So now we start with the first of three DIY manuals for the de- enerator.

We'll start with the panel board. It is relatively easy to build.

Required tools :

1:) Soldering iron, best adjustable, solder and a suction pump

:) a cutter

3:) multimeter

Here are some tips :

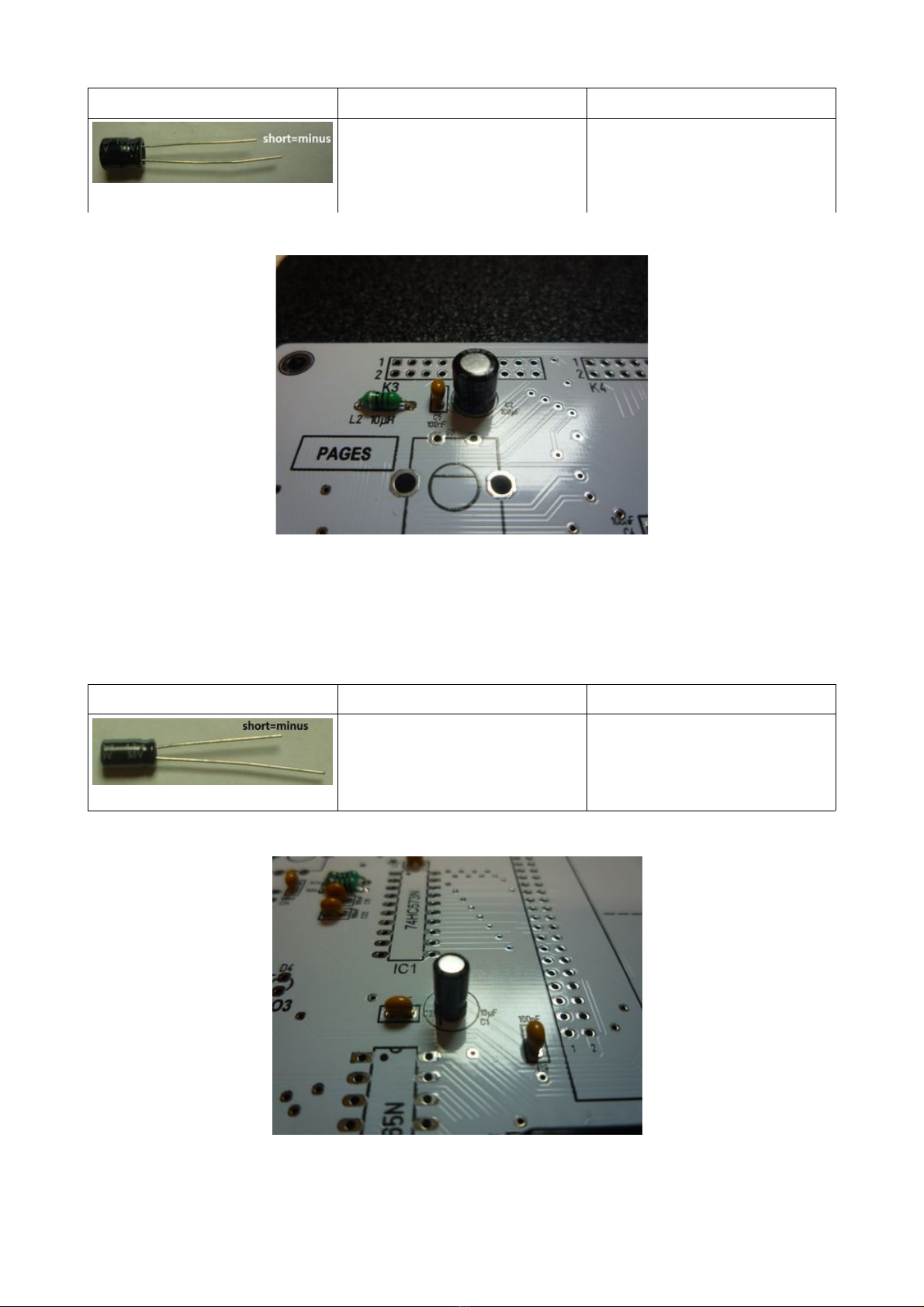

Guys, pick up the circuit board and take a look at it first.

The solder pads are so big that there should be no problems. Check that you have the

right tip on the soldering iron and also look at the regions on the board where the wires

come a little closer together. In these regions you should then solder more carefully.

Please remember - one part is quickly soldered in but it is very tricky to get it out !

If you don't know 100% exactly which part should be soldered in - leave it off and call or

mail us and ask. It's better to ask once than to search for errors for hours afterwards.

I can understand that you want the de-generator to be finished quickly, but if you work too

fast you make mistakes very quickly.

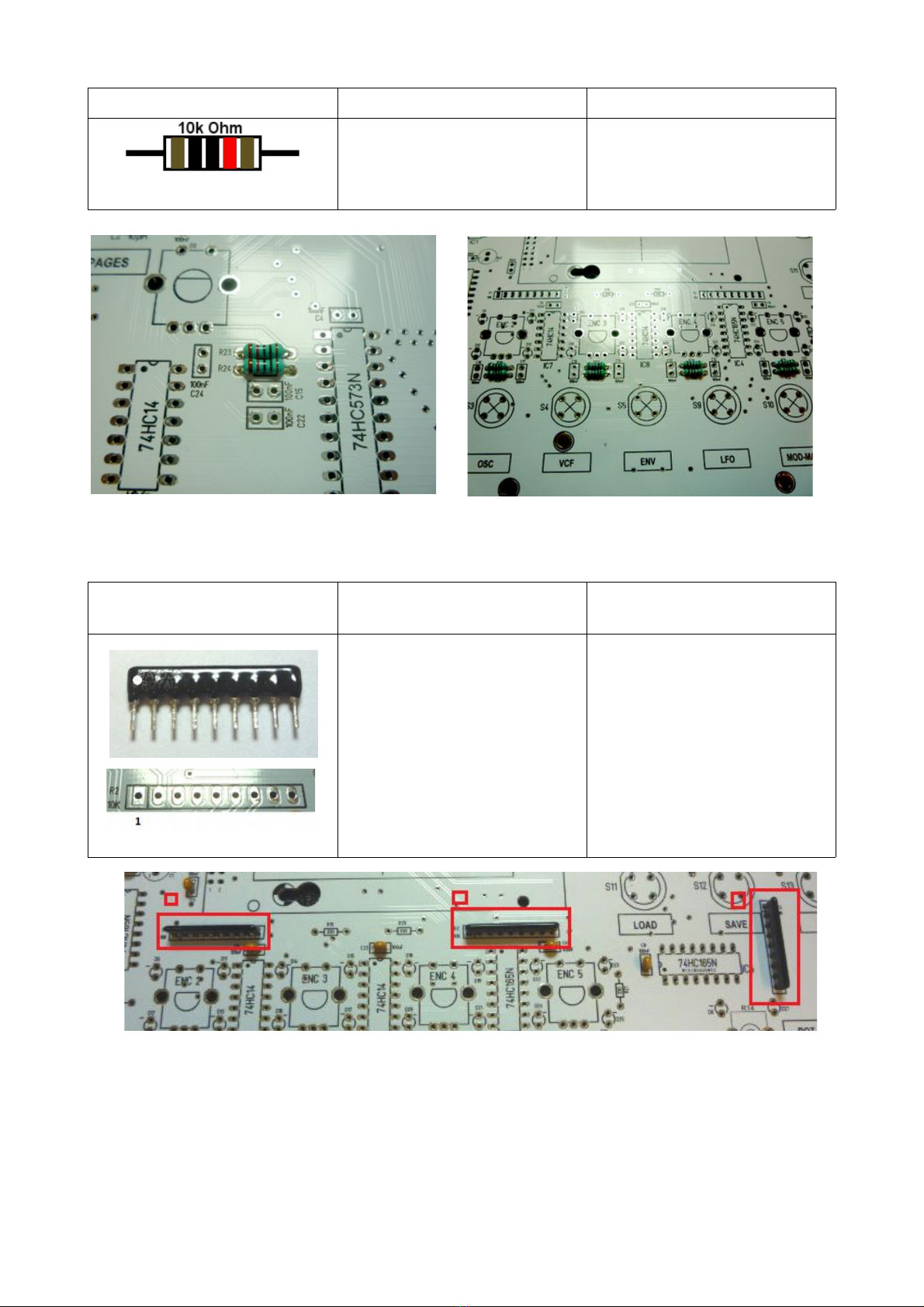

Please also check the connectors K3,K4,K14 and the MIC connector.

These are soldered in almost last, and at the bottom.

The enclosed microphone should also be soldered quickly so that it does not get too hot.

Of course you have to make sure that all potentiometers, encoders and switches are

soldered straight onto the board. If you have the Plexiglas case you can use the top side

as a template.

If the components are soldered on crooked, the housing will not fit afterwards and "it looks

sh***t (bad).

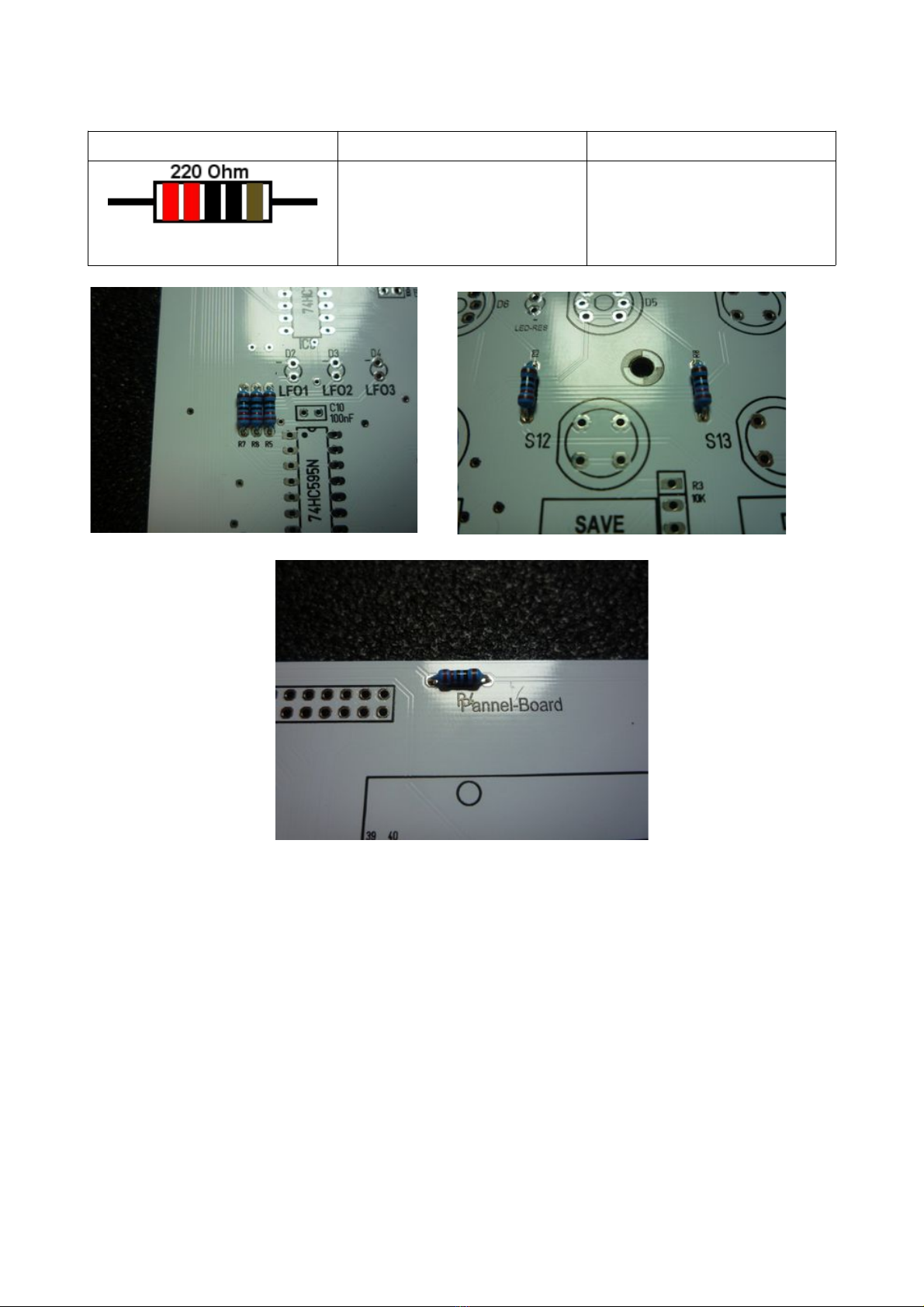

For people who want to install LEDs with other colors :

Different coloured LEDs can be used. The total current for 4 LEDs should not exceed 5..8

mA. This applies to the LEDs, the encoders ,3,4,5 and the freely programmable

potentiometers 1 and .

4 LEDs each are connected in parallel and have one series resistor. Thus the series

resistor is decisive for the total current, since the LED voltage is always the same, no

matter how many LED's are connected in parallel. The total current is divided into 4 partial

currents of the individual LEDs.

Here some information .

3