PROGRAMIX 50 & PROGRAMIX 100

A. EQUIPMENT DESCRIPTION.......................................................................................................................3

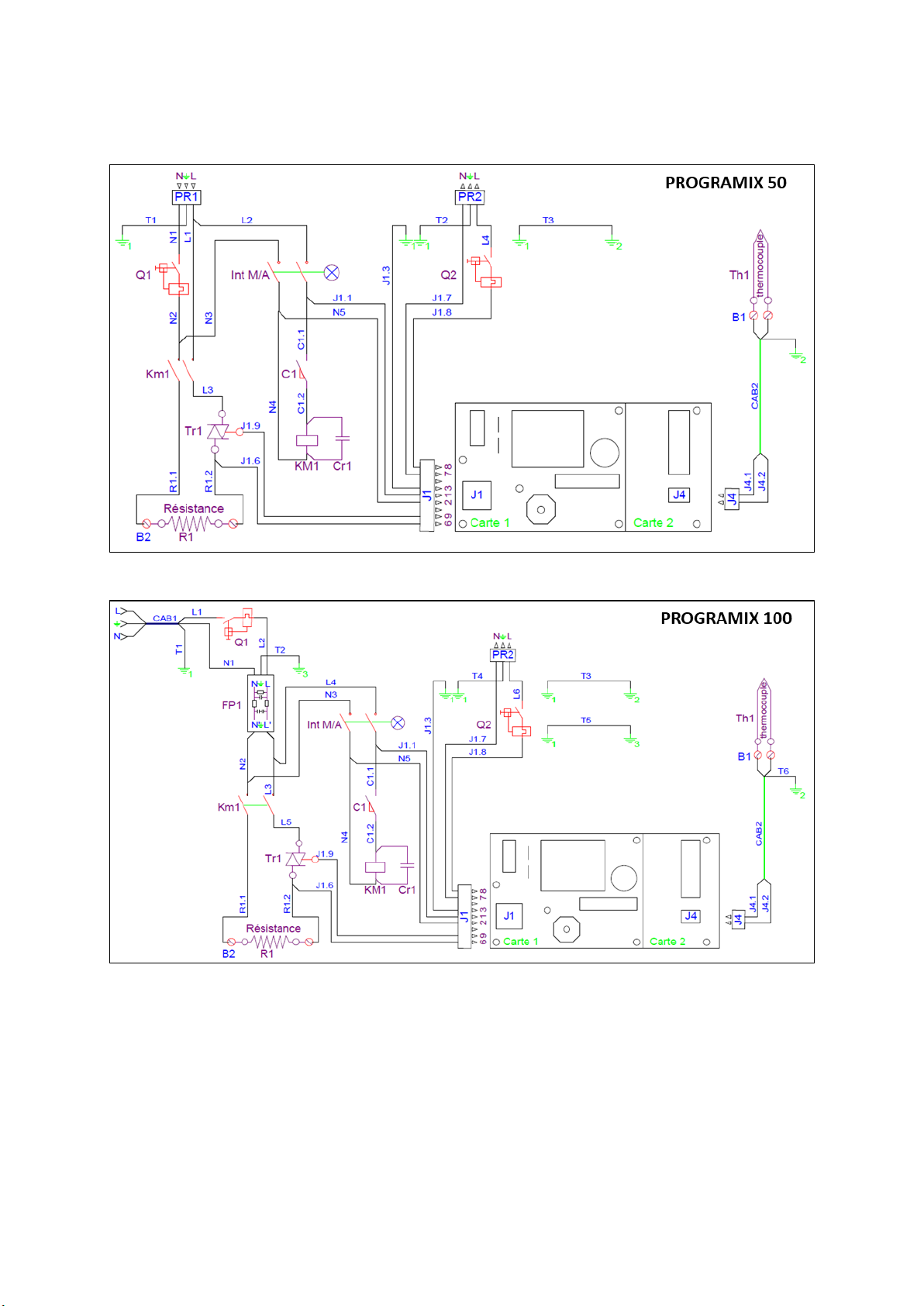

B. ELECTRICAL DIAGRAM .............................................................................................................................4

C. INSTRUCTIONS FOR USE ..........................................................................................................................5

1. SAFETY INSTRUCTIONS .....................................................................................................................5

1.1. USE ............................................................................................................................................5

1.2. SAFETY INSTRUCTIONS ..............................................................................................................5

1.3. WASTE DISPOSAL.......................................................................................................................6

2. EC DECLARATION OF CONFORMITY..................................................................................................6

3. TECHNICAL INFORMATION...............................................................................................................7

3.1. TECHNICAL DATA.......................................................................................................................7

3.2. CONDITIONS OF USE, TRANSPORT AND STORAGE ....................................................................8

3.3. ACCESSORIES .............................................................................................................................8

4. INSTALLATION AND START-UP..........................................................................................................8

4.1. UNPACK.....................................................................................................................................8

4.2. INSTALLATION ...........................................................................................................................9

4.3. START-UP...................................................................................................................................9

5. PROGRAMMING .............................................................................................................................10

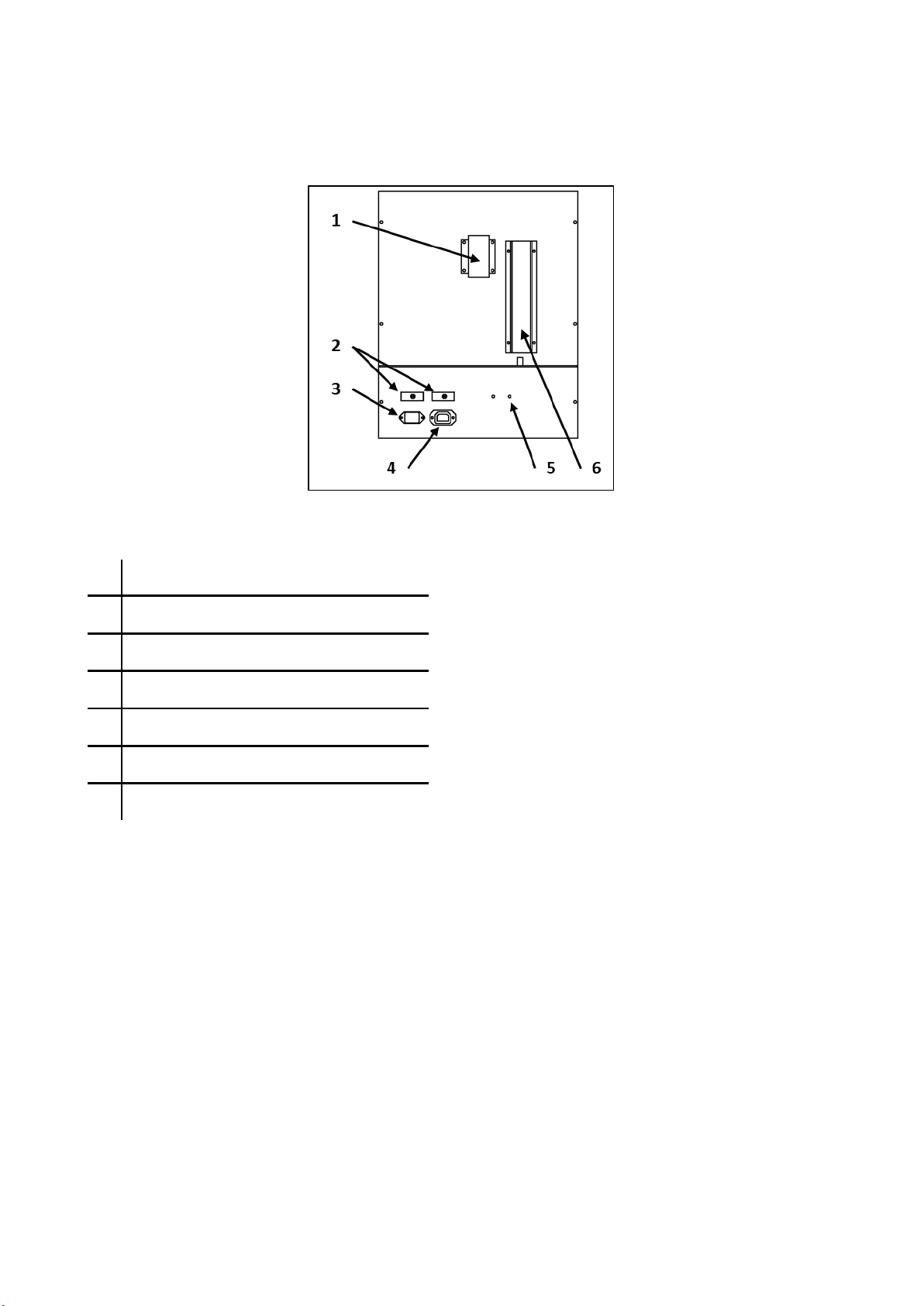

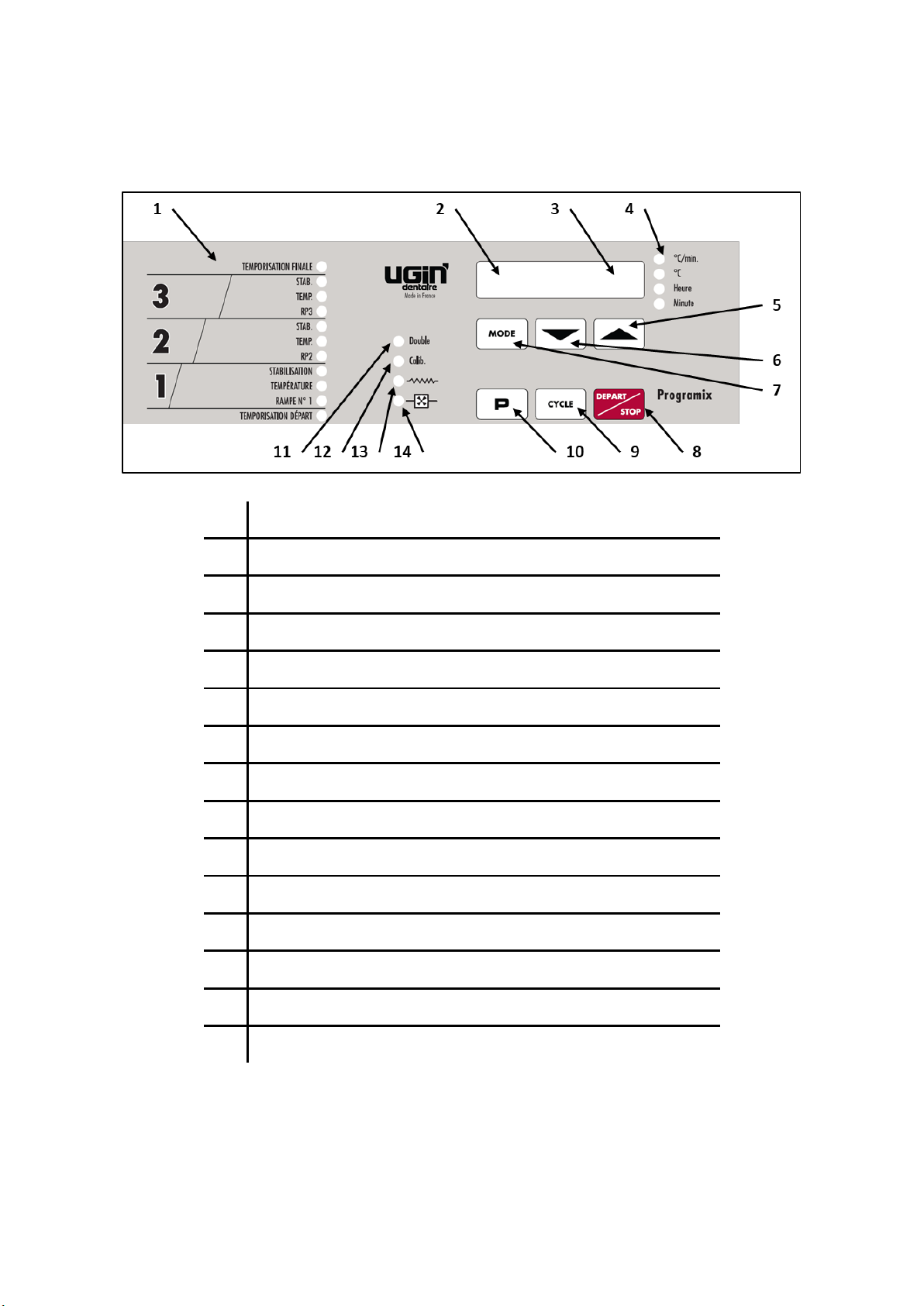

5.1. Description of the control panel..............................................................................................10

5.2. OPERATING PARAMETERS.......................................................................................................11

5.3. DEPARTURE DELAY ..................................................................................................................11

5.4. 1st, 2nd AND 3rd STAGE AND DELAY FINAL.................................................................................11

5.5. PROGRAM NUMBER DISPLAY ..................................................................................................12

5.6. TEMPERATURE/TIME DISPLAY.................................................................................................12

5.7. INDICATOR OF THE UNIT DISPLAYED ON THE PANEL (No. 3)...................................................12

5.8. MODE KEY ...............................................................................................................................12

5.9. FORWARD AND REVERSE KEY..................................................................................................12

5.10. START/STOP TOUCH CONTROL................................................................................................13

5.11. CYCLE ADVANCE KEY ...............................................................................................................13

5.12. PROGRAM SELECTION KEY ......................................................................................................13

5.13. INDICATORS.............................................................................................................................13

6. USE .................................................................................................................................................14

7. CALIBRATION..................................................................................................................................15

8. PROTECTION...................................................................................................................................16

9. MAINTENANCE AND TROUBLE-SHOOTING.....................................................................................17

9.1. MAINTENANCE ........................................................................................................................17

9.2. TROUBLE-SHOOTING..................................................................................................................18

9.3. THERMOCOUPLE REPLACEMENT.............................................................................................19

9.4. MUFFLE REPLACEMENT...........................................................................................................19

10. TABLE OF PROGRAMS.....................................................................................................................20

10.1. TABLE OF SINGLE PROGRAMS (No. 0 to No.19) ......................................................................20

10.2. TABLE OF DOUBLE PROGRAMS (No. 20 to No. 29) .................................................................21

Non-contractual images

Translation into English from original in French