LEAFLET S/C 120.415.482

© 2006 Tyco Safety Products PAGE 1 of 5

T210+ TEST SOURCE

FIL 0055

42/06

T210+ TEST SOURCE - OPERATING INSTRUCTIONS

1. INTRODUCTION

The T210+ Test Source is used to test Thorn Security S200 and

S200+ Series of infra-red flame detectors in both safe and

hazardous areas.

The T210+ is ATEX/IECEx approved for use in zones 1 and 2

for group IIC gasses rated T1 - T4. Approval for zone 0 is not

available for this type of equipment, although it is understood

that dispensation may be obtainable on a site-by-site basis from

the Factory Inspectorate.

WARNING:

UNDER NO CIRCUMSTANCES OPEN THE

T210+ HOUSING IN A HAZARDOUS AREA.

BATTERY CHANGES MUST BE MADE IN A

SAFE AREA.

2. DESCRIPTION

The T210+ consists of a module mounted in a cradle which can

be hand held or secured to an extendable pole. The module is

self-aligning on the detector by means of an adaptor secured to

the front of the cradle. The assembly is then held against the

detector to check the response time and sensitivity of the

detector.

The Test Source is enclosed in a glass filled polyester housing

which is approved as an increased safety or ‘e’ housing. It

contains a bulb which is electrically pulsed by an intrinsically

safe circuit to simulate typical flame flicker. Infra-red radiation

from the lamp is focused by a parabolic reflector through a

sapphire window onto the detector.

The unit is powered by a Baseefa approved PP3 battery (see 5.4).

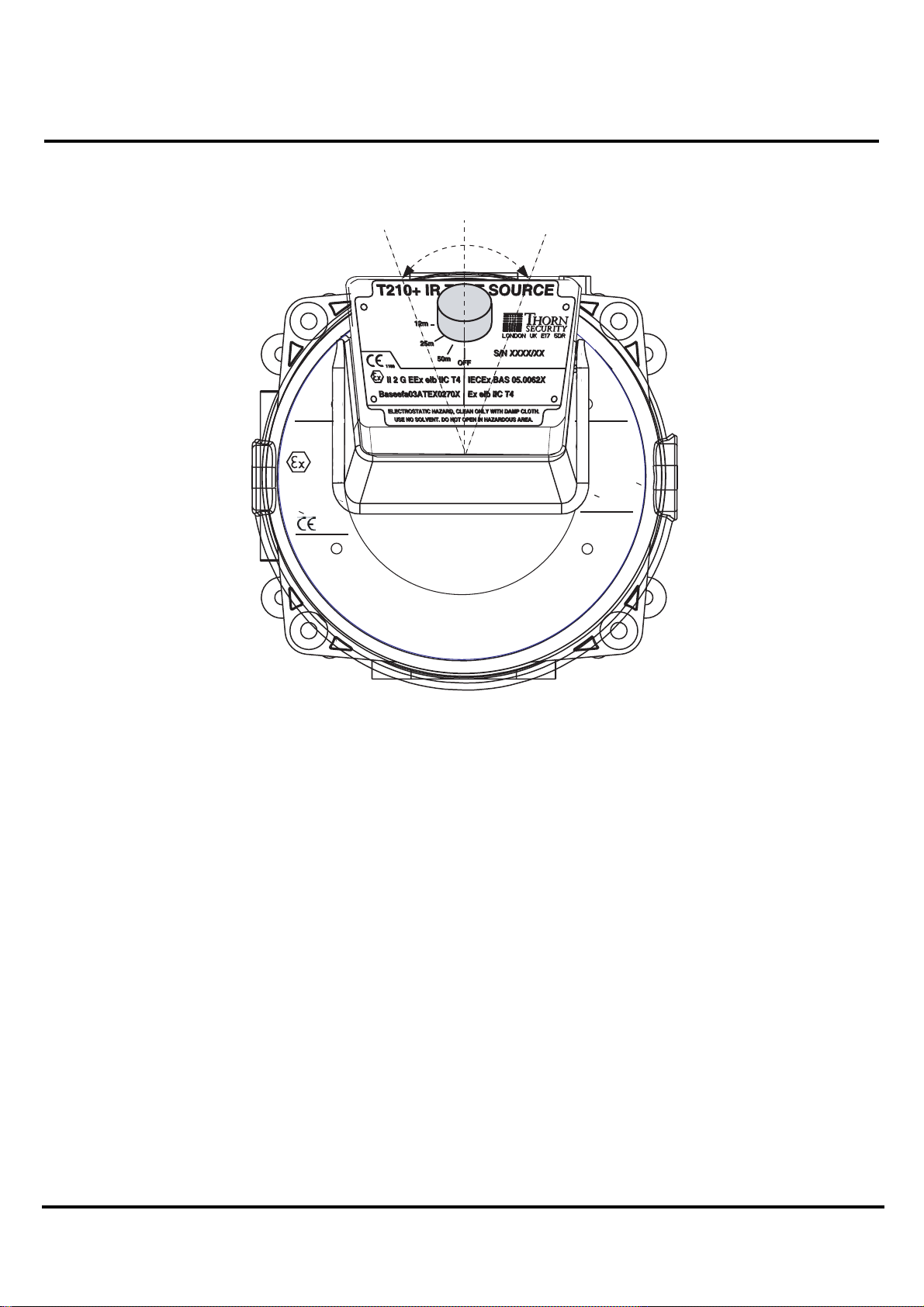

The T210+ is switched on with a rotary selector switch knob

located on the rear of the unit.

The switch has four positions:

1) OFF Off

2) 50m To test detectors set to 50m

range

3) 25m To test detectors set to 25m

range

4) 12m To test detectors set to 12m

range

Care must be taken to switch off the unit when not in use to avoid

battery drain.

3. PREPARING T210+ FOR USE

1) To assemble the T210+ to the S200 adaptor S/C No.

592.001.014, see Fig 1.

a) Assemble the S200 adaptor moulding/‘U’

bracket to the T210+ front plate using the three

screws provided.

b) Attach the pole bracket to the ‘U’ bracket/pole

stub assembly using the wing nut and nylon

washers provided. Tighten securely.

Note: Hereafter, the term T210+, refers to the T210+

fitted with the S200 adaptor, brackets and pole

stub.

2) To fit battery (in safe area) see below.

a) Ensure that the PP3 battery is fully charged.

b) Ensure that the T210+ rotary switch is in the

‘OFF’ position.

c) Remove the four back cover corner screws. Lift

off the box front containing the PCB and battery

holder. A lanyard is fitted to the T210+ to avoid

straining the lead connecting the lamp assembly

on the front box to the PCB on the back box.

d) Align the PP3 battery with the battery holder,

ensuring correct polarity alignment and push the

battery into the holder.

Note: The circuit is polarity protected but the unit will not

work with battery inserted the wrong way round.

e) Turn the rotary switch to the 12m position and

check that the lamp flashes. Turn the rotary

switch to the 25m position and check that the

lamp flashes more dimly. Turn the rotary switch

to the 50m and check that the lamp is very dim.

f) Turn the rotary switch to the OFF

position. Reassemble the back case to the front

cover with the four screws. Do not over tighten.

WARNING:

THIS IS A CALIBRATED UNIT. DO NOT

DISMANTLE THE REFLECTOR CLAMP

ARRANGEMENT.