FLOOD PUMPER 120V

PART LIST

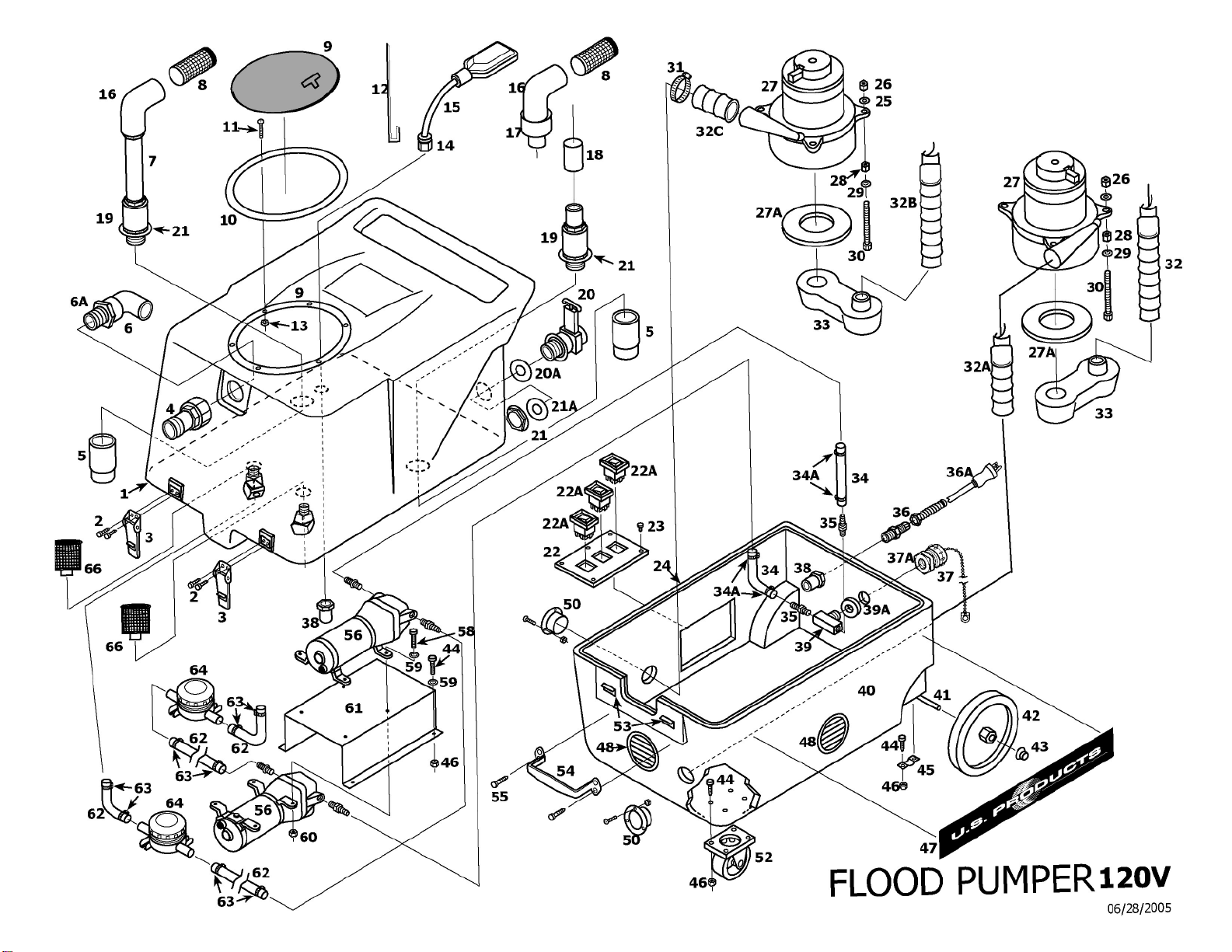

#1 FP389 Recovery Tank, Complete

#2 382C Screw, Stainless Steel, 8-32" X 7/8"

#3 908 Latch

#4 2077 Hose Barb, Vacuum Inlet

#5 2073 Elbow, PVC, 2”

#6 2075 Adaptor, PVC, 1-1/2”

#7 935 Pipe, PVC

#8 929 Filter, Vacuum Inlet

#9 2070B Lid, with Ring** (see Misc.)

#10 1129 Gasket, for Lid** (see Misc.)

#11 382 Screw, 10/32 x 7/8”, S/S

#12 2082 Bracket, Float

#13 17 Lock Nut, Nylon, 10-32, S/S

#14 230 Retainer, Cord, Water Tight

#15 2068 Float Switch

#16 900 Elbow, PVC, 90 Degrees

#17 935 Pipe, PVC, 1-1/2 ID

#18 2081 Check Valve

#19 900A Reducer, PVC

#20 903 Drain Gate* (see Misc.)

#20A 187 O-Ring, Small

#21 185 Nut, Cast Aluminum

#21A 190 O-Ring, Large

#22 2006 Switch Plate

#22A FP311 Switch, Pump, Vacuum, w/Cover

#23 28 Screw, #4 x 3/8”

#24 FP228A Gasket, Base

#25 14 Washer, 3/16"

#26 8 Lock Nut, 1/4-20

#27 FP324 Vacuum Motor Complete w/Connectors

#27A 2013 Gasket, Vacuum Motor

#28 136 Nut, 1/4-20

#29 137 Washer, Lock, 1/4"

#30 135 Bolt, 1/4-20 x 3-1/2”

#31 156 Hose Clamp, Size 28

#32 1302 Hose, Vacuum, 2” x 13”

#32A 430 Hose, Vacuum, 2” x 9”

#32B 1301 Hose, Vacuum, 2” x 18”

#32C 430 Hose, Exhaust, 2” x 2”

#33 MA-6 Manifold, Black

#34 2079 Hose, 3/4”, Polywire, 11”

#34A 380 Hose Clamp

#35 378 Hose Barb, 3/4” x 1/2 m.p.t., Brass

#36 184 Cord Retainer

#36A 495A Power Cord, Yellow, 25’

#37 237 Cap, with Chain and Hose Connection

#37A 239 Adapter, 3/4” Hose x 3/8 m.p.t., Brass

#38 937 Reducer, PVC

#39 152 “T”, brass

#39A 152A Washer, Flat, S/S, 7/8”

#40 BS-6 Base, Black

ITEM PART # DESCRIPTION ITEM PART # DESCRIPTION

#41 910 Axle, 18-13/16”

#42 2003 Wheel, 8”

#43 27A Axle Cap, Black

#44 5 Bolt, 1/4-20 X 3/4”

#45 180 Bracket, Axle

#46 8 Lock Nut, 1/4-20

#47 2071 Label, USP

#48 928 Louver, 3”

#50 FP220 Flange, Exhaust, Complete

#52 2002 Castor, Swivel, 3”

#53 909A Latch Strike for Latch, S/S

#54 2010 Handle, Chrome

#55 193 Screw, 1/4-20 X 3/4”

#56 2067 Pump, Diaphram, Sump, Complete

#58 204 Screw, S/S, 12-24 X 1-1/4"

#59 14 Washer, 3/16”, Flat

#60 204A Lock Nut, 12-24, S/S

#61 2076 Bracket, Mounting, Pump

#62 2079 Hose, 3/4”, Polywire, 7”

#63 380 Hose Clamp

#64 2074 Filter, Pump, Inline, S/S

#66 2069 Filter, Pump, 60 Mesh, in Tank

Micellaneous Parts / Assessories

*FP231A Drain Gate Assembly, Complete

with O-Rings and Nut.

**2070 Lid with Ring (Machines made

before 8-03)

**2070A Gasket, for Lid (Machines made

before 8-03)

#919C Vacuum Hose, 2” X 25’

#956A Hose, Dump 3/4” X 50’

#717 Hose Cuff Reducer

#971 Bag, Mesh, White

#2088 Pre-Filter, Inlet

06/27/2005