FIGURE 2

TYPICAL ASSEMBLY ARRANGEMENT

(2 IN. DELUGE SYSTEM WITH ELECTRIC ACTUATION SHOWN)

14

5

13

6

15

17

1

2

11 8

9

10

3

7

12

4

18

16

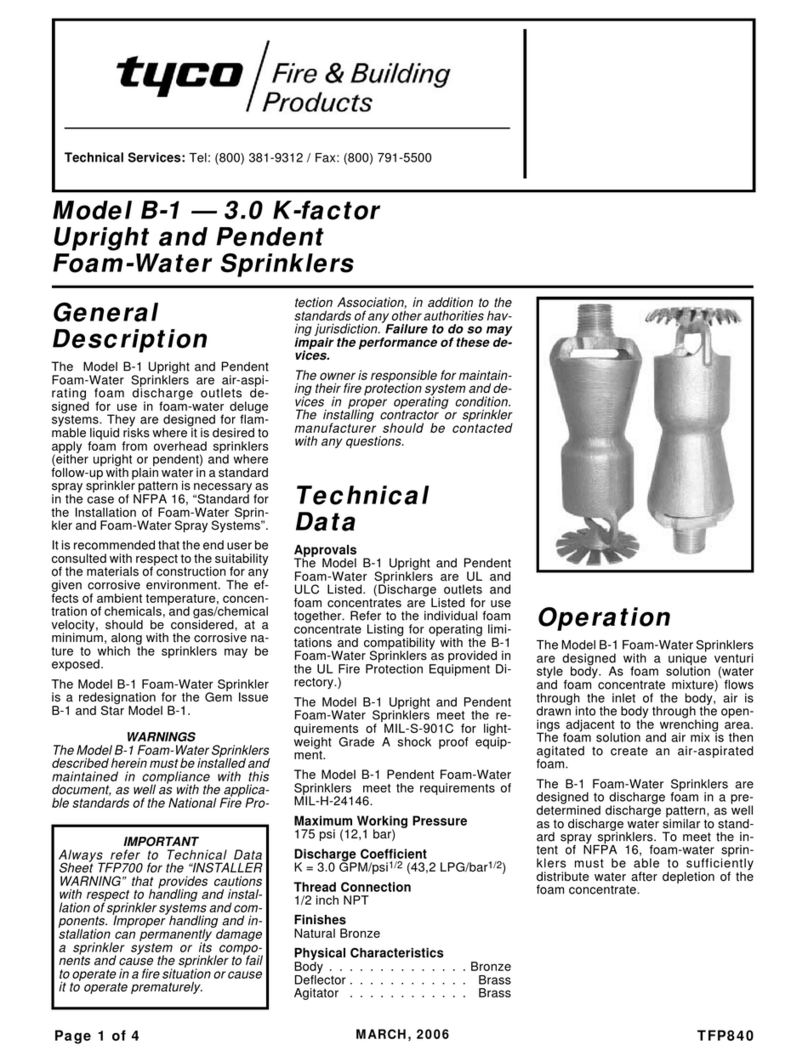

Construction

The Red-E Cabinet is constructed of a

minimum thickness of 14 gauge steel,

and is free standing. The standard

paint finish is bright red and black. The

front doors of the enclosure are fully

hinged and removable and open nearly

to the cabinet floor level, allowing easy

access to the couplings when connect-

ing the water supply and drain.

The compressor is stored near the

bottom of the cabinet on a pull out

drawer for access through the double

doors. Pre-drilled holes on tabs along

the base provide an anchor point for the

cabinet to be secured to the floor when

required. Industrial grade rollers at the

bottom of the cabinet are standard.

Internal controls that provide functions

to reset a system after operation, for

example, alarm test valve, main drain

valve, are individually tagged for easy

identification. All prefabricated piping

is Schedule 40 steel.

A splash-resistant drain cup is pro-

vided that ensures water does not

splash into the cabinet during flow

testing. The discharging water can be

observed through a clear tube attached

to the drain cup. It is designed with a

fail-safe feature allowing water to over-

flow in the event the drain is blocked.

The hard piped funnel drain is con-

nected through a swing check valve to

the main drain header, eliminating the

need to run a separate drain line from

the funnel. The cabinet floor is provided

with a drain opening to allow water to

drain out. A plug is also provided to

prevent water from draining from the

cabinet if necessary.

For dry pilot trim arrangements, the air

supply connection for cabinets without

compressors (that utilizes AMD-1) are

terminated at a common height across

all model sizes allowing the connec-

tion of groups of cabinets easier. This

allows a single tank mounted compres-

sor sized to meet the requirements

of the largest system in the group to

supply all the cabinets in the group, or

alternatively, connect to the factory air

supply. The air supply line contains a

tee and plug which is used to connect

a hydraulic test pump that pressurizes

the sprinkler system above the butterfly

valve for hydraulic testing of the system

in accordance with NFPA 13.

Table A provides a list of riser compo-

nents and a cross reference to indi-

vidual technical data sheets, as well

as individual component laboratory

approval information.

Figure 1 provides dimensional infor-

mation for Red-E Cabinets, and Figure

2 illustrates the typical assembly

arrangement.

Design

Considerations

The open nozzles and/or sprinklers, fire

detection devices, manual pull stations,

and signaling devices that are to be uti-

lized with the Red-E Cabinet must be

UL Listed, ULC Listed, C-UL Listed, or

FM Approved, as applicable. With ref-

erence to Figure 3, the system designer

must consider and make preparations

for use of a Red-E Cabinet as follows:

• Adequate floor space to facilitate

opening of the cabinet doors

• Minimum ambient temperature of

40°F (4°C)

• Installation of a suitably sized water

supply to the water supply header

(Port B, Figure 1)

• Installation of system piping (Port A,

Figure 1) including open nozzles and/

or sprinklers from the Red-E cabinet

outlet

• Installation of drains from main drain

header (Port C, Figure 1)

• Installation of the detection system

components and alarms

• Power supply to Red-E Cabinet

• Separate power supply to the air

compressor (dry pilot actuation)

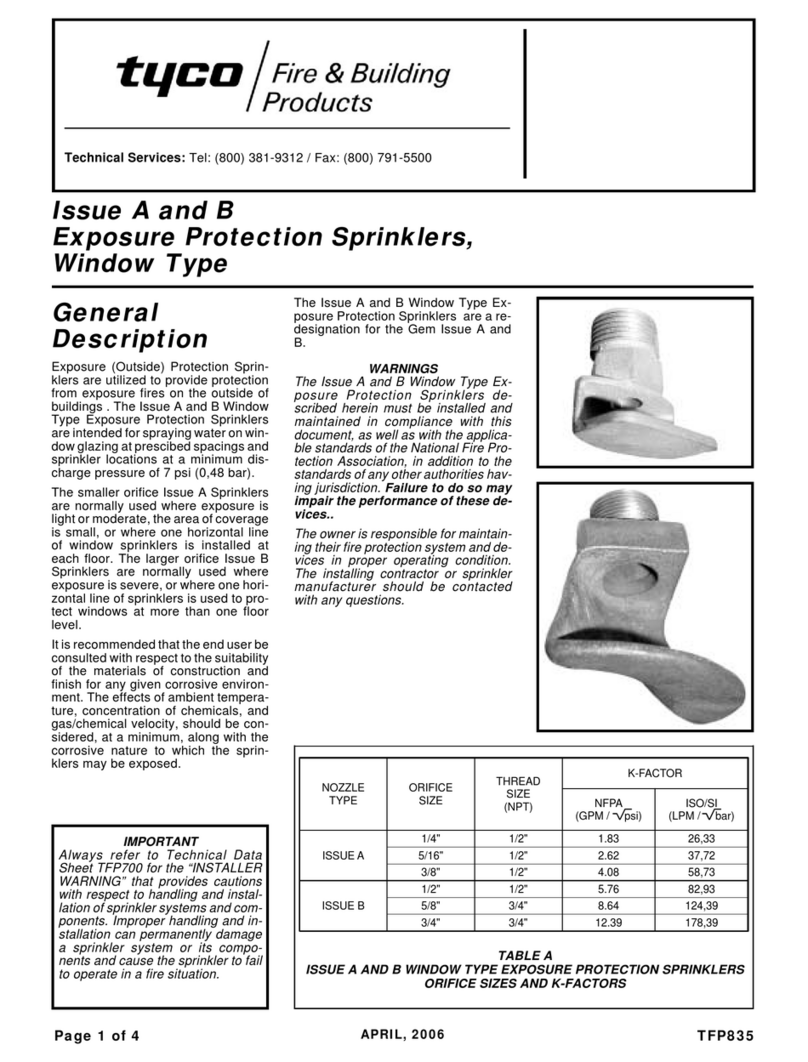

1 - Supply Header

2 - Drain Header

3 - Supply and Drain Header

Connections on Left or

Right Side

4 - System Discharge

Connection

5 - DV-5

A

Valve with Deluge

Trim

6 - Manual System Shut-Off

Valve

7 - System Pressure Gauges

8 - Manual Control Station

9 - Splash-Proof Drip Cup

10 - Drain Header Integrated

Drip Cup Connection

11 -Waterow Pressure Alarm

Switch

12 -Main Drain Valve

13 -Releasing Panel

14 - Electrical Conduit

Connections

15 - Main Compartment

Access Doors with Lock

16 - System Air Compressor

for Dry Pilot Actuation

Congurations

17 - Manual System Shut Off

Valve

18 - Air Tank for Dry Pilot

Actuation Congurations

TFP1301

Page 3 of 8