TTM NoXygen C625 User manual

2022-09

TTM NoXygen®C625

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

Degasser

2022-09

2 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

Upon delivery

Instructions: Immediately upon receiving, check to ensure that

the delivery is complete and that nothing is damaged.

Report any transport damage immediately.

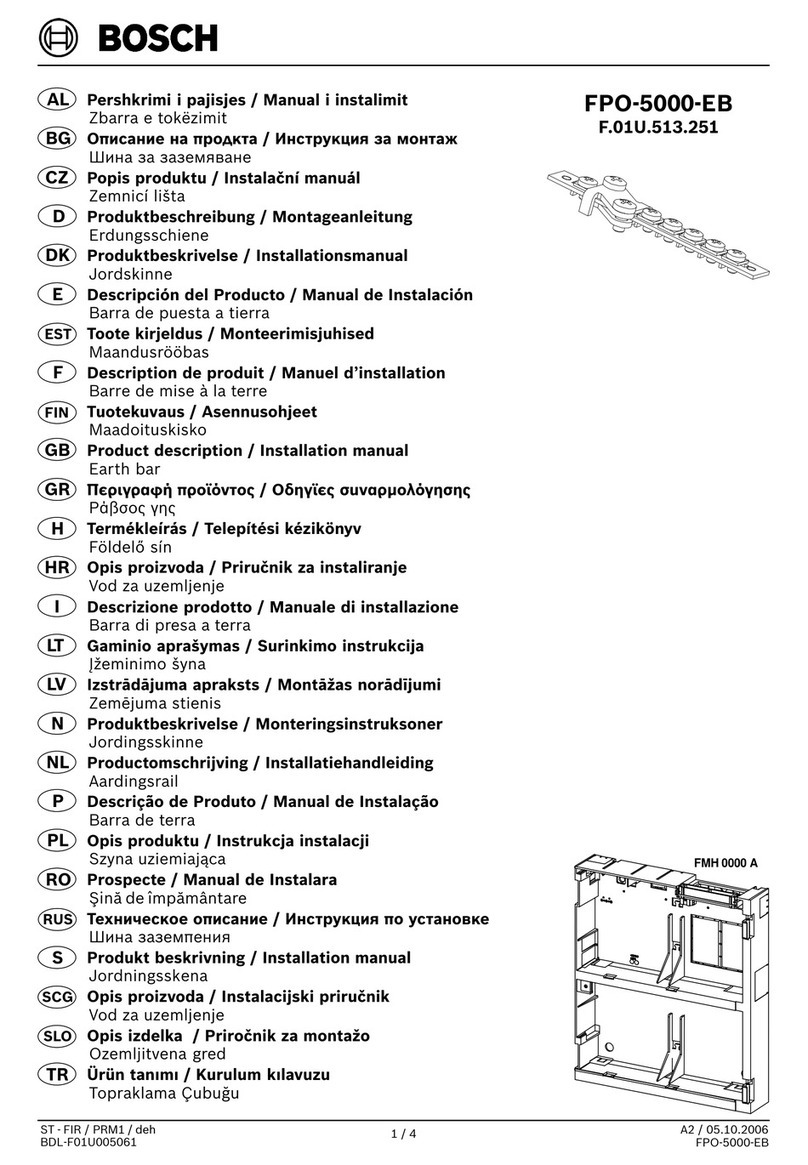

A. Main line

B. Inlet with shut-off valve

C. Treatment chamber

D. Return with shut-off valve

B

C

D

A

Principle of Operation

Table of Content

General

Principle of Operation................................................... 2

Technical Data.............................................................. 2

General Safety Instructions .......................................... 3

Installation ................................................................. 4

Pipe connection .......................................................... 4

Electrical Connection .................................................. 4

Commissioning and Operation ........................... 5

Display ....................................................................... 6

Use of Display Buttons................................................. 6

Factory Reset ............................................................... 6

Operating Modes .................................................... 6

Options ...................................................................... 7

Maintenance.............................................................. 8

Functional Control....................................................10

Troubleshooting........................................................11

Technical data

Art.no .................................................... 515180

System pressureat the connection point,

max.:.....................................................+0,8 – +2,5 bar

Allowable operational temperature:........0 – +60 °C

Ambient temperature: 0 – +40 °C

Allowable fluids: Water and deionised water

Ethanol* less than 30 vol%

Kilfrost max 30 vol%

Pressure classification: ..........................PN10

Capacity, degassed fluid:.......................min. 100 l/h

Connection dimension:..........................DN15

Electrical data:.......................................1~230 V, 50 Hz, plug

External fuse: ........................................10 A

Nominal power: .....................................0,5 kW

Nominal current: ....................................3 A

Protective class: ....................................IP44

Energy usage: .......................................25 kWh/year *

Alarm output, max load: ........................24 V, 1,0 A

Sound level:...........................................58 dB

Weight:..................................................19 kg

*) Operation with 30 days of fast degassing gives a

energy consumption of 80 kWh in the first year.

TTM NoXygen®is environmentally assessed.

Width: 540 mm

Height: 560 mm

Depth: 190 mm

540

190

500

560

370

45

250

1/2” inv. gänga

360 (upphängning) 90

12

int. thread

(Wall mount)

TTM NoXygen® C625

Installation, operating and maintenance instructions

2 (9)

2022-09

3 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

General safety instructions

TTM NoXygen®C625 is designed for stationary operation; it

is not meant for mobile system operation. The stipulated war-

ranty period applies only to a maximum of 10,000 degassing

intervals per year.

Installation must be done in accordance with national regula-

tions. Installation must be done by professionals and specially

trained staff. Information on the manufacturer, year of manu-

facture, serial number and technical data can be read on the

data plate affixed to the TTM NoXygen®C625 unit.

Take measures for temperature and pressure fusing in the

system so that the stated, allowable maximum and minimum

operating parameters are not exceeded or undercut, respec-

tively. TTM NoXygen®C625 must only be used in systems for

containing allowable fluids.

Systems using expansion vessels and pressurised expansion vessels

When operating TTM NoXygen®C625, there must be 3 litres of free expansion volume in the system.

Without this, the pressure in the system will increase and the system safety valve may release fluid in order

to reduce the pressure. If this occurs, the system’s expansion vessel like has the wrong input pressure or

there is too little room for expansion and it needs to be replaced with a larger expansion vessel.

Rule of thumb: The input pressure must be 70% of the system pressure.

NOTE: The pressure at the safety valve opening should be 30% above the system pressure.

Systems using pressure maintenance systems with compressors or pumps

Systems with pressure maintenance vessels/compressor vessels for expansion can begin to work intermit-

tently with the degasser, i.e., the expansion vessel empties and fills according to TTM NoXygen®C625's

oprertation cycles. A surge vessel measuring 50 litres should be installed in connection with the pump expan-

sion. (See the image below). The reason why this happens is that the nominal value between the opening and

the magnetic valve and the pump switch is too narrow.Then check the system pressure and system height so

that the correct system pressure is set and then give the nominal value a larger pan.

System pressure and filling of system fluid

As gasses are removed from the system fluid, the

fluid decreases in volume and the pressure within the

system is reduced. Therefore it is important to moni-

tor the system pressure and to add more system fluid

when necessary. A high gas content and continuous

operation of TTM NoXygen®can result in the system pressure falling very quickly.

An initial inspection is therefore recommended after only 24 hours of operation

System pressure

System pressure = system height (m) + 5 m.

Example

System height = 5m + 5m => 1 bar of system pressure

• Before maintenance work, the plug must be disconnected from the wall socket.

• Installation, maintenance and troubleshooting should only be carried out by

qualified personnel.

• The TTM NoXygen is usually maintenance-free but an annual function check

is recommended to ensure maintained performance, see function check page 10.

• Checking and cleaning of pre-filters should be done in conjunction with the

function check.

• In dirty systems cleaning of pre-filters needs to be done more frequently,

see page 8 and 9.

IMPORTANT!

TTM NoXygen® C625

Installation, operating and maintenance instructions

3 (9)

2022-09

4 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

Installation

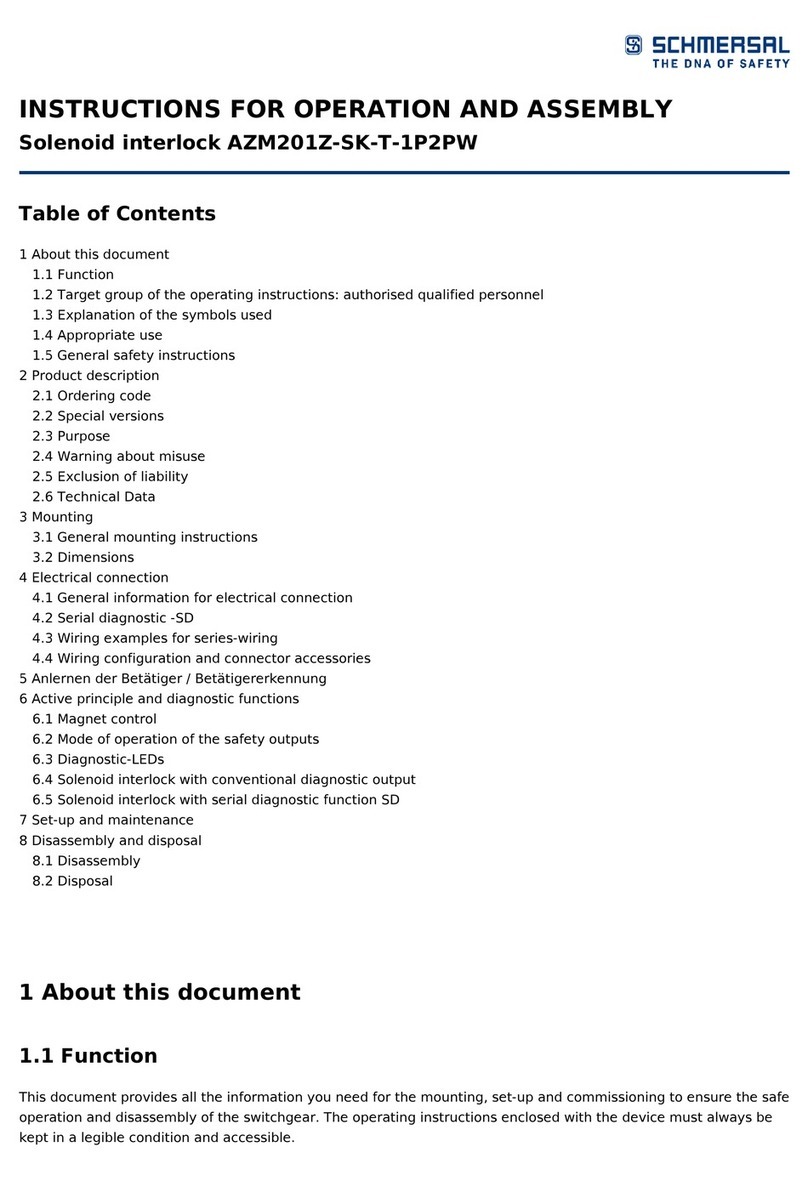

Pipe connection

• TTM NoXygen®is fitted with a ½” internally threaded connection.

The connection is made with a steel-braided hose to system’s return

conduit in front of the pump and exchanger.

• Connection to the system must always be made to the upper side

of the pipe unless a TTM MAG 54 or 76 filter is installed in front of

NoXygen on the incoming conduit.

• The distance between connection points shall be at least 300 mm

(Fig. 1 och 2).

Drip Tray

The drip tray’s ½” connection is connected to the floor drain (Fig. 3).

Mounting

For floor mounting, the TTM NoXygen®is placed on its feet so that it is

horizontal.

For wall mounting, hang the TTM NoXygen®in the unit's wall brackets so

that it hangs horizontally (Fig. 4 and dimensional drawing page 2).

Electrical Connection

TTM NoXygen®is connected by plugging in the wall plug to an earthed

socket 1-230 V, 50 Hz Alternatively, it can be connected to a fixed

earthed connection with a circuit breaker. The electrical unit should be

equipped with a residual current device.

Connection to External Monitoring (DUC)

The TTM NoXygen®is equipped with a built-in potential-free changeover

contact for buzzer alarm (Fig. 5). The switching pin is mounted externally

on the right side of the TTM NoXygen®and the alarm connector is plugged

into outputs Aand Cfor NC (Normally Closed during operation) and into

Band Cfor NO (Normally Open during operation). Operation indication is

given when the TTM NoXygen®is in operation mode (green light is on) on

the control panel.

Fig. 2.

Fig. 1

Fig. 3

Fig. 5

TTM

NoXygen®

A (NC) Normal operation

B (NO) Powerless / On alarm

C (Common)

A

B

C

Coupling pin at

normal operation

OBS!

Existing cables in the coupling slot

should not be moved or

disconnected. NC: A + C (normally closed) during operation

NO: B + C (normally open) in operation

Fig. 4

360 mm C/C

Drill hole

Ø12x80mm

Wall plug

12x60mm

French wood screw

galvanized 8x70mm

Main flow V

Circulation water

≥300

High gas

Low gas

High gas

Low gas

Main flow V

Circulation water

Main flow V

Circulation water

≥300

High gas

Low gas

High gas

Low gas

Main flow V

Circulation water

TTM NoXygen® C625

Installation, operating and maintenance instructions

4 (9)

2022-09

5 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

Commissioning and operation

1. Starting TTM NoXygen®

Press

MOVEO

twice to start the TTM NoXygen. When the green LED lights up, the unit is now in operation.

2.2 Press

MOVEO

to check date

settings "hh-mm-ss".

2.3 Press

MOVEO

to check start

time for maintenance

degassing "Tstart".

2.4 Press

MOVEO

to check the

number of hours the degasser

should be active during main-

tenance degassing, "Toperat".

2. Kontroll och ändring av driftinställningar

MOVEOMOVEOMOVEO

Start?

T Pint 1,2

0

T Pint 1,2

0

MOVEOMOVEO

MOVEO

PROGV 2.16

hh-mm-ss

MOVEOMOVEO

MOVEO

Progv 2.16

yy-mm-dd

Progv 2.16

yy-mm-dd

Settings

To change settings, press

simultaneously

MOVEO

+

MOVEO

(up arrow

and down arrow), to get to the

change mode ("Settings" is

displayed on the display).

Simultaneously press

MOVEO

+

MOVEO

once more to change values

(settings start flashing).

Confirm and save the setting with

MOVEO

. For further instructions, see page 6.

MOVEO

Progv 2.16

Tmanoperat 30d

2.1 Press

MOVEO

to check date

settings "yy-mm-dd".

MOVEOMOVEO

2.6 Press

MOVEO

to check how long

the TTM NoXygen will run in fast

degassing mode "Days left".

2.5 Press

MOVEO

to select how long

the TTM NoXygen will run in fast

degassing mode "Tmanoperat".

3. Spara inställningar

Progv 2.16

Tstart 13:00

Progv 2.16

Topreat 1

Progv 2.16

Tmanoperat 30d

Progv 2.16

Days left 30

Progv 2.16

yy-mm-dd

TTM NoXygen® C625

Installation, operating and maintenance instructions

5 (9)

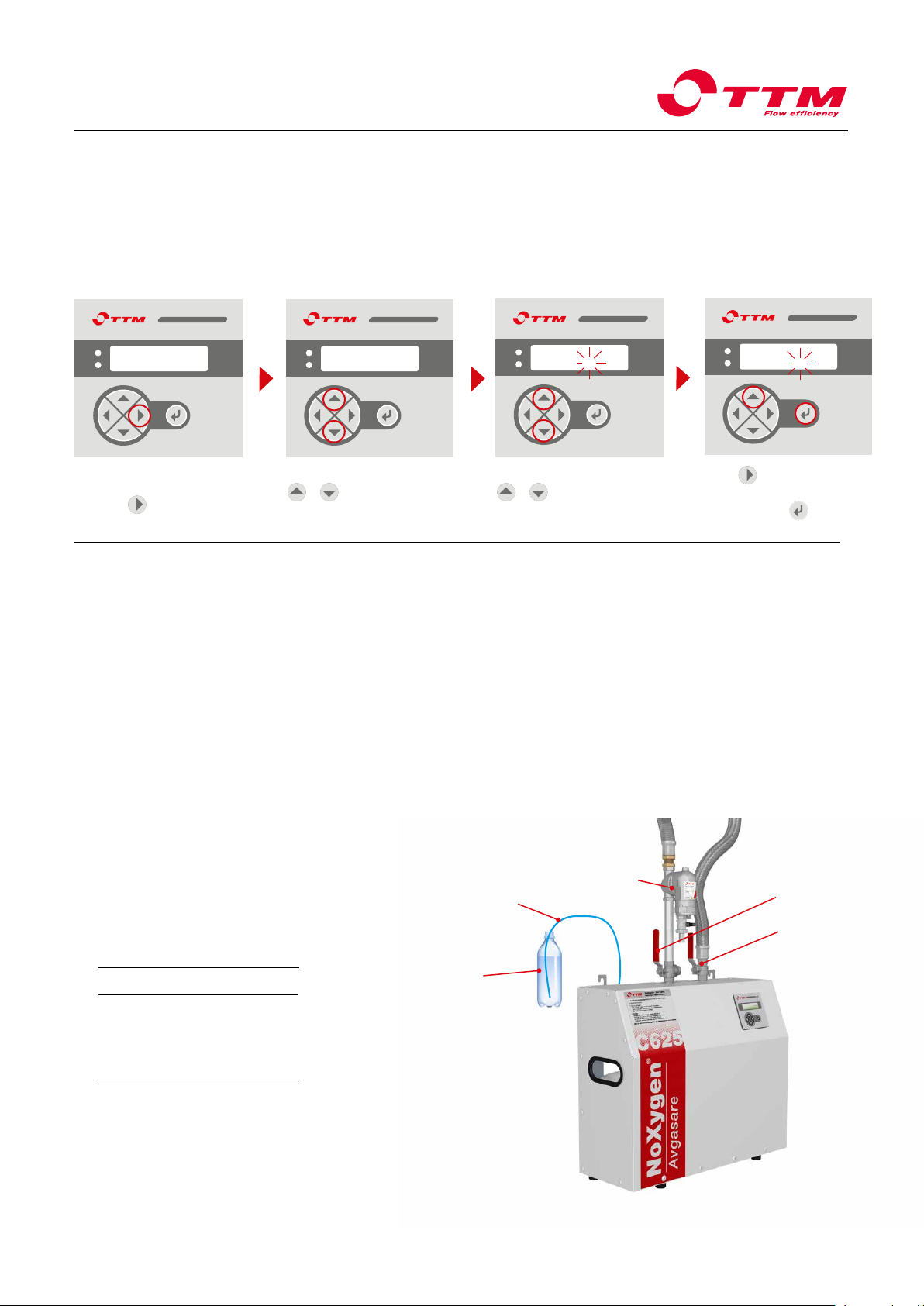

1. Menu for setting of nominal value:

2. Search value to be changed:

3. Menu for changing of nominal value:

4. Set the new nominal value:

5. Lock nominal value:

Up or down

2X to get to the

main menu

Up/down

simultaneously

Up/down

simultaneously

2022-09

6 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

Display

MOVEO

TTM NoXygen®

PROGRV 2.16

Use of display buttons

The ENTER button is used in order to:

- start and stop TTM NoXygen®("Start?" or "Stop?"

is shown on the display).

- confirm the set nominal value (setting of the nominal value,

see under the arrows below).

- go back to starting page on the display. If "Start?" or

"Stop?" can be seen on the display when returning to

the menu, press on an arrow button.

ARROWS

- the up and down arrows are pushed simultaneously in

order to get to the menu for setting the nominal value

(Settings on the display).

- Press the right or left arrow until the value to be modified

is shown on the display.

- Press the up and down arrows simultaneously again and

adjust the nominal values with the up or down arrow

(the value to modify blinks on the display).

- Confirm with ENTER.

Factory Reset:

• Unplug the unit. When in a non-powered state, press

the left and down arrows simultaneously as you

reconnect the plug.

• Hold until “OFF NOW” is shown on the display.

• Release the arrows and unplug the unit again.

• Reconnect NoXygen with the contact.

• NoXygen is now factory reset.

Operating modes

Fast degassing/Intensive degassing

For new installations and system fluid replacement, fast

degassing is recommended. Fast degassing means that the

TTM NoXygen®runs continuously between 00:00 on Monday

and 23:59 on Friday.

The preset value is 30 days of fast degassing, which in most

cases is sufficient to degass the system. In large systems or in

systems with many air pockets, longer time may be needed to

remove all air. It is possible to increase the number of days in

fast degassing mode up to 90 days.

Explanation of display messages:

Pint Displays the current pressure inside the vacuum

chamber of the NoXygen®.

Date Setting the date "yy-mm-dd".

Clock Setting of the clock "hh-mm-ss".

Tstart The time when TTM NoXygen®shall start in

timer operation.

Toperat How many hours the TTM NoXygen®shall run in

maintenance degassing per day.

Tmanoperat How many days TTM NoXygen®should be

degassed per month.

Days left How many days of fast degassing mode

remains before the TTM NoXygen®enters the

maintenance degassing.

Maintenance degassing

When the system is degassed, there is very little air left in the

system and it only costs money to keep the degasser active

around the clock and increases wear on the unit.

There is always some air leakage into the system that needs

to be taken care of. During maintenance degassing, the TTM

NoXygen®only runs for a few hours per day, which is sufficient

to take care of the system air leakage. The number of hours

per day needed to maintain low gas levels is shown in the table

below.

Recommended operating time per day

System volume Operating time

5 000 litres 1 hour

10 000 litres 2 hours

15 000 litres 3 hours

20 000 litres 4 hours

25 000 litres 5 hours

Red LED indicates

alarm.

Green LED indicates

that the unit is in

operation.

Enter

Arrows right/left,

up/down.

TTM NoXygen® C625

Installation, operating and maintenance instructions

6 (9)

2022-09

7 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

261

Ø75

Ø140

410

DN15 (1/2”)

DN15 (1/2”)

DN15 (1/2”)

IN

Avtappning

UT

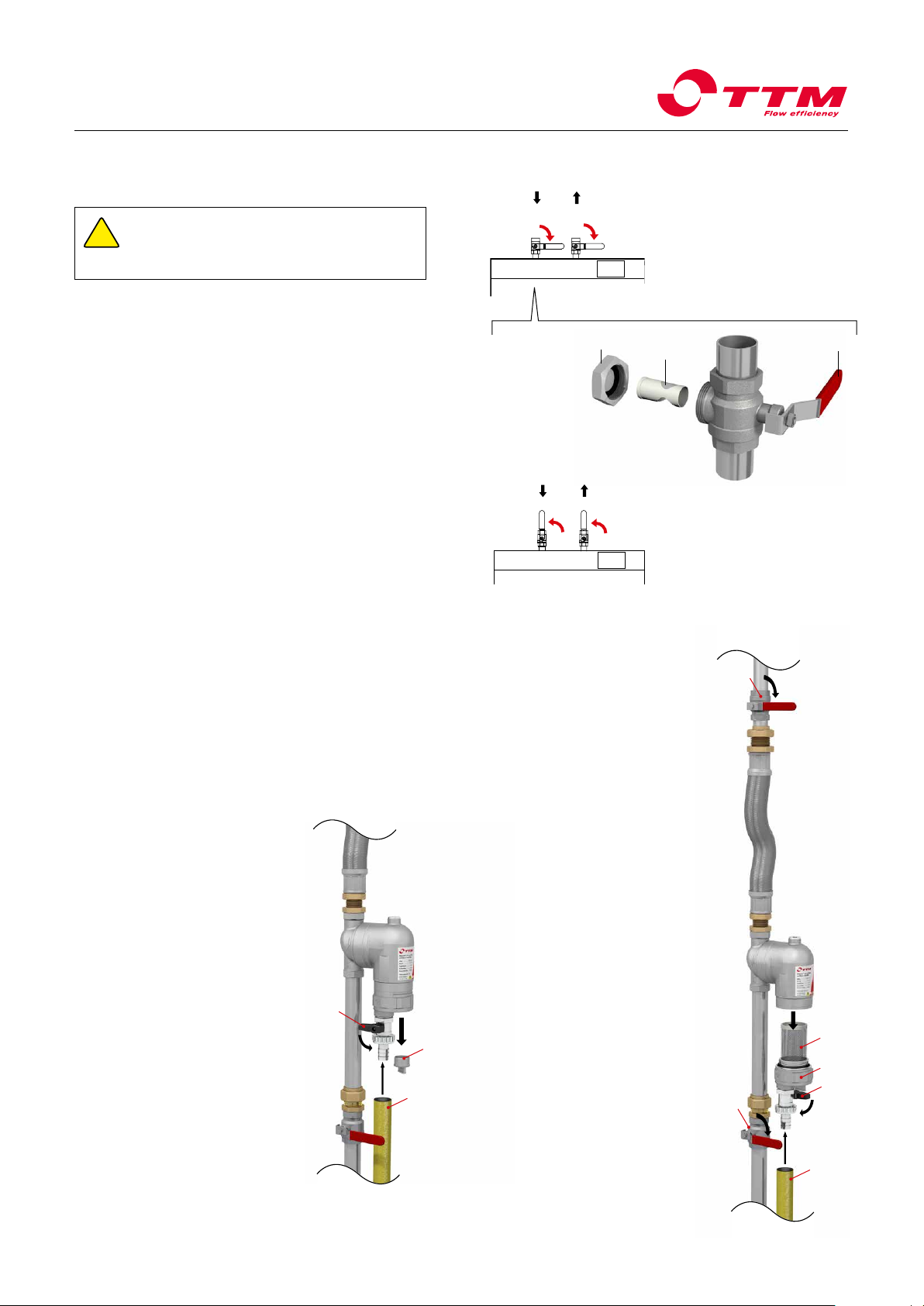

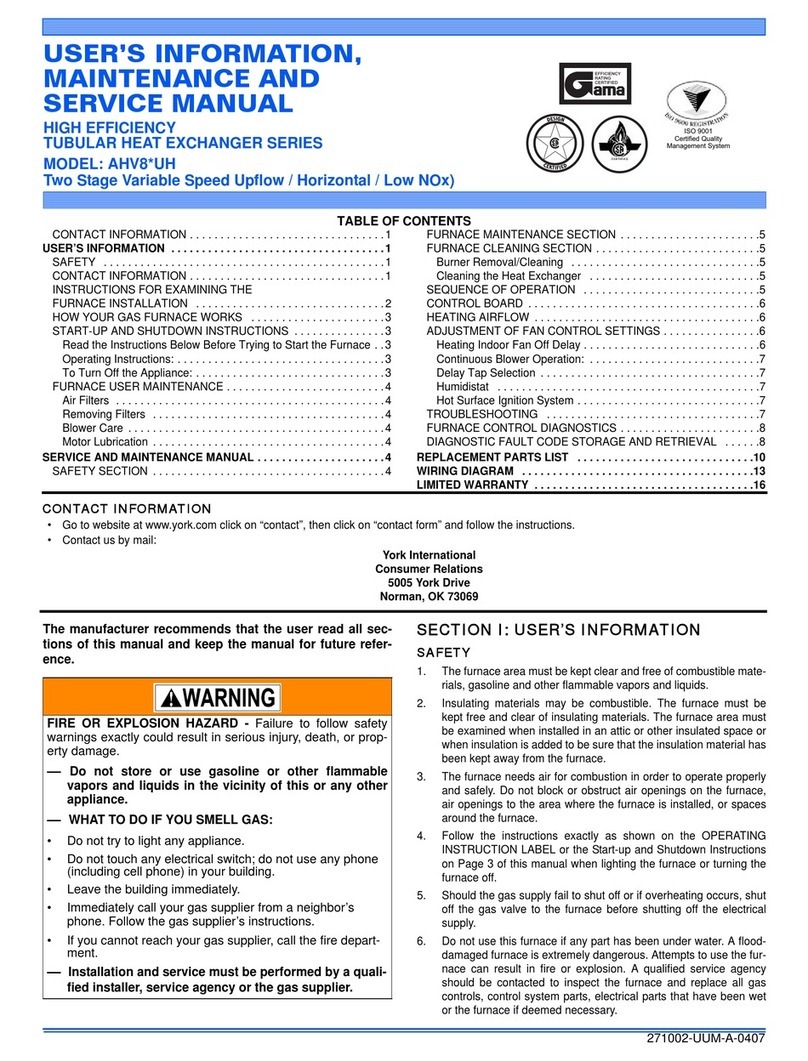

When the gas level in a system fluid is lowered, magnetite and other sediments are often

released from the inner walls of the system. These cause wear and tear on pumps and pipe

walls, among other things, and can also cause clogging of the system. TTM MAG 76 and

TTM MAG 54 effectively remove magnetite and other particles from the system fluid, which

means:

• Fewer operating interruptions. Magnetite clogs valves and other

devices and can also make wet pumps to stick together when they are shut off.

• Longer system lifetime. Magnetite and other particles have a grinding effect that

wears away at the system. The magnetite is magnetic and is attracted to the magnetic

field in pumps, where it wears away at axle seals, for example, which often results in

leakage.

• Protects the degasser. I system med hög förekomst av partiklar förhindrar TTM MAG

54/76 att avgasningsprocessen försämras på grund av igensättning av avgasaren.

The recommendation is to install TTM MAG 76 or TTM MAG 54 along with TTM NoXygen®.

It is especially important to install Mag 76 when it is known that magnetite or other particles

in the system fluid.

Installation

When installed in combination with the TTM NoXygen®degasser, the TTM MAG 54/76 is

connected to the system (½" female pipe thread) and then mounted directly on the shut-off

valve on the inlet of the TTM NoXygen®. When connecting to the TTM NoXygen®, first fit the

supplied clamping ring coupling, then connect the flat end of the TTM MAG 54/76 to the

clamping ring coupling.

TTM Offset is a Equalisation vessel used together with the TTM

NoXygen®in heating/cooling and recycling systems that are sensitive to

pressure variations e.g. pump expansion systems.

TTM Offset counters the pump expansion system turning on and

creating noise in the property’s system. It can also contribute to longer

durability in pump expansion systems, as the shutdowns do not occur

as often.

The TTM Offset is equipped with a control valve that is used as a

shut-off or drain valve when checking and adjusting the pressure

in the leveling vessel.

Installation

1. Close the shut-off valve to the system.

2. Remove the protective cover on the drain valve.

3. Open the drain valve (the spindle located on the side) and let the

water drain out.

4. Remove the black protective cover and take off the valve cap to

air valve.

5. Adjust the rubber lock pre-pressure so that this corresponds to

70-80% of the system pressure by releasing or replenishing air

through the air nipple.

6. Close the drain valve and reinstall the valve bonnet and

protective cover.

7. Reassemble the protective cover to the drain valve.

8. Open the shut-off valve to the system.

TTM MAG 54 och TTM MAG 76

TTM Offset 510 Art.no: 506430

TTM NoXygen®

Degasser

TTM MAG 54

Magnetite filter

Main pump

TTM Flexible

hose

TTM Offset

Equalisation

vessel

Return flow

TTM GeniX®

Pressurization unit

Art.no: 506188Art. no: 514428

100 57

190

255

Utv.

DN15 (1/2”)

UT

Inv.

DN15 (1/2”)

Ø15 mm

slang-

anslutning

TTM MAG 76

TTM NoXygen® C625

Installation, operating and maintenance instructions

7 (9)

Options Female

Male

OUT

Hose

connection

Drain

OUT

2022-09

8 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

Mounting the strainer basket

5. Replace the strainer basket Cin the inlet valve. Ensure that the filter

basket is entirely submerged and sits evenly with the valve body.

6. Make sure that the protective cap gasket is correctly located. Screw

the protective cap Bon the inlet valve with a spanner.

7. Turn the inlet and outlet valve handle A to the open position.

Disassembly of the inlet valve

3. Loosen the protective cap Bon the inlet valve with a spanner.

Let the gasket remain in the protective cover.

4. Remove the filter basket Cand clean it and the protective

cap with water.

Before starting cleaning of the inlet valve, ensure that:

1. The inlet and outlet valve handle A is in the closed position.

2. The TTM NoXygen® is turned off or the the main power is isolated. A

B

C

Inlopp Utlopp

Cleaning the filter basket of the inlet valve

Maintenance

Maintenance of TTM MAG 54

A

A

Inlopp Utlopp

!WARNING

If TTM NoXygen®is installed in a heating system then hot

pressurised system fluid may leak out when the protec-

tive cap B is unscrewed.

A

A

Inlet

Inlet

Outlet

Outlet

Cleaning the particle filter

1. Switch off both TTM NoXygen®and the main

power.

2. Close both inlet valves 1.

3. Install hose 6on the hose connector.

4. Empty the magnetite filter by opening the

drain valve 3. Leave the water to run until the

housing is empty of water.

5. Unscrew the bottom insert 4.

6. Unscrew the magnet insert 2 (see image 1).

7. Clean the particle filter 5and other parts

with lukewarm water.

8. Screw the magnet insert back in place 2.

9. Ensure the particle filter 5 and the O-ring

are correctly installed and screw the bottom

insert 4into the housing.

10. Close the drain valve 3.

11. Open both inlet valves 1.

12. Start TTM NoXygen®.

Cleaning the magnetite trap

1. Switch off both TTM NoXygen®and the

main power.

2. Close both inlet valves 1

(see image 2).

3. Install hose 6on the hose connector.

3. Unscrew the magnet insert 2.

4. Empty the particle trap by opening

the drain valve 3. Leave the water to run

until the housing is empty or until the fluid

is clear and without contaminants.

5. Close the drain valve 3and screw the

magnet insert back in place 2.

6. Open both inlet valves 1

(see image 2).

7. Start TTM NoXygen®.

(Image 1)

TTM MAG 54 should be inspected and cleaned regularly, at least

twice per year. The intervals depend on the quantity of particles and

magnesite in the system fluid. If you know the system fluid is very dirty,

the filter should be inspected and cleaned more often. One sign that

TTM MAG 54 requires cleaning is, for example, that TTM NoXygen®

runs for long intervals exceeding 3 minutes “pump start to pump start”

(see Operating and maintenance instructions for TTM NoXygen®).

(Image 2)

2

4

5

1

6

1

3

6

3

TTM NoXygen® C625

Installation, operating and maintenance instructions

8 (9)

2022-09

9 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

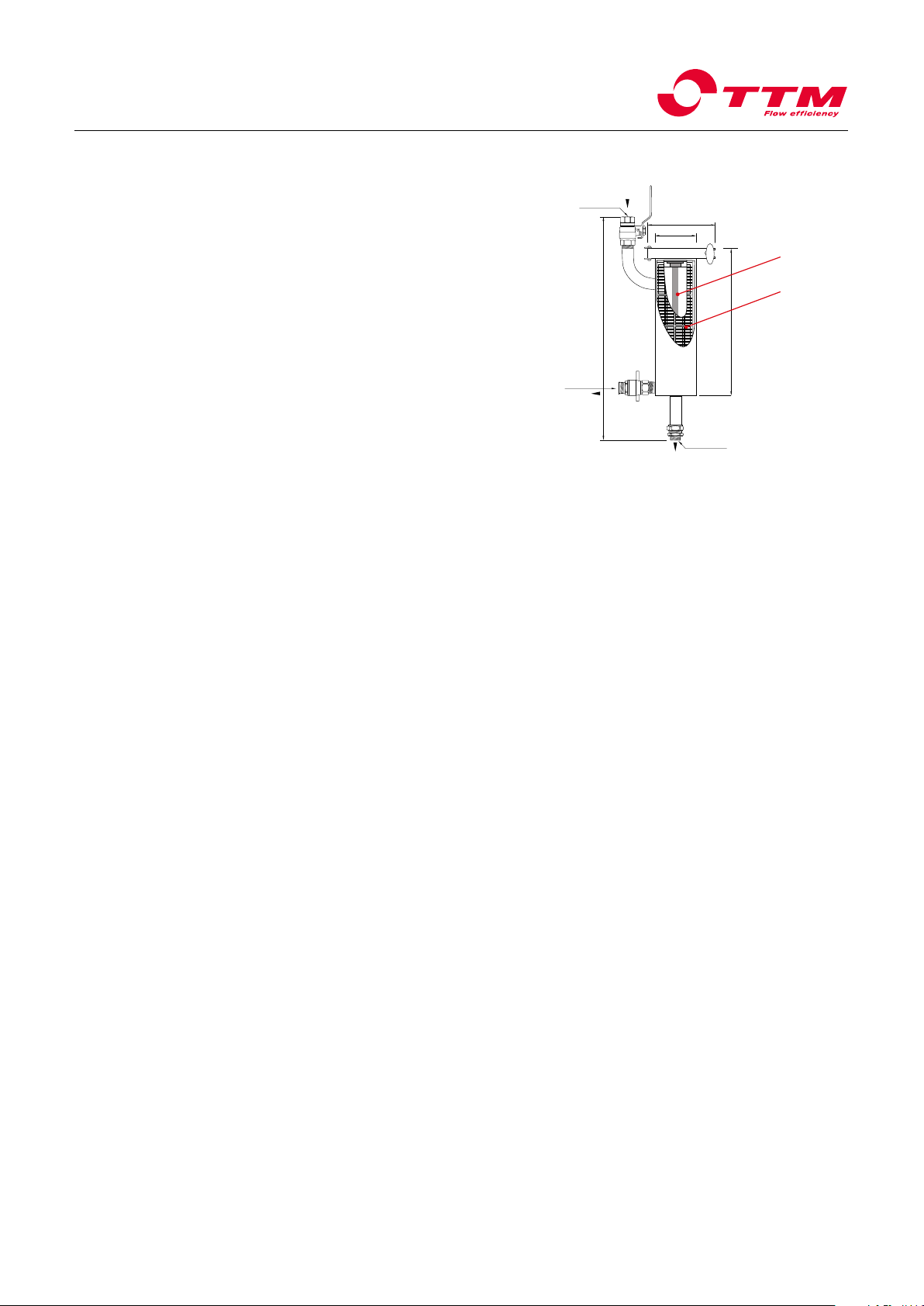

Maintenance of TTM MAG 76

TTM MAG 76 must be checked and cleaned regularly – at least twice per

year. The interval depends on the quantity of dirt and magnetite in the

system fluid. One sign that TTM MAG 76 requires cleaning is, for example,

that TTM NoXygen®runs for long intervals exceeding 3 minutes “pump

start to pump start”.

Note: Copper paste/silicone grease must be applied to the thread of the

clamp ring once per year or every time the filter is opened.

1. Switch off TTM NoXygen®.

2. Shut off the shut off valves on the inlet to

TTM MAG 76 and the inlet to TTM NoXygen®.

3. Place a container under the drain valve or connect a hose to it.

4. Open the drain valve.

5. Undo the clamp ring and lift out the magnetic rod and filter cartridge.

6. Wipe off the black magnetite that has collected on the magnetic rod.

7. Clean the filter cartridge or replace it if it is damaged.

8. Refit the filter cartridge and magnetic rod and fix into place with the

clamp ring. Grease the clamp ring threads with copper paste/silicone

grease before tightening.

2. Replaceable filter cartridge

Article no: u2001217

1. Magnetic rod

261

Ø75

Ø140

410

DN15 (1/2”)

DN15 (1/2”)

DN15 (1/2”)

IN

Avtappning

UT

1

2

Drainage

OUT

Maintenance

TTM NoXygen® C625

Installation, operating and maintenance instructions

9 (9)

2022-09

10 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

Before the function check, the pre-filters must be cleaned (see page 8) and the system pressure

needs to be at least 0.8 bar for the function check to be made.

MOVEO

TTM NoXygen®

Degasser

Blue

control hose

Transparent

bottle

filled with

water.

TTM MAG 54

Magnetite

separator Shut off valve

Shut off valve

1. Expansion vessel control

Check that the expansion tank is correctly adjusted with cor-

rect pre-pressure and that there is free expansion volume. The

TTM NoXygen®C625 requires at least 3 litres of free expansion

space. If it is suspected that the expansion space is too small,

install TTM Oset expansion vessel(art.no. 506430).

2. Pressure sensor control

Check that the "Pint" pressure on the TTM NoXygen®display

in idle mode is between minimum 0.8 bar and maximum 2.5

bar (the unit will not start if the pressure is below 0.8 bar, see

troubleshooting action 1.1). If the pressure on the display does

not match the system pressure, see troubleshooting action 7.

Also check that the "Pint" reaches at least -0.7 while the pump

is running. If not, see troubleshooting action 2.

3. Operating cycle time control

The time from pump start to pump start should not exceed the

recommendations in the table below. Long cycle times indicate

clogging of lters or ow restrictors.

See troubleshooting action 3.

4. Leakage control

Check that no uid is leaking from the blue control hose, when

the "Pint" pressure is equal to the system pressure of the plant,

in case of leakage, contact TTM. Check that no system uid

is leaking from any of the connections to the pump or vacuum

chamber.

5. Degassing capability control

When the TTM NoXygen® starts, close the shut-o valve on the

inlet and check that the "Pint" pressure reaches at least -0.7. If

not, see troubleshooting action 2. Allow the machine to stand

with the valves closed for at least 5 minutes and check that the

pressure does not change. If the pressure increases, there is a

leak, see troubleshooting action 5:3.

Preparation before function check - Test run settings

Functional control

Progv 2.16

Tmanoperat 0d

MOVEO

Progv 2.16

Tmanoperat 0d

Then press simultaneously

MOVEO

+

MOVEO

to activate

"Settings".

Then press simultaneously

MOVEO

+

MOVEO

to activate

editing mode.

Press

MOVEO

to set "Tmanope-

rat = 1d". Confirm by saving

the setting with

MOVEO

.

MOVEO

Progv 2.16

Tmanoperat 1d

MOVEO

Set the TTM NoXygen® to

continuous operation by

pressing

MOVEO

until

"Tmanoperat"appears on the display.

Settings

Set the TTM NoXygen®to continuous operation by adjusting "Tmanoperat" to 1day

TTM NoXygen® C625

Installation, operating and maintenance instructions

10 (9)

Pressure Time

1,0 bar 95 seconds

1,5 bar 90 seconds

2.0 bar 85 seconds

2,5 bar 80 seconds

2022-09

11 (12)

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar | Sweden | Tel. + 46 480-41 77 40 | [email protected] | www.ttmenergi.se

For latest updates visit www.ttmenergi.se

Solution

Raise the system pressure to at least 0.8 bar.

Check that there is voltage to the TTM NoXygen®.

Check that the TTM NoXygen®is in operating mode.

Press twice, then enter.

Check and change settings if necessary.

If necessary, change start time Tstart and/or operating

time "Toperat" or change time and date settings.

Ventilate the pump. NOTE It may take up to 10 minutes

for the pump to vent itself.

Check that the shut-off valves to the system are open.

Check that nothing else is blocking the flow paths.

Close the shut-off valve on the inlet and check if negative

pressure is created. If negative pressure is created,

check that there is a flow restrictor in the tank by loose-

ning the hose connection at the tank and removing the

insert. There should be three sleeves in the insert.

Clean any pre-filters and the strainer on the inlet

valve. If necessary, check the flow restrictors according

to 2.3.

Increase the set point between the solenoid valve and

the pump.

Install the Offset Equalizing vessel at the pressure

maintenance vessel, see instructions on page 2.

Install a new safety valve.

TTM NoXygen®requires 3 litres of free expansion space.

Install a TTM Offset Equalizing Vessel at the pressure

holding vessel, see instructions on page 2.

Check oxygen content. At oxygen levels below 1 mg/l, it

may take several cycles before air bubbles are released

through the vent.

Contact TTM.

Connect the control hose to a bottle of water if it is not

already connected and check that water is not being

sucked from the bottle into the TTM NoXygen®. If this is

the case, contact TTM.

Check that a vacuum is building up (at least -0.8 bar).

Check that the shut-off valves of the system are open.

Clean inlet valve filters and any pre-filters, see mainte-

nance instructions.

Contact TTM.

Cause

1:1 The system pressure is lower than 0.7 bar.

1:2 The control panel is without power.

1:3 Green LED is not lit.

1:4 Date or time is incorrectly set.

1:5 TTM NoXygen®is in maintenance mode and

start and run time settings put the unit in sleep

mode.

2:1 Air in the pump.

2:2 Flow at the outlet is obstructed.

2:3 Flow restrictor on inlet misadjusted.

3:1 See recommended operation cycle times in

the table under function check on page 10.

4:1 Set point between solenoid valve and pump is

set too narrow on the pressure retaining vessel.

4:2 There is no free expansion volume in the

system.

5:1 Fault in safety valve.

5:2 There is no free expansion volume in the

system.

6:1 The system is degassed or the gas content is

low.

6:2 The deaerator is clogged with dirt and

cannot open to release air.

6:3 The check valve on the air vent is leaking.

6:4 The degassing function is not working.

7:1 Restricted or no flow through inlet.

7:2 Pressure sensor is defective.

Issue

1. TTM NoXygen®does not

start.

2. A negative pressure is not

created in the TTM NoXygen®

(at least -0.7 bar).

3. The time between degassing

cycles is too long.

4. The systems's pressure ves-

sel works intermittently with the

TTM NoXygen®.

5. The system safety valve

releases system fluid.

6. No air bubbles comes out

of the control hose (NOTE: the

control hose needs to be placed

into a bottle of water).

7. System pressure does not

match the pressure on the

display.

Troubleshooting

TTM NoXygen® C625

Installation, operating and maintenance instructions

11 (9)

© All rights reserved TTM Energy Products AB, Kalmar

We reserve the right to make design changes and for any printing and factual errors. 2022-09

TTM Energiprodukter AB

Slöjdaregatan 1 | 393 66 Kalmar, Sweden | Tel. +46 480-41 77 40 | [email protected] | www.ttmenergi.se

För senaste uppdateringar se www.ttmenergi.se

Table of contents

Other TTM Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Maico

Maico EW-S Mounting and operating instructions

Huvema

Huvema XOTR 60 S instruction manual

Emerson

Emerson Leroy Somer DIGISTART D3 user guide

York

York AHV8 UH Series User's information, maintenance and service manual

Hofmann

Hofmann Monty 3300-24 Smart Operation manual

Nidec

Nidec Leroy-Somer TAL 044 Installation and Maintenance