TTI PantherPatrol Service manual

Manufacturer of The Safest Tanks in Motion

www.tti.com.au

PantherPatrol™

Equipped to Defend

HANDBOOK

OPERATOR’S

TTi’s PantherPatrol™HandBook

2Call 1800 816 277www.tti.com.au 2

Table of Contents

Introduction 3

Risk Assesment 4

Operating Instructions 5

Start Up Procedure 6

Quick Fill Unit 7

Using Pump 9

Maintenance 10

Warranty 11

Warranty Limitations 12

Warranty Registration Card 13

TTi’s PantherPatrol™HandBook

3Call 1800 816 277www.tti.com.au 3

Introduction

Please carefully read your operators handbook before mounting or using your Fire

Attack Unit. Keep your handbook in a safe place.

Congratulations on your purchase of a PantherPatrol Fire Fighting Unit which is

complete and ready to mount onto a suitable ute or truck.

Your Safety

• When mounting to any vehicle, please ensure that you have read the Vehicle

Owner’s Manual and that you comply with all the weight restrictions as specified

by the vehicle manufacturer, as overloading can cause injury or death.

• To ensure your own safety and that of your employees, if applicable you must

comply with all relevant environmental, work place health and safety legislation

and codes of practice. In particular, be aware of Rural Fire Service guidelines for

safety when fighting fires or backburning.

• Select and wear appropriate Personal Protection Equipment in accordance with

state regulations and your own safe work practices.

• Improper or careless use of this unit can cause serious injury. Minors should never

be allowed to use this. Should not be used when bystanders or animals are in the

area.

• Never leave the unit unattended without turning off the engine and relieving the

line pressure,

• You must be in good mental health to operate this unit and not be under the

influence of alcohol or any drugs that could impair your vision, physical strength,

dexterity, judgment, or other mental capacity .

• All operators must be trained in safe use of this unit.

TTi’s PantherPatrol™HandBook

4Call 1800 816 277www.tti.com.au 4

Risk Assesment

Product Information Risk Assessment Sheet

TTi - PantherPatrol Unit

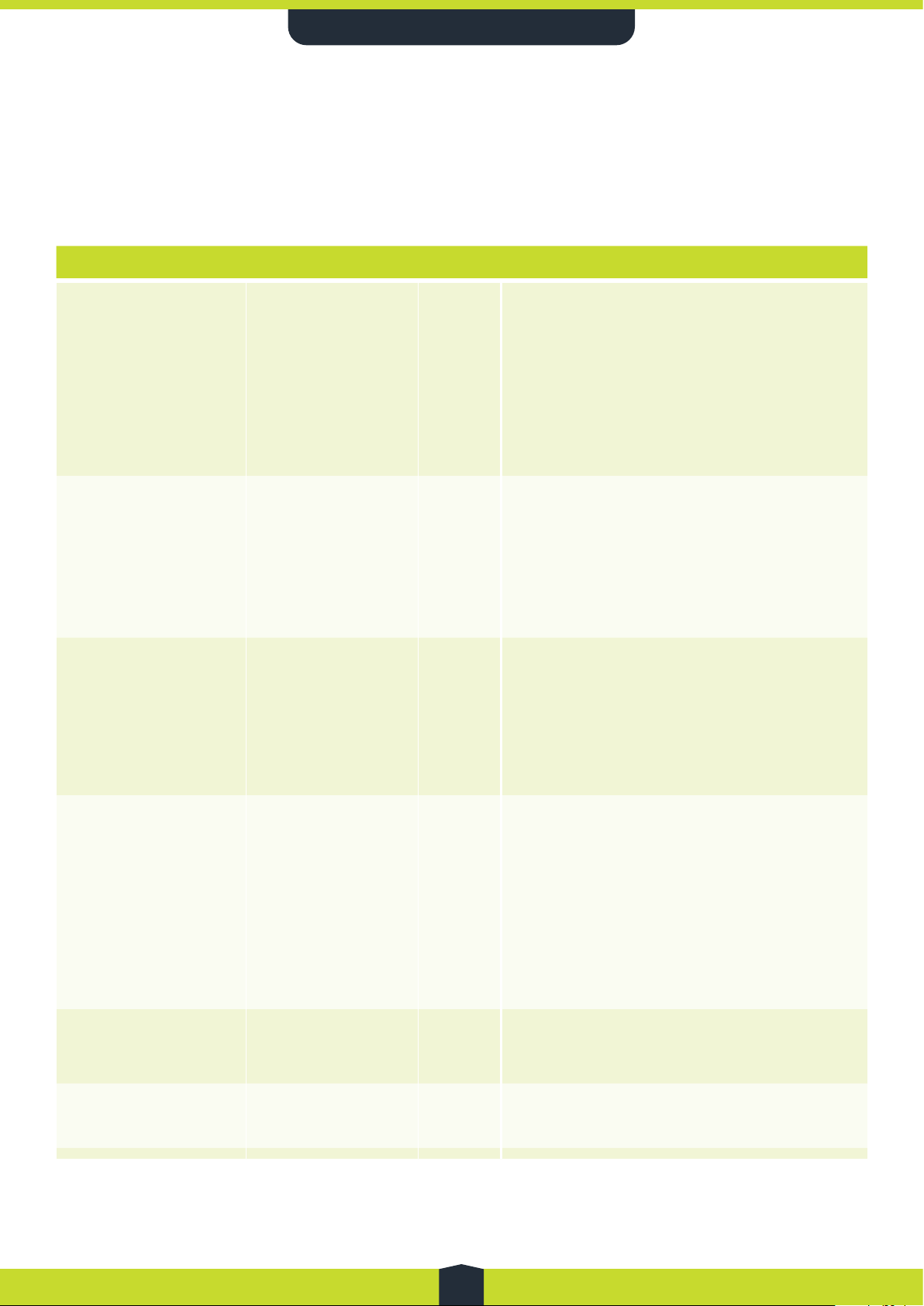

TASK HAZARDS RISK CONTROL MEASURES

Partially fill the

tank with water,

start the motor &

test the spray unit

Manual handling;

slips, trips

or falls; petrol;

fumes; fingers

jammed

Med

• Concentrate on task;

• follow safe manual handling techniques:

• don’t lift on your own if > 20kg, bend

knees & keep back straight

• keep fingers clear

• keep unit at least 8m away from overhead

powerlines

• fire extinguisher nearby

• follow warning stickers on tanks

• wear PPE for petrol & fumes-mask & gloves

Check weather

conditions

& select the

appropriate

PPE to suit the

chemicals to be

used

Manual handling;

slips, trips or falls Low

• Put on PPE as per the chemical

requirements in the Material Safety Data

Sheet-coveralls, gloves, safety footwear,

glasses & respirator;

• Follow safe manual handling techniques:-

don’t lift on your own if >20kg, bend

knees & keep back straight.

Mix chemicals

(if applicable)

Fill spray tank/fire

fighting units

As above; spray

drift, chemical

spillage, emission

of vapors or

flammability;

weather; untrained

visitors

Med

• As above;

• User trained in the state’s chemical mixing

& administration course eg Chem. Cert;

• Follow the relevant Environment Protection

Authority requirements; fire extinguisher

present;

• Keep visitors away from the job unless

wearing full PPE.

Use spray or fire

fighter units.

As above; loss

of load; heat

& cold; noise;

exceed load limit

of vehicle; hose

entanglement;

exhaust fumes;

terrain & slopes;

run over by unit

High

• As above

• Wear clothes to suit heat & cold;

• Wear hearing protection if noise > 85 dBa;

• Follow the manufacturer’s safe operation

instruction for the vehicle and the spray

unit

• Don’t overload - water weighs 1kg for

every 1 litre

• Secure load to vehicle;

• Keep hose tidy;

• Put unit brakes on.

Clean up,

maintenance &

storage

As above High

• As above;

• Continue to wear PPE for clean up;

• Store unit in a dry, well ventilated area.

Burn Risk

Hot exhaust/muffler Med

• Do not reach over hot exhaust

• Do not service engine while hot

• Wear appropriate PPE

TTi’s PantherPatrol™HandBook

5Call 1800 816 277www.tti.com.au 5

Operating Instructions

Before First Use

1. Check all hoses, connections and hose clamps to ensure that the unit has been

delivered to you without transportation loss or damage.

2. Before attempting any spraying with your new unit, operate it with water only

to familiarize yourself with its features and capabilities and to ensure that your

sprayer has arrived in a safe working condition. Please contact your dealer

immediately should anything appear to have been damaged.

3. Couple the unit to the towing vehicle by placing the tow hitch over the tow ball

of the vehicle. Ensure it locates correctly.

4. Plug the 7-pin trailer plug on to the plug of the towing vehicle ensuring that they

firmly lock. Test the brake lights and indicators.

5. Prepare the engine for use as per the engine manual supplies with your sprayer.

Ensure that the correct quantity and type of oil is used when filling the engine.

Operation

• Fill tank from appropriate water source. Open ball valve on suction hose at

bottom of tank. Start motor and allow to warm up. Bypass valve is fitted to the

top of the pump and should be adjusted to allow bypass for warm-up period.

• Unlock hose reel to allow hose to be pulled out. When using the fire fighter adjust

the nozzle to desired spray pattern. Increase engine speed and adjust bypass

to achieve desired flow rates. When job is finished turn engine off, rewind hose

onto reel and lock reel to prevent unwinding. Close ball valve on suction hose.

Please note that the unit is designed for fire fighting use and not for chemical

spraying. Please consult the manufacturer for further information.

TTi’s PantherPatrol™HandBook

6Call 1800 816 277www.tti.com.au 6

Start Up Procedure

Prepare the engine for start up as per the engine manual and pump manual.

Add the spray solution to the tank (See “Mixing and Filling”).

Ensure that the pressure regulator lever is in the ‘open’ position and the pressure

adjusting knob is screwed out (anti-clockwise). Failure to do so will invalidate pump

warranty.

Start the engine and allow it to warm up. Run the pump with the regulator lever

in the BY PASS position in order to discharge entrapped air from the system for at

least two minutes before changing the regulator to the closed position. (Rotate

clockwise)

To set the correct spraying pressure, open the flow through the hand gun (discharge

solution back to tank) and turn the pressure regulator knob in a clockwise direction

until the required pressure is achieved. Spray nozzle pressure will vary according to

hose length, nozzle size, etc. When the hand gun is released the increased pressure

in the system will be automatically adjusted by the pressure regulator valve and

excess flow will be returned to the spray tank.

Maintenance

After use the sprayer must be thoroughly decontaminated, inside and out, to

prevent damage to the unit from corrosion or abrasion.

When storing the unit ensure that it is clean and dry and store in a well ventilated

place.

If operating in areas where freezing occurs we recommend leaving anti-freeze in

the pump, regulator and handgun while not being used to prevent possibility of

frost damage.

TTi’s PantherPatrol™HandBook

7Call 1800 816 277www.tti.com.au 7

Quick Fill Unit

Aussie pumps are designed for sucking water directly out of dams. The quick fill unit

is a quick, environmentally safe way of sucking up water to fill the water tank.

When using the quick full unit,

1. Remove the camlock cap from the discharge port of the pump

2. Detach the suction line connected to the pump and place it on the discharge

outlet directly above

3. Attach the camlock fitting on the ‘quick fill kit’ to the suction line of the pump

4. Lower the opposite end of the quick fill hose with the filter into the external water

source

5. Prime the pump by unscrewing the red cap on the top of the pump and filling it

with water. Once full, screw the red cap back into place.

6. Open the tap on the outlet of the water tank and start the engine

Ensure water is being sucked in by the pump and discharged into the tank.

Suction from

Tank

Camlock

Cap

Quick Fill

Hose

Position of Hoses

Quick FillingNormal Operation

TTi’s PantherPatrol™HandBook

8Call 1800 816 277www.tti.com.au 8

Ref Part No. Description Qty

133-103231 Tank, 15/55(g/L)

233-103230 Tank, 25/95 (g/L)

233-103245 Tank, 40/150 (g/L)

233-103246 Tank, 60/225 (g/L)

2TL-6B Lid, Tank

333-103234 Harness, Wire, SS,

4EF1000 Pump, Everflo, 1 GPM

EF2200 Pump, Everflo, 2.2 GPM

533-103126 Screw, Machine, 10-24 x 5/8, 1 GPM pumps only

33-103127 Screw, Machine, 10-24 x 1”, 2.0 GPM pumps

633-103131 Washer #10, 2.0 GPM pumps only

7A38 Fitting, 3/8”MNPT x 3/8”HB. 2.0 GPM pumps

83204-1407 3204-1407 Hose, rubber, 3/8”

9SHC-F Clamp, hose

10 33-103121 Strainer, Inlet

11 SG-5524 Wand, with filter

12 SG-5524-18 Nozzle Tip, Assembly

13 GC-100-KIT Clip, Gun (Pair)

14 W406-V Washer, Garden Hose

15 3N34 Cap, Garden Hose

3204-1407 Hose, rubber, 3/8”, intake, 15/55 (G/L) & 25/95

(g/L) tanks

3204-1407 Hose, rubber, 3/8”, intake, 40/150 (G/L) &60/225

(g/L) tanks

SS-MANUAL-MM Manual, (not shown)

TTi’s PantherPatrol™HandBook

9Call 1800 816 277www.tti.com.au 9

Using Pump

Contents

6 meters of 38mm Suction Hose

Camlock Fittings

Foot Strainer

Warnings

Do not change hoses while engine and pump are operating. Observe all precautions

listed in Firefighters Operators Manual, Be aware of hazards working near water

sources particularly dams and rivers - slipping, falling, drowning and use safe work

practices at all times.

Operation

1. Turn off engine

2. Remove camlock cap from large on pump - see below.

3. Dettach the suction line on pump and reattach to discharge port of pump

4. Attach suction hose from bottom fill kit to suction of pump

5. Place foot strainer and hose into water source Ensure strainer is deep enough in

water to prevent sucking air

6. Open ball valve at tank

7. Start engine and operate until tank is full. Nb. TTi recommend removing tank lid

while filling

8. When tank is full turn engine off, close valve at bottom of tank and reverse steps

4 to 2 and unit is ready to use

TTi’s PantherPatrol™HandBook

10 Call 1800 816 277www.tti.com.au 10

Maintenance

Maintenance

• Service motor & pump in accordance with instructions in the manufacturers

manuals as supplied with this Fire Fighting unit

• Periodically [at least annually] check all hoses, nozzles and fittings for any sign

of wear. Replace any parts which are worn or defective.

• If hose reel has not been used for any length of time. Unwind it fully to check that

hose is in good order, pressurise the line & check operation of spray nozzle etc.

Rewind & lock reel on completion as per hose reel instruction above.

• Check oil level in motor regularly & drain & replace oil according to manufacturer’s

recommenda- tions in manual supplied.

• If Fire Fighting unit is to be stored for any length of time, disconnect battery,

ensure tank is empty & no lines are under pressure. Store unit in a clean, dry, and

well-ventilated area.

TTi’s PantherPatrol™HandBook

11 Call 1800 816 277www.tti.com.au 11

Warranty

Warranty Policy

TTI will, at its option, repair or replace, without charge, any part covered by this

warranty which is found to be defective in material and/or workmanship within one

(1) year* after date of sale to the original retail purchaser unless the product is used

for rental purposes, in which case this warranty is limited to ninety (90) days. Upon

request, the customer will make the defective part available for inspection and/

or return the defective part to TTI, transportation charges prepaid. All parts and

components are covered by this warranty except the following, which are warranted

separately by their respective manufacturers: - engines, gearboxes, pumps &

regulators. TTi does not assume any warranty obligation, liability or modification for

these items, which are covered exclusively by the stated warranty of the respective

manufacturers.

What this Warranty Does Not Cover?

a] This warranty does not cover defects caused by depreciation or damage caused

by incorrect mounting, normal wear, accidents, improper maintenance, improper

use or abuse of the product, alterations or failure to follow the instructions and

warnings provided.

b] The customer shall pay any charges for making service calls, clean up time and

transport charges.

c] The use of non-genuine parts on equipment supplied by TTi will automatically

negate any warranty.

How to Optain Service Under this Warranty?

Warranty service can be arranged by contacting your dealer or by contacting Trans

Tank International, Call 03 5866 3266. Proof of warranty registration and date of

purchase may be required to verify warranty coverage. Any efective parts returned

to us must be accompanied by a Return Goods Note. This form can be obtained by

TTi’s PantherPatrol™HandBook

12 Call 1800 816 277www.tti.com.au 12

Warranty Limitations

a] There is no other express warranty. Any warranty that may be implied from this

purchase including merchantibility and finess for a particular purpose is hereby

limited to the duration of this warranty and to the extent permitted by law. Any and

all implied warranties are excluded.

b] TTI will not be liable for any incidental, consequential or special damages and/

or expenses in connection with the purchase or use of this equipment, to the extent

permitted by law.

c] Only the warranty expressed in this limited warranty shall apply and no dealer,

distributor, or individual is authorized to amend, modify, or extend this warranty

in any way. Accordingly, additional statements, whether oral or written, do not

constitute warranties by TTi, and should not be relied upon.

Whilst every care has been taken in the preparation of these instructions, no liabilities

can be accepted with regard to errors or omissions. Product specifications are

subject to change in line with our commitment to continuous improvement.

TTi’s PantherPatrol™HandBook

13 Call 1800 816 277www.tti.com.au 13

Warranty Registration Card

To validate your warranty, please complete registration on-line at:

www.tti.com.au/warranty-registration

Alternatively if you are unable to register on-line fill in all the details below, copy

I have read and understood the instructions in this booklet.

[located on side of tank]

Model:

Serial Number:

Date Purchased:

Purchaser’s Name:

Post code:

Purchaser’s Address:

Phone #: Mobile #:

Email Address:

Purchaser’s Signature:

/.

/.

/.

/.

www.tti.com.au

1800 816 277

sales@tti.com.au

PO Box 137, Nathalia, VIC, 3638

Murray Valley Hwy, Nathalia, VIC 3638

Table of contents

Other TTI Firefighting Equipment manuals

Popular Firefighting Equipment manuals by other brands

ADC

ADC EcoDry ADFG Installation & operator's manual

Waterous

Waterous CM Series Operation and maintenance manua

Autronica

Autronica BS-200 System description

Task Force Tips

Task Force Tips BLITZTAC Portable Monitor Instructions for installation, operation and maintenance

Tyco

Tyco EC-HS quick start guide

ZURN

ZURN PEX installation guide