US SAWS Surface Preparation ◆ 877-817-6687 ◆ 11 High Street, Sueld, CT 06078 ◆ www.ussaws.com

Warranty

is document is not to be used as a guide in determining policies and procedures for US Saws and Blades Incorporated (USSB Inc)

products. It is to be used in determining wether a warranty is justied and as a procedural guide in completing a USSB Inc warranty

claim form.

Warranty Responsibility

e distributor or the end user must prepare a Machine Warranty Information Card when the machine is delivered. Failure to comply

will make any and all warranties on this equipment null and void. Credit for warranty repairs will be given only aer receipt of the

WARRANTY CLAIM FORM, properly completed with all the required details. Submittal details are described later in this document.

Warranty Policy

1. USSB Inc. warrants it’s products against defects in material and workmanship under normal and proper use for a period of 90 days

from the date of delivery; in the case of Rental Fleet Machines.=, date of assignment to Rental Fleet. Such warranty is extended only

to the buyer who purchases the equipment directly from USSB Inc or it’s authorized distributor. is warranty does not include

expendable parts, such as, but not limited to, plugs, cutters, blades, blast wheel, wear parts, liners, and seals.

2. e obligation under this warranty is strictly limited to the replacement or repair, at USSB Inc’s opinion, of machines and does not

include the cost of transportation, loss of operating time, or normal maintenance services.

3. is warranty does not apply to failure occurring as a result of abuse, misuse, negligence, corrosion, erosion, normal wear and tear,

alterations or modications made to the machine without express written consent of USSB Inc.

4. Warranty request must be submitted in writing within 30 days aer failure.

5. Written authorization to return merchandise under warranty must rst be obtain from USSB Inc.

6. USSB Inc reserves the right to inspect and make the nal decision on any merchandise returned under warranty.

7. USSB Inc oers no warranty with respect to accessories , including, but not limited to, engines, motors, batteries, tires, and any

other parts not manufactured by us but which the original manufacturer warrants.

8. USSB Inc reserves the right to make product changes or improvements without prior notice and without imposing any obligation

upon itself to install the same on its products previously sold.

9. e above warranty conditions can only be altered by USSB Inc. USSB Inc must conrm alterations in writing for each specic

transaction.

10. USSB Inc reserves the right to establish specic warranty terms for use or demo machines on an individual transaction basis.

Invoices covering such merchandise will clearly state the provisions of the applicable warranty for each specic transactions.

11. WE DO NOT AUTHORIZE ANY PERSON, REPRESENTATIVE OR SERVICE OR SALES ORGANIZATION TO MAKE ANY

OTHER WARRANTY OR TO ASSUME FOR US ANY LIABILITY IN CONNECTION WITH THE SALE OF OUR PRODUCTS

OTHER THAN THOSE CONTAINED HEREIN.

12. UNDER NO CIRCUMSTANCES SHALL USSB INC BE LIABLE TO CUSTOMER OR ANY OTHER PERSON FOR ANY

DIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES RESULTING FROM THE USE OF THE PRODUCT OR ARISING

OUT OF ANY BREACH OF ANY WARRANTY OR FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES OF ANY

CHARACTER, INCLUDING WITHOUT LIMITATIONS, DAMAGES FOR ANY LOSS OF GOODWILL, WORK STOPPAGE,

OR ANY AND ALL OTHER COMMERCIAL DAMAGES OR LOSSES.

13. USSB INC WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE, WHICH

WARRANTIES ARE EXCLUDED.

Part Number Description

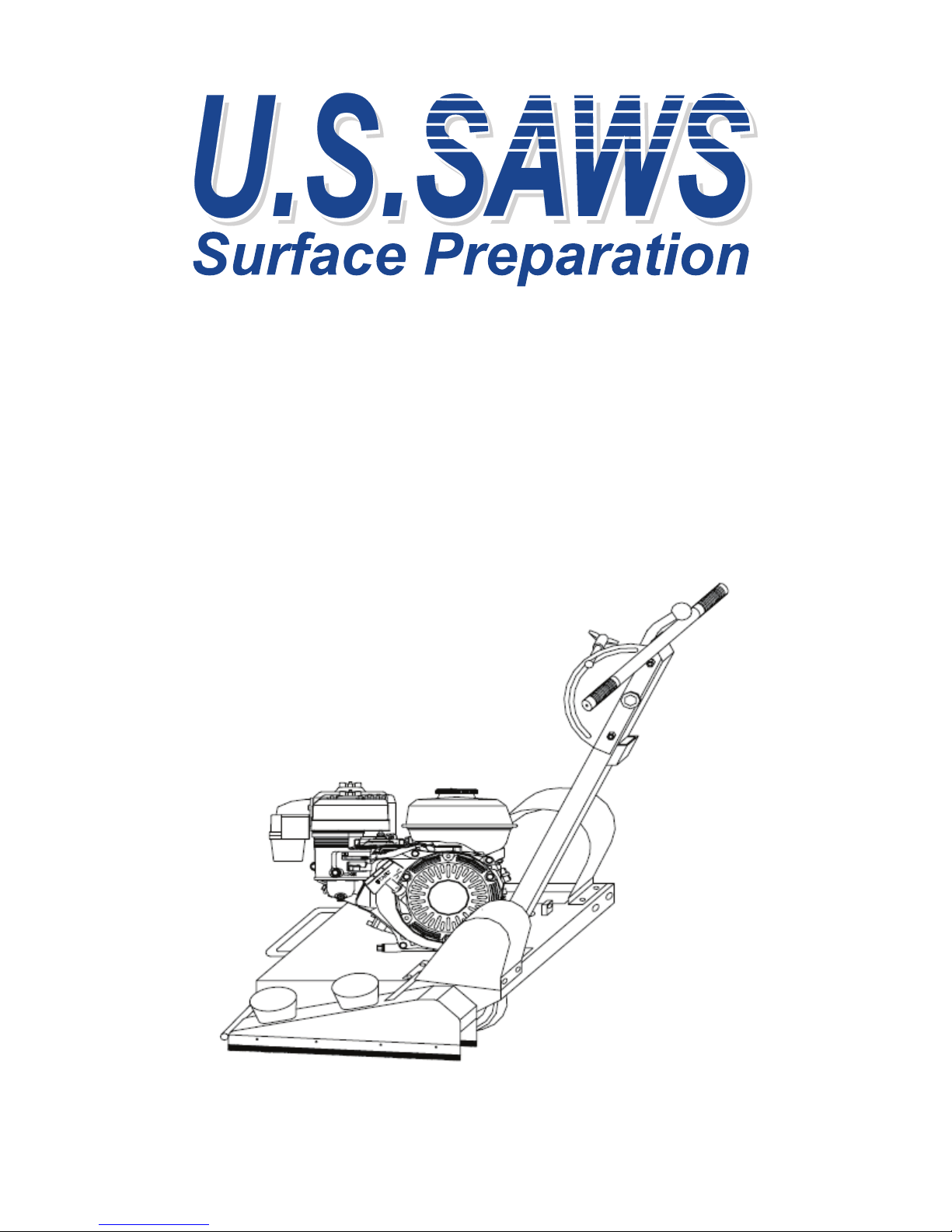

SX90102 CC100 9 HP Honda gas powered stand up crack chasing saw with vacuum

hose adapter.

CCB06250PD 6”x.250”x5/8” Rectangular Segments with DPH and Kicker Segments

CCB06375PD 6”x.375”x5/8” Rectangular Segments with DPH and Kicker Segments

CCB06500PD 6”x.500”x5/8” Rectangular Segments with DPH and Kicker Segments

CCB06250PVD 6”x.250”x5/8” “V” Shaped Segments with DPH and Kicker Segments

CCB06375PVD 6”x.375”x5/8” “V” Shaped Segments with DPH and Kicker Segments

CCB06500PVD 6”x.500”x5/8” “V” Shaped Segments with DPH and Kicker Segments