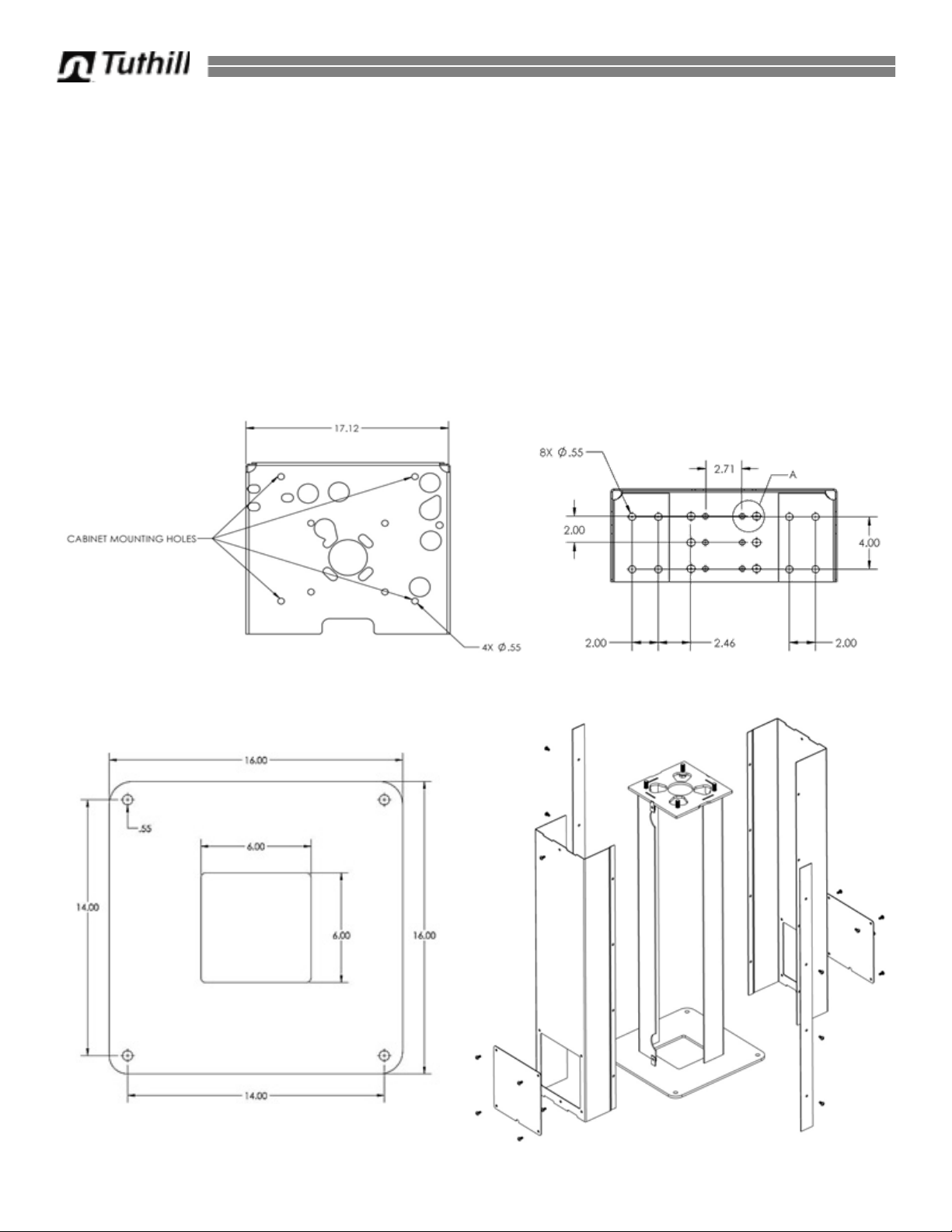

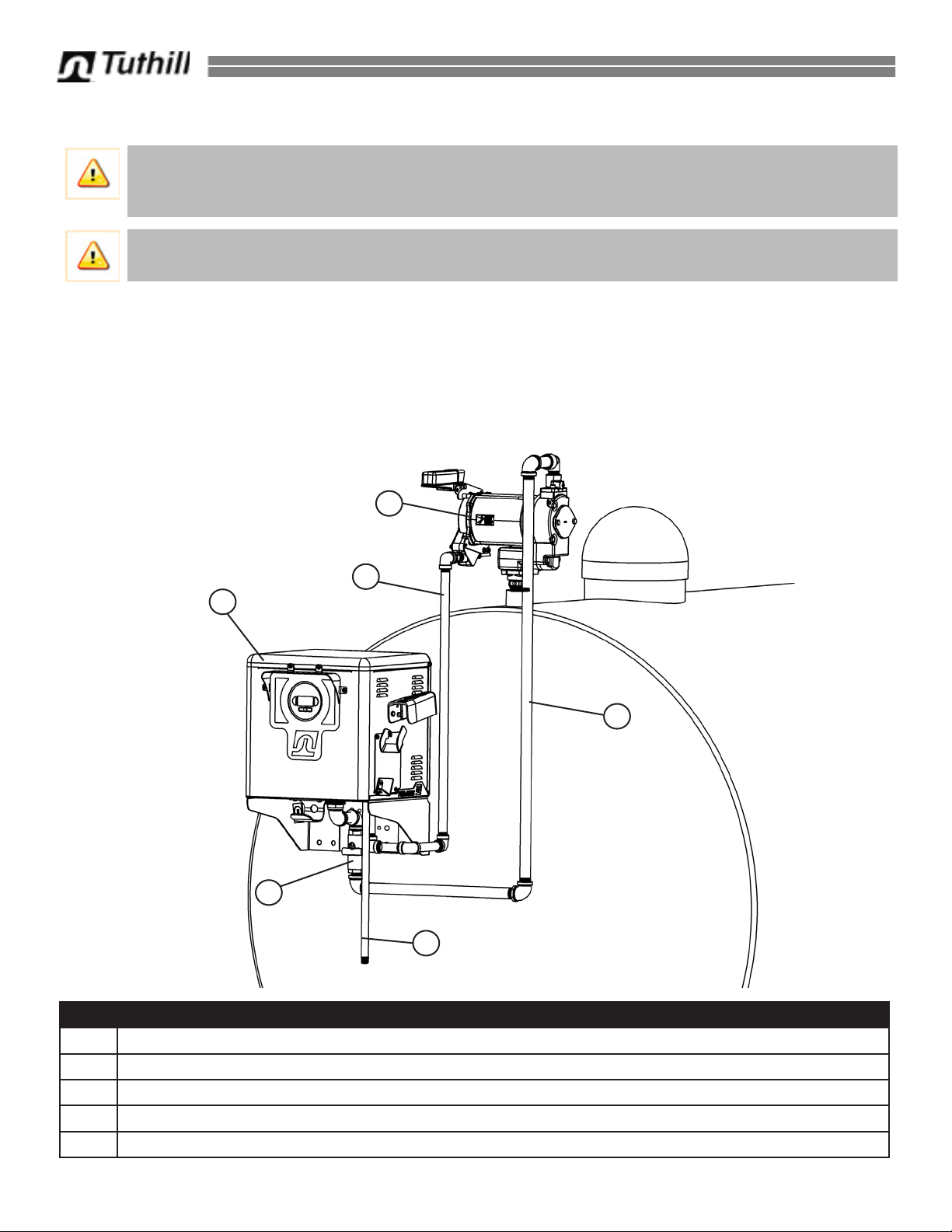

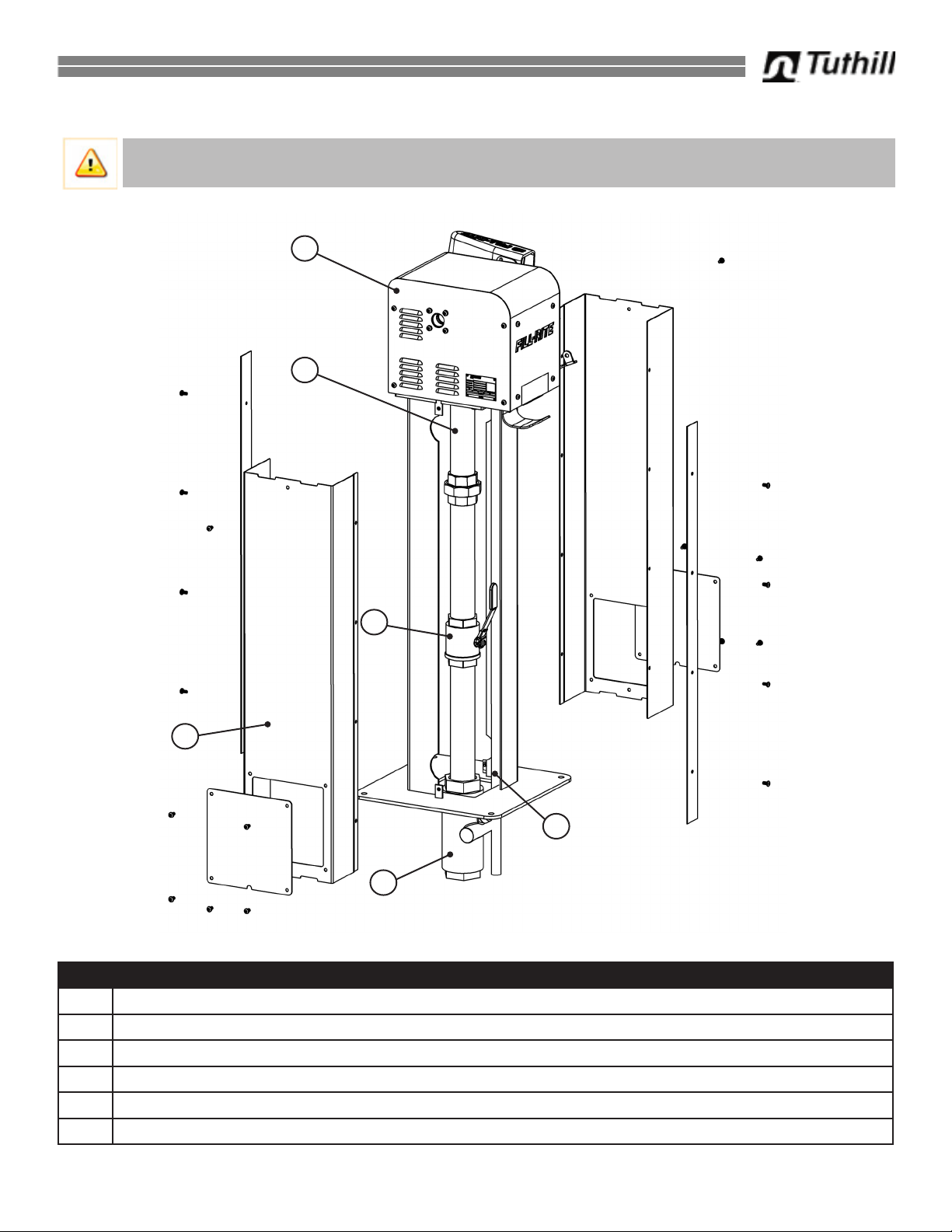

Mechanical Installation

1. Install the pump (if not included) securely to the top of the fuel tank

per the instructions included with the pump.

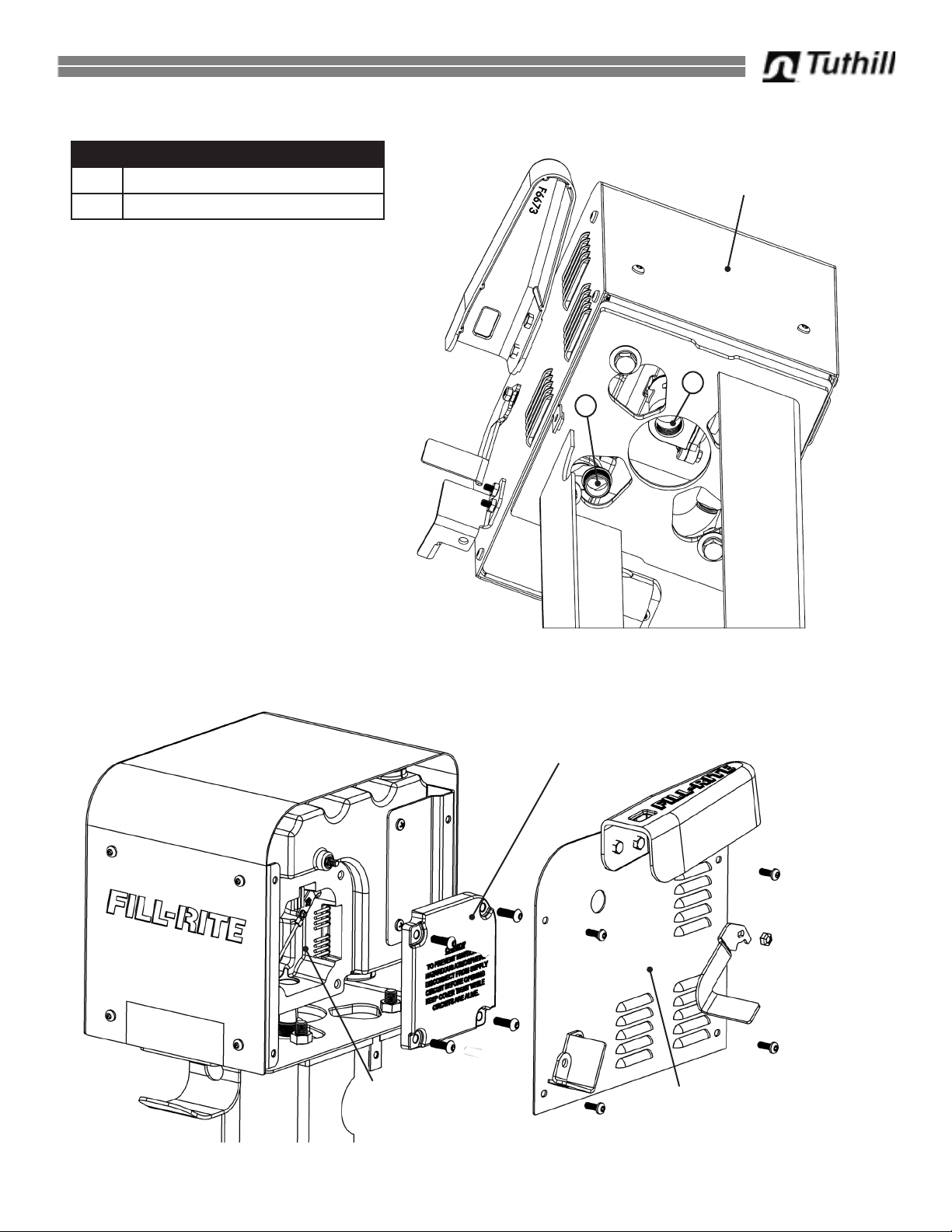

2. Install mounting plate or pedestal as applicable for your installation.

3. Place dispenser on mounting plate or pedestal; using the 4 – 1/2 x

13 screws, and grommet washers, attach the dispenser securely to

the mounting surface through the 4 holes located in bottom of the

dispenser cabinet base (gure 1).

4. Installations must include an Emergency Shut-Off Valve (not

supplied) to the dispenser inlet. Position valve so it can be rigidly

mounted and is not dependent on the dispenser for support.

5. Carefully measure and install pipe between the pump and

Emergency Shut Off Valve. The pipe is not intended to support

the pump or the dispenser in any manner.

NOTE: Dimensional drawings to aid in installation are located on page 4.

CAUTION! Threaded pipe joints and connections should be sealed with the appropriate

sealant or sealant tape to minimize the possibility of leaks.

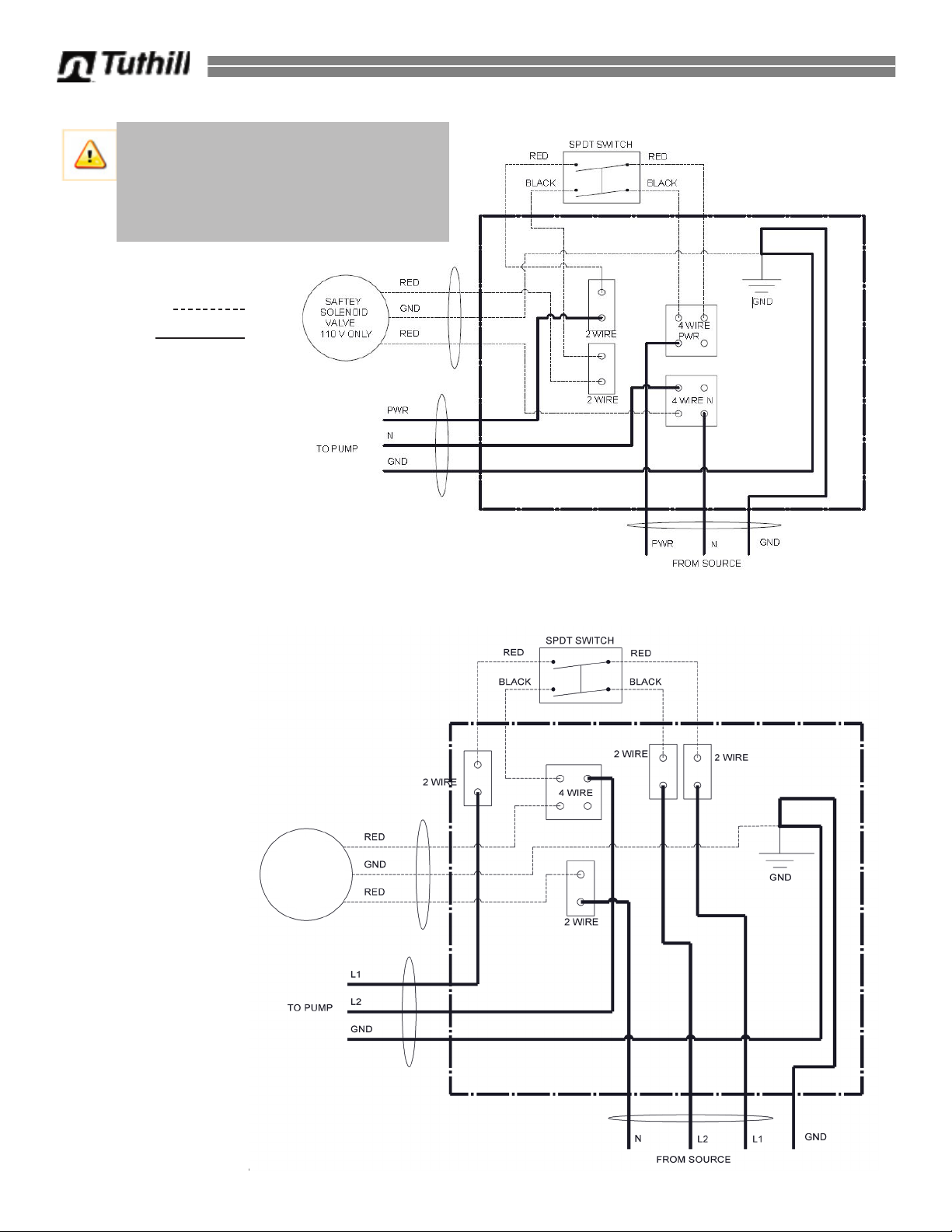

Electrical Installation

WARNING! Overall dispenser installation and electrical wiring should be performed ONLY

by a licensed electrician and service personnel in compliance with local, state, and national

electrical code NEC/ANSI/NFPA 70, NFPA30, NFPA 30A, and NFPA 395 as appropriate to

the intended use of the dispenser. Threaded rigid conduit, sealed ttings, and conductor seal

should be used. The pump must be properly grounded. Improper installation or use of this

dispenser can result in serious bodily injury, or death!

CAUTION! All electrical appliances should operate at the rated nameplate voltage. Power

should be supplied to this dispenser from a dedicated circuit breaker appropriately sized to

handle the pump being used with the dispenser. No other equipment should be powered

by this circuit. Wiring must be of sufcient size to carry the correct current for the pump.

Voltage drop will vary with distance to pump and size of wire; refer to the National Electrical

Code (NEC), or local codes, for voltage drop compensation to be sure you are using the

correct size wire for your application.

Refer to the section of this manual pertaining to your particular model for detailed wiring information.

All wiring connections must be made inside the explosion proof junction box built into every dispenser

cabinet. Use extreme caution when wiring in this junction box to maintain the integrity of the

explosion proof design. The 300 Series pump inside the FR302DPUU cabinet has a wiring junction

box on the pump for the pump wiring (see diagram page 12 and 13).

5

Figure 1

Cabinet Dispenser Electrical Rating

Model Voltage (VAC) Frequency (Hz) Current (A) Power (HP)

FR102PHU

FR902DPU

125 60 20 1

250 60 20 2

FR302DPU 115/230 60/50 9.8/4.9/11.4/5.7 3/4