1-1

enough to penetrate tight places, they

should be durable so they can withstand

exposure to the elements, and they must

resist the accumulation of dirt.

Suitable oils include Alsop, Bullshot,

Campagnolo, Finish Line, Lube Wax, Phil

Wood Tenacous Oil, Pedros, Superlube,

and Triflow.

Motor oil, WD40, 3-in-1 Oil, sewing machine

oil, gun oil, and other common oils are not

suitable and should not be used.

In general, applying oil from a drip appli-

cator is superior to using aerosols. Aerosols

promote over-lubrication, which leads to

excessive accumulation of dirt. Apply oil

sparingly. Apply enough oil to do the job,

but not so much that it starts to drip from

the component. After applying any oil,

wipe off the excess.

THREADLOCK

A threadlocking compound should be

used on most fasteners on the A2B Metro.

Threadlocking compound prevents loos-

ening caused by vibration and helps seal

out moisture.

Loctite 242 (blue) or its equivalent is rec-

ommended for threadlocking applica-

tions. Loctite 242 is a medium-strength

threadlocking compound that permits dis-

assembly with common hand tools.

Before applying Loctite to threads, clean

oil, grease, and other residue from the

thread surfaces. Apply a small amount of

Loctite. Excess compound could work its

way down the threads and bond parts

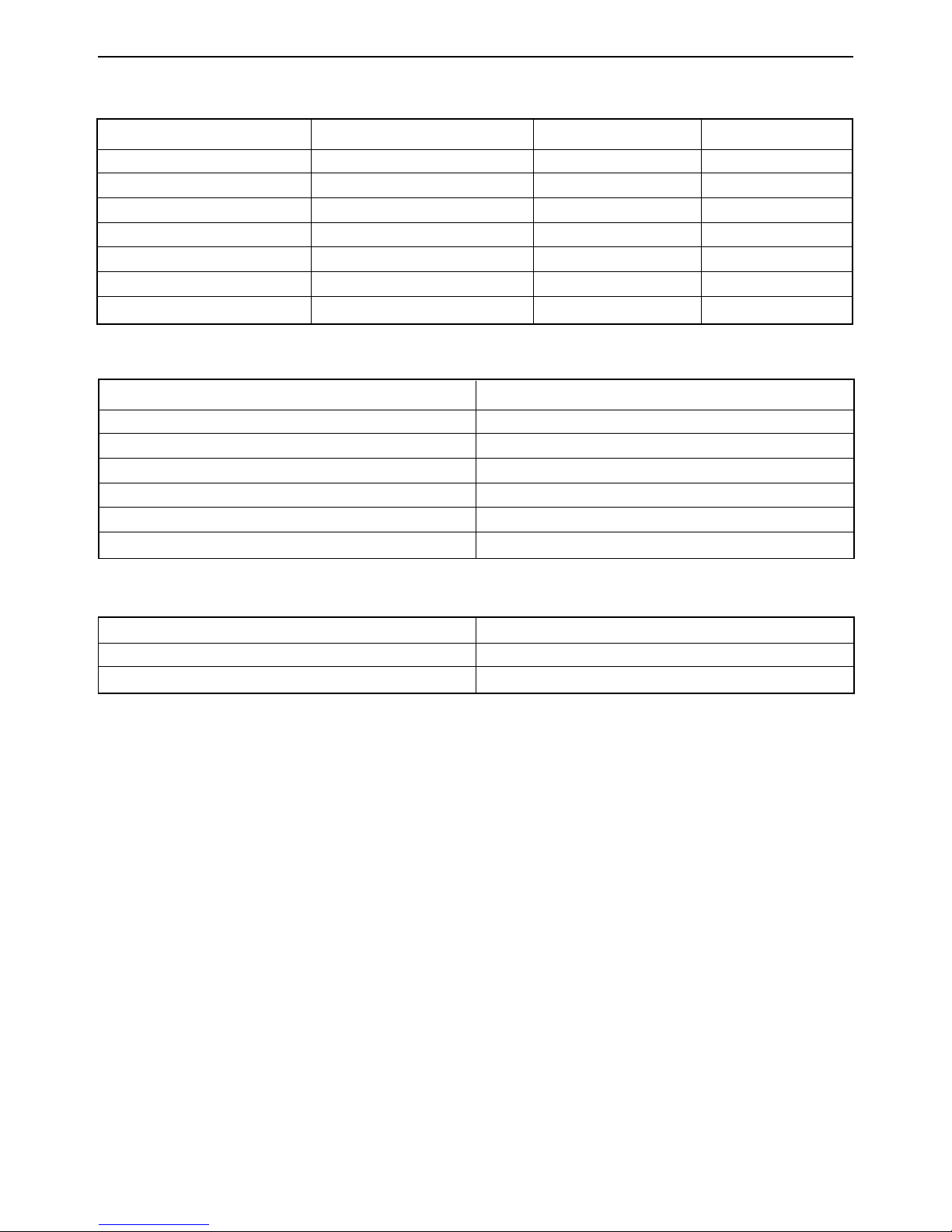

together. Table 5 (this chapter) provides

torque specifications and Loctite recom-

mendations for particular fasteners.

TERMS

Left and Right

The terms left and right in this manual

refer to the rider’s point of view when

seated on the A2B Metro and facing for-

ward. The right side of the A2B Metro is the

chain side. The left side is the brake side.

NOTE, CAUTION and WARNING

The terms NOTE, CAUTION and WARNING

have specific meanings in this manual. A

NOTE provides additional information to

make a procedure easier or clearer.

A CAUTION emphasizes precautions that

must be taken to avoid damage to tools or

the A2B Metro. Disregarding a CAUTION

could lead to mechanical damage.

A WARNING emphasizes a situation where

negligence could lead to injury or death.

Take WARNINGS seriously. Failure to heed a

WARNING could result in serious personal

injury or death.

LUBRICANTS

Grease

In general, use a lithium-based grease

where grease is called for in this manual.

Always use grease made specifically for a

bicycle, such as grease from Bullshot,

Campagnolo, and Shimano.

Oil

Always use oils made specifically for

bicycle use. Bicycle oils need to be thin

Chapter One

GENERAL INFORMATION