AeroCut nano+ SERVICE MANUAL

2

Contents

1. Installation......................................................................................................4

2. General instruction.........................................................................................6

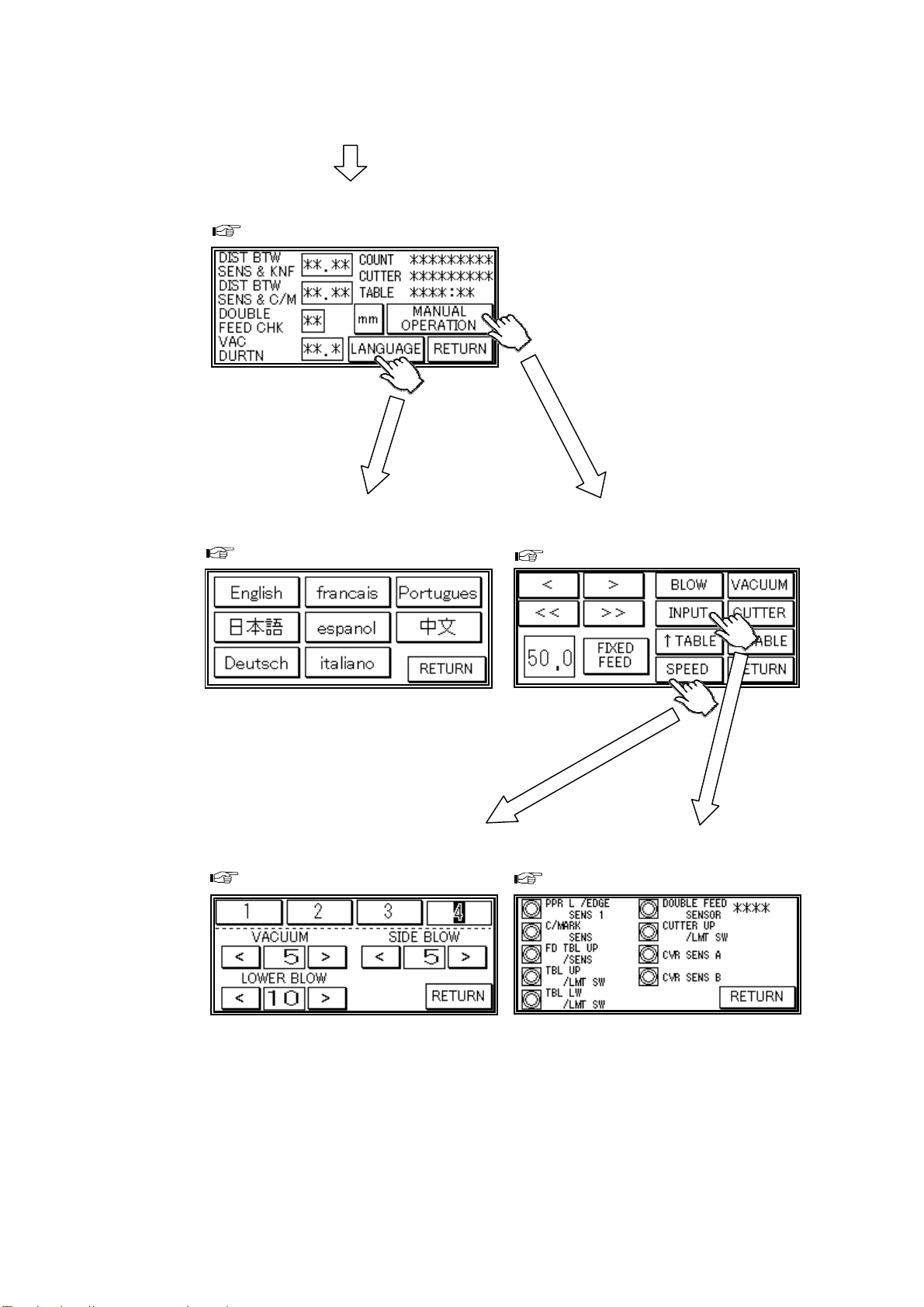

3. Touch panel operation....................................................................................9

3- (1) MANUAL CONTROL screen................................................................9

3- (2) Maintenance screen............................................................................9

3- (3) SERVICE MENU screen ....................................................................11

3- (4) MANUAL OPERATION screen...........................................................11

3- (5) SPEED screen .................................................................................. 12

3- (6) INPUT DATA CHECK screen.............................................................12

3- (7) LANGUAGE screen...........................................................................12

4. Paper jam.....................................................................................................13

5. Replacement of parts ...................................................................................15

5- (1) Guillotine ...........................................................................................15

5- (2) Slitter.................................................................................................16

5- (3) Feed belt Unit....................................................................................17

6. Adjustment.................................................................................................... 18

6- (1) Feed sensor position.........................................................................18

6- (2) Double feed sensor adjustment......................................................... 26

6- (3) Sensitivity of Cutmark sensor............................................................27

6- (4) Guillotine angle.................................................................................. 28

6- (5) Cutting location (Guillotine) ............................................................... 28

6- (8) PCB (CPU board) setting .................................................................. 30

7. Program update............................................................................................31

7- (1) Outline............................................................................................... 31

7- (2) Connecting software install................................................................ 32

7- (3) Touch panel update...........................................................................39

7- (4) PCB (CPU board) update..................................................................42

8. Cleaning & greasing.....................................................................................48

9. Recommended replacement parts................................................................49

10. Error messages..........................................................................................50

11. Troubleshooting..........................................................................................53

12. Drawing...................................................................................................... 55

12- (1) Drawing........................................................................................... 55

12- (2) Board Details................................................................................... 57

12- (3) Input/Output LED Details................................................................. 59

12- (4) Tap Voltage Details.......................................................................... 60