64220, Rev. 1/April 2019

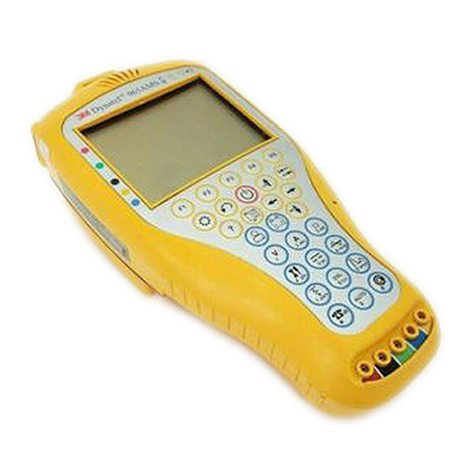

3M™ GMI™ PS200-LMP AUTO BUMP/CALIBRATION STATION

LIST OF FIGURES

iv

LIST OF FIGURES

Fig. # Figure Title Page #

2-1 PS200-LMP Auto Bump Calibration Station ..............................................................................2-1

3-1 Calibration Gas Setup.........................................................................................................................3-1

3-2 Gas Cylinder Labels............................................................................................................................ 3-2

3-3 Attach Regulator to Gas Cylinder..................................................................................................3-2

3-4 Connecting Tubing to a Barbed Fitting........................................................................................3-3

3-5 Connect Tubing to ‘Gas 1’ Inlet of ABC .......................................................................................3-3

3-6 ‘Air’ Inlet Connection .........................................................................................................................3-4

3-7 Connect Power Supply to ABC ......................................................................................................3-5

4-1 Warm-up Sequence (0-1 seconds) .................................................................................................4-1

4-2 Warm-up Sequence (1-24 seconds)...............................................................................................4-1

4-3 Warm-up Sequence (24-28 seconds)...........................................................................................4-1

4-4 Warm-up Sequence (28-29 seconds)...........................................................................................4-1

4-5 Warm-up Sequence (29-30 seconds)...........................................................................................4-1

4-6 Warm-up Sequence (30 seconds)..................................................................................................4-1

5-1 ABC ON Indicator ................................................................................................................................5-1

5-2 Open Front Cover ................................................................................................................................5-1

5-3 Locate Monitor on Gas Supply Nozzle ........................................................................................5-2

5-4 Monitor Correctly Seated.................................................................................................................5-2

5-5 Close Front Cover...............................................................................................................................5-3

5-6 Calibration in Progress ......................................................................................................................5-3

5-7 Monitor in HIHI Alarm .......................................................................................................................5-4

5-8 PASS Indication ...................................................................................................................................5-4

5-9 FAIL Indication .....................................................................................................................................5-4

5-10 Lift Monitor Clear of Gas Nozzle ...................................................................................................5-5

5-11 Test Error................................................................................................................................................5-5

6-1 ABC ON Indicator ................................................................................................................................6-1

6-2 USB Memory Stick Contents............................................................................................................6-1

6-3 PS200-LMP Settings .........................................................................................................................6-2

6-4 View Certificate...................................................................................................................................6-2

6-5 Certificate Details ...............................................................................................................................6-3

6-6 Results on USB Memory Stick.........................................................................................................6-3

6-7 Calibration Certificate .......................................................................................................................6-4

6-8 Bump Test Certificate........................................................................................................................6-5

6-9 Generated Certificates Folder ....................................................................................................... 6-6

6-10 Generated Certificates Files........................................................................................................... 6-6

7-1 USB Memory Stick Contents............................................................................................................ 7-1

7-2 PS200-LMP Settings .......................................................................................................................... 7-1

7-3 Select Bump Test or Calibrate ........................................................................................................ 7-2