PUMP FORHYDRAULICSYSTEMS -page7 of75

InstallationandMaintenanceManual

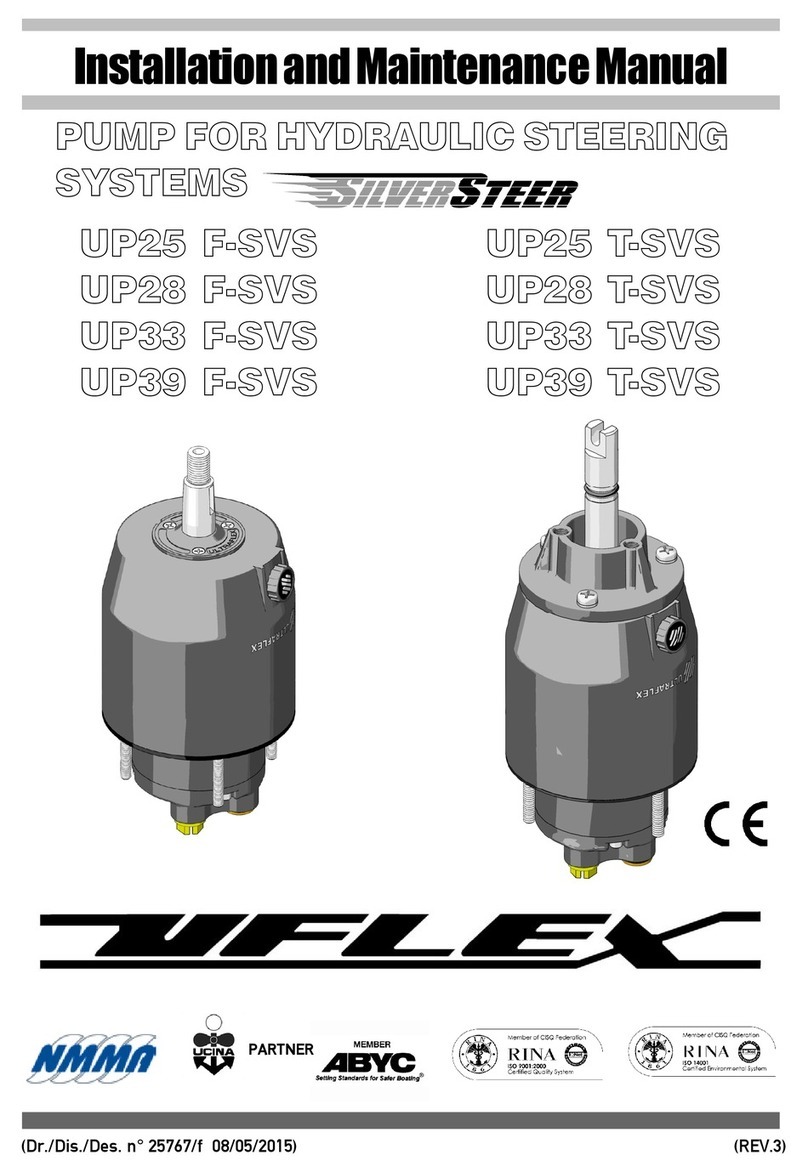

ULTRAFLEX

ENGLISH

TheUP56-UP68 pumpmustnotbeinstalledonraceboats.

TheUP56-UP68 pumpisprovidedwith(external)pressurereliefvalve(seepictureabove)thatmustbe

placedabsolutelybetweenpumpandcylinderasshownintheparagraph3.5.

All ULTRAFLEX steeringsystemsmustnotbeinstalledonboatsequippedwithengines whosemaximum

horsepowerishigherthanthehorsepowerratingapprovedbyboatmanufacturer.

1.2Warningsfortheproductcorrectuse

Donotmodifythesteeringcylinderinanywaytofitittoyourapplication,otherwise thecylinderwillno

longeroperateinsafetyanditwill endangertheboatandtheoccupants.

WARNING

WARNING

WARNING

DANGER

1PRODUCTDESCRIPTION

1.1Hydraulicsteeringsystemoperation

All ULTRAFLEX hydraulicsteeringsystemsaredesignedinconformitywithUNI-EN-ISO10592 andA.B.Y.C.P21

regulations. All ULTRAFLEX steeringsystemscanoperateattemperatures between-18°C(0°F)and+77°C(+170°F).

Allthecomponentsaremadeforthemarineenvironment,usingmaterialsandworkingprocesses which

offerlonglifeandsafetyunderthemostextremeconditions. Ahydraulicsteeringsystemconsistsofa

steeringpump,acylindertiedtotherudderortotheoutboardor

sterndriveengineandtheconnectinghoses (see picture).Undernormal

operatingconditions, aturnofthesteeringwheelwill pumptheoil,

whichflowsinthroughthehosestothecylinder,accordingtotheturn

direction.Withtheconsequentcylindermovementtheoilwill flowtothe

pumpthroughthehoses andatthesametimemoves theengineorthe

helmwhichareconnectedtothecylinder.Thepumpsareequipped

withavalve, whichpreventsoutgoingfluidfromreturningalongthe

samehose. It also allowstheoperationofthesteeringsystemswithtwo

ormoresteeringstations.Thecylindersaredoubleactingandmaybe

balancedorunbalanced.Intheunbalancedcylindersthetwochambers

havedifferentvolumes andso theyneedadifferentnumberofturnsof

thesteeringwheelandadifferentrotationeffort.Thebalancedcylinders

havesamenumberofsteeringwheelturnsinordertomovethehelm

fromthecentertotheendstrokeinthetwooppositedirections. Awell

balancedsteeringsystemneedsacorrectchoiceofthepumpforthe

cylinder. ULTRAFLEX produces differentpumpmodels,whichhavedifferentcapacity(cm3ofoilmovedeach

steeringwheelturn)andforeachtypeofinstallation.Whilechoosingthepumpitisimportanttoconsider

thecylindervolume. Thenumberofstarboard andportturnsis determinedbytheratio betweenthecylinder

volumeandthepumpcapacity.

Example:ifthepumphas acapacityof28cm3 [1,7cu.in.]andthecylinderhas avolumeof120 cm3 [7,3cu.in.],the

formulalookslikethis: 120/28=4,2.Accordingly,thesteeringwheelwill turn4,2 times beforethecylinderwill

completelyturnfromonesidetotheother.Incase ofinstallationswithdoublecylindersconnectedin

parallelthecylindervolumemustbeadded.Applicationswithless than4turnsarenotrecommended,as

theyneedahighereffort,alsoapplicationswithmorethan8turnsarealsonotrecommended,asthe

response oftheboattosteeris slowly.Themaximumoperatingpressureis 7,0MPa(70 bar)(1000 PSI).

pump

l

l

hydraulichose

l

cylinder

helm

l

l

pressurereliefvalve