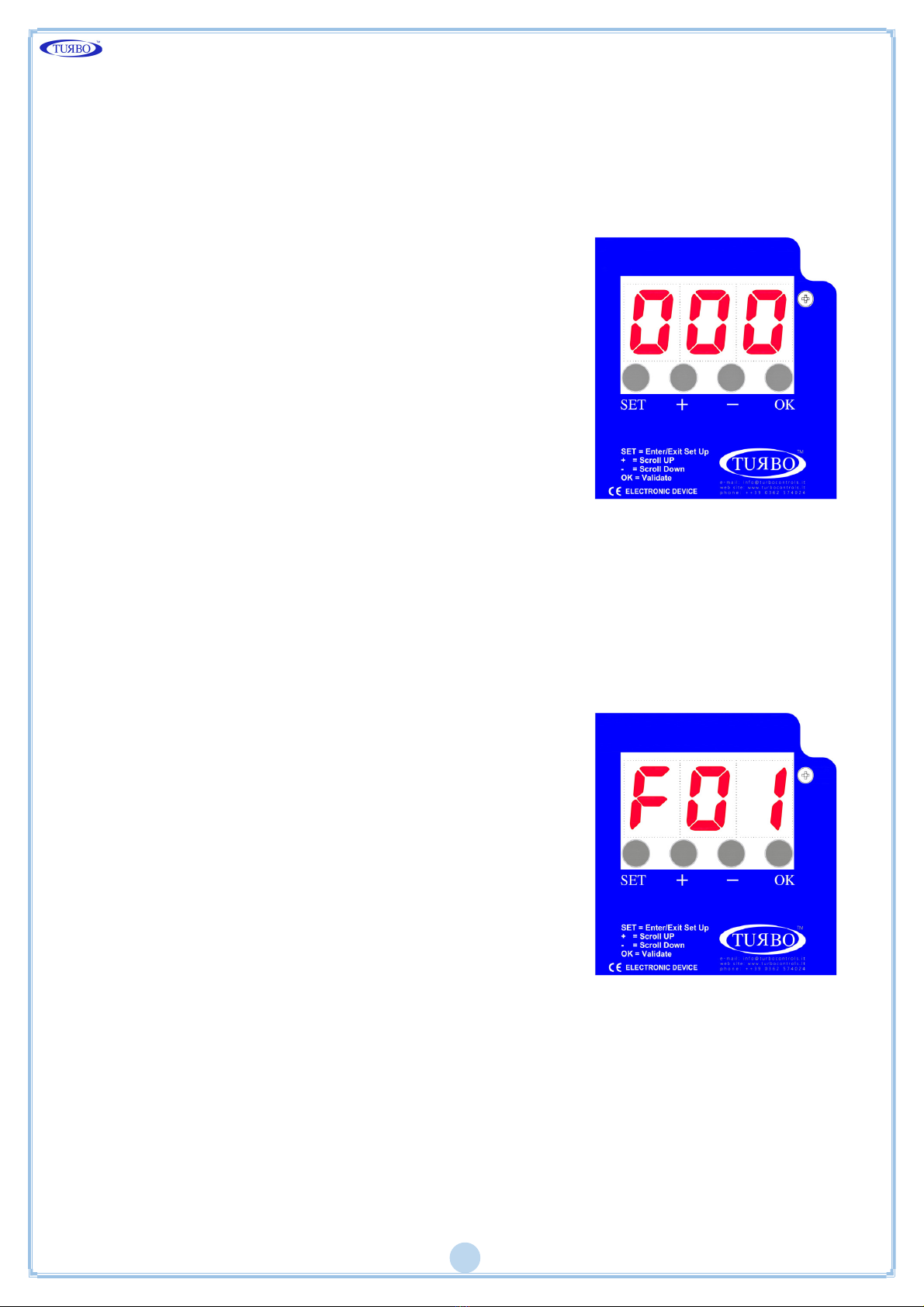

Description Of Operation

The installed SW version and the s mbol ---, meaning that coherence between

settings stored in E2Prom and the set jumpers is being checked, will appear on

the displa when the sequencer is powered up. A corresponding error code will

appear in case of discrepancies between settings (see Alarms Table). Onl editing

functions will be allowed on the unit. The operator ma switch off the unit and

configure the jumpers correctl .

S mbol 0_0 will appear on the displa if the test is entirel successful. The

following pages will then appear:

OFF if the enabling contact is open (14-15).

-0- if the enabling contact (14-15) is closed and the fan is off.

Operative mo e

The device works as a programmable c cle sequencer. The connected outputs will

be activated at the programmable frequencies. The firing and pausing times can

be set on the configuration menu.

Cleaning Function With Fan Off (PCC)

This function allows to carr out one or more cleaning c cles (the number of

c cles is defined b F13) when the fan is off. The on or off state of the fan ma

be determined b the state of the contacts 12-13 (contacts open = fan off) if

F11=0, or ma be determined automaticall (with F11=1) when the dP pressure

drops under the threshold defined in F12. The pulse time of the valves will alwa s

be that defined in F02, while the pause time in this case is defined in F14.

The displa alternatel shows the number of the valve activated and the word PCC.

Number Of Output Selection

The number of outputs (solenoid valves) on which the sequencer will run the

cleaning c cle can be selected. Cleaning will be carried out in order from the first

to the last solenoid valve. The valves can be adjusted b the F04 function.

Fuse

A fuse which can be reset in case of need is located near the power terminal

board. Use a dela ed fuse 5x20mm as shown in the table on next pages.

SD Memory Car

The Micro SD memor card slot is located on the bottom right of the control unit

under the pol carbonate lid.

The card is not supplied with the control unit. A card with a maximum of 32GB

can be used.

The card must be formatted FAT32, which is the format recognized b all devices

and operating s stems.

Before removing the memor card, press the OK button with the control unit on,

wait for the cd (card) indication and the alternating flashing of the horizontal

lines of the third figure ≡. The card can now be safel removed. The Micro SD

Card connector is push-pull.

Press upwards and extract the card to remove it.