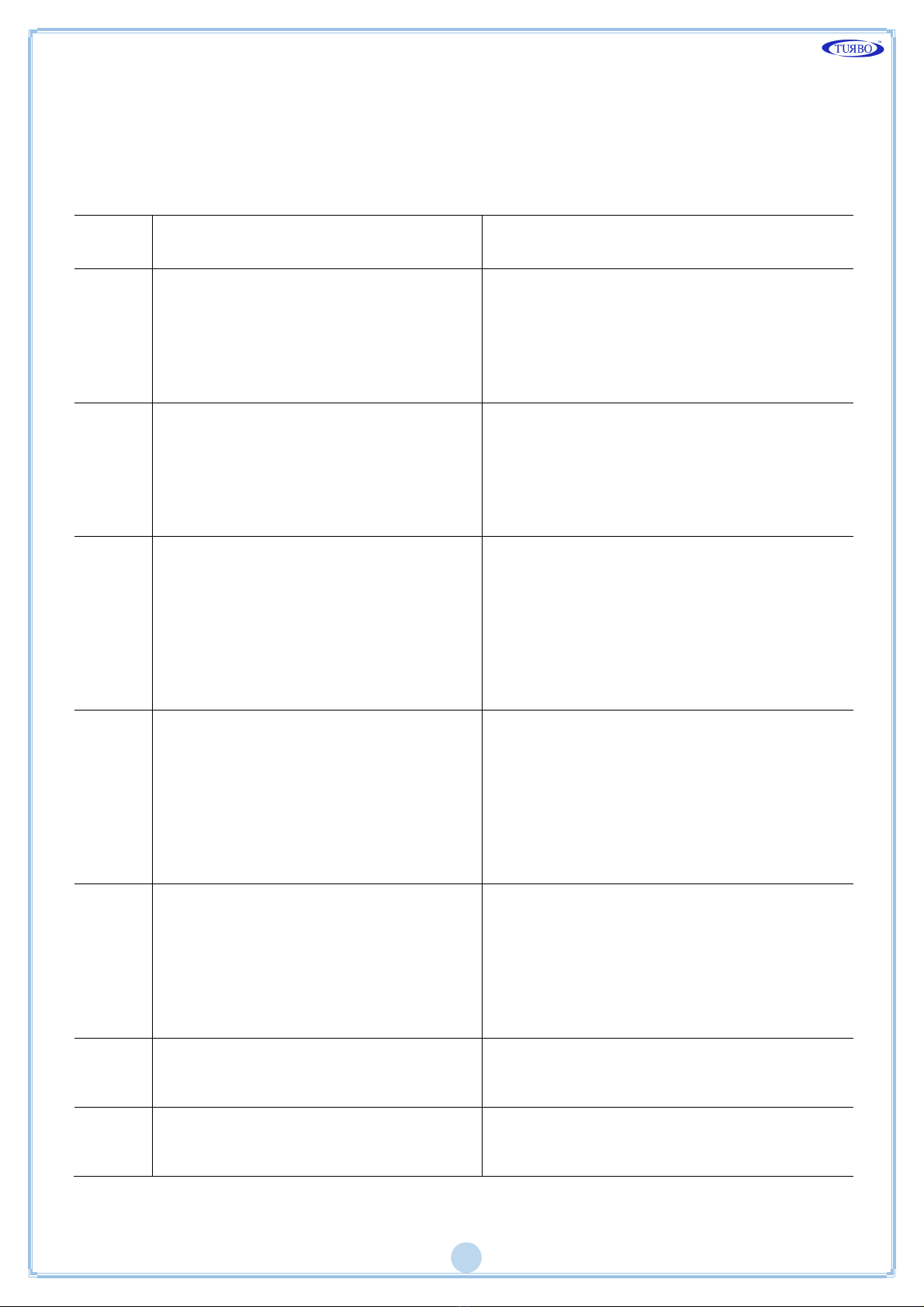

Alarms

The unit runs a number of checks during the start-up c cle and during normal

operation. The possible alarms and respective solutions are shown in the

following table.

A. No.

Description Action

E01 F05 set to 24Vdc – AC jumper

detected

- For 24Vdc, switch the device off and

move the AC/DC jumpers to DC. Jumper

see table next pages.

- For 24Vac, press OK, then press SET,

set the function F05 using “+” and “-”,

select A24 and press OK to confirm.

E02 F05 set to 24Vac – DC jumper

detected

- For 24Vac, switch the device off and

move the AC/DC jumpers to AC. Jumper

see table next pages.

- For 24Vdc, press OK, then press SET,

set the function F05 using “+” and “-”,

select d24 and press OK to confirm.

E03 F05 set to 24Vac or dc. Voltage out

of range detected

- To use 24V valves, switch the device

off and move the output voltage

selection jumper to 24V. Jumper see

table next pages.

-

If the jumper is in the correct position,

press OK, then SET, select the F05

function with “+” and “-”

(as jumper) and press OK.

E04 F05 set to 115V. Voltage out of

range detected

- To use 115V valves, switch the device

off and move the output voltage

selection jumper to 115V. Jumper see

table next pages.

- If

the jumper is in the correct position,

press OK, then SET, select the F05

function with “+” and “-”

(as jumper) and press OK.

E05 F05 set to 230V. Voltage out of

range detected

- To use 230V valves, switch the device

off and move the output voltage

selection jumper to 230V.

-

If the jumper is in the correct position,

press OK, then SET, select the F05

function with “+” and “-”, set a24, d24

or 115 (as jumper) and press OK.

E06

Solenoid valve current lower than

minimum threshold or disconnected

solenoid valve

Check correct connection of the solenoid

valve and respective data. The alarm is

self-reset.

E07 Solenoid valve current higher than

maximum threshold

Check correct connec

valve and respective data. The alarm is

self-reset.