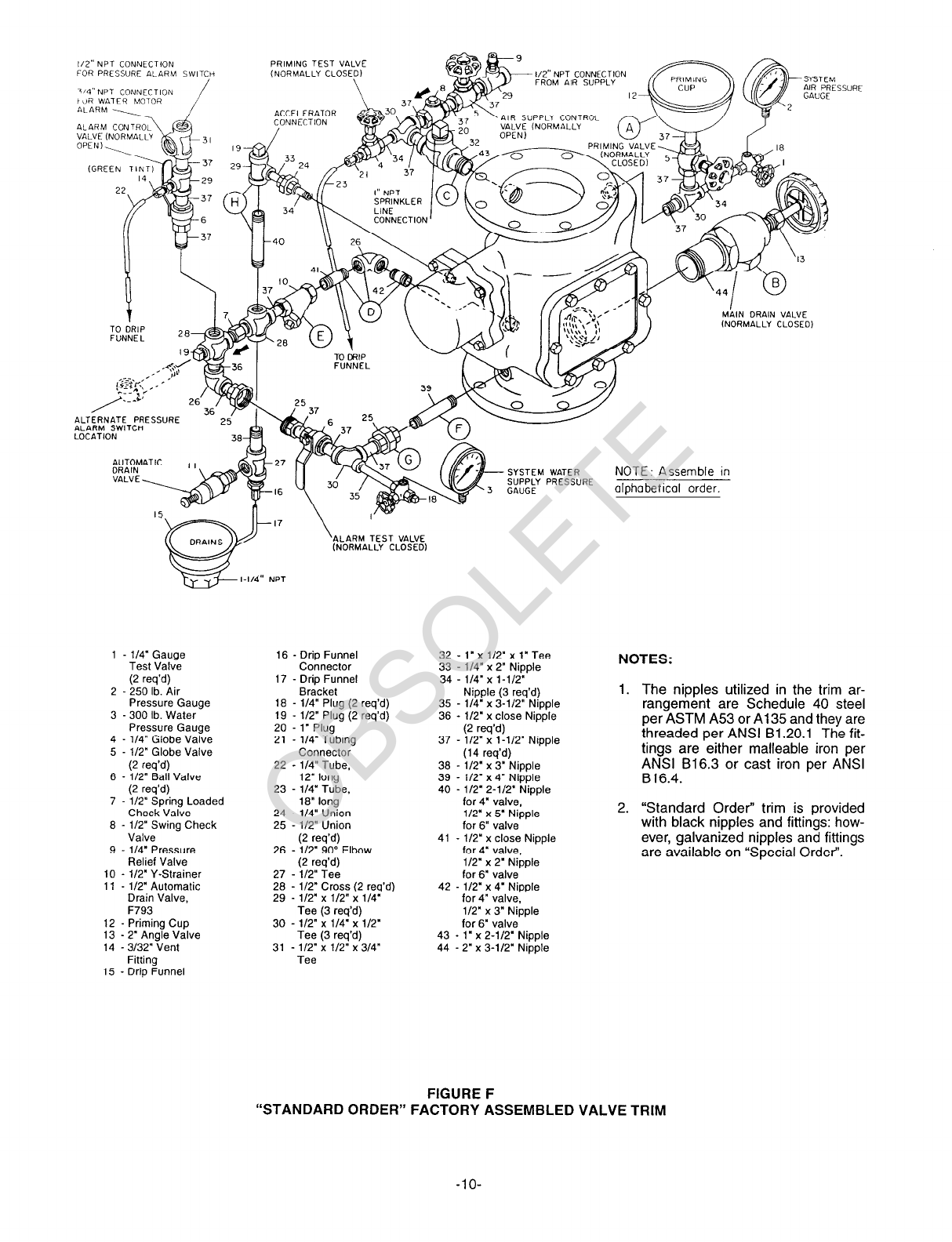

NOTES

Proper operation of the Model

F302lF3021 Dry Pipe Value depends

upon its trim being installed in ac-

cordance with the instructions given

in this TechnicalData Sheet. Failure

to follow the trim diagram or the in-

structions given in this Technical

Data Sheet may prevent the

F302lF3021 Valve from functioning

properly, as well as void listings, ap-

provals, and the manufacturer’s war-

ranties.

The F302lF3021 Valves are shipped

with a restraining wire tied around

the Clapper Latch and Clapper Arm

to prevent movement of these compo-

nents during shipment.The restrain-

ing wire must be removed. Failure to

do so will prevent the F302lF3021

Valvefrom functioning properly.

The F302lF3021 Valve must be in-

stalled in a readily visible and acces-

sible location.

The F302lF3021 Valve and associ-

ated trim must be maintained at a

minimum temperature of 40°F/4”C.

Heat tracingofthe F302lF3021 Valve

or its associated trim is notpermitted.

Heat tracing can result in the forma-

tion of hardened mineral deposits

which are capable of preventing

proper operation.

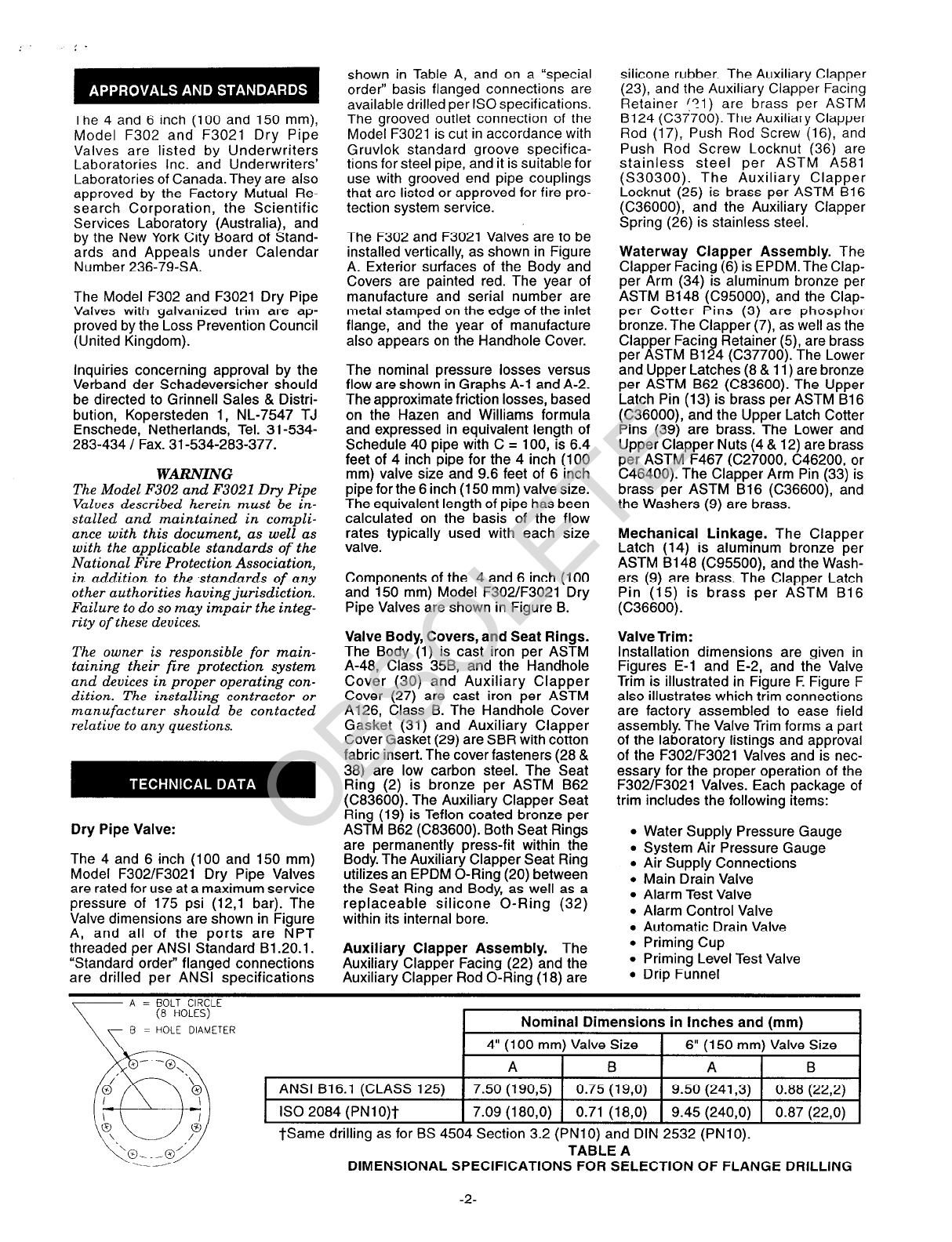

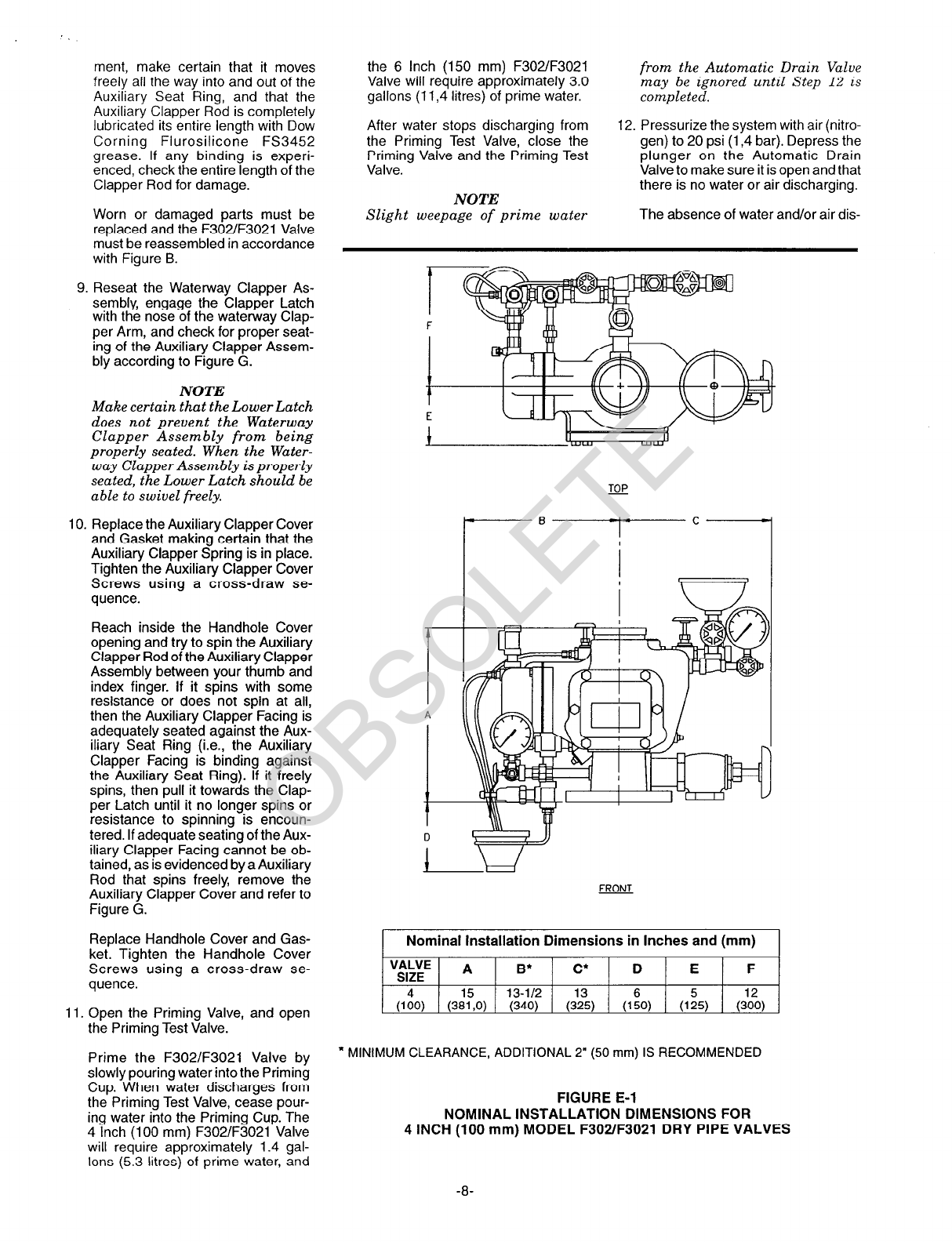

The Model F302IF3021 Dry Pipe Valve

is to be installed in accordance with

the following criteria:

1. All nipples, fittings, and devices must

be clean and free of scale and burrs

before installation. Use pipe thread

sealant sparingly on male pipe

threads only

2. The F302/F3021 Valve must be

trimmed in accordance with Figure

E

3. Care must be taken to make sure

that check valves, strainers, globe

valves, etc. are installed with the flow

arrows in the proper direction.

4. Drain tubing to the drip funnel must

be installed with smooth bends that

will not restrict flow.

5. The main drain and drip funnel drain

may be interconnected provided a

check valve is located at least 12

inches (300 mm) below the drip fun-

nel.

6. Suitable provision must be made for

disposal of drain water. Drainage

water must be directed such that it

will not cause accidental damage to

property or danger to persons.

7. Unused pressure alarm switch

and/or water motor alarm connec-

tions must be plugged.

8. The Pressure Relief Valve provided

with the Valve Trim is factory set to

relieve at a pressure of approxi-

mately 45 psi (3,l bar), which can

typically be used for a maximum nor-

mal system air pressure of 40 psi

(2,8 bar). The Pressure Relief Valve

may be reset to a lower or higher

pressure; however, it must be be re-

set to relieve at a pressure which is

in accordance with the requirements

of the Authority Having Jurisdiction.

To reset the Pressure Relief Valve,

first loosen the jam nut and then

adjust the cap accordingly - clock-

wise for a higher pressure setting or

counterclockwise for a lower pres-

sure setting. After verifying the de-

sired pressure setting, tighten the

jam nut.

9. Installation of an Air Maintenance

Device, as described in the Techni-

cal Data Section, is recommended.

10. An Inspector’s Test Connection as

required By NFPA 13 must be pro-

vided on the system piping at the

most remote location from the

F302lF3021 Valve.

11. Conduit and electrical connections

are to be made in accordance with

the requirements of the authority

havina iurisdiction and/or the Na-

tional”El&tric Code.

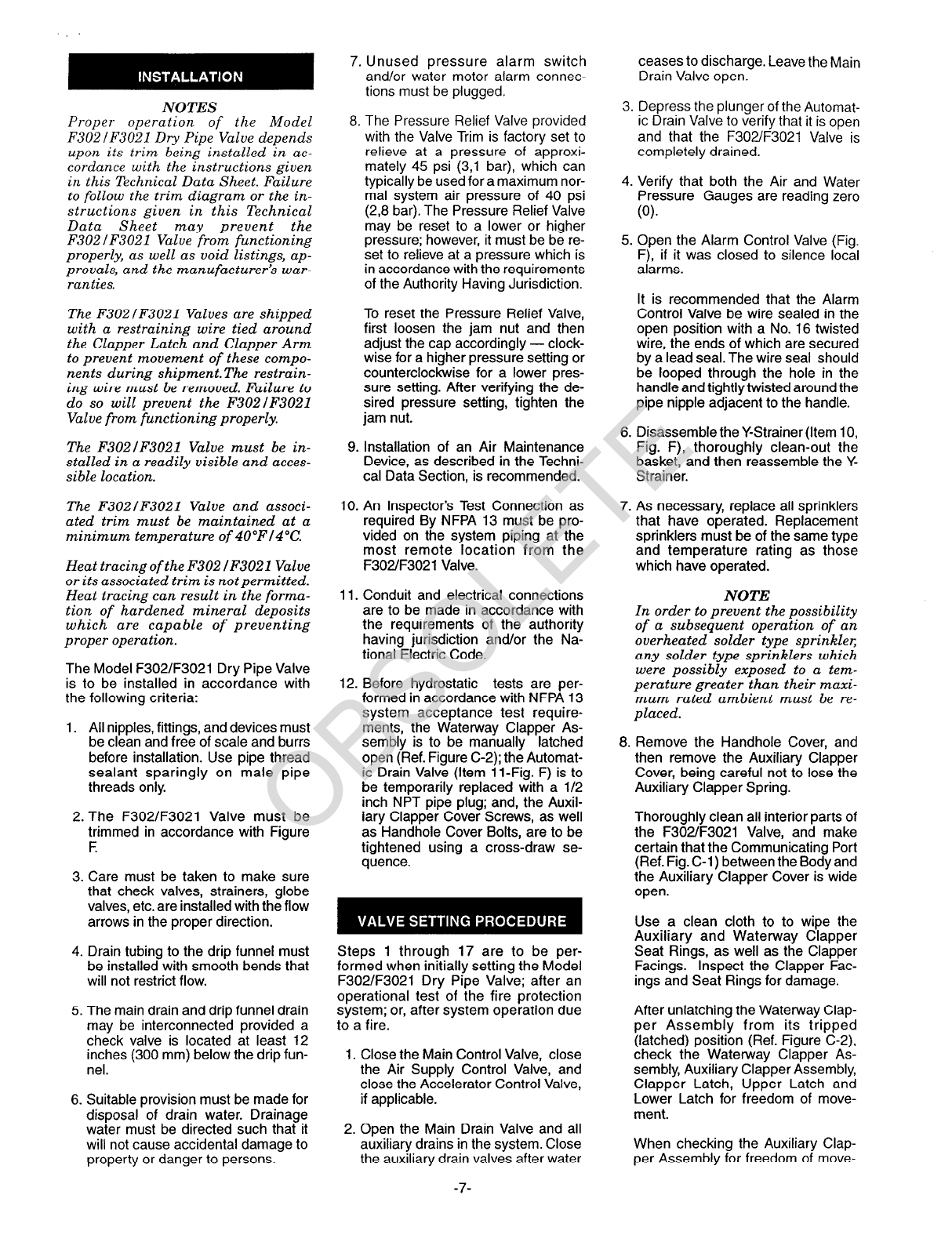

12. Before hydrostatic tests are per-

formed in accordance with NFPA 13

system acceptance test require-

ments, the Waterway Clapper As-

sembly is to be manually latched

open (Ref. Figure C-2); the Automat-

ic Drain Valve (Item 1l-Fig. F) is to

be temporarily replaced with a l/2

inch NPT pipe plug; and, the Auxil-

iary Clapper Cover Screws, as well

as Handhole Cover Bolts, are to be

tightened using a cross-draw se-

quence.

Steps 1 through 17 are to be per-

formed when initially setting the Model

F302lF3021 Dry Pipe Valve; after an

operational test of the fire protection

system; or, after system operation due

to a fire.

1. Close the Main Control Valve, close

the Air Supply Control Valve, and

close the Accelerator Control Valve,

if applicable.

2. Open the Main Drain Valve and all

auxiliary drains in the system. Close

the auxiliary drain valves after water

3.

ceases to discharge. Leave the Main

Drain Valve open.

Depress the plunger of the Automat-

ic Drain Valve to verify that it is open

and that the F302/F3021 Valve is

completely drained.

4. Verify that both the Air and Water

Pressure Gauges are reading zero

(0).

5. Open the Alarm Control Valve (Fig.

F), if it was closed to silence local

alarms.

It is recommended that the Alarm

Control Valve be wire sealed in the

open position with a No. 16 twisted

wire, the ends of which are secured

by a lead seal. The wire seal should

be looped through the hole in the

handle and tightly twisted around the

pipe nipple adjacent to the handle.

6. Disassemble the Y-Strainer (Item 10,

Fig. F), thoroughly clean-out the

basket, and then reassemble the Y-

Strainer.

7. As necessary, replace all sprinklers

that have operated. Replacement

sprinklers must be of the same type

and temperature rating as those

which have operated.

NOTE

In order to prevent the possibility

of a subsequent operation of an

overheated solder type sprinklel;

any solder type sprinklers which

were possibly exposed to a tem-

perature greater than their maxi-

mum rated ambient must be re-

placed.

8. Remove the Handhole Cover, and

then remove the Auxiliary Clapper

Cover, being careful not to lose the

Auxiliary Clapper Spring.

Thoroughly clean all interior parts of

the F302/F3021 Valve, and make

certain that the Communicating Port

(Ref. Fig. C-l ) between the Body and

the Auxiliary Clapper Cover is wide

open.

Use a clean cloth to to wipe the

Auxiliary and Waterway Clapper

Seat Rings, as well as the Clapper

Facings. Inspect the Clapper Fac-

ings and Seat Rings for damage.

After unlatching the Waterway Clap-

per Assembly from its tripped

(latched) position (Ref. Figure C-2),

check the Waterway Clapper As-

sembly, Auxiliary Clapper Assembly,

Clapper Latch, Upper Latch and

Lower Latch for freedom of move-

ment.

When checking the Auxiliary Clap-

per Assembly for freedom of move-

-7-