sotera.com | tuthill.com 8

| 400B SERIES ELECTRIC DIAPHRAGM PUMPS OWNER’S OPERATION MANUAL

Routine Maintenance Schedule

1. Always check oil level by the sight glass prior to any fluid transfer.

The ideal oil level should be at the mid line or halfway point of

both site glasses. Add SAE 30W oil as needed to maintain the

necessary level

2. Inspect all external Torx(r) head screws are tight. If any screws appear

to be loose, torque to 75 in‑lbs

3. Inspect all motor flange hex head bolts are tight. If any bolts appear

to be loose, torque to 50 in‑lbs

4. Either annually or after 500 hours of usage, drain the existing

SAE 30W weight oil through a site glass port and replace with

approximately 16 oz of the same oil

Regular maintenance is critical to maintaining performance and extending the life of your 400B Series pump.

• Always turn off the transfer pump and disconnect from a power source

prior to servicing

• Always flush the pump completely prior to any service or disassembly.

Tuthill recommends the use of water for flushing agricultural and

industrial chemicals. For petroleum‑based products such as oils and

lubricants, flushing with diesel fuel is acceptable

• DO NOT PRESSURIZE THE FLUSHING FLUID. Damage to the pump

will occur. Instead, submerge the suction tube or inlet adapter in the

flushing fluid, then operate the pump as normal for approximately

15‑30 seconds or until the flushing fluid returns to its initial color.

Allow the pump to air dry prior to any service

• DO NOT SUBMERGE THE ENTIRE PUMP OR ELECTRICAL MOTOR IN

THE FLUSHING FLUID, ONLY THE SUCTION TUBE OR INLET ADAPTER

• Do not allow chemicals, lubricants, or oils to remain in the internal

pump cavity for any extended period of time. Crystallization or a glum

could become present, adversely affecting pump performance

• Tuthill highly recommends flushing the pump after each use to avoid

‘dry out’ and contamination between fluid transfers

• The interior pump cavity is filled with SAE 30W oil by the factory

in order to lubricate the internal gear drive mechanism and yoke

assembly. Certain pump repairs will require the draining of this fluid.

If necessary, remove one of the site caps found on the exterior of the

pump body and drain the oil through this port. Replace with new SAE

30W oil after repairs are completed through the same port. Tuthill

recommends 16 oz of oil to be placed inside the cavity or until level is

halfway within the site glass

Best Operational Practices

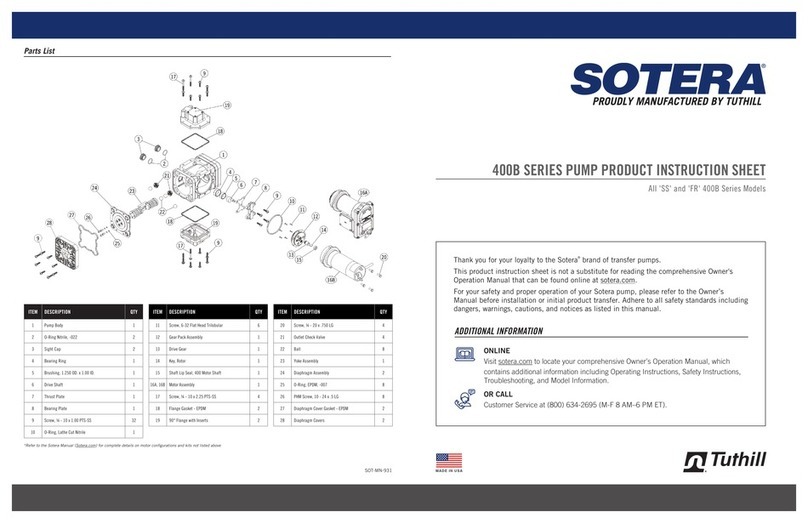

Individual Pump Component Removal and Replacement (refer to exploded pump view, page 13)

Use care in removing the diaphragm and check valve assemblies to avoid damage to the pump body. DO NOT pry the

diaphragm/check valve assembly away from the pump body with sharp or metal tools. Scratching or otherwise damaging

the pump body may cause leaks.

Do not attempt to replace individual parts. Replace entire assembly when required (kit 400F6557).

DO NOT DISASSEMBLE EXTERNAL GEAR ASSEMBLY. The planetary gears and ring gear are marked for proper assembly

and must not be altered.

Never disassemble yoke assembly. This is under extreme pressure and injury could result.