PUMP FORHYDRAULICSYSTEMS - page7 of71

Installationandmaintenancemanual

ULTRAFLEX

ENGLISH

1.2Warningsforthecorrectproductuse

1PRODUCTDESCRIPTION

1.1Hydraulicsteeringsystemoperation

All ULTRAFLEX hydraulicsteeringsystemsaredesignedinconformitywithUNI-EN-ISO10592 andA.B.Y.C.P21

regulations.AllULTRAFLEX steeringsystemscanoperateattemperatures between-18°C(0°F)and+77°C

(+170°F).All thecomponentsaremadeforthemarineenvironment,usingmaterialsandworkingprocesses

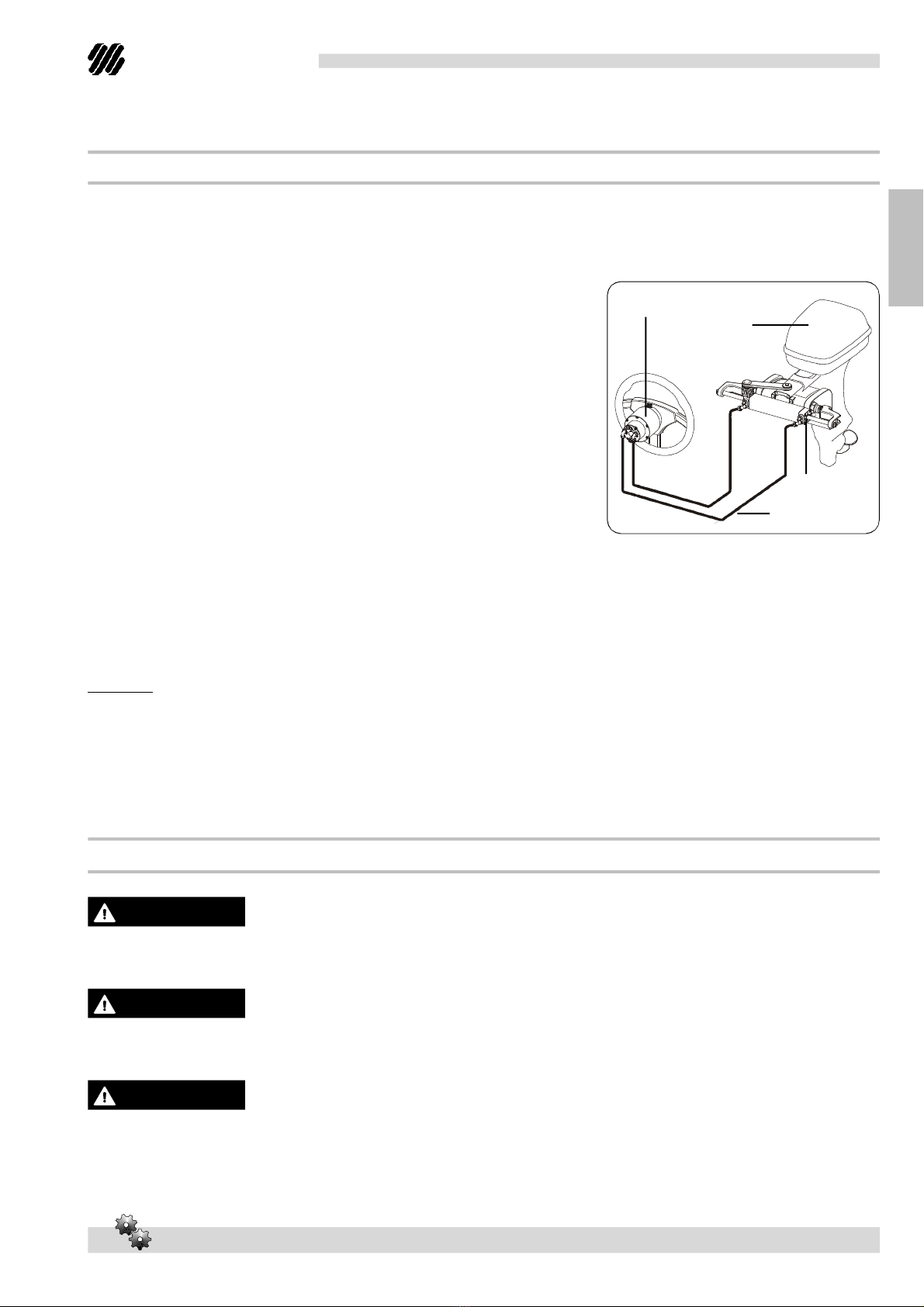

whichofferlonglifeandsafetyunderthemostextremeconditions. Ahydraulicsteeringsystemconsistsof

asteeringpumplocatedonthedashboard,acylindertiedtothe

rudderortotheoutboardorsterndriveengineandtheconnecting

hoses (seepicture).Undernormaloperatingconditions,aturnof

thesteeringwheelwill pumptheoil,whichflowsinthroughthe

hoses tothecylinder,accordingtotheturndirection.Withthe

consequentcylindermovementtheoilwill flowtothepumpthrough

thehoses andatthesametimemoves theengineorthehelmwhich

areconnectedtothecylinder.Thepumpsequippedwithanonreturn

valve, whichpreventsoutgoingfluidfromreturningalongthesame

hose. allowtheoperationofthesteeringsystemswithtwoormore

steeringstations.Thecylindersaredouble-actingandtheycanbe

balancedorunbalanced.Inunbalancedcylindersthetwochambers

havedifferentvolumes andthereforetheyrequireadifferentnumber

ofsteeringwheelturnsandadifferentsteeringwheelrotationeffort

withthe samemovementinthetwo directions. The balancedcylinders

requirethesamenumberofturnsofthesteeringwheeltomovethehelmfromthecentretotheendof

strokeinthetwoopposeddirections.

Awellbalancedsteeringsystemneedsacorrectchoiceofthepumpforthecylinder. ULTRAFLEX produces

differentpumpmodels,whichhavedifferentcapacity(cm3ofoilmovedeachsteeringwheelturn)andfor

eachtypeofinstallation.Whilechoosingthepumpitisimportanttoconsiderthecylindervolume.The

numberofstarboard andportturnsis determinedbytheratio betweenthecylindervolumeandthepump

capacity.

Example:ifthepumphas acapacityof28cm3 [1,7cu.in.]andthecylinderhas avolumeof120 cm3 [7,3cu.in.],the

formulalookslikethis: 120/28=4,2.Accordingly,thesteeringwheelwill turnabout4times beforethecylinder

willcompletelyturnfromonesidetotheother.Incase ofinstallationswithdoublecylindersconnectedin

parallelthecylindervolumemustbeadded.Applicationswithless than4turnsarenotrecommended,as

theyneedahighereffort,also applicationswithmorethan8turnsarenotrecommended,as theresponse

oftheboattosteeris slowly.

ULTRAFLEX steeringsystemsmustnotbeinstalledonraceboats.

All ULTRAFLEX steeringsystemsmustnotbeinstalledonboatsequippedwithengines whose maximum

horsepowerishigherthanthehorsepowerratingapprovedbyboatmanufacturer.

Do notmodifythepumpinanywaytofitittoyourapplication,otherwise thepumpwill nolongeroperatein

safetyanditwillendangertheboatandtheoccupants.

WARNING

WARNING

DANGER

l

engine

hydraulichoses

cylinder

l

l

l

pump