1. CORRECT APPLICATION

BrakeMate® is to be used only as described in this Operating Manual.

The BrakeMate® Hub/Rotor Trolley and the BrakeMate® Service Trolley are

engineered specifically for this task and are not to be used for general lifting or any

other purpose. BrakeMate® is designed to be used in a workshop environment on a firm,

level surface.

2. DESCRIPTION OF BRAKEMATE® SYSTEM

a. SYSTEM OVERVIEW

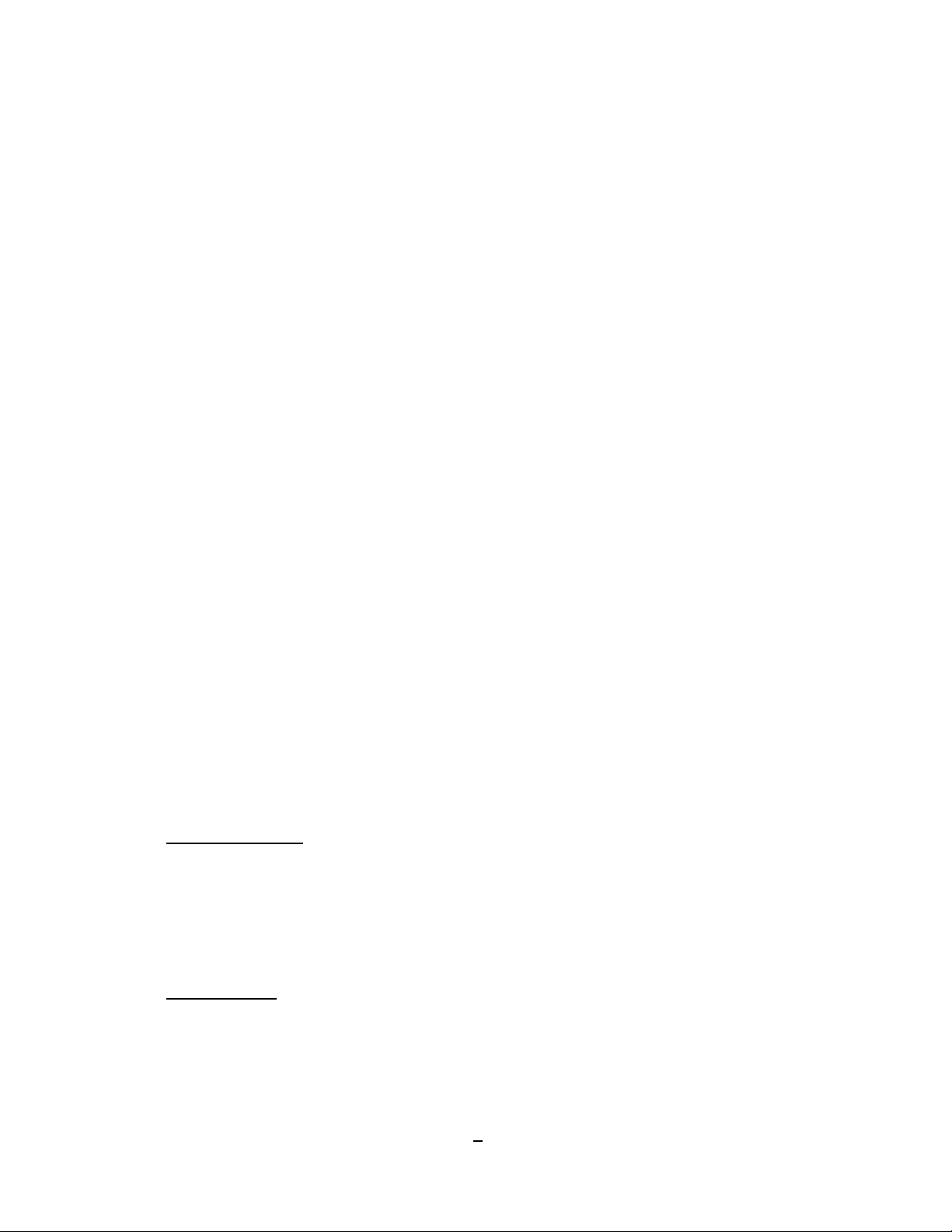

BrakeMate® is designed to eliminate the need for manual lifting of heavy brake

components when servicing disc brakes and bearings on heavy vehicles. The system

also utilises hydraulics to remove the hub/rotor assembly from the vehicle and

separate these components. BrakeMate® is comprised of two trolleys, the Hub/Rotor

trolley and the Service Trolley.

BrakeMate® is designed to assist with the following tasks.

- Removing and refitting calliper.

- Removing and refitting hub and rotor.

- Separation of hub and rotor.

- Changeover of rotors.

-Controlled realignment of hub to axle.

b. MAIN TECHNICAL DATA

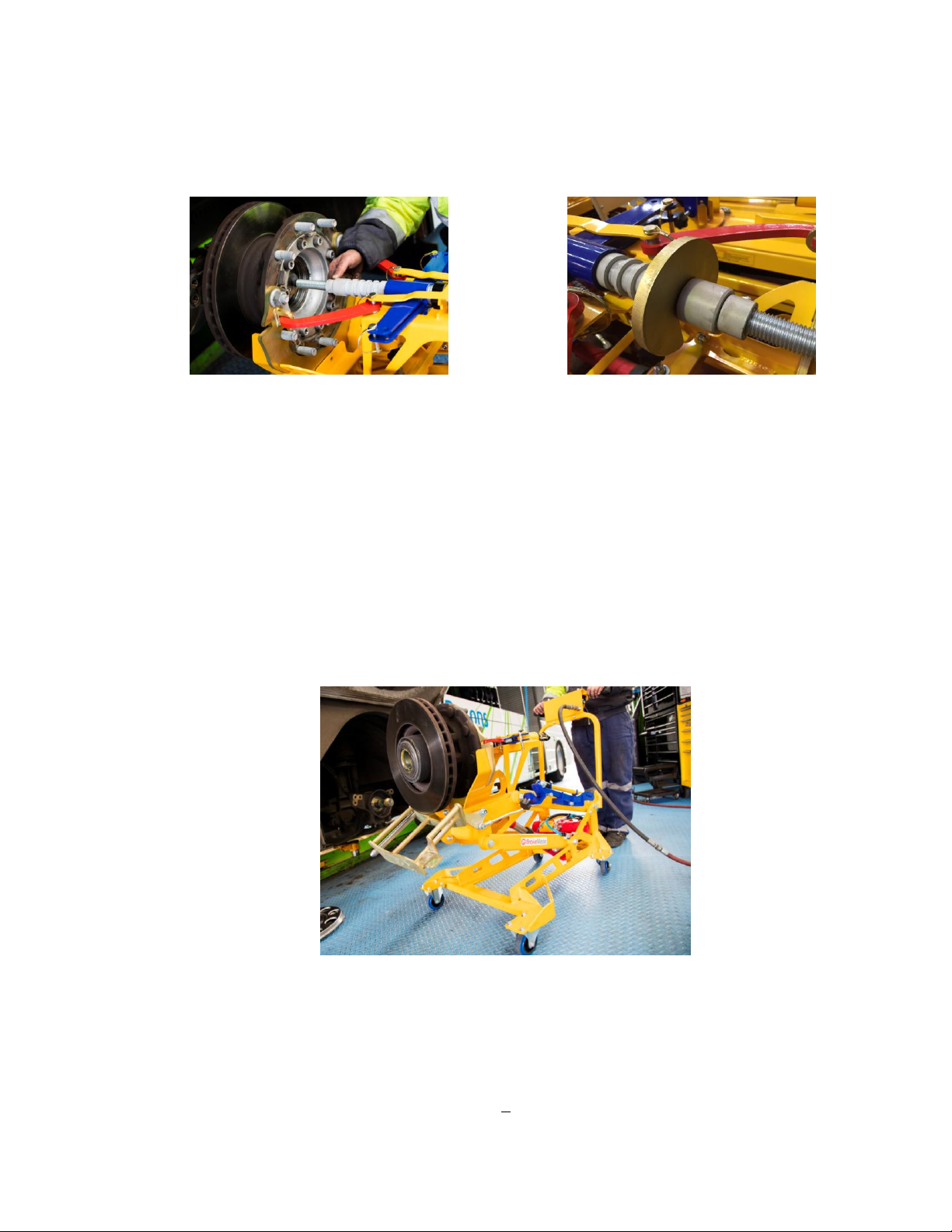

Hub/Rotor Trolley (Fig. 1)

The BrakeMate® Hub/Rotor Trolley is operated by an air over hydraulic system. The air

operated hydraulic pump is rated at 5000 PSI and controls the up/down motion of the

trolley via the main ram. A limit switch stops the unit at working height and also protects

the ram from over travel. An additional manually operated10 tonne hydraulic ram is

used to remove the hub from the axle and separate the hub/rotor assembly.

Service Trolley (Fig. 2)

The BrakeMate® Service Trolley contains a manual hydraulic ram controlled by a foot

pump and pressure release lever. The Service Trolley has a maximum lift height of

1300mm.

3