Table of contents

1

General............................................................................................................. 1-1

1.1

Intended applications ......................................................................................................... 1-1

1.2

Information on the product ................................................................................................. 1-1

1.2.1

Manufacturer's address .........................................................................................1-1

1.2.2

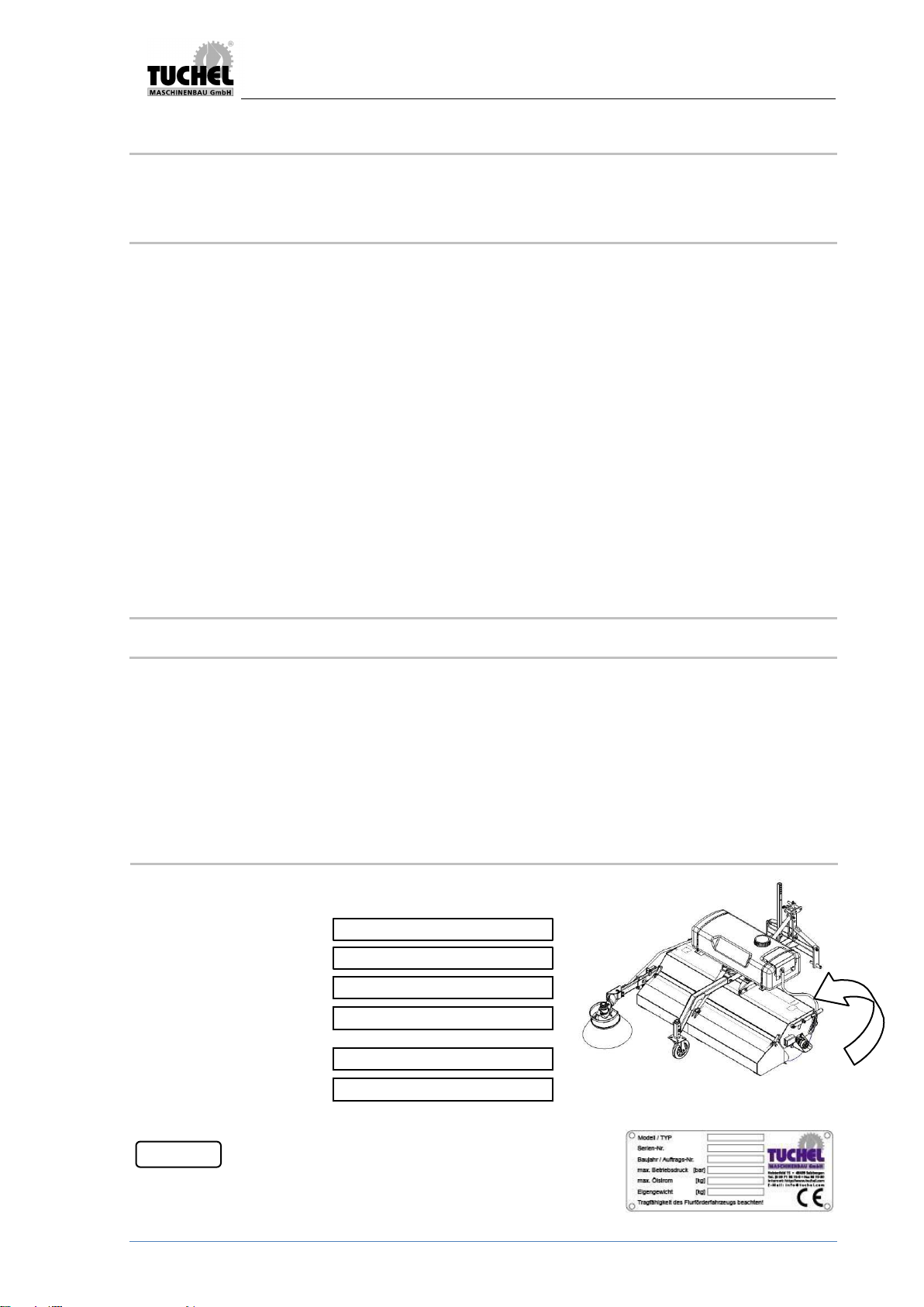

Descriptive label..................................................................................................... 1-1

1.2.3

Conformity declaration...........................................................................................1-2

1.2.4

Information for inquiries and orders.......................................................................1-3

1.2.5

Formal information for operating instructions ........................................................1-3

1.2.6

Details of operating pressures...............................................................................1-4

1.2.7

Connections...........................................................................................................1-4

1.2.8

Approved utilisation................................................................................................1-4

1.2.9

Technical data sheet..............................................................................................1-5

2

Safety information...........................................................................................2-7

2.1

Safety-conscious working practices...................................................................................2-7

2.2

Organisational measures ...................................................................................................2-8

2.2.1

Obligations of the owner........................................................................................2-8

2.2.2

Obligations of the operator .................................................................................... 2-8

2.2.3

Qualifications of the persons and activities carried out .........................................2-9

2.3

Product safety ..................................................................................................................2-10

2.3.1

Safety-oriented operation of the sweeper............................................................2-10

2.3.2

Safety and protection equipment.........................................................................2-10

2.3.3

Structural modifications........................................................................................2-10

2.3.4

Spare parts, wear parts and consumables..........................................................2-10

2.3.5

Warranty and liability............................................................................................2-11

2.4

Basic Safety Instructions..................................................................................................2-11

2.4.1

General safety and accident prevention instructions...........................................2-11

2.4.2

Hydraulic system..................................................................................................2-13

2.4.3

Sweeper...............................................................................................................2-14

2.4.4

Cleaning, servicing and maintenance..................................................................2-15

2.5

Actvity-related safety instructions and important information...........................................2-16

2.6

Warnings and instruction notes........................................................................................2-17

3

Product description...................................................................................... 3-19

3.1

Overview –Components..................................................................................................3-19

3.1.1

Description of product and accessories...............................................................3-20

3.2

Add-on parts.....................................................................................................................3-20

3.2.1

Main brush ...........................................................................................................3-21

3.2.2

Guide rollers.........................................................................................................3-21

3.2.3

Lateral adjustment ...............................................................................................3-21

3.2.4

3rd Support wheel.................................................................................................3-22

3.2.5

Road traffic equipment.........................................................................................3-22

3.2.6

Water-spray system:............................................................................................3-22

4

Coupling and uncoupling the sweeper ....................................................... 4-23

4.1

First installation onto carrier vehicle.................................................................................4-23

4.2

Installation of Sweeper PLUS 560 ...................................................................................4-24

4.2.1

Three-point linkage - "front mounting".................................................................4-25

4.2.2

Three-point linkage - "rear mounting"..................................................................4-26

4.2.3

A-frame ................................................................................................................4-27

4.2.4

Wheel loader attachment system ........................................................................4-28

4.2.5

Fork-arm attachment ...........................................................................................4-29

4.3

Operation..........................................................................................................................4-30

4.3.1

Transport..............................................................................................................4-30

4.3.2

Start-up ................................................................................................................4-31

4.3.3

Set / adjust side brush .........................................................................................4-33

4.3.4

Rotation speed adjustment..................................................................................4-34