ENG1

TABLE OF CONTENTS

Page

Section I General Information.................................................................................................................................................................................................. 1

Section II Safety and Warnings ................................................................................................................................................................................................. 2

Section III Icons, Specications, and Conformity..................................................................................................................................................................... 3

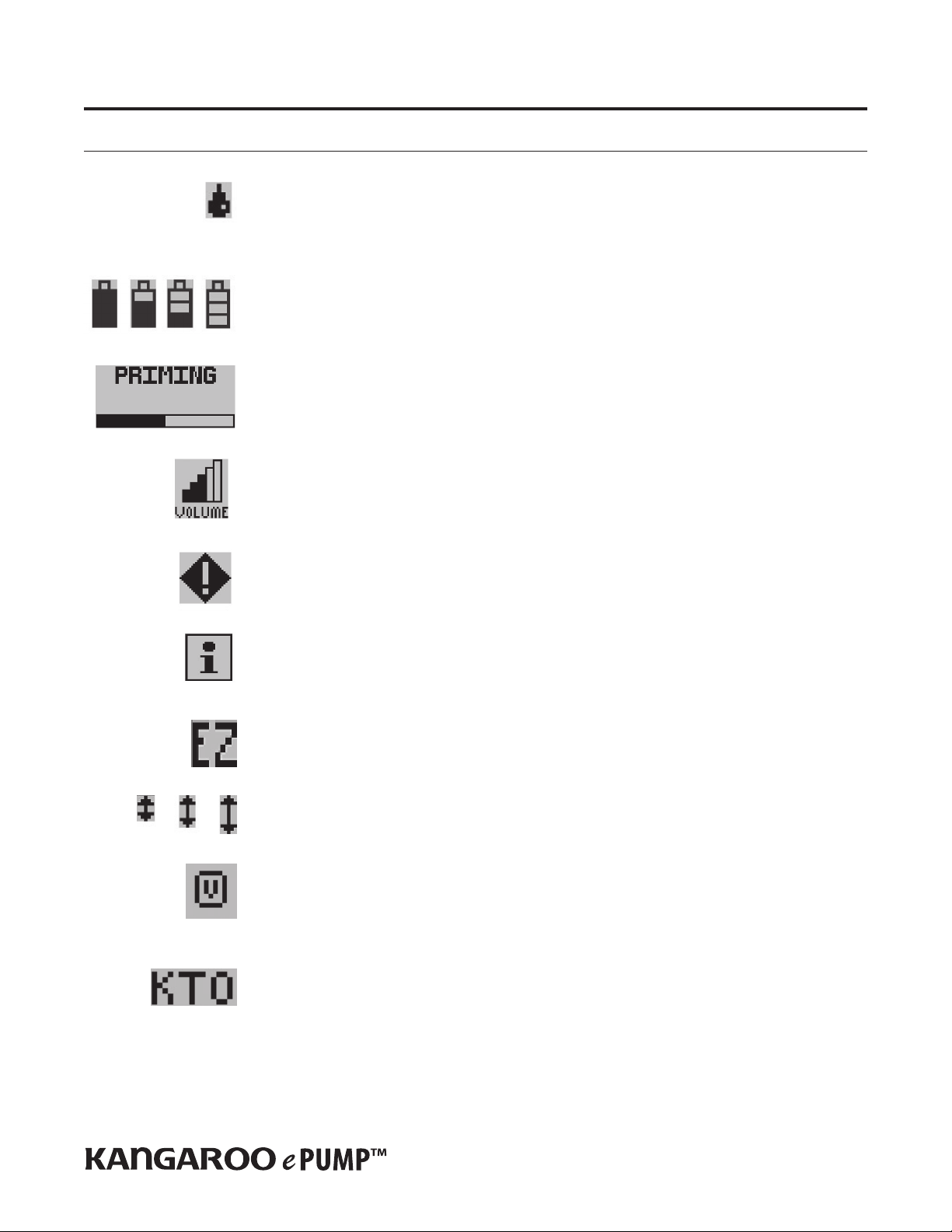

Icon Information............................................................................................................................................................................................................ 3

Specications................................................................................................................................................................................................................. 4

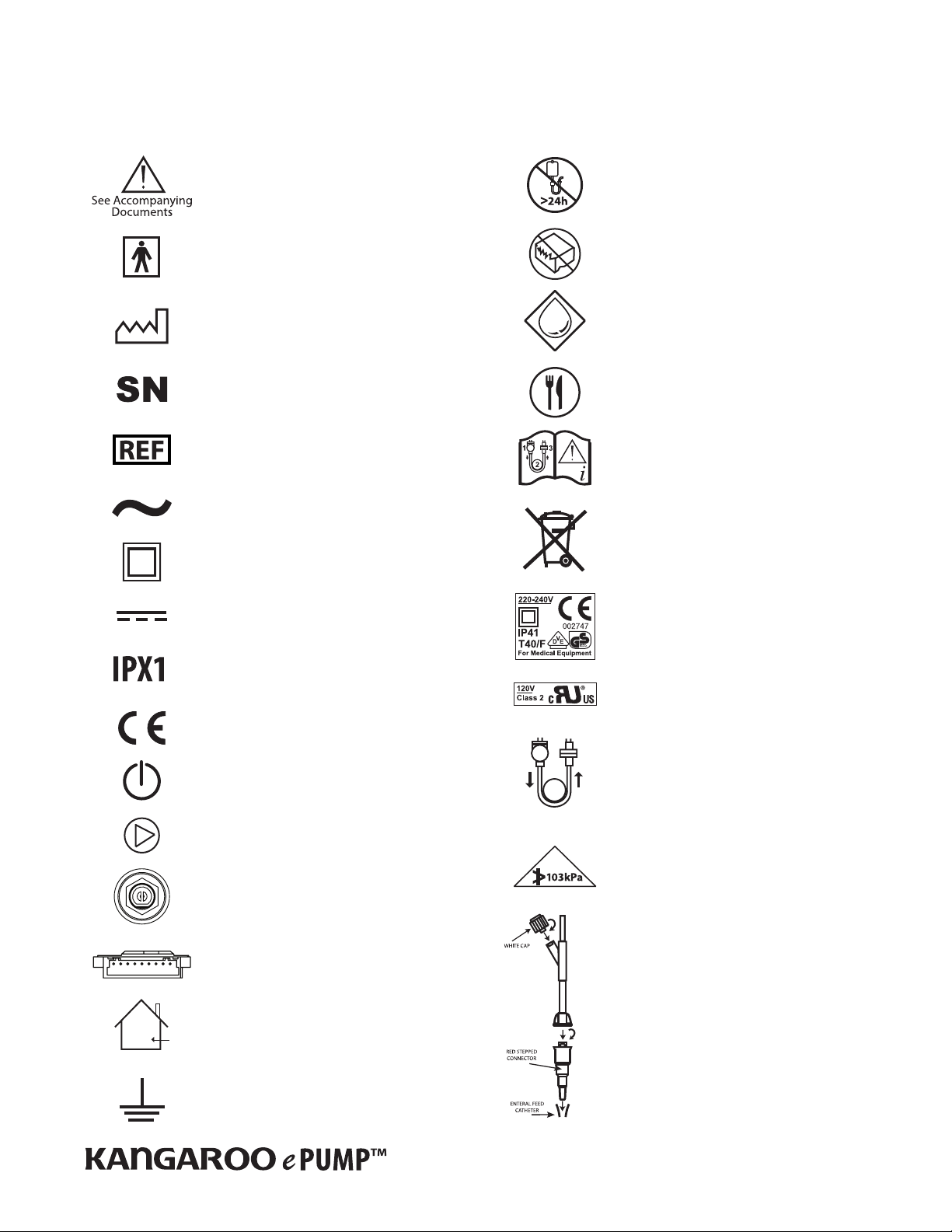

Symbols on Pump and Accessories................................................................................................................................................................................. 5

Electromagnetic Conformity Declaration ....................................................................................................................................................................... 6

Section IV Cleaning Procedures.................................................................................................................................................................................................. 7

Section V Operating Procedures................................................................................................................................................................................................ 8

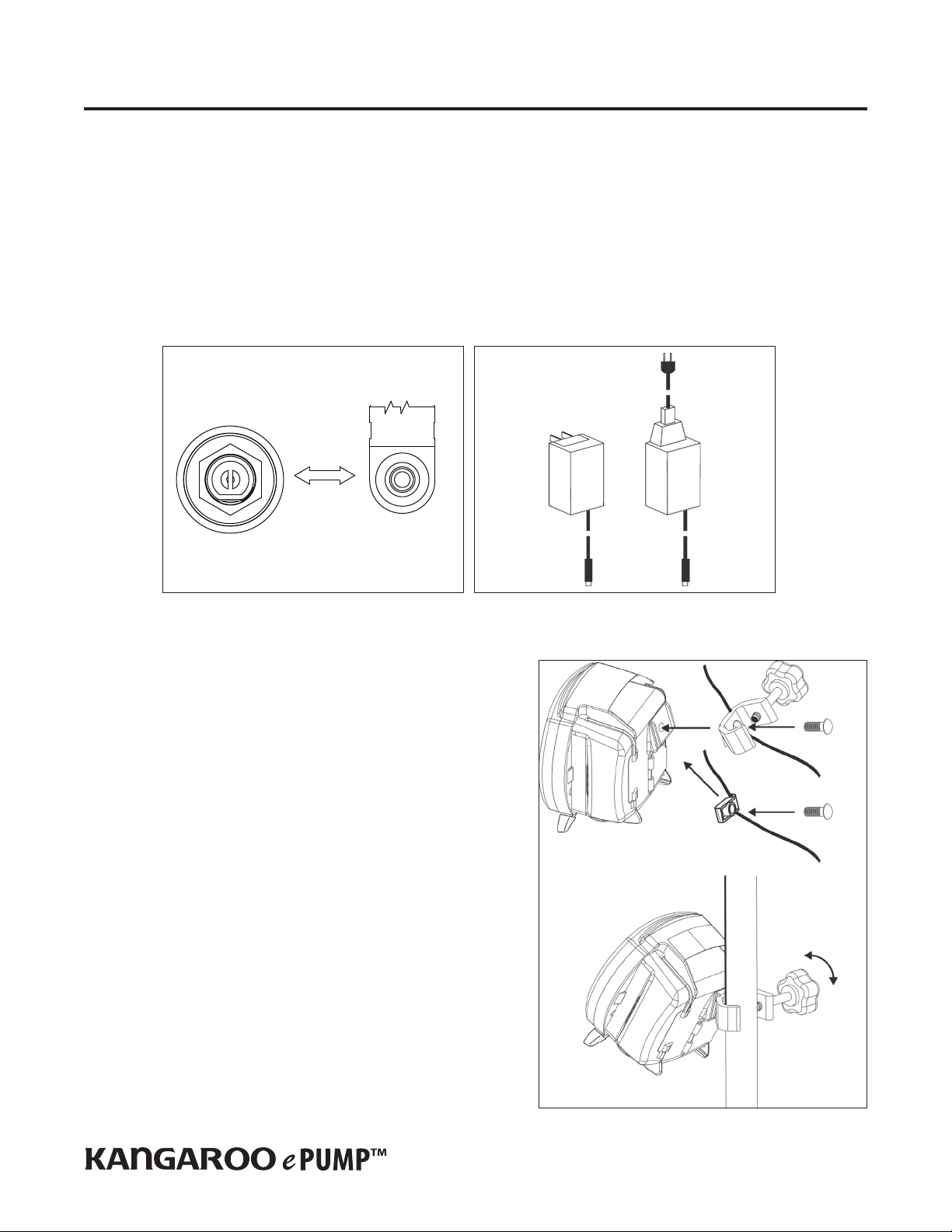

Initial Setup ................................................................................................................................................................................................................... 8

Attaching the A/C Adapter Power Cord.......................................................................................................................................................................... 8

Battery Setup................................................................................................................................................................................................................. 8

Attaching Pole Clamp .................................................................................................................................................................................................... 8

Instructions for Use........................................................................................................................................................................................................ 9

Quick Start ..................................................................................................................................................................................................................... 9

General Startup.............................................................................................................................................................................................................. 9

Placement/Mounting .................................................................................................................................................................................................... 9

A/C Power Operation ..................................................................................................................................................................................................... 9

Battery Power Operation ............................................................................................................................................................................................... 9

Power On/O................................................................................................................................................................................................................. 9

Language Selection, First Power Up.............................................................................................................................................................................. 10

Keep or Clear Prior Pump Settings ................................................................................................................................................................................ 10

Section VI Error Codes and Troubleshooting Guide................................................................................................................................................................ 10

System Error ................................................................................................................................................................................................................. 10

Hold Error...................................................................................................................................................................................................................... 11

Rotor Error .................................................................................................................................................................................................................... 11

Feed Error ..................................................................................................................................................................................................................... 11

Flush Error..................................................................................................................................................................................................................... 11

Flow Error ..................................................................................................................................................................................................................... 11

Pump Set Dislodged Error............................................................................................................................................................................................. 11

Battery Low .................................................................................................................................................................................................................. 11

Feeding Complete......................................................................................................................................................................................................... 11

Pump Set Use >24 Hours Warning ...............................................................................................................................................................................11

LED Array ...................................................................................................................................................................................................................... 11

Section VII Re-Certication of Performance Test..................................................................................................................................................................... 12

Section VIII Re-Certication Troubleshooting Guide................................................................................................................................................................ 12

Section IX Re-Certication Test Documentation .................................................................................................................................................................... 14

Section X Pump Flow Accuracy Test......................................................................................................................................................................................... 14

Section XI Maintenance.............................................................................................................................................................................................................. 15

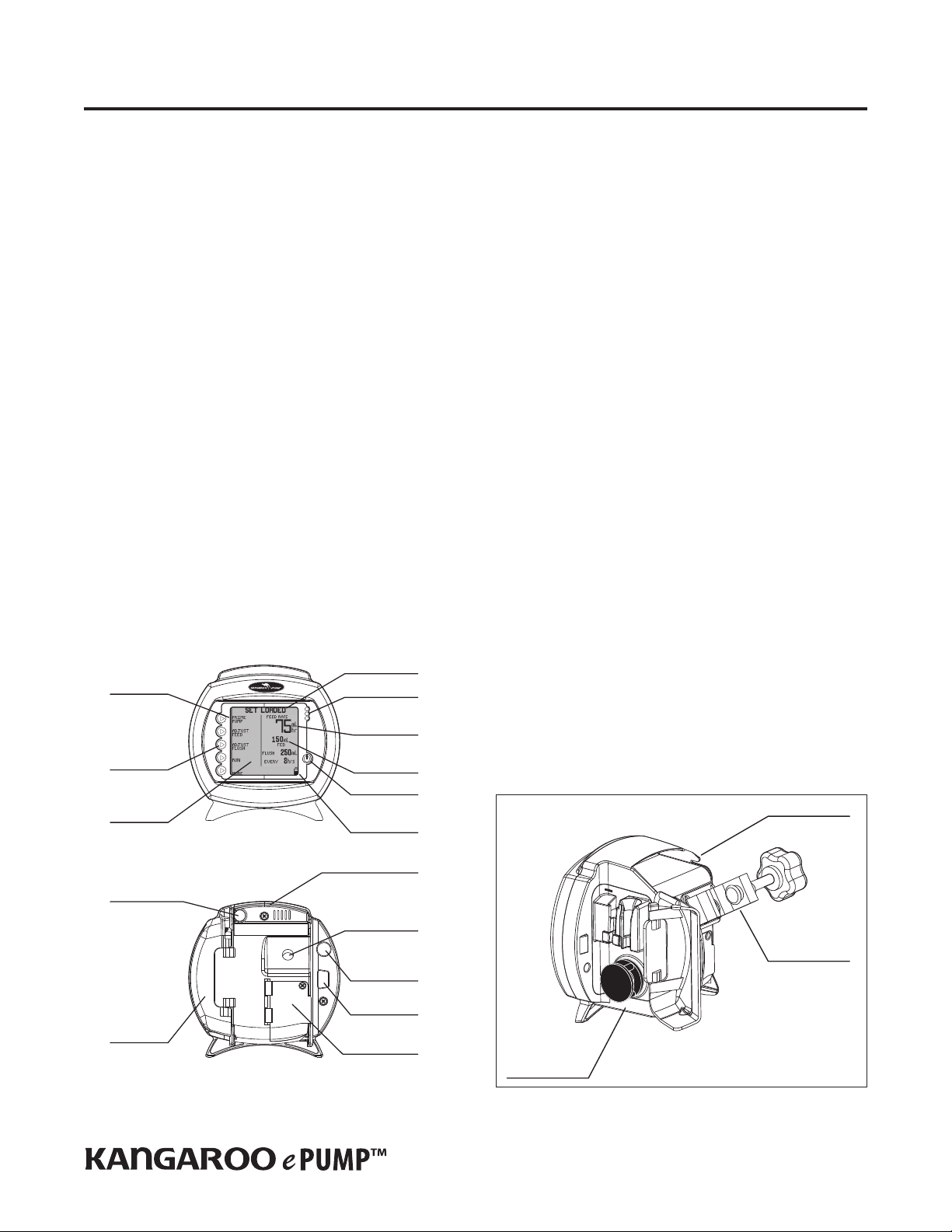

Section XII Assembly Diagrams and Reorder Numbers........................................................................................................................................................... 18

Assembly Diagrams ...................................................................................................................................................................................................... 18

Serviceable Parts Table................................................................................................................................................................................................. 23

Accessory Table............................................................................................................................................................................................................. 23

Section XIII Customer Service....................................................................................................................................................................................................... 24

Section XIV Warranty .................................................................................................................................................................................................................... 24

Section XV AccuSystem√TM........................................................................................................................................................................................................... 24

This product contains software solely owned by Tyco. Tyco grants the user a non-exclusive, limited license to use the software according to the operating instructions. A copy of the

license can be obtained from Tyco.

EN