Table of contents

3

Preface.............................................. 2

1 General ........................................ 4

1.1 Purpose........................................................ 4

1.2 ProductSpecications ................................. 4

1.2.1 General...................................................................4

1.2.2 Manufacturing Address...........................................4

1.2.3 Type Label..............................................................4

1.2.4 Labelling .................................................................5

1.2.5 Declaration of conformity........................................5

1.2.6 Specicationsforenquiriesandorders ..................5

1.2.7 Maximumloadspecications .................................5

1.2.8 Connections ...........................................................6

1.2.9 Energy consumption...............................................6

1.2.10 Intended usage.......................................................6

1.2.11 Technical data sheet ..............................................7

2 Safety........................................... 8

2.1 Labelling of notices in the operating manual 8

2.2 Qualicationandtrainingofpersonnel......... 8

2.3 Dangers in the case of nonobservance of the

safety notices ............................................... 8

2.4 Safety-oriented work............................ 9

2.5 Safety notes for the operator/user ............... 9

Start-up ...............................................................9

Transport / transport trips.....................................9

Operation .............................................................9

Hydraulic equipment ............................................10

Detachment..........................................................10

2.6 Safety notices for carrying out service,

inspection and installation work ................... 10

2.7 Unauthorised conversion and spare parts

manufacturing .............................................. 10

2.8 Modes of operation that are not permitted... 11

2.9 Notice signs on the machine........................11

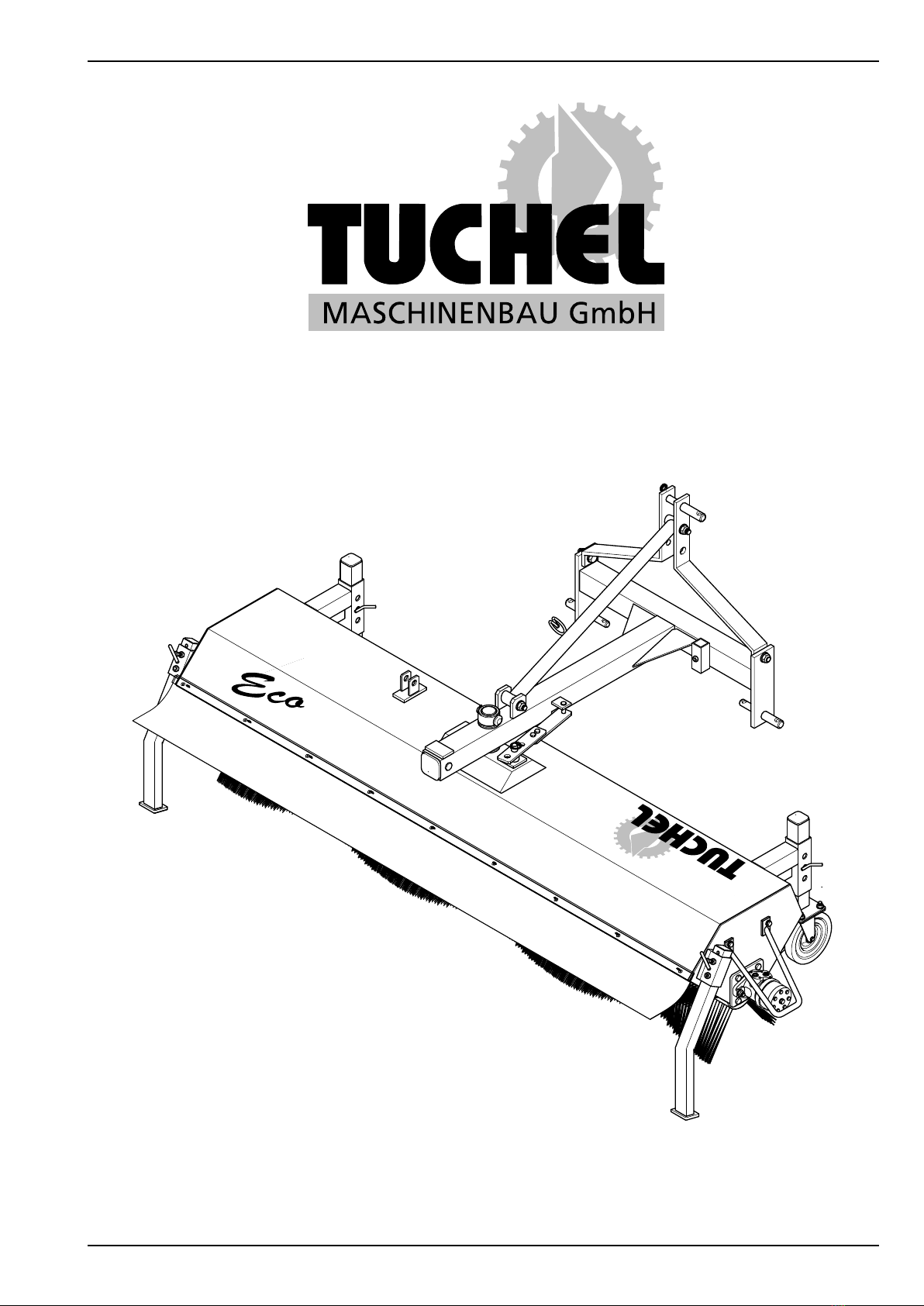

3 Eco Sweeping Machine.............. 12

3.1 Description of the product and accessories . 12

3.2 Storage ........................................................ 13

Take the ground pressure off the sweeping drum 13

Sweeping machine without collector vessel.........13

General storage ...................................................13

3.3 Attachment................................................... 14

Mounting before initial attachment .......................15

3.3.1 3-point linkage rear attachment..............................15

Conversion for front attachment...........................16

3.3.2 Yard loader - Attachment........................................17

3.3.4 Fork arm - Attachment............................................17

3.3.3 Front attachment - coupling triangle.......................18

3.4 Operation ..................................................... 18

3.4.1 Transport trips ........................................................19

3.4.2 Start-up...................................................................19

Sweeping machine - Position in front of the carrier

vehicle................................................................19

3.4.3 Rpm adjustment .....................................................19

3.4.4 Emptying the dirt collection vessel .........................20

Mechanic operation..............................................20

Hydraulic operation ..............................................20

3.4.5 Conversion to the open sweeping Eco sweeping

machine..................................................................20

3.4.6 Inclination for open sweeping.................................21

Mechanic operation..............................................21

Hydraulic operation ..............................................21

3.4.7 Overload protection ................................................22

3.4.8 Readjustmentofthesweepingprole ....................22

3.5 Detachment.................................................. 23

3.5.1 3-point linkage - Detachment .................................23

3.5.2 Yard loader - Detachment.......................................24

3.5.3 Coupling triangle - Detachment..............................24

3.5.4 Fork arm receptacle - Detachment.........................24

4 Service and maintenance .......... 25

4.1 General ........................................................ 25

4.2 Replacing sweeping drums..........................26

4.5 Replacement of the Vulkollan rail ................ 27

4.7 Malfunctions;causesandrectication ......... 27

4.8 Hydraulic circuit diagrams............................28

Notizen: ............................................................ 30

Table of contents