9

Follow the instructions and ensure that the correct measurement units box

is ticked (Item 4, above).

The date and time can be adjusted using this also (Item 5, above).

2.6 Peak reset

To reset the peak ow before taking another reading, press the ‘Reset’

button. The peak ow will immediately reset to zero, ready for the next

reading to be taken.

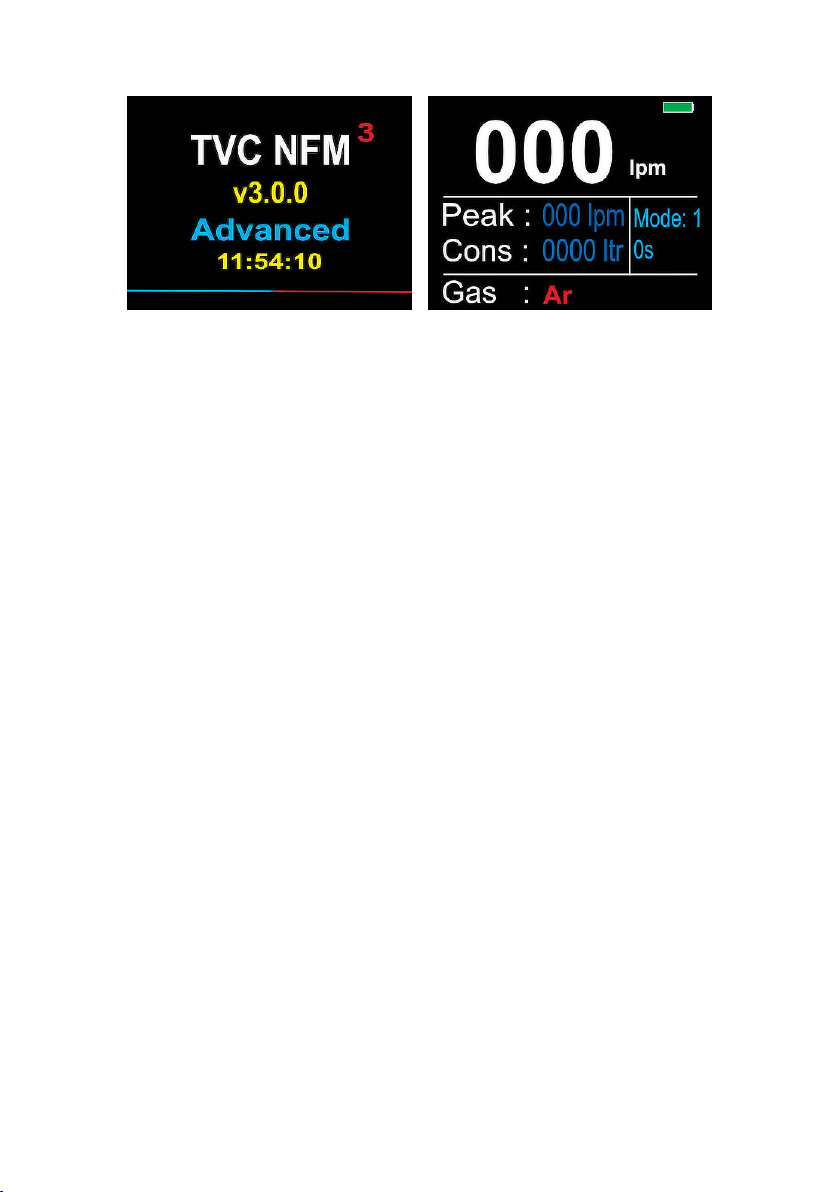

2.7 Data logging (NFM3 Advanced only)

The optional data logging facility records ow results and surge data on

the NFM3’s internal memory. Recorded data is downloaded from the

NFM3 via USB connection for direct import into the included data viewing

and reporting software.

There are two modes for data logging:

Mode 1 Quick ‘screen print’ of results.

Mode 2 Logs gas over a set time, taking a gas reading

every 20 milliseconds.

2.7.1 Mode 1

1Switch on the NFM3 Advanced unit.

2By default, the NFM3 is already in ‘Mode 1’. This provides

a quick ‘screen print’ of the results.

3Once the gas ow has been read, the screen will display

the average gas ow, peak ow and gas consumed. To log

this on the NFM3’s internal memory, press the ‘Log’ button.