U.S. General 5223 User manual

17-PIECE

HEAVY DUTY SLIDE

HAMMER KIT

Model

5223

INSTRUCTIONS AND

PRECAUTIONS

Visit our website at: http://www.harborfreight.com

SAVE THESE

INSTRUCTIONS.

READ ALL

PRECAUTIONS AND

INSTRUCTIONS.

Copyright©2009 by Harbor Freight Tools®. All rights

reserved. No portion of this document or any artwork

contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight

Tools. Diagrams within this document may not be drawn

proportionally. Due to continuing improvements, actual

product may differ slightly from the product described herein.

Tools required for assembly and service may not be included.

For technical questions or replacement parts,

please call 1-800-444-3353.

SPECIFICATIONS

Functions (8):

Internal or external 3-jaw puller

Internal or external 2-jaw puller

Puller hook

Rear axle puller

Dent puller

Threaded Puller/Wrench Adapter

UNPACKING

When unpacking, make sure that the item is

intact and undamaged. If any parts are missing or

broken, please call Harbor Freight Tools at

1-800-444-3353 as soon as possible.

IMPORTANT SAFETY INFORMATION

Wear ANSI-approved safety goggles and heavy-1. duty work gloves during assembly and use.

Inspect before every use; do not use if parts are2. damaged.

Do not use for aircraft purposes; use as intended3. only.

Do not modify Slide Hammer to perform a task4. other than what it was designed for.

Read vehicle owner’s manual and instruction5. manual for Jack (not included) for proper jacking

positions (where applicable) before use.

Assemble only according to instructions.6. Improper assembly can create hazards.

This product is not a toy. Do not allow children to7. play with or near this item.

Maintain product labels and nameplates. These8. carry important safety information. If unreadable

or missing, contact Harbor Freight Tools for a

replacement.

Harbor Freight Tools is not responsible for9. cosmetic damages to vehicle’s appearance due

to improper use or lack of experience for using

this type of tool.

ASSEMBLY INSTRUCTIONS

Read the ENTIRE IMPORTANT SAFETY

INFORMATION section at the beginning

of this document including all text under

subheadings therein before set up or use

of this product.

Page 2 For technical questions, please call 1-800-444-3353. SKU 5223

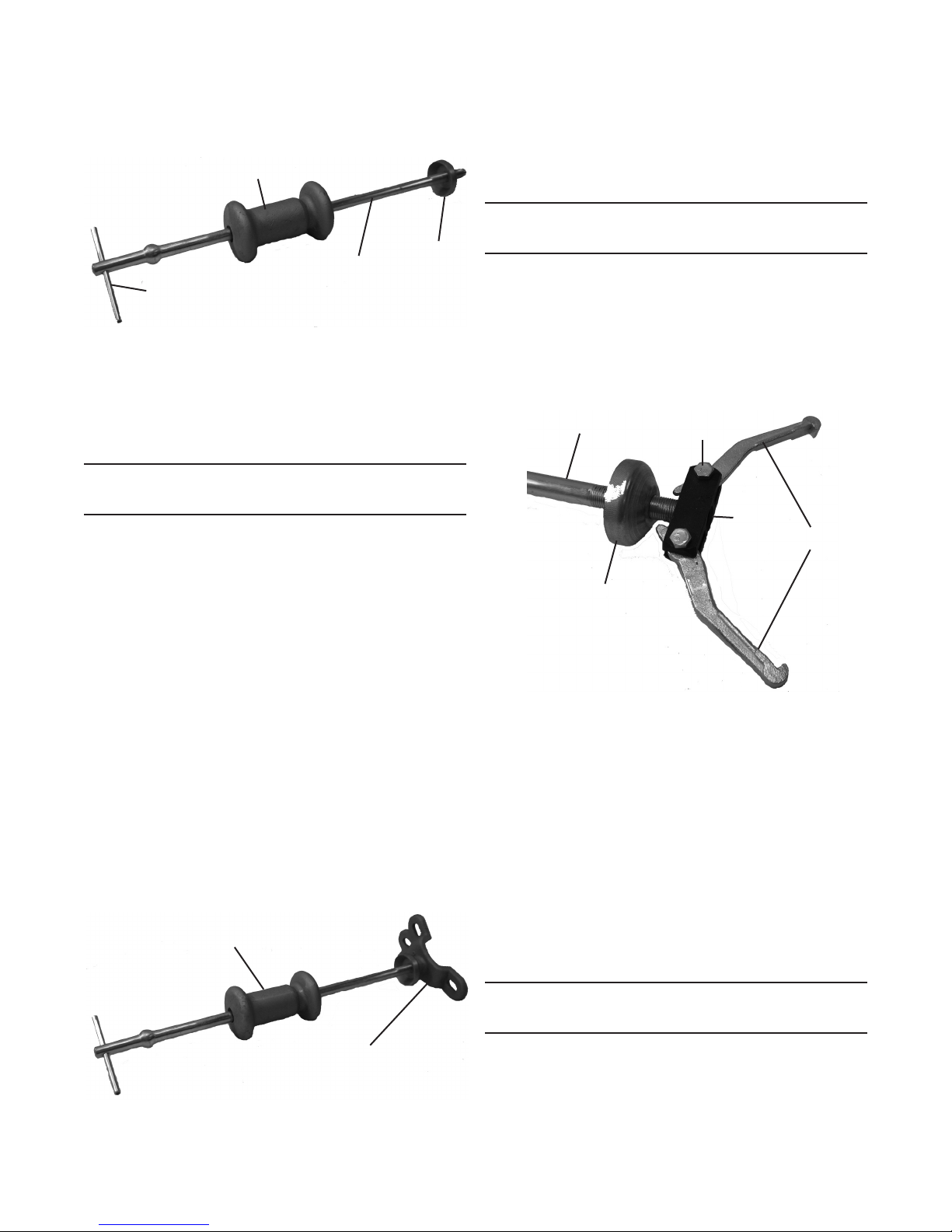

Slide the plane end of the Slide Hammer (12)1. onto Spindle (11). See Figure 1. Insert Cross

Bar (9) into eyelet at the end of the Spindle.

Note:2. The Lock Nut serves as a Hammer Stop

for the forward motion of the Slide Hammer (12)

and should be assembled prior to every task that

requires a pulling attachments. See Figure 1.

PULLING OPERATION

(HUB/AXLE/DRUM)

Thread hollow end of Lock Nut (3) onto Spindle.1.

Jack up the vehicle according to your vehicle’s2. Owner’s Manual. Make sure the car is safely

supported by Jack Stands (not included).

Remove the wheel and tire and any nuts, bolts or3. accessories (such a brake calipers) that may get

in the way of removing the Hub/Axle/Drum.

Bolt the Rear Axle Puller (2) onto the Hub/Axle/4. Drum using the original lug nuts. If your vehicle

has a four-bolt Hub, match the Rear Axle Puller

to two axle bolts. If it has a ve-bolt Hub, match

to three axle bolts. Tighten the lug nuts.

Remove the Spindle (11), Handle Cross Bar (9),5. Lock Nut and Slide Hammer from the carrying

case. Assemble according to Figure 1.

Thread the Spindle into the Rear Axle Puller hub6. until its non-threaded end exits the hub. Turn

the Lock Nut (3) forward until it seats against the

Rear Axle Puller hub and hand tighten.

Push the Slide Hammer towards the vehicle.7. Forcefully pull the Slide Hammer toward the

Handle end of the Slide Screw.

Repeat Step 6 until the Hub/Axle/Drum comes8. off.

JAW OPERATION OR EXTRACTION

(EXTERNAL GRIP)

Attach the hollow end of the Lock Nut (3) onto1. the Spindle.

Depending on the application or requirement, use2. the Screws and Nuts to attach the Jaws to the

2 or 3 Jaw Puller Adapters (6 or 10). Thread the

adapter onto the Spindle until non-threaded end

of the Spindle exits the Adapter.

To grip the work piece externally, claws of the3. Jaws should be facing inward, as shown in

Figures 3 and 4.

Clamp the Jaws onto the object to be pulled.4. Turn Lock Nut (3) clockwise against the end of

the Jaws, forcing them apart, causing the claws

to be pushed inward against the work piece.

Tighten the Screws and Nuts rmly.

Push the Slide Hammer towards the work-piece,5. and then forcefully pull it back towards the cross

par end. Repeat as needed, and adjust the

required force based on job requirement or your

physical ability.

JAW OPERATION OR EXTRACTION

(INTERNAL GRIP)

Attach the conic end of the Lock Nut (3) onto the1. Spindle.

Depending on the application or requirement, use2. the Screws and Nuts to attach the Jaws to the

Lock Nut

(3)

Spindle

(11)

Figure 1

Slide Hammer (12)

Figure 2

Rear Axle Puller (2)

Slide Hammer

(12)

Cross Bar (9)

Figure 3

Jaws (4)

Lock Nut

(3)

Spindle (11)

2-Jaw

Puller

Adapter

(6)

Screw

and Nut (1)

Page 3For technical questions, please call 1-800-444-3353.SKU 5223

2 or 3 Jaw Puller Adapters (6 or 10). Thread the

adapter onto the Spindle until non-threaded end

of the Spindle exits the Adapter.

To grip the work piece internally, claws of the3. Jaws should be facing outward.

Back-off the Lock Nut (3) to permit the jaws to4. be attached to the workpiece. Turn the Lock Not

forward, causing the claws to expand and grip

the work piece rmly. Tighten the fasteners.

Push the Slide Hammer towards the work-piece,5. and then forcefully pull it back towards the cross

par end. Repeat as needed, and adjust the

required force based on job requirement or your

physical ability.

OPERATION

(DENT PULLING)

Attach hollow end of the Lock Nut onto Spindle.1.

Drill a 1/8” hole into the center of the dent.2.

Place the Self-Threading Screw (13) through the3. Dent Puller Adapter (7). See Figure 5.

Thread the Self-Threading Screw into the drilled4. hole using a #2 Phillips screwdriver.

Thread the Spindle into the Dent Puller Adapter.5. Thread the Lock Nut (3) against the Dent Puller

Adapter and hand tighten. See Figure 5.

Push the Slide Hammer toward the object to be6. pulled. Gently pull the Slide Hammer toward the

Handle Cross Bar.

CAUTION!7. Do not use excessive force when

pulling dents. Sheet metal can easily bend.

Repeat Step 5 until dent has been pulled out.8.

OPERATION

(HOOK/THREAD PULLING)

Identify the lip area you will be inserting the Pull1. Hook (5) into or onto.

Thread the Puller Hook onto the end of the Slide2. Screw. See Figure 6.

Place the Puller Hook tip onto the edge of the lip3. of object to be pulled.

Push the Slide Hammer toward the object to be4. pulled. Gently pull the Slide Hammer toward the

Handle Cross Bar.

Repeat Step 4 until object has been pulled out.5.

The Screw Adapter (8) can be used for larger6. cross sections, heavier sheet metal, and

concentrated deep dents. See Figure 7.

Follow the Steps 1-5 until threaded object has7. been pulled out.

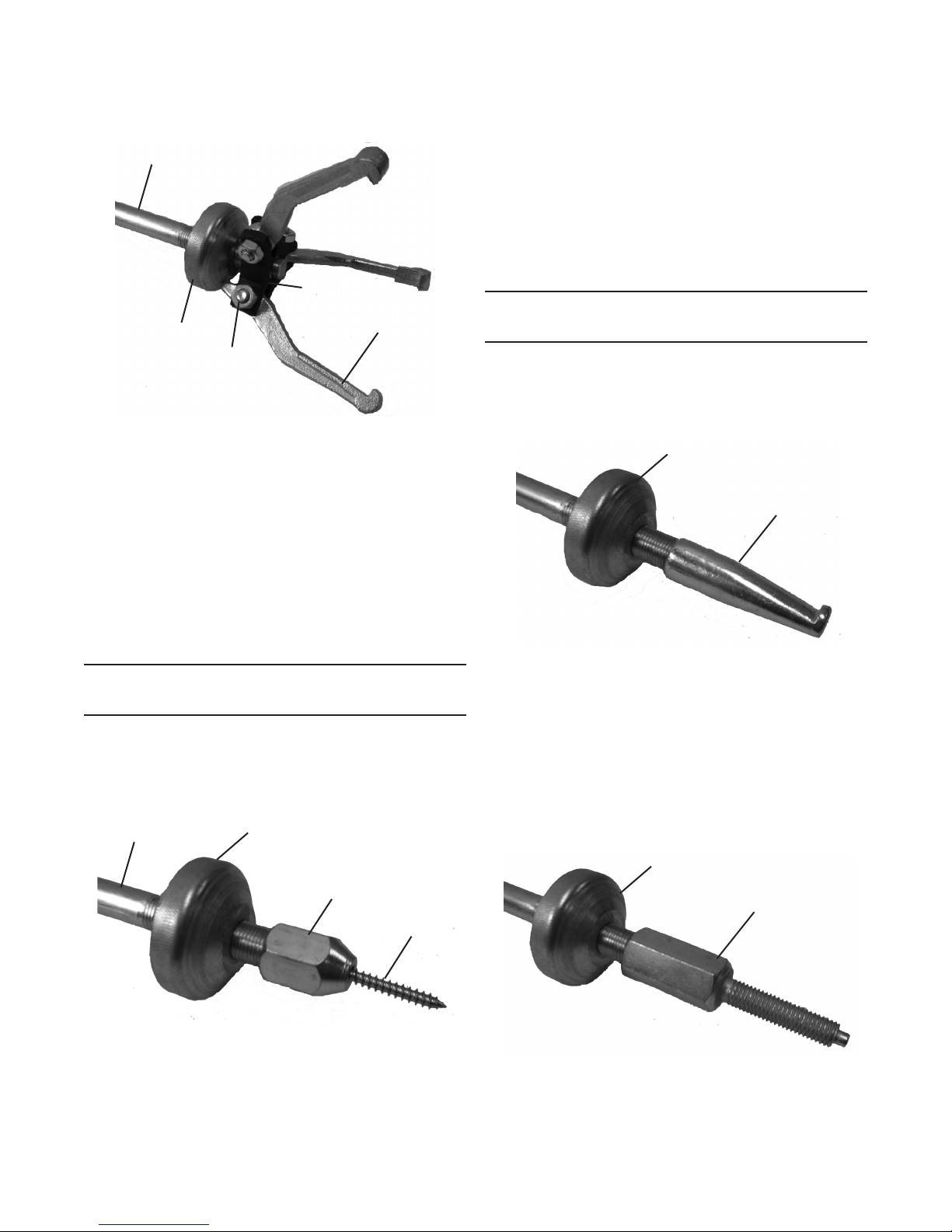

Figure 4

Spindle (11)

Lock Nut

(3)

Jaws (4)

3-Jaw

Puller

Adapter

(10)

Screw

and Nut (1)

Figure 5

Lock Nut

(3)

Self-Threading

Screw (13)

Dent Pull

Adapter (7)

Lock Nut

(3)

Figure 6

Puller Hook (5)

Figure 7

Lock Nut

(3)

Screw Adapter (8)

Spindle (11)

Page 4 For technical questions, please call 1-800-444-3353. SKU 5223

PARTS LIST & ASSEMBLY DIAGRAM

Part Description Qty.

1 Screw and Nut Set (M8 x 1.25) 3

2 Rear Axle Puller 1

3 Lock Nut 1

4 Jaw 3

5 Puller Hook 1

6 2-Jaw Puller Adapter 1

7 Dent Puller Adapter 1

8 Screw Adapter (M12 x 1.75) 1

9 Handle Cross Bar 1

10 3-Jaw Puller Adapter 1

11 Spindle 1

12 Slide Hammer 1

13 Self-Threading Screw 1

Record Serial Number Here:

Note:If product has no serial number, record month

and year of purchase instead.

Note:Some parts are listed and shown for illustration

purposes only, and are not available individually

as replacement parts.

LIMITED 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to

assure that its products meet high quality and durability

standards, and warrants to the original purchaser that this

product is free from defects in materials and workmanship

for the period of 90 days from the date of purchase.

This warranty does not apply to damage due directly or

indirectly, to misuse, abuse, negligence or accidents,

repairs or alterations outside our facilities, criminal

activity, improper installation, normal wear and tear, or

to lack of maintenance. We shall in no event be liable for

death, injuries to persons or property, or for incidental,

contingent, special or consequential damages arising

from the use of our product. Some states do not allow

the exclusion or limitation of incidental or consequential

damages, so the above limitation of exclusion may

not apply to you. THIS WARRANTY IS EXPRESSLY

IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or

part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of

the complaint must accompany the merchandise. If our

inspection veries the defect, we will either repair or

replace the product at our election or we may elect to

refund the purchase price if we cannot readily and quickly

provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no

defect, or that the defect resulted from causes not within

the scope of our warranty, then you must bear the cost

of returning the product.

This warranty gives you specic legal rights and

you may also have other rights which vary from state to

state.

3491 Mission Oaks Blvd. • PO Box 6009 •

Camarillo, CA 93011 • (800) 444-3353

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN THIS DOCUMENT AS

A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY

OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE

IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS,

AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT

PARTS THERETO.

1

2

3

4

5

67

9

10

11

12

13

8

Other U.S. General Tools manuals