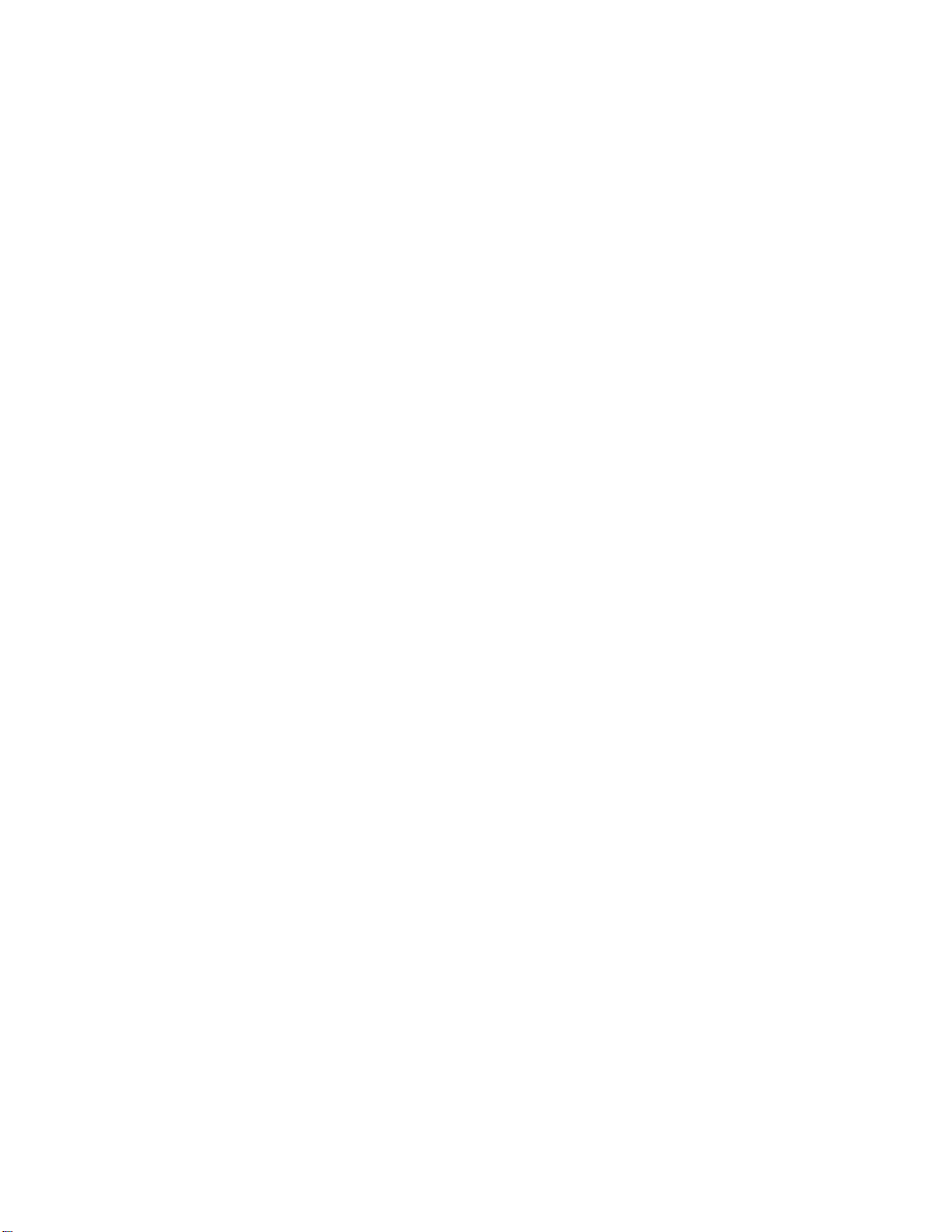

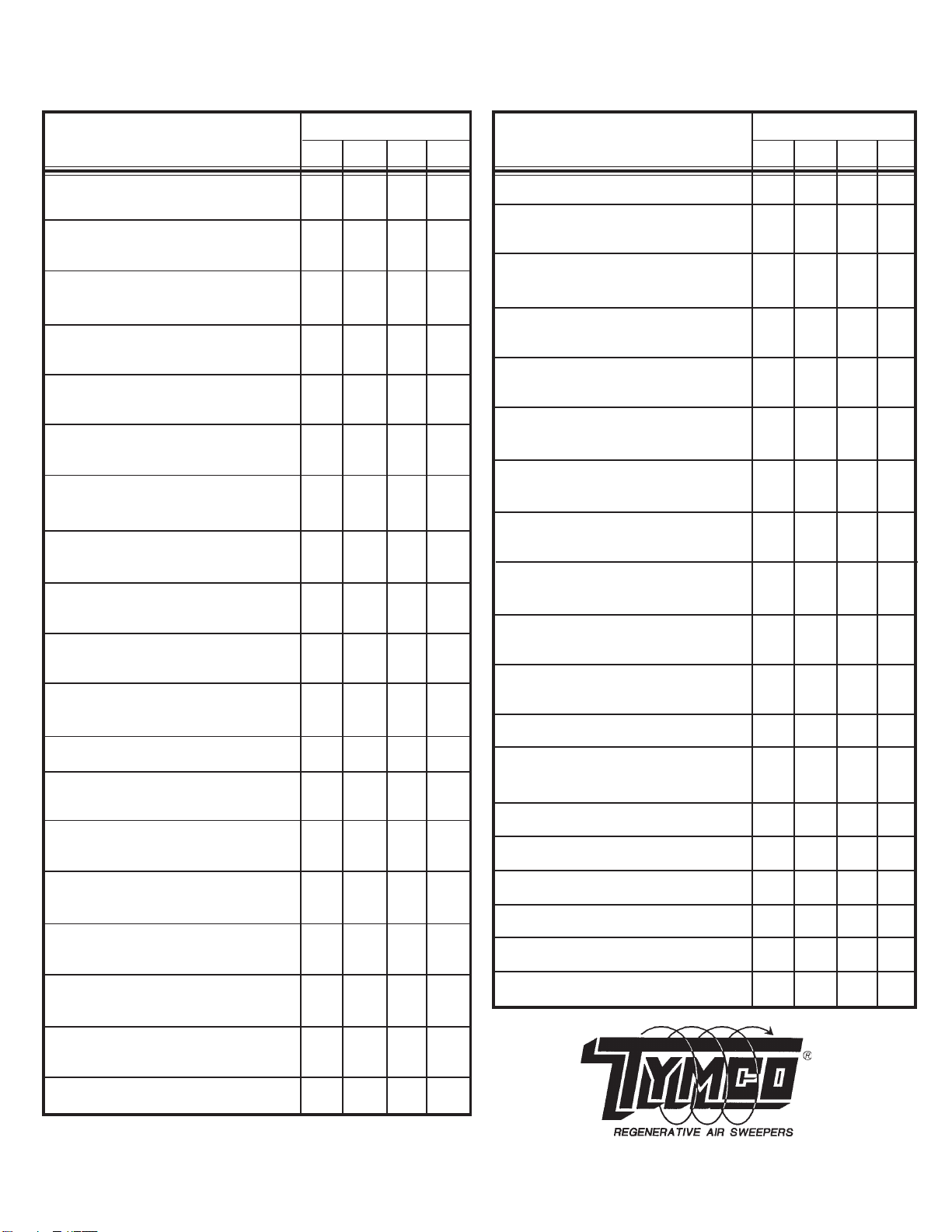

TIL-064 / August 4, 2006

TYMCO REGENERATIVE AIR SWEEPER INSPECTION

AND REPETITIVE TASK SCHEDULE

600 500X 435 210

ADJUSTMENT OF GUTTER BROOM(S) A/R A/R A/R A/R

CLEANING OF GUTTER BROOM D D D D

TORQUE MOTOR SHAFT AREA

ROTATE PRESSURE AND SUCTION 75 75 75 75

HOSES 1/4 TURN HRS HRS HRS HRS

CHECK OF HYDRAULIC TANK D D D D

FLUID LEVEL

CHANGE OF HYDRAULIC 100 100 100 100

SYSTEM FILTER HRS HRS HRS HRS

TANK BREATHER FILTER N/A 100 N/A N/A

HRS

RETURN LINE FILTER - RESTRICTION N/A 100 N/A N/A

INDICATOR HRS

CHARGE LOOP FILTER - RESTRICTION N/A 100 N/A N/A

INDICATOR HRS

HYDRAULIC SYSTEM OIL CHANGE 1000 1000 1000 1000

NOTE: INITIAL CHANGE AT 100 HRS HRS HRS HRS HRS

CHANGE OF WATER PUMP OIL 150 150 150 150

(IF APPLICABLE) HRS HRS HRS HRS

CLEANING OF SPRAY NOZZLE TIPS A/R A/R A/R A/R

AND SCREENS

DRAIN WATER TANK D D D D

CLEANING OF HOPPER AND DUST D D D D

SEPARATOR CHAMBER

AUXILIARY ENGINE FLUID LEVEL CK. D D D D

WASHDOWN OF ENGINE RADIATOR(S) D D D D

FUNCTIONAL TEST SWEEPER LIGHTS D D D D

FUNCTIONAL TEST OF TRUCK BRAKES D D D D

FUNCTIONAL TEST OF TRUCK LIGHTS D D D D

MOUNT TRUCK FLUID LEVEL CHECK D D D D

PERFORM MODEL

600 500X 435 210

GUTTER BROOM(S) FOR IMPACT D D D D

DAMAGE/WEAR

PICK-UP HEAD BLAST ORIFICE FOR D D D D

LODGED FOREIGN MAT'L/ADJUSTMENT

PICK-UP HEAD TURNING VANES 100 100 100 100

FOR WEAR/FOREIGN MATERIAL HRS HRS HRS HRS

PICK-UP HEAD SKID PLATES FOR D D D D

WEAR AND IMPACT DAMAGE

PICK-UP HEAD CURTAINS FOR D D D D

WEAR/DAMAGE

PRESSURE AND SUCTION HOSES 100 100 100 100

FOR WEAR HRS HRS HRS HRS

HYDRAULIC SYSTEM FOR PLUMB- D D D D

ING OR COMPONENT LEAKAGE

WATER PUMP OIL LEVEL D D D D

(IF APPLICABLE)

WATER FILLER HOSE FILTER D D N/A N/A

SCREEN

WATER PUMP SUCTION HOSE D D D D

PRE-FILTER

ALL HOPPER AND TRANSITION D D D D

SEALS FOR WEAR/DAMAGE

HOPPER SCREEN FOR DAMAGE D D D D

DUST SEPARATOR LINER FOR D D N/A N/A

WEAR/DAMAGE

DUST SEPARATOR DOOR CLOSED D D N/A N/A

BEFORE OPERATING

BLOWER WHEEL FOR 100 100 100 100

WEAR/DAMAGE HRS HRS HRS HRS

ACCESSIBLE AREAS OF BLOWER 100 100 100 100

HOUSING LINER FOR WEAR/DAMAGE HRS HRS HRS HRS

BLOWER LIP FOR WEAR/DAMAGE 100 100 100 100

HRS HRS HRS HRS

ENGINE AIR INTAKE FILTER D D D D

RESTRICTION INDICATORS

MOUNT TRUCK TIRES D D D D

INSPECT MODEL

D = DAILY

HRS = HOURLY INTERVALS

A/R = AS REQUIRED