AeroDieCut OPERATION MANUAL

3

Contents

1Introduction.......................................................................................................................5

1.1. Names of parts..........................................................................................................5

1.2. Paper weight / quality................................................................................................6

2. Operating instructions ......................................................................................................7

2.1. Turning the power on ................................................................................................7

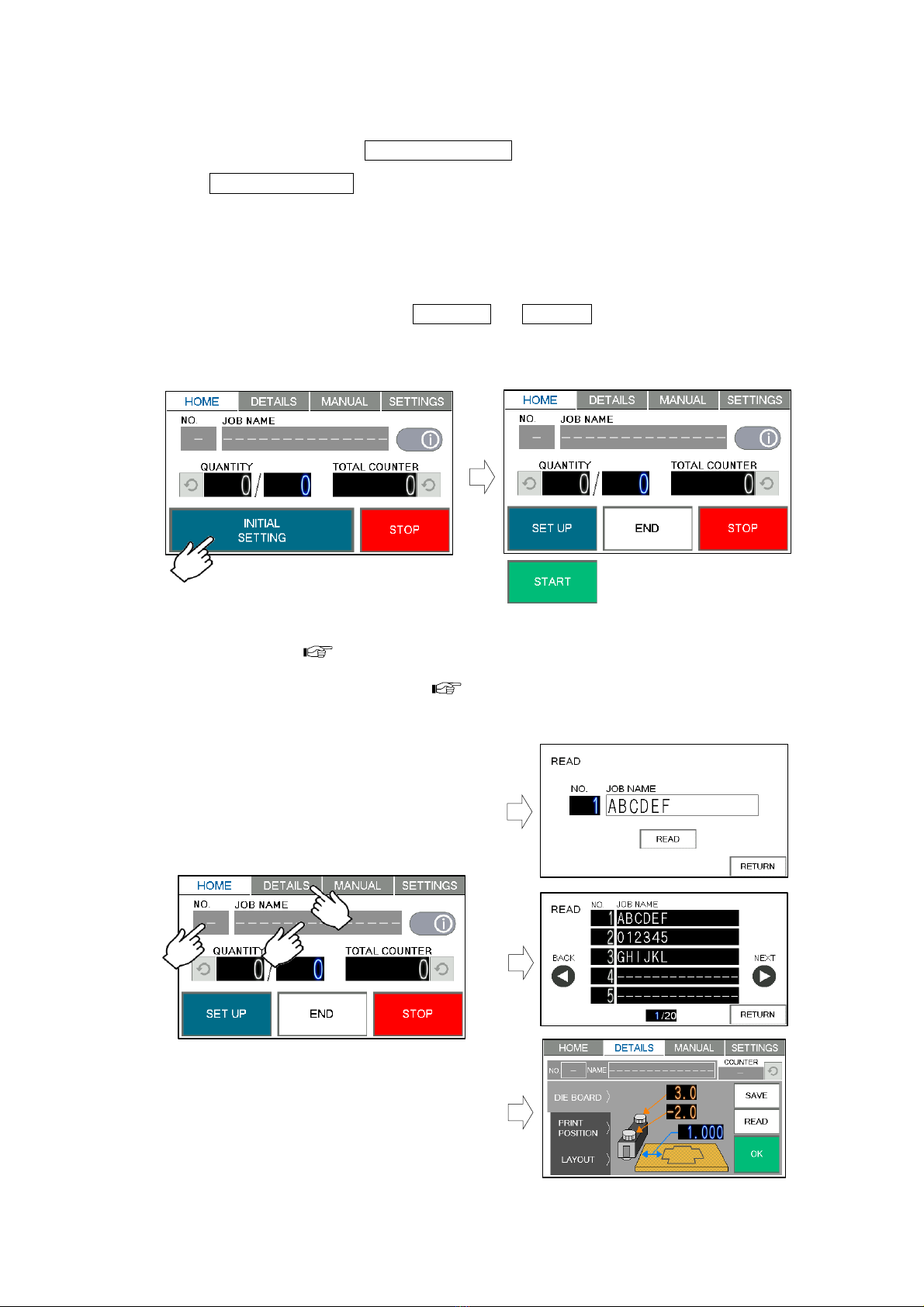

2.2. Initial setting ..............................................................................................................8

2.3. Job select ..................................................................................................................8

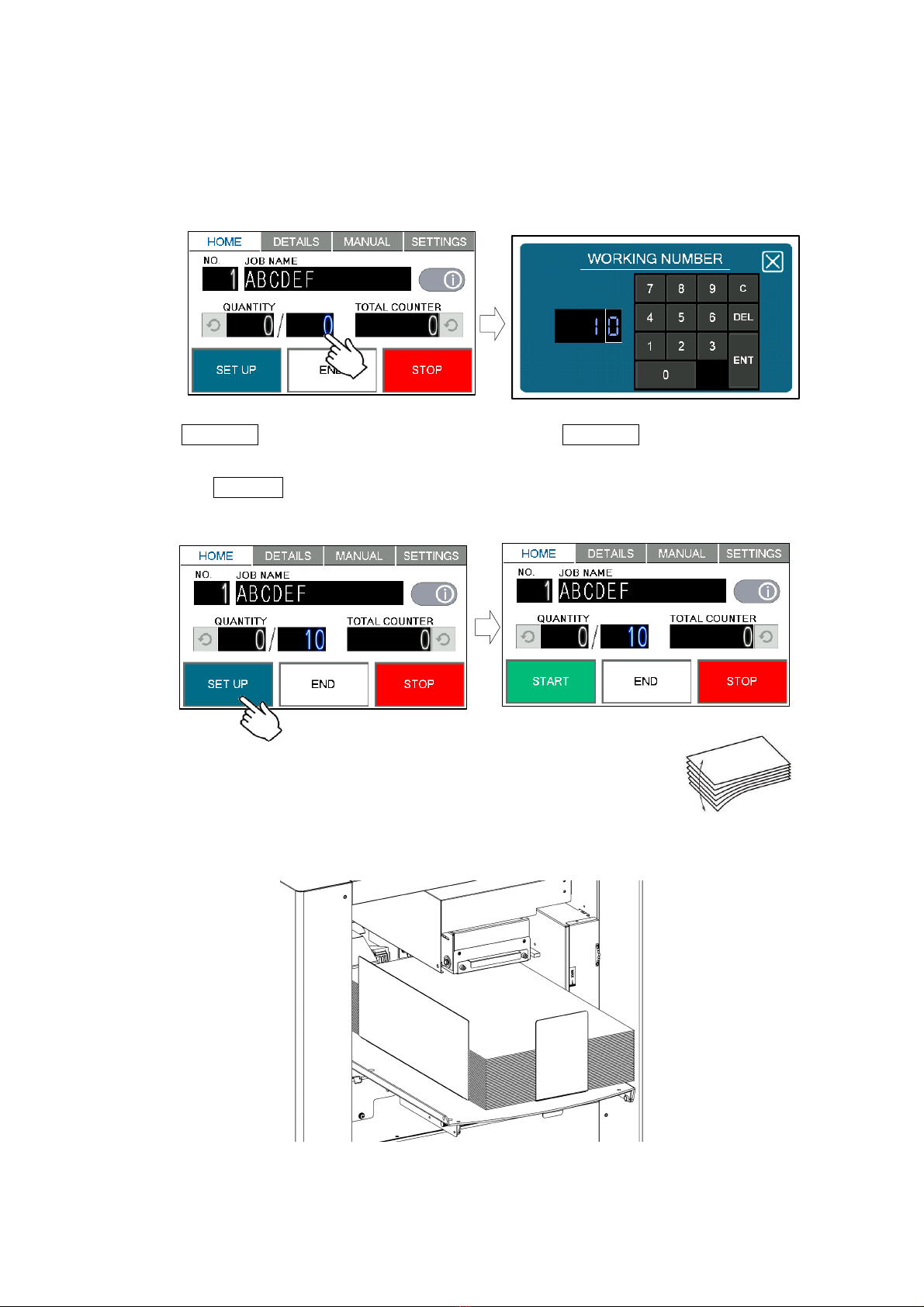

2.4. Paper setting .............................................................................................................9

2.5. Check the condition of the Press plate .................................................................. 10

2.6. Job start ..................................................................................................................11

2.7. Interruption ............................................................................................................. 12

2.8. Power off ................................................................................................................ 12

3. Job data......................................................................................................................... 13

3.1. Details screen ........................................................................................................ 13

3.2. Imposition control screen ....................................................................................... 14

3.3. Data inputs ............................................................................................................. 15

3.3.1. Explanation of each data inputs ..................................................................... 15

3.3.2. Inputs .............................................................................................................. 16

3.4. Data save ............................................................................................................... 18

3.5. Data read ............................................................................................................... 20

3.5.1. Read from Job No........................................................................................... 20

3.5.2. Read from Job-data list .................................................................................. 21

3.5.3. Read input data .............................................................................................. 22

3.6. Change saved data................................................................................................ 22

3.7. Delete saved data .................................................................................................. 23

4. Die board setting ........................................................................................................... 24

4.1. Die board Changing ............................................................................................... 24

4.2. Adjustment of the level of pressurization............................................................... 27

5. Manual control............................................................................................................... 28

5.1. Manual control screen............................................................................................ 28