9

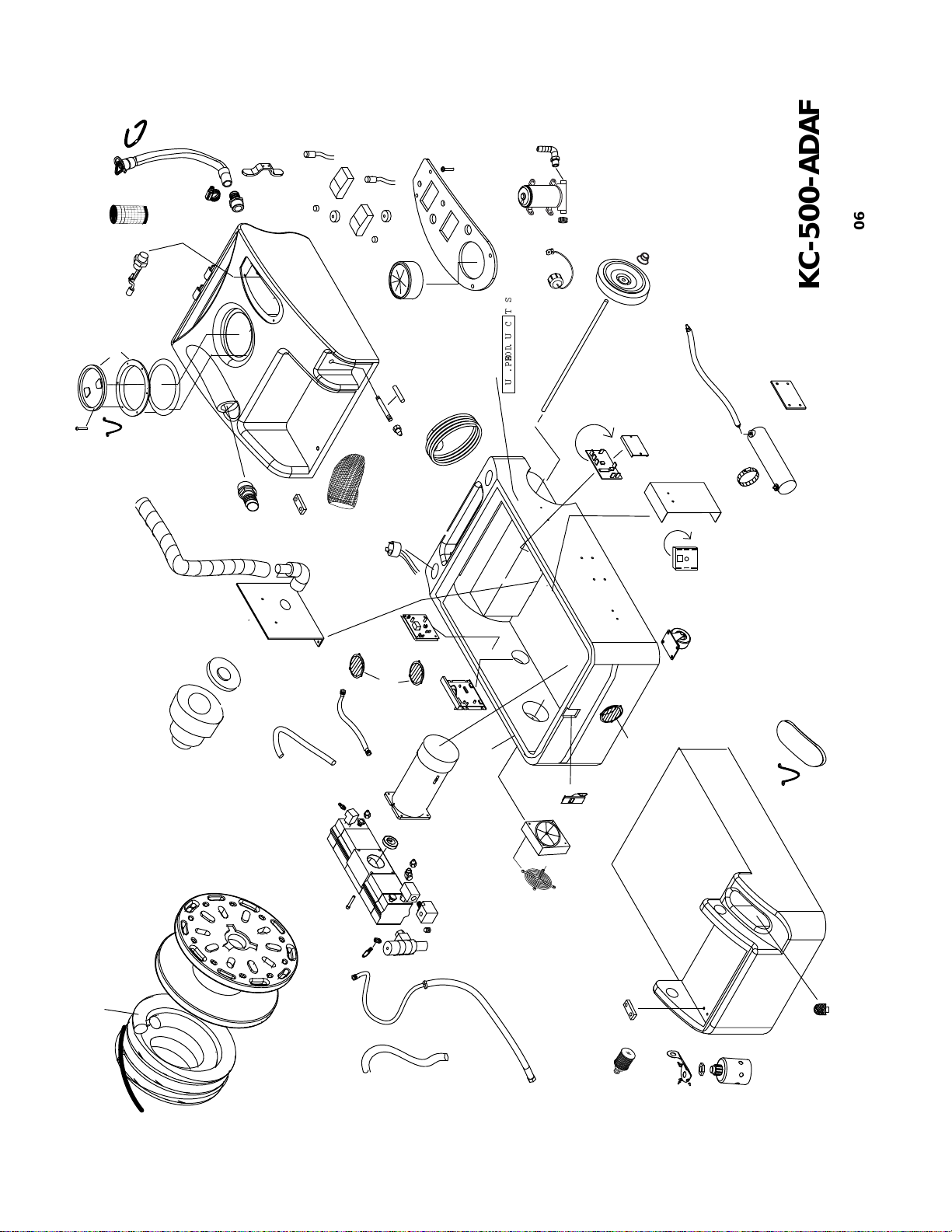

KING COBRA-500-ADAF

Part List

1 FP436 Chain, for lid

2 901B Lid, for solution tank

3 HKCR-1 Holding Tank

4 1088 Glide, Teflon, for reel

5 913 Vacuum motor

6 959 Gasket, vacuum

8 1136 Hose, vacuum

9 926 Manifold, gasket

10 907 Hose barb, vacuum inlet

11 2086A Lid & Ring, vacuum tank

12 1074 Gasket, vacuum lid

13 2026 Float, electronic

14 926 Filter, vacuum inlet

15 1060C Cap, drain hose

16 1060B Hose, drain

17 1518 Clamp, hose

18 CWKC-BLK Cord Wrap

19 1130 Strap, hook & loop

20 1088 Glide, for reel

21 925 Hose, pump inlet, 1/2” X 24”

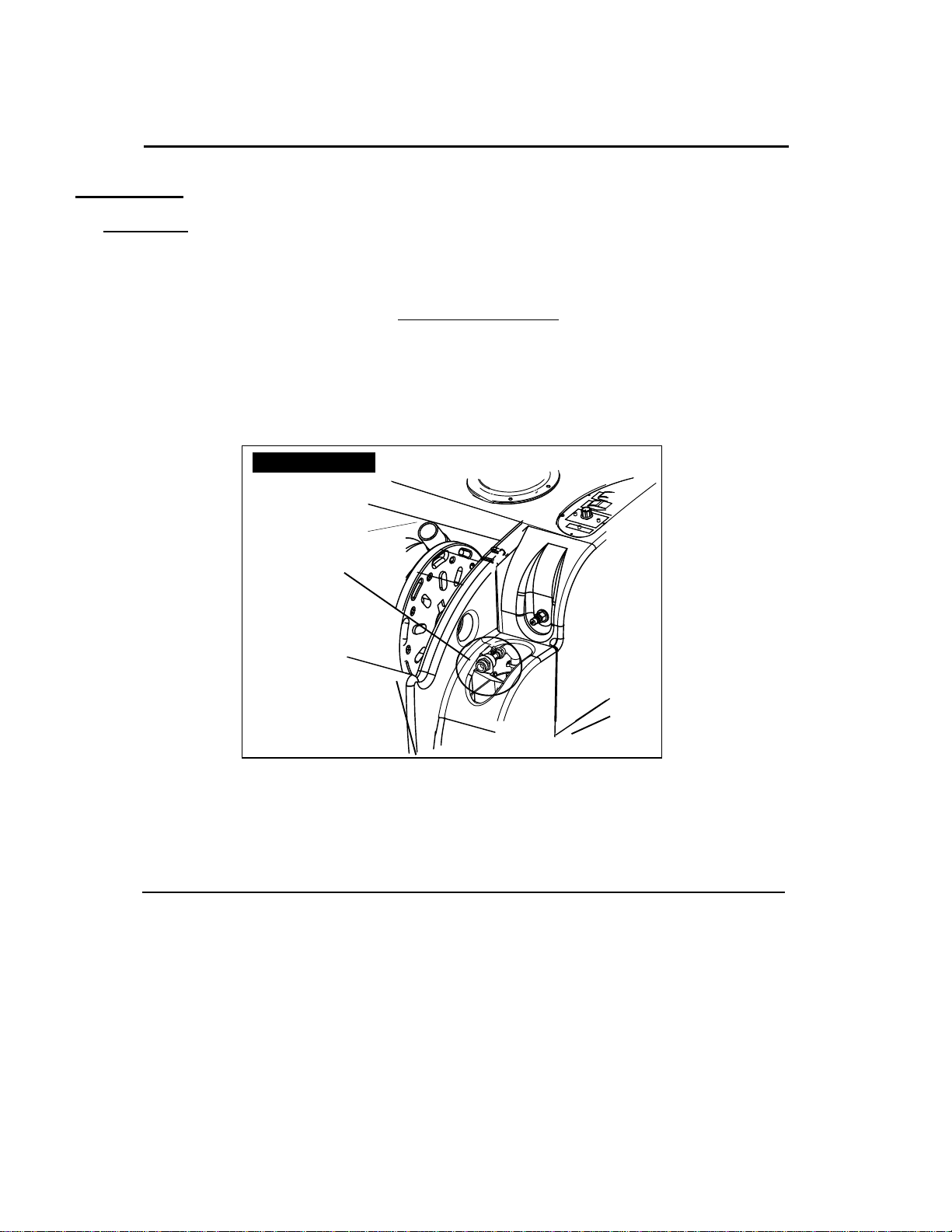

22 FP410 Pump complete, no motor

23 948B Motor, pump drive

24 945D Valve, pressure regulator

25 944 Hose, pump to gauge

26 946 Hose, pump bypass, 3/8” X 24”

27 FP411A Hose, pump to heater, w/QDs

28 928 Louver, 3”

29 FP361 Control board, pump motor speed

30 2088 Pre-filter, vac inlet

32 FP225 Control board, vacuum soft start

34 1062 Receptacle, power cord

35 1057B Power cord, 25 ft

37 45 Quick disconnect, solution output

38 1146 Pipe, 1.4 pipe X 6.85”

39 1144A Tubing, 5/8” X 5”

40 HKCR-1 Tank, solution holding

42 78B Light, Red

44 248 Knob, red

45 FP347 Potentiometer, with wires, for heat

47 FP346 Switch, Heat Bypass

48 FP345 Switch, Vacuum

49 249 Knob, Pump pressure control

50 FP399 Potentiometer, with cable, pump

52 78 Light, green

54 951B Gauge, pump pressure

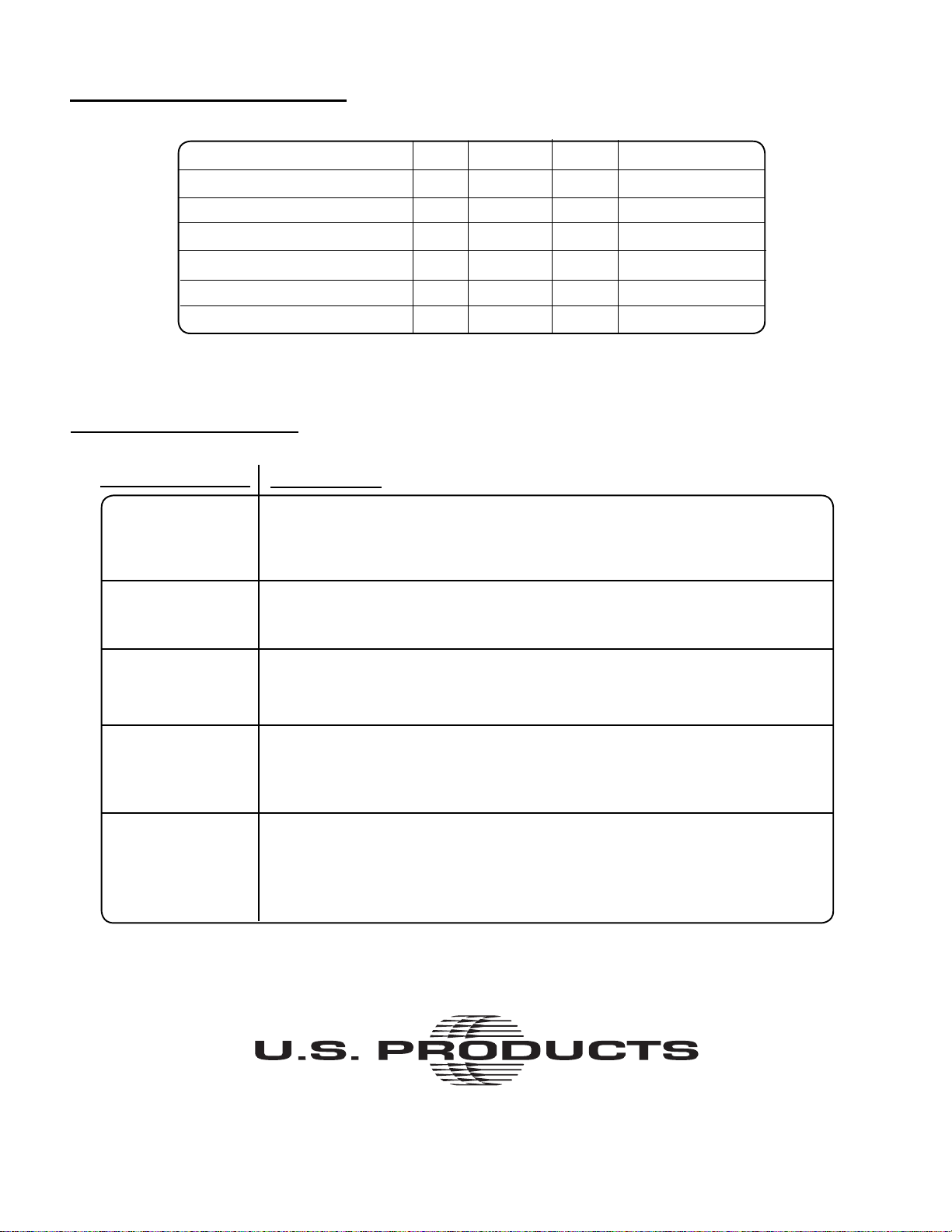

ITEM PART No DESCRIPTION

120V

6-4-2009

55 943B Plate, switch holding

56 2067 Pump, auto pump out

58 1081 Elbow/Hose barb, 90°

59 239 Coupling, Hose adaptor

60 237 Cap, for hose fitting

61 1128 Label

62 910-21.00 Axle rod, 21”

63 2084 Wheel, 10”

65 27A Axle cap

66 932B Circuit board, dual circuit detect

67 FP336 PCB mounting track, 4”

69 FP194E Heat repair kit

70 918 Heat sink plate

72 198 Clamp, hose

73 FP348 Heat exchanger, complete

75 1134 Hose, Heater to outlet, 29”

77 445 Plate, heater mounting

79 901B Lid, for solution holding tank

80 805 Chain

81 BKCR-BLK Base compartment

82 1043A Gasket, 93.5”

83 1014 Fan, cooling

84 2015 Guard, fan

85 908A Latch and strike

89 HKCR-1 Holding tank

90 2069 Filter, dump pump inlet

91 1320A Bracket

92 1310A Valve, auto-fill shut-off

94 207A Filter, solution pump inlet

ITEM PART No DESCRIPTION

Miscellaneous parts and Assemblies

FP409 Pump and motor, complete w/unloader

950CP Pump rebuild kit, valves and O-Rings

250 Pump rebuild kit, piston and seals

SYP1 Priming hose

FP350C Pressure line and vacuum hose, complete

FP469 Swivel and hose assembly, 16-1/2”

948C Brush, carbon, for pump motor (order 2)