Emai

l:info

@tria

ngul

arw

ave.com • Triw[email protected] • Website:www.Triangularwave.com2

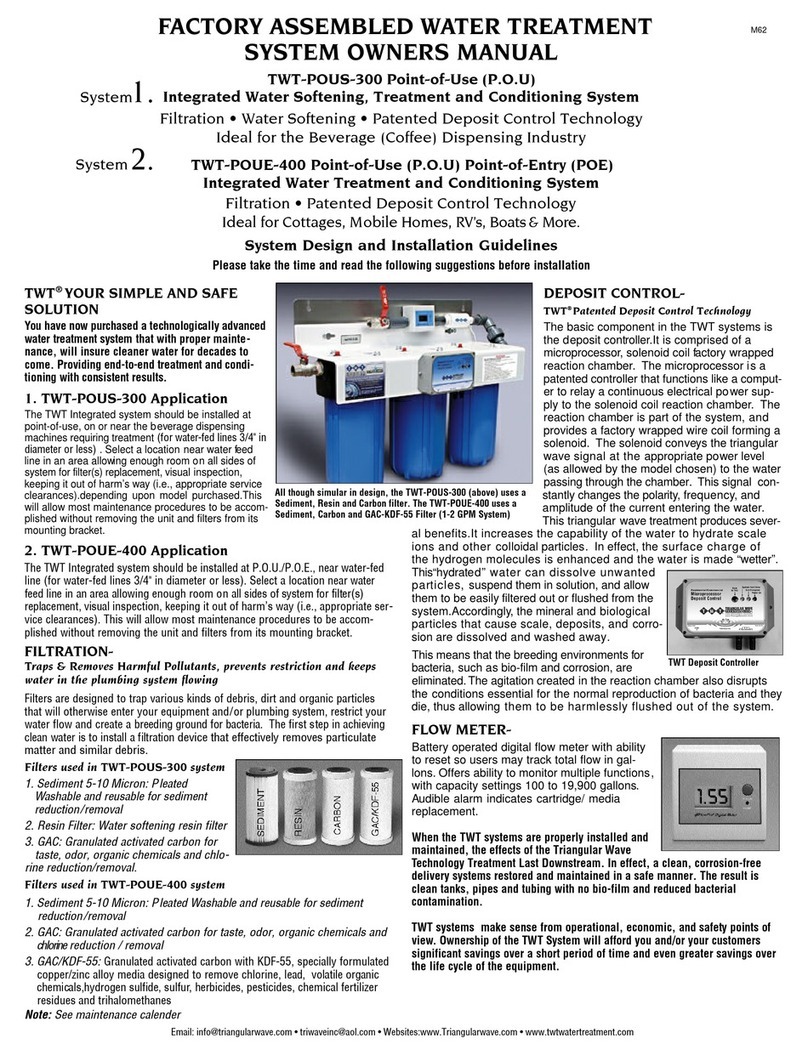

OPERATING PRINCIPLES

The Triangular Wave IonGuard Purification System

disinfects water through a process called ionization.

That process utilizes a low voltage direct current [DC]

to place precise and minute amounts of copper and

silver ions into water systems. Copper ions kill algae

and silver ions kill bacteria. An ion is merely an elec-

tronically charged atom or group of atoms. An atom

acquires this charge by gaining or losing electrons.

Negatively charged electrons are one of the three

major subatomic particles; the others being protons,

which have a positive charge, and neutrons, which

have no charge.

Ions in the Triangular Wave system are positively

charged; algae, bacteria and other particles in the

water are negatively charged. The positive to

negative attraction allows the ions to attach to the

organisms, penetrate their cell walls and kill them.

The IonGuard Purification System is an electrolytic

copper/silver ion generator.The system units contain

specifically cast copper/silver alloy electrodes. These

electrodes are mounted in a PVC housing designed

specifically for easy access.

When the system is used in conjunction with a filter,

the dead bacteria with the silver ion attached to it will

be large enough for the filter to remove. Normal filter

backwashing will then remove the dead particles.

The criteria for copper and silver in water are as

follows:The EPA standard for drinking water is 1.0

ppm (parts per million) maximum for copper and 50

ppb (parts per billion) maximum for silver.The system

is programmed so that a water test showing 0.25

ppm to 0.35 ppm copper automatically provides the

proper ratio of silver. This will produce drinking water

quality in any water system treated. The system

requires no chemicals in their function of controlling

algae and bacteria.

A “current source” generator powers the IonGuard

Purification System. “Voltage source”generators

power other ionization units. In all ionization units,

copper and silver ions plate off of the electrodes and

enter the water. Over time, the electrodes will

become smaller, and the gap between the electrodes

will become larger. The current source generator will

automatically compensate for the change in gap size;

while the voltage source generators must be manual-

ly inspected and adjusted. The current source gener-

ators on the Triangular Wave IonGuard System offers

trouble free operation.

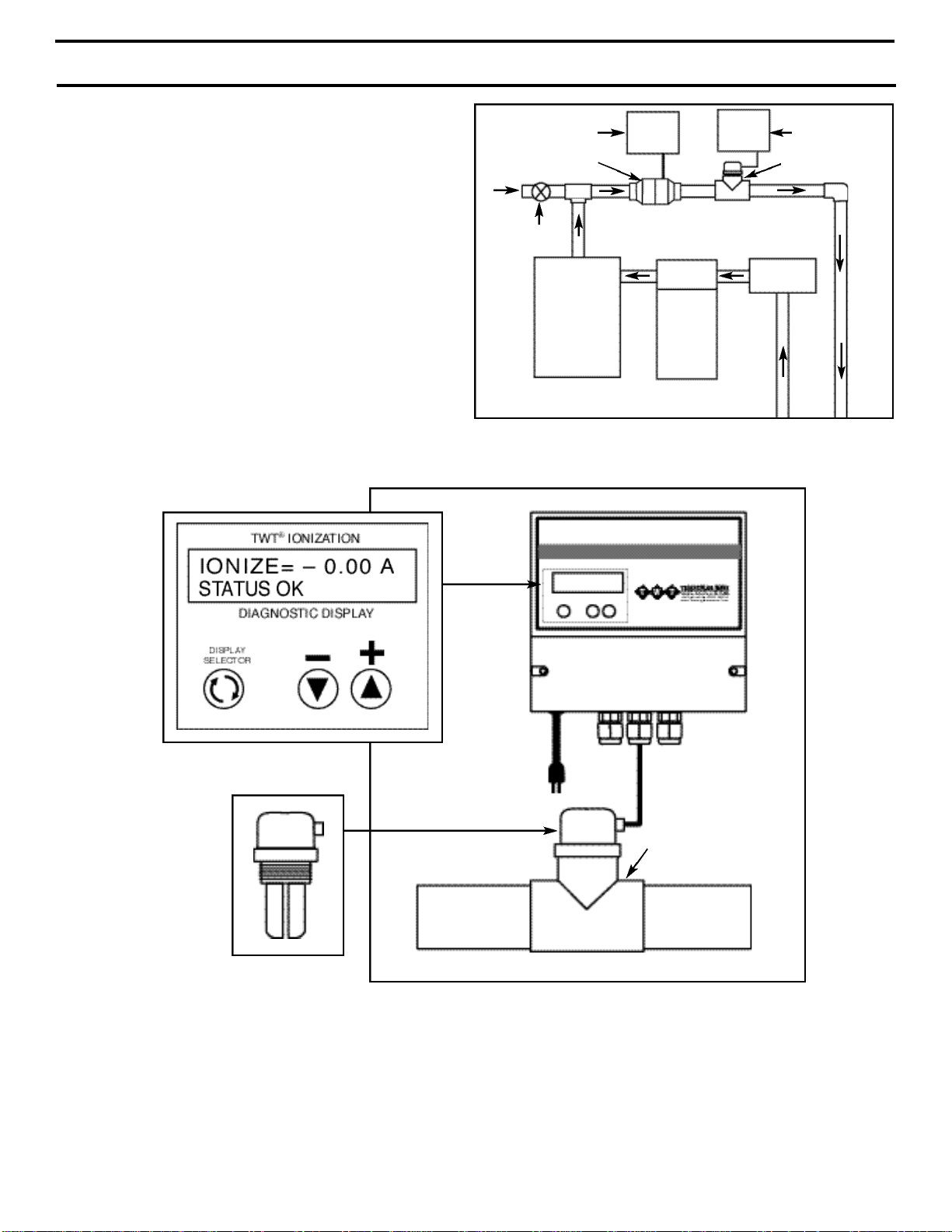

We recommend that the IonGuard Purification

System be installed downstream of a Triangular

Wave Deposit Control System. The Deposit Control

will keep the IonGuard System electrodes free of

scale and other deposits for more effective results.

And, at the same time, the Deposit Control System

will help eliminate scale and biofilm deposits through

the entire water system. (see diagram A Page 1)

Without the Triangular Wave Deposit Control System

in place, the ionization electrodes may develop either

a layer of scale or oxidation. In either case, it is

necessary to periodically clean the electrodes with

an acid solution. The Deposit Control System

Reduces the need for periodic cleaning.

INSTALLATION

SECTION 2

SECTION 3

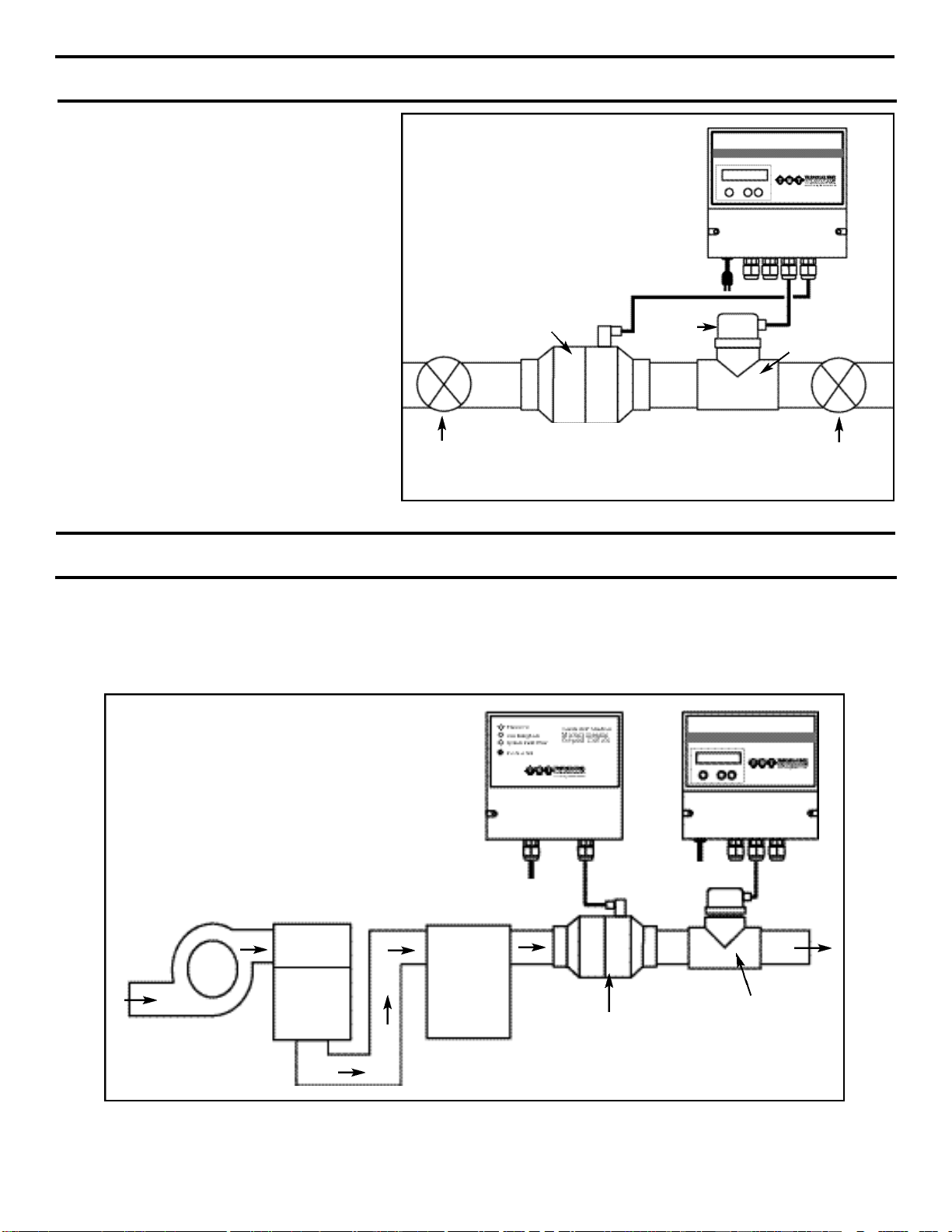

In general, installation of the IonGuard System should

follow these seven steps: Select a location on the

recirculating water line to insert the Ionization PVC

“T-Housing”. The location should be downstream of

the pump, filter, and Triangular Wave Deposit Control

System. [Recommended]

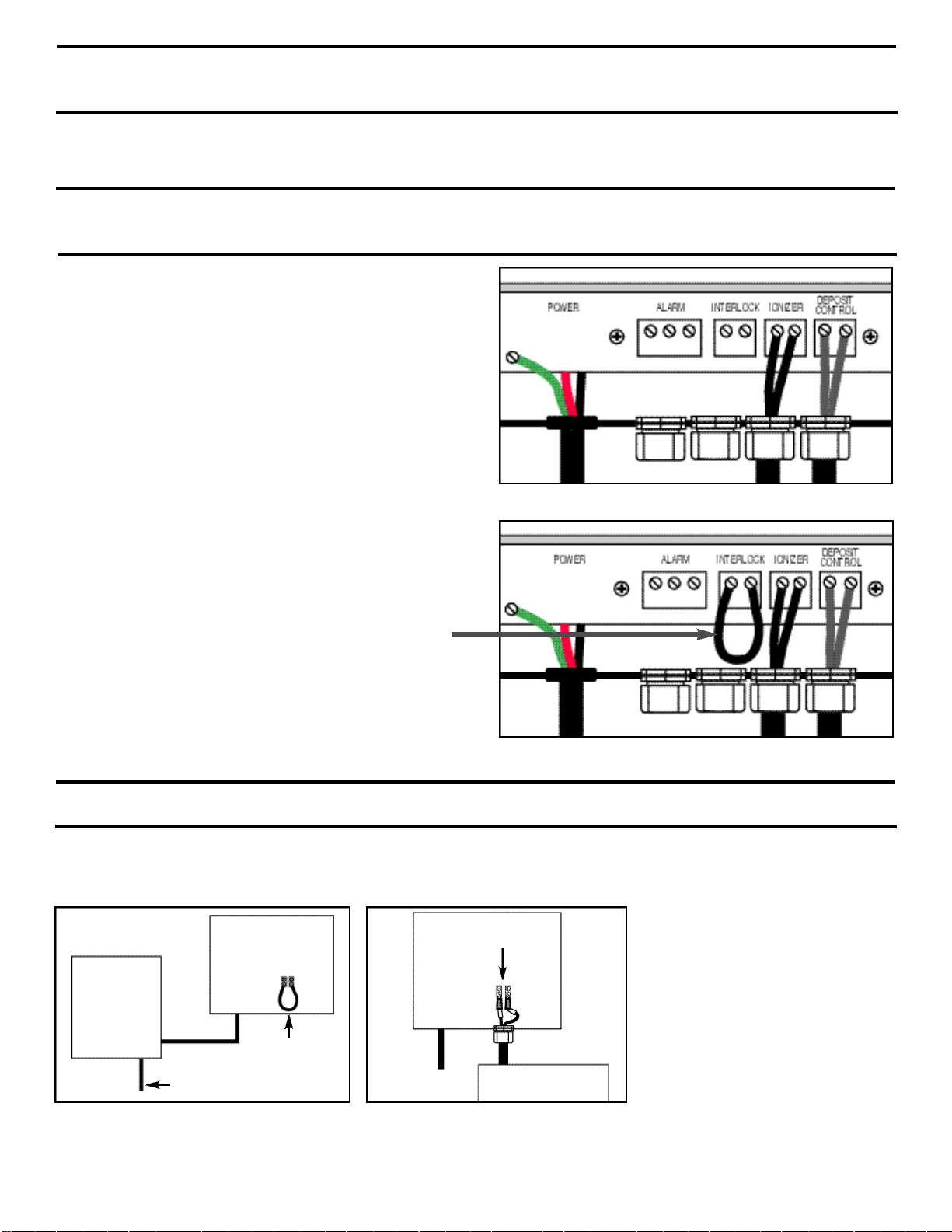

•Select a location on a wall to install the Power

Supply/Electronic Control Unit. The IonGuard

System installation kit includes 15 feet of wire in

a conduit/electrode wire assembly, which should

allow adequate flexibility when installing to Power

Supply.

• Install the two isolation valves (not included, in

those cases where equipment is below water

level) and the PVC “T-Housing”.

• Install the Power Supply/Electronic Control Unit.

•Install the Copper/Silver Ionization Electrodes

into the PVC “T-Housing”.

• Connect the conduit/electrode wire assembly

between the Power Supply and the Ionization

Electrodes.

• Connect the Ionization Power Supply to electrical

power.