4

CAUTION: Wear proper safety equipment when han-

dling hazardous fluids.

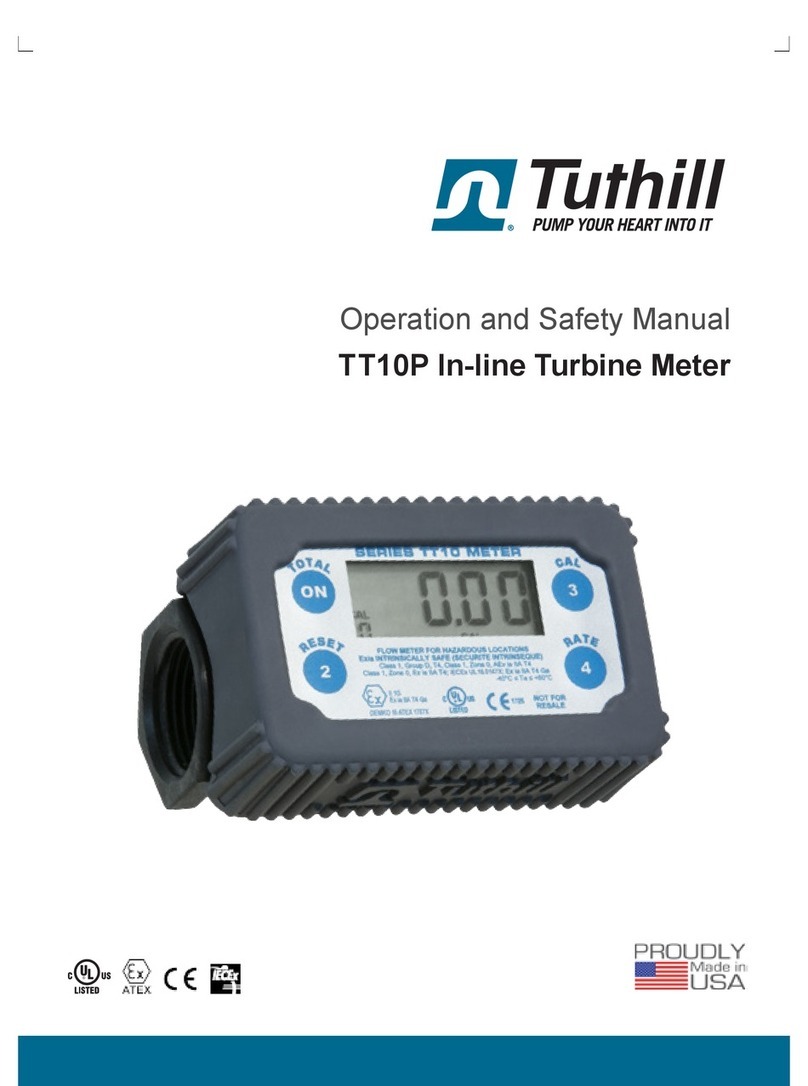

•Turns meter on when off.

•Displays accumulated total as long as it is

held on. If accumulated total is larger than

9999, the numbers will scroll across the

screen.

•When held for 1 second, it resets current total

to zero. Also resets to normal operating

mode when in CAL or FLSH mode.

•When held for 3 seconds, it allows changes

to the calibration factor displayed in the

bottom left corner. Repeated activation will

increment the number up to 19 and back to

zero. When desired number is displayed,

press button 2 to lock in the new number

and return to normal operation.

•When held for 3 seconds, FLSH is displayed.

Fluid dispensed will not be added to either

the accumulated total or current total. Press

button 2 to return to normal operation.

CAUTION: Meter will count air if you dispense air.

Before initial operation or when air has entered the system,

prime the meter by dispensing fluid until all trapped air has

been removed. Meter is now ready to operate

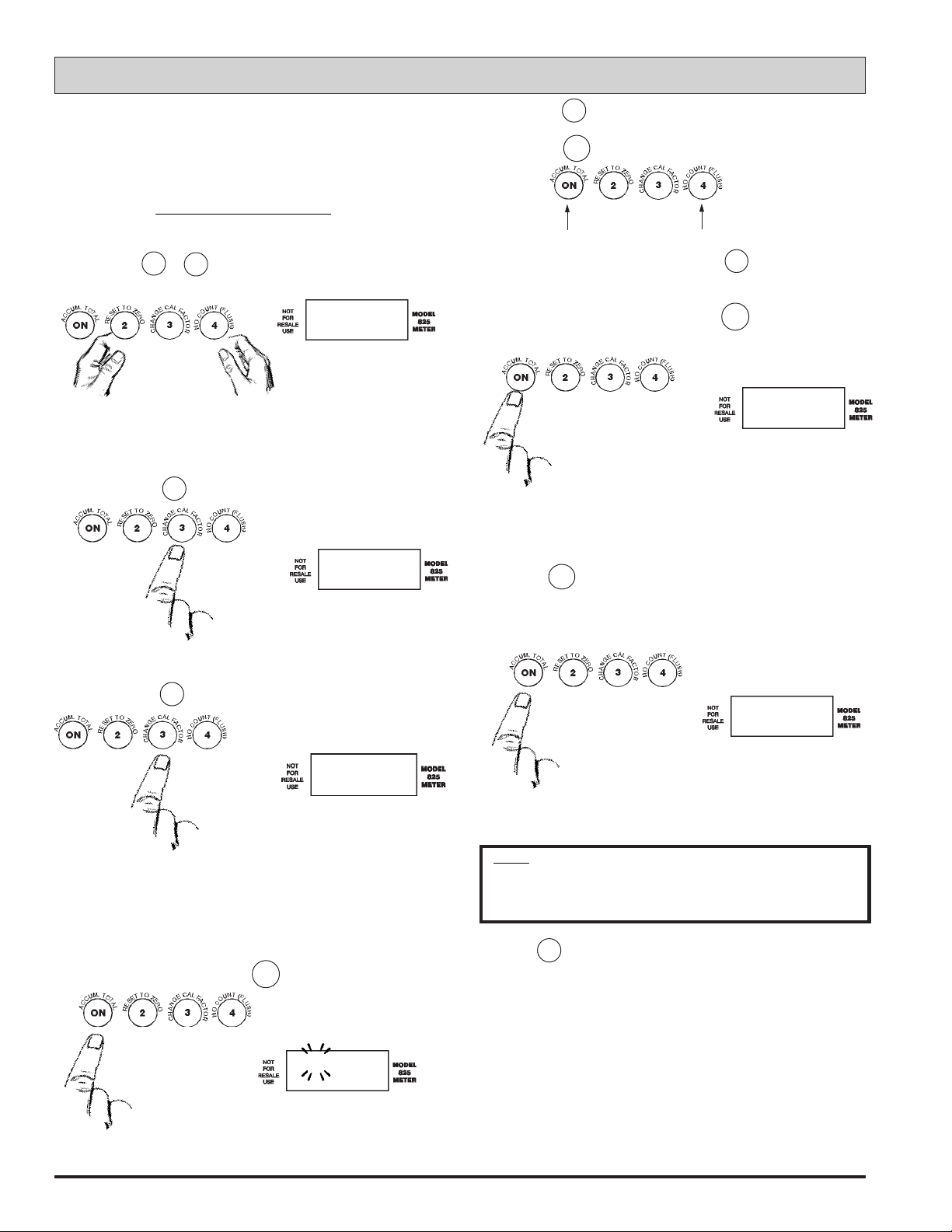

1. Press ON button to turn meter on. Current total, unit of

measure, and calibration factor are displayed. The meter

also turns on automatically and begins recording when fluid

starts flowing through it.

2. Hold button 2 for one second to set current total to "0.00."

3. Begin dispensing.

NOTE: Meter display automatically goes blank after 60 sec-

onds of inactivity and automatically comes back on when flow

resumes. No data is lost during periods of inactivity.

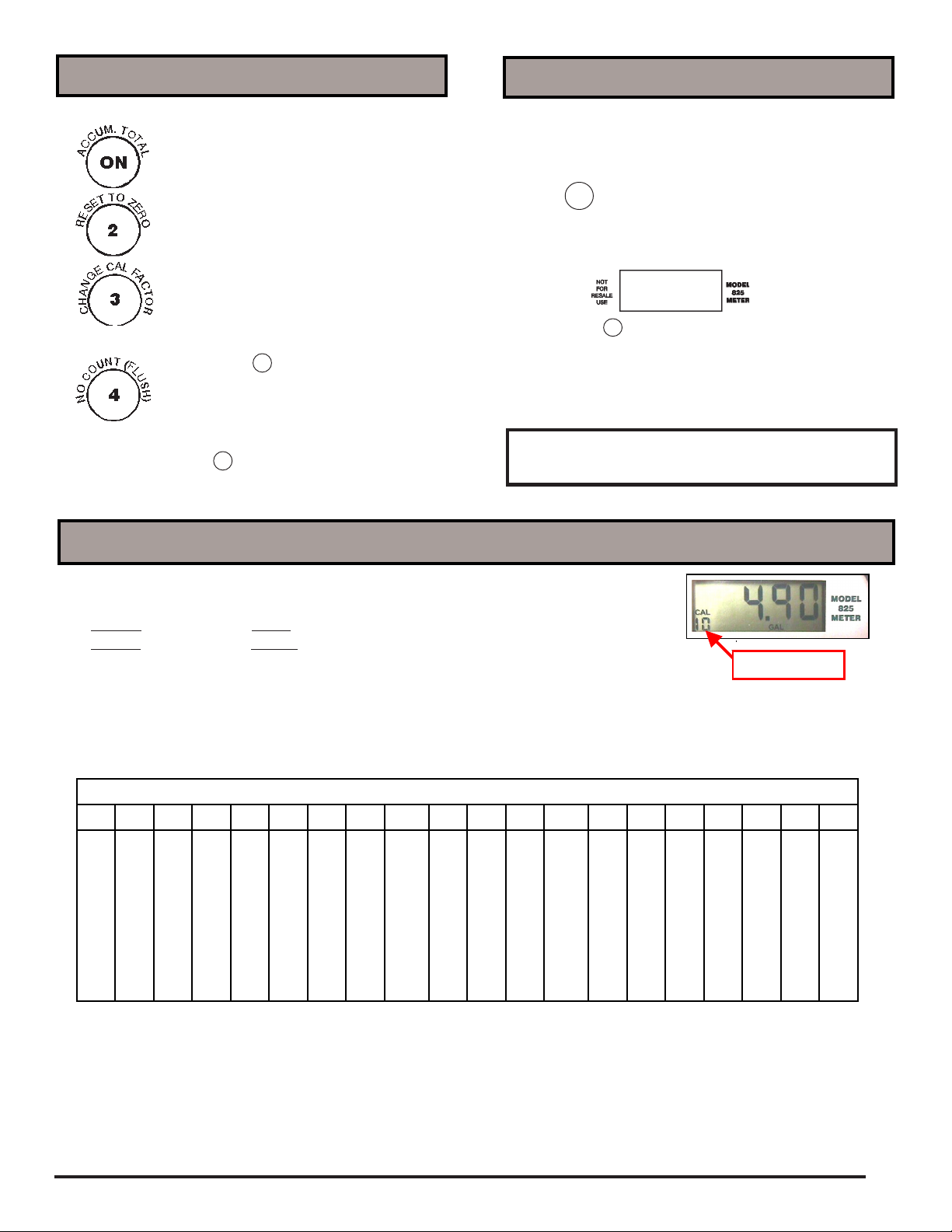

GAL

CAL

4

3.25

OPERATIONAL FUNCTIONS

CALIBRATION USING THE "CAL" FACTOR

TheThe

TheThe

The thinnerthinner

thinnerthinner

thinner the fluid, thethe fluid, the

the fluid, thethe fluid, the

the fluid, the lowerlower

lowerlower

lower the CAL numberthe CAL number

the CAL numberthe CAL number

the CAL number..

..

.

TheThe

TheThe

The thickerthicker

thickerthicker

thicker the fluid, thethe fluid, the

the fluid, thethe fluid, the

the fluid, the higherhigher

higherhigher

higher the CAL numberthe CAL number

the CAL numberthe CAL number

the CAL number..

..

.

•CAL 4 is set for thin fluids like water•CAL 4 is set for thin fluids like water

•CAL 4 is set for thin fluids like water•CAL 4 is set for thin fluids like water

•CAL 4 is set for thin fluids like water..

..

.

•CAL 19, the highest number•CAL 19, the highest number

•CAL 19, the highest number•CAL 19, the highest number

•CAL 19, the highest number, is set for very thick fluids like cold molasses., is set for very thick fluids like cold molasses.

, is set for very thick fluids like cold molasses., is set for very thick fluids like cold molasses.

, is set for very thick fluids like cold molasses.

•Each number changes the meter accuracy by about 1%.•Each number changes the meter accuracy by about 1%.

•Each number changes the meter accuracy by about 1%.•Each number changes the meter accuracy by about 1%.

•Each number changes the meter accuracy by about 1%.

CAL Factor

USE

01234567 8 910111213141516171819

Water

Kerosene

GRAMOXONE

INTEON™@ 50°F

Anti-Freeze @ 70°F

ROUNDUP® @ 50°F

TREFLAN™ @ 50°F

ATRAZINE 4L @ 50°F

10 wt Oil @ 70°F

DUAL® @ 50°F

BICEP® @ 50°F

Molasses @ 32°F

Table #1: Suggested CAL Factor settings for Common Fluids

Note: The suggested CAL factors are for REFERENCE ONLNote: The suggested CAL factors are for REFERENCE ONL

Note: The suggested CAL factors are for REFERENCE ONLNote: The suggested CAL factors are for REFERENCE ONL

Note: The suggested CAL factors are for REFERENCE ONLYY

YY

Y..

..

.