Page 7

English

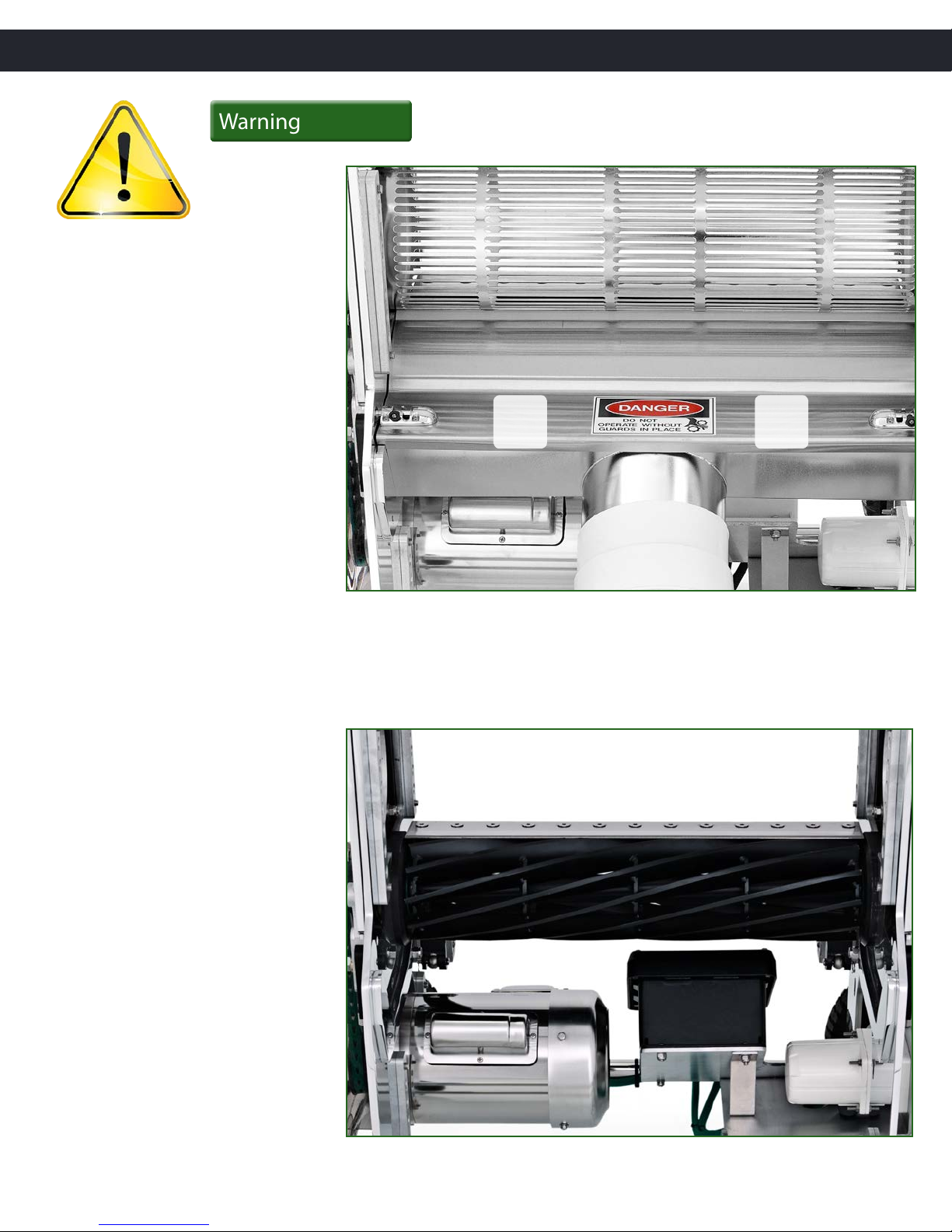

Never put objects into the tumbler that cannot be

processed by the unit. Hard metallic objects that the

operator does not notice can cause extensive damage

and/or bodily harm.

Never plug in the unit with protective shrouds removed.

For safe use of your machine, DO NOT change or modify any part of the

machine or accessories.

Never let the machine run unattended.

Do not attempt service that is not covered in this manual yourself as doing

so may expose you to dangerous voltage or other hazards.

Damage requiring service must be referred to qualied service personnel.

If unit does not operate normally by following operating instructions, adjust

only those controls that are covered in the instructions. Improper adjustment

may result in damage and may require extensive work by qualied service

personnel to restore the unit back to its normal operation.

Replacement parts must be specic to this unit and supplied by the

manufacturer. Unauthorized substitutions may result in re, shock or bodily

harm.

After completion of any service work, ask to ensure safety checks were

performed to determine the unit is in proper operating condition.

Keep unit well ventilated to prevent overheating.

Careless or improper use of this unit may cause serious

or fatal injury.

To reduce the risk of injury, keep body parts away from fast moving parts.

To reduce risk of injury, do not wear loose clothing or jewellery when

operating the machine. Sleeves should be rolled past the elbows and long

hair conned. Do not wear gloves.

To reduce risk of injury, safety glasses must be worn.