2

Table

1. General Presentation..................................................................................3

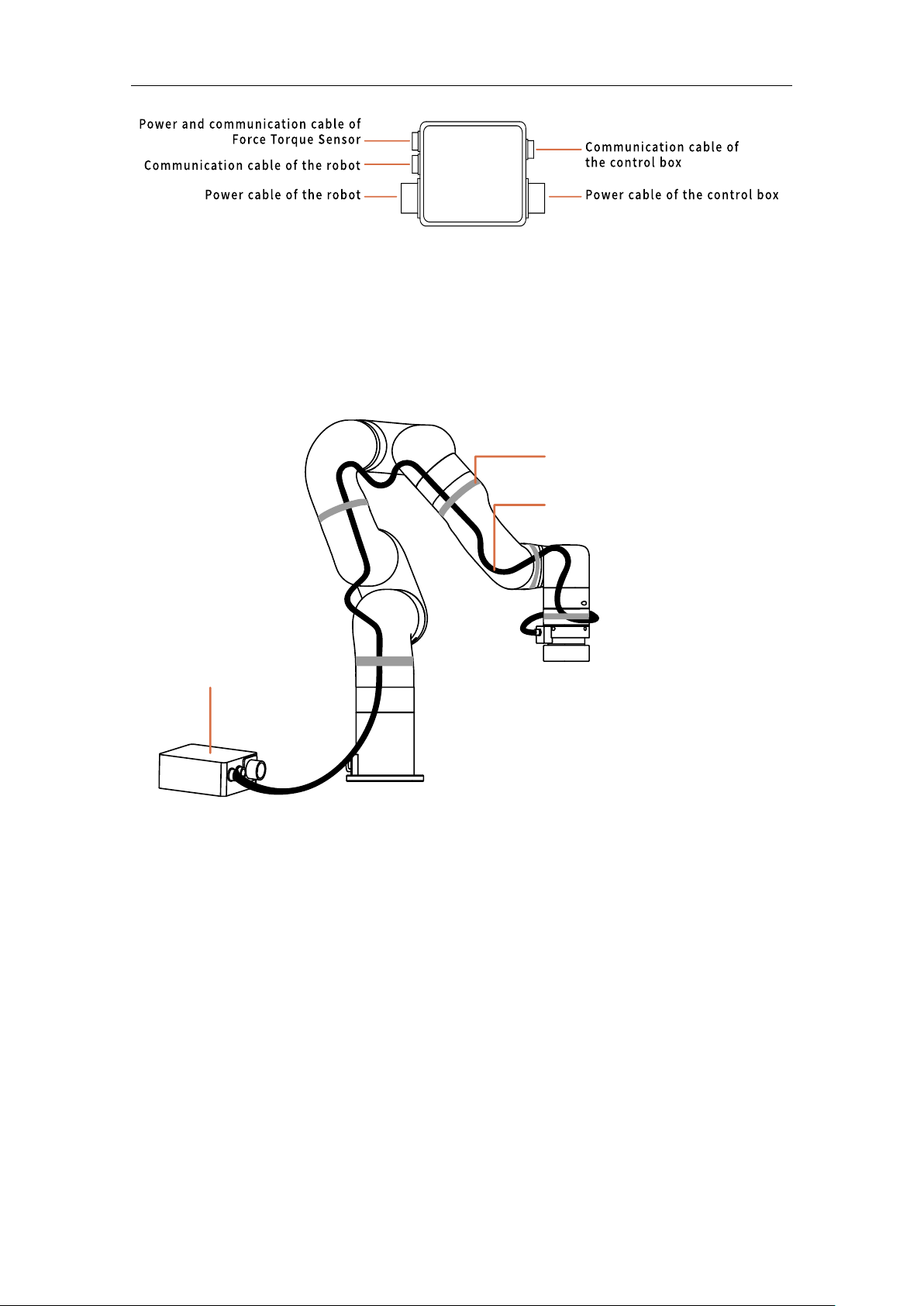

1.1. 6 Axis Force Torque Sensor Introduction...........................................3

1.2. Singal Hub ................................................................................................3

2. Safety..............................................................................................................4

2.1. Warning .....................................................................................................4

2.2. Risk Assessment and Final Application.............................................5

2.3. Validity and Responsibility ...................................................................6

3. Installation ....................................................................................................6

3.1. Scope of Delivery ....................................................................................7

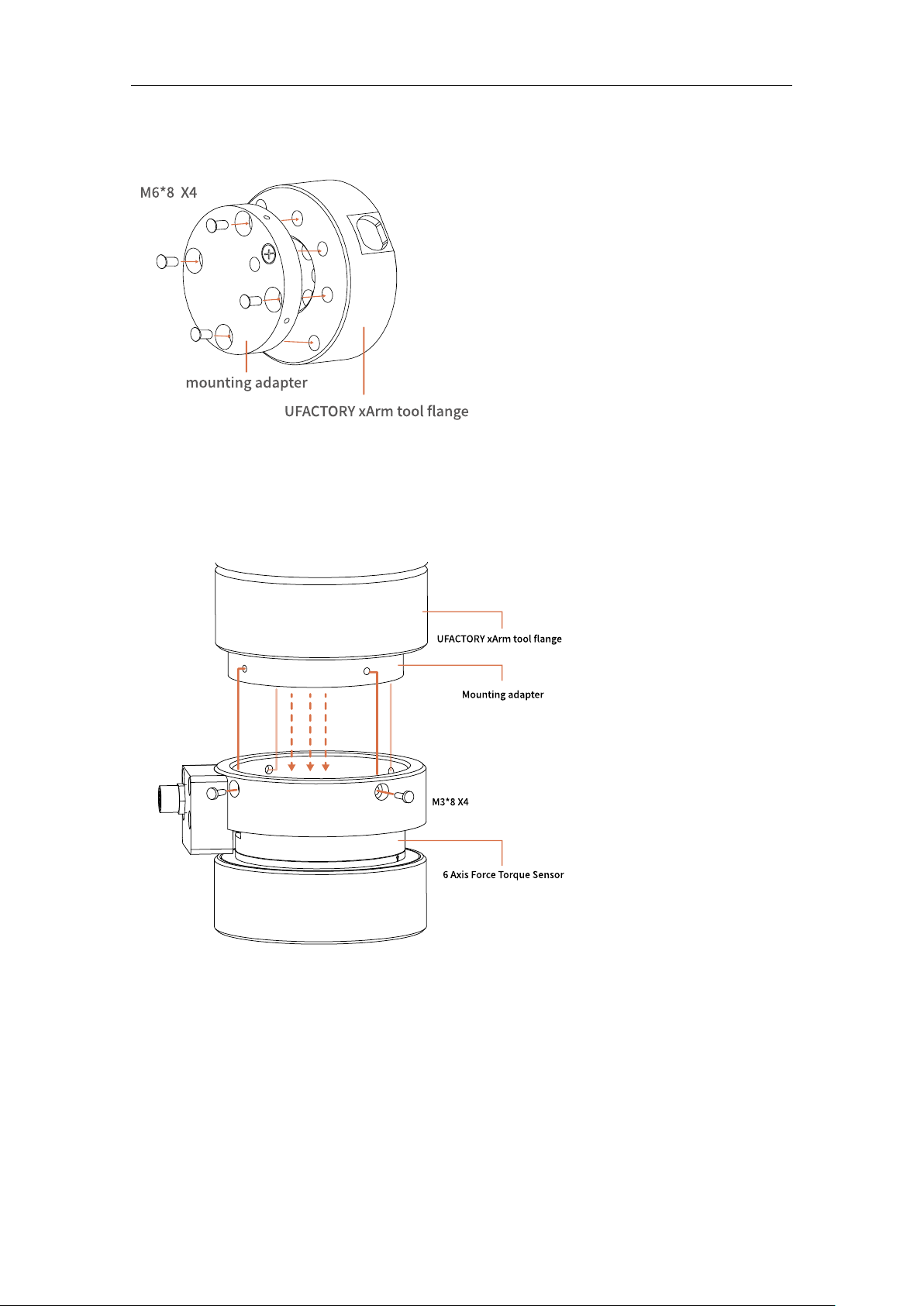

3.2. Mechanical Installation .........................................................................8

4. Control..........................................................................................................11

4.1. Control 6 Axis Force Torque Sensor through Python-SDK ..........11

4.2. Control 6 Axis Force Torque Sensor through C++ SDK .................11

5. 6 Axis Force Torque Sensor Error Code ................................................12

6. 6 Axis Force Torque Sensor Specifications..........................................13

7. After-sales Service ....................................................................................14