音等,應該立即停止使用,並與本公司或本公司經銷

商或維修中心連絡。

4. 避免讓手機頭及軟組織接觸(燙傷風險由於按鈕升溫發熱)。

1. 請參考產品規格表正確使用 KaVo®MULTIflex®、W&H®Roto Quick®、

NSK®QD-J®等快速接頭。

2. 使用上述品牌快速接頭時,請依照上述品牌快速接頭使用方法進行安裝及拆卸動作。

1. 請依右圖的箭頭方向施作,取下鑽針或安裝鑽針,並確認無脫落之虞

安裝完成。

2. 請戴上保護手套進行,應避免直接接觸使用過之鑽針,預防交叉感染

病毒之可能。

3. 更換鑽針,使用前請確認鑽針是否夾緊,否則有脫落而傷害醫師、患

者或第三者的風險。

4. 鑽針請使用ISO標準規格(如規格表中所述)。當鑽針未處於良好狀

況時,如受損、彎曲或直徑過小、長度不適合等情況時,不可使用,

否則有脫落而傷害人體的風險及縮短轉子壽命後果。

5. 鑽針未停止前,請勿按壓按鈕,否則將造成內部機件損壞。

1. 請洽當地經銷商並由專業維修工程師進行更換轉子及測試。

2. 使用不合適之轉子或零配件,會造成手機損壞或導致使用時發生危險之可能。

4. 清潔劑必須不含腐蝕性或化學殘留可能。建議使用酒

精含量80%的藥用酒精。

5. 當噴孔阻塞時,請使用清潔針來進行冷卻水/氣孔暢通工作,以避免因工作溫度過高發生

牙齒傷害之危險(如右圖)。

1. 請戴上保護手套將手機自快速接頭上移除。

2. 清洗必須使用酸鹼值中性清潔劑。使用清潔的布浸入清

潔劑,仔細擦拭手機的外部和表面,最重要為連接面及

縫隙,務必去除殘留物。

3. 不可將手機及轉子浸泡在消毒劑或水中,亦不可進行

超音波清洗。

七. 手機清潔

九. 滅菌方法

TTBIO 建議滅菌方法根據EN13060

1. 將手機置放於單次使用的消毒袋中進行高溫高壓消毒程式,並全程密封消毒袋,直

到使用前才能拆封,避免中途不必要的接觸感染風險。

2. 請使用符合您當地政府法規標準之滅菌設備及程式,進行高溫高壓消毒作業。

3. 滅菌程序請勿使用化學蒸汽或將手機浸泡滅菌消毒液中,否則有發生危險及損壞的

可能性。

4. 本手機建議滅菌條件為134°C持續4分鐘,乾燥時間為15分鐘。

十. 聲明

1. 此說明書的內容係經過嚴謹的核對,然而我們無法保證錯誤絕對不會產生;因此對任何

直接或間接因本說明書引起的損失與傷害,我們無法承擔任何的責任。

2. 製造商保有尺寸、規格更改權利,不另做說明。

3. 本產品必須由合格牙醫師來操作使用,並且只有適用在牙科口腔治療用,不可轉用其他

用途,否則有發生危險的可能性。

4. 本產品請依本說明書正常操作,使用期限請參照外盒上條碼貼紙。

5. 適用範圍:本產品供口腔科夾持高速牙科車針進行鑽、磨牙等手術用。

※KaVo® 與MULTIflex® 皆為 Kaltenbach & Voigt GmbH CO. ,Germany註冊之商標。

※W & H® 與Roto Quick® 皆為 W&H Dentalwerk Burmoos GmbH S.A. Austria註冊之商標。

※NSK® 與QD-J® 皆為 NAKANISHI INC. Japan註冊之商標。

十一. 品質政策與售後服務

雷虎公司的產品在出廠前皆經過嚴謹的品質確認程序,但請留意:不正確的使用方法或未

使用本公司建議的零配件或未經過認可的改裝本產品,皆可能造成產品的壽命縮短與危

險,因此我們建議您:對我們的產品有疑問時,請攜帶產品及您的購買證明文件,向本公

司授權的經銷商洽詢。

0JL0067V5

2021.01

八. 潤滑及保養

1. 下述保養油請使用醫療級牙科手機專

用保養油,任何非牙科手機專用保養油

皆有減短轉子壽命及危害人體之可能。

2. 300系列手機潤滑轉子,請將保養油罐上

噴嘴套入牙科手機噴油栓(圖1),插入

手機銜接快速接頭位置(如圖2),注入保養油約2~3秒。

3. 請在每一次滅菌前進行潤滑保養,並將手機裝回導管接頭或快速接頭,啟動手機運轉

20~30秒將多餘保養油及污穢物排出手機本體。

4. 各型手機潤滑夾持機構保養,請將保養油罐上噴嘴套入轉軸噴油栓,插入夾持鑽針處

(如圖3),注入保養油約1秒(每週至少一次)後,再進行步驟 2。

5. 拆封第一次使用前,請于上油後輕踩開關以低轉速運轉約30秒,再以全轉速運轉約

20~30秒,將多餘的保養油排出。

圖1 圖 2 圖3

2797 www.ttbio.com

Tiger 300

系列

品名:"雷虎生技" 牙科手機及其附件 (未滅菌)

許可證字號:衛署醫器製壹字第004431號

藥商名稱:雷虎生技股份有限公司

藥商地址:台中市西屯區工業區六路7號2樓

製造廠名稱:雷虎生技股份有限公司

製造廠地址:台中市西屯區工業區六路7號

T:300,000~ 360,000 M:360,000~440,000

This manual suits for next models

6

Other TTBIO Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual