Page 5SKU 92649 For technical questions, please call 1-800-444-3353

PRODUCT OVERVIEW

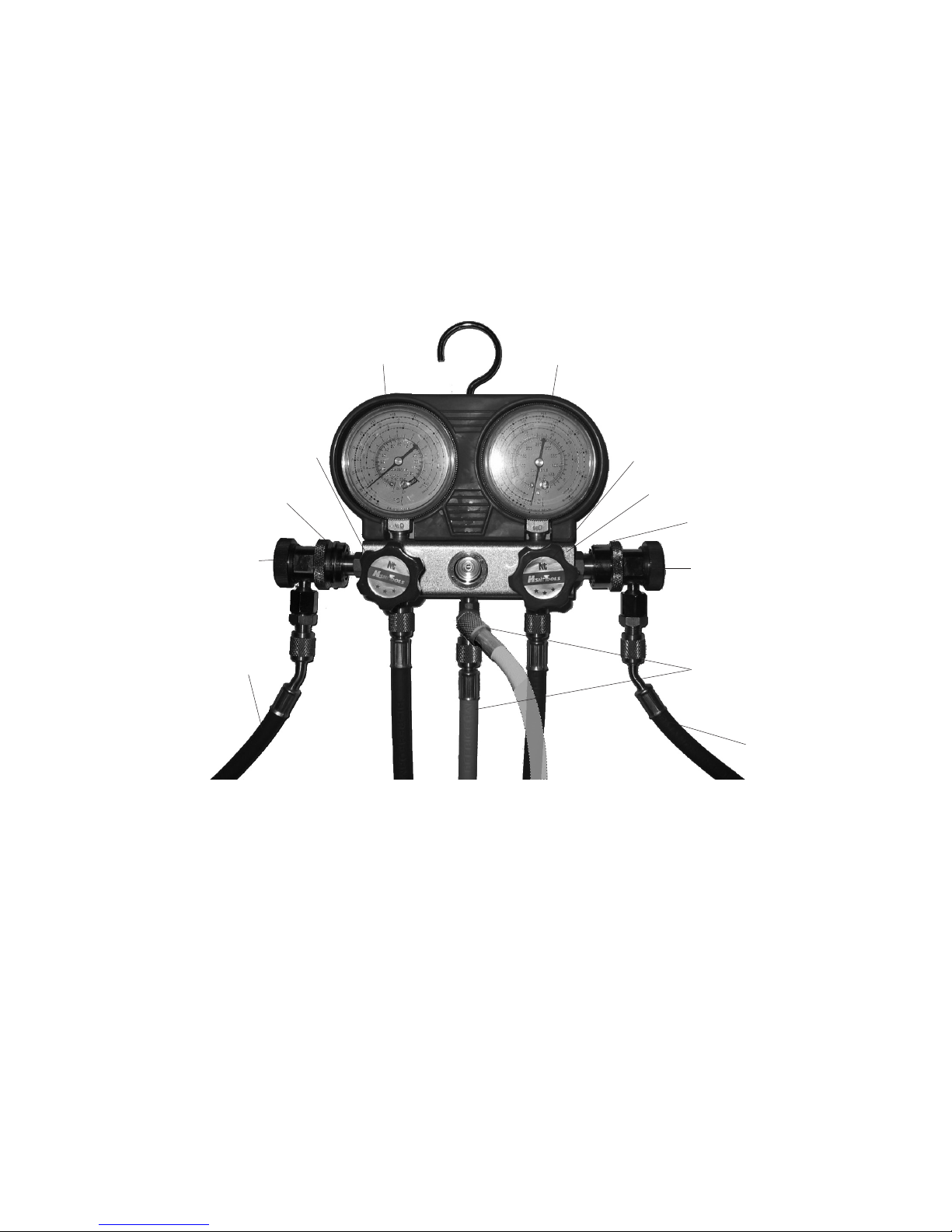

1. The A/C Manifold Gauge Set is designed to test automotive air conditioning systems.

By comparing the high side and low side pressure reading to the vehicle manufacturer’s

A/C system specifications, a probable faulty condition may be determined.

2. The High Pressure Gauge (3) is used to measure compressor discharge pressure.

The Low Pressure Gauge (5) is used to measure suction, or low side pressure. (See

FIGURE 1 on page 6.)

3. The Red and Blue Thumb Handles (11) control the flow of refrigerant to and from the

Yellow Refrigeration Charging Hose (18), also called the Service Hose. The actual use

of these Thumb Handles will not be explained in this manual. (See FIGURE 1.)

4. The valves on the Red High Pressure Coupler (22) and Blue Low Pressure Coupler (23)

control the input to the High Pressure Gauge (3) and Low Pressure Gauge (5) from the

Red High Pressure Hose (17) and Blue Low Pressure Hose (19). (See FIGURE 1.)

5. The Yellow Refrigeration Charging Hose (18), also called Service Hose, is connected

to a vacuum pump for purging the system (cleaning or evacuating). The Yellow Refrig-

eration Charging Hose (18) also is connected to a container of R-134A Refrigerant for

charging (filling) the system. For testing, the Yellow Hose (18) not used and is attached

to both branches of the T-fitting (16) on the Manifold Body (2) (see FIGURE 1).

6. General instructions for testing an A/C system are outlined in this manual. Specific

procedures for each individual system type and model should be referenced in the

vehicle manufacturer’s specific A/C system service manual.

7. Although this kit may have some utility in these procedures, instruction is NOT provided

for the evacuation and recovery of the system. All technicians opening the refrigeration

circuit in automotive air conditioning systems MUST be certified in refrigerant recovery

and recycling procedures - see box on front cover.

Operation

Refer to the Assembly Drawing on page 8.

To Conduct a Static A/C Pressure Reading:

1. Make sure the vehicle’s engine is NOT running, and the A/C system is OFF.

2. Turn the Red Thumb Handle (11) and BlueThumb Handle (11) clockwise, to the CLOSED

position. See FIGURE 1 on page 6.

WARNING: DO NOT, AT ANY TIME, OPEN the Thumb Handles (11) or refrigerant will be

leaked to the atmosphere and the A/C system may become contaminated.

3. Note: Before connecting the Red High Pressure Coupler (22) and the Blue Low Pres-

sure Coupler (23) make sure the Control Valves are closed. To close, turn each control

valve counterclockwise.

4. Connect the Red High Pressure Coupler (22) to the A/C system high side line.

See FIGURE 1 on page 6.

5. Connect the Blue Low Pressure Coupler (23) to the A/C system low side line.

See FIGURE 1 on page 6.

6. Connect both ends of the Yellow Refrigeration Charging Hose (18) to both branches of

the T-fitting (16) on the Manifold Body (2). See FIGURE 1 on page 6.

7. Turn the Control Valves of the Red High Pressure Coupler (22) and Blue Low Pressure

REV 05f