Page 1 of 2 AUGUST 2012 G988

Grinnell Mechanical Products

Model CB800

Circuit Balancing Valve

Worldwide

Contacts

www.grinnell.com

Installation

Instructions

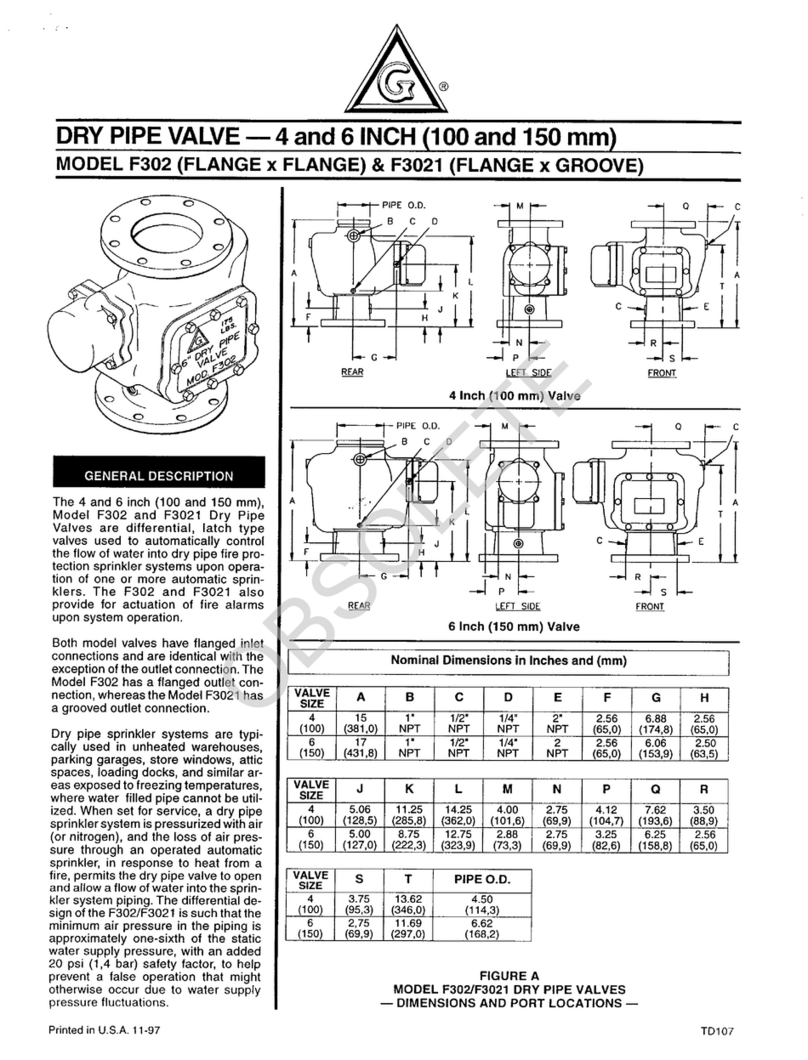

GRINNELL CB800 Circuit Balancing

Valves are designed for installation in

hot water heating and chilled water

air conditioning systems and serve to

achieve a hydronic balance between

the various circuits of the system.

These installation instructions are

designed for the Grooved, Flanged,

Threaded, and Soldered type Circuit

Balancing Valves.

General Instructions

Always read and understand the in-

structions. Never remove any piping

component without verifying that the

system is depressurized and drained.

It is the designer’s responsibility to se-

lect products suitable for the intend-

ed service and to ensure that pressure

ratings and performance data are not

exceeded.

It is recommended that the valve be

installed in the return line.

Install the valve with the flow in the

same direction as the arrow cast in

the body.

Valve must be installed with a mini-

mum of 3D (3 x nominal pipe diam-

eter) of straight pipe in the upstream

side.

Valve may be installed in the vertical

or horizontal position, with the hand-

wheel up, down or on the side.

Presetting:

The required preset value can be ob-

tained by referencing the flow chart

for the appropriate size of valve. (See

reference documents on www.grin-

nell.com) Following the steps below,

adjust the basic and fine adjustment

scale on the handwheel to match the

selected presetting.

Step 1. The preset value of the valve

is adjusted with the handwheel (See

Figure 1 or 2).

Step 2. Turn the handwheel so that

the arrow on the sliding indicator

matches the basic adjustment value.

One complete turn of the handwheel

adjusts the indicator one full position.

The fine setting is displayed in the

scale under the handwheel and in-

dicates 1/10th of a turn of the

handwheel.

Step 3. With the valve open to the

preset value, use a small screwdriver

and gently pry the cover plug out of

the hand-wheel. Using a 3 mm Allen

key for the 1/2 to 2 inch, 4 mm Allen

key for the 2-1/2 to 6 inch, or a 10 mm

screwdriver for the 8 to 12 inch, insert

the tool into the screw (see Figure 1 or

2) and turn clockwise until tight. This

will lock the hand-wheel so that the

valve can not be opened beyond the

preset value. The hand-wheel may still

be turned to the closed position. Re-

place the cover plug.

Repositioning the

Handwheel

Depending on the position of the valve

in the system, it may be desirable to

move the 1/2 inch to 6 inch handwheel

and adjustment scales to make it eas-

ier to read.

Step 1. Ensure the valve is closed

and the adjustment scale is set at 0.

Step 2. Use a small screwdriver and

gently pry the cover plug out of the

hand-wheel.

Step 3. Use a 12 mm socket for the

1/2 inch to 2 inch handwheel and

6 mm Allen key for the 2-1/2 inch to 6

inch handwheel to remove the Allen

screw (See Figure 1).

Allen Wrench

Handwheel

Figure 1

1/2 inch to 6 inch

handwheel Presetting and rePositioning

Indicator

Sliding

Marking Fine Setting Scale

(Peripheral Scale)

Handwheel

Cover Plug

Screw

Sealing Wire

Hole For

Sealing Wire

Hole For

(Longitudinal Scale)

Basic Setting Scale

1/10th of a turn

complete turns

Lead

seal

Cover

plug

Handwheel

Figure 2

8 inch to 12 inch

handwheel Presetting

and rePositioning