www.ultravation.com

3

Electrical Requirement:

Always follow all local electrical codes when

installing our water treatment equipment.

1. Provide a properly grounded 115V/60 HZ dedicated

electrical outlet. Avoid using outlets that are

switch controlled.

2. Maximum amperage required is 5 amps.

3. Make sure the electrical service provides power 24

hours per day. We recommend installing a surge

protector to protect unit from power surges, which

are not covered by warranty.

!! DO NOT UNDER ANY CIRCUMSTANCE WIRE THE

UV UNIT TO THE WELL PUMP SWITCH OR WELL

PUMP ELECTRICAL SUPPLY!!!

Power Supply Installation:

1. Choose a wall placement that is dry and clear of all

piping and metal objects, and within 4 feet of the UV

vessel and the electrical outlet.

2. Remove cover from power supply for mounting.

3. Secure power supply to wall with screws. (not

provided)

4. Properly ground the power pack to the UV vessel.

Quartz and O-ring Installation:

1. Wipe the quartz sleeve with household alcohol to

remove dirt, oil and fingerprints.

2. Carefully place the quartz sleeve into the top opening

of the vessel.

3. Lubricate the o-ring with silicone (which is supplied)

then place the o-ring over the top of the quartz

sleeve.

4. Hand-tighten the clear gland nut onto the nipple

located on the top of the vessel. DO NOT OVER

TIGHTEN OR THE QUARTZ SLEEVE MAY

SHATTER. WHEN OPERATING, THE CLEAR

GLAND NUT WILL GLOW BLUE.

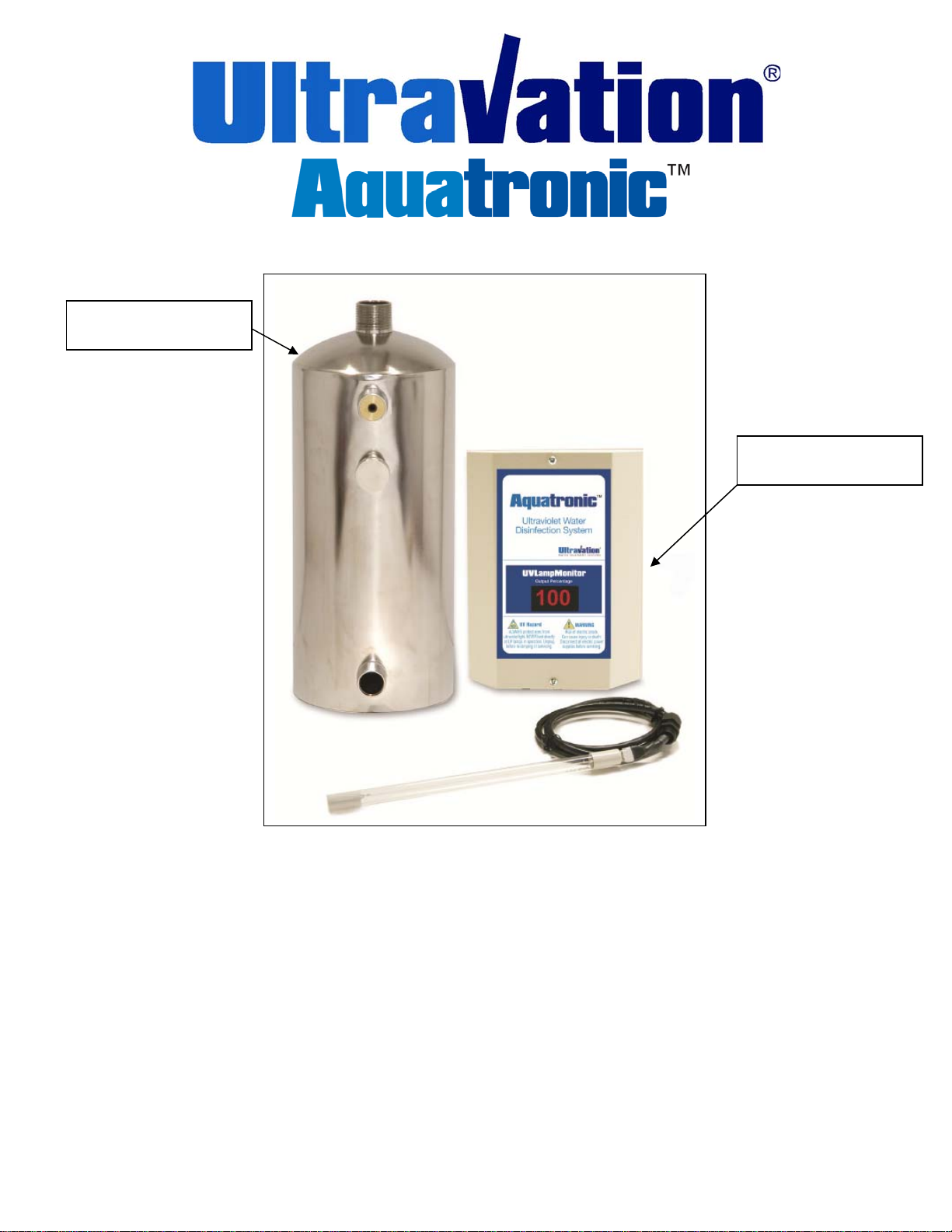

SS Vessel Installation:

1. The ultraviolet unit is designed to be installed in a

vertical position. The unit is supplied with (2)

brackets to support the unit.

NOTE: The upper bracket has a grounding lug

attached to it.

2. Place the top bracket (larger one) over the nipple

located at the top of the vessel. The end of the

bracket with the three holes should be facing up

towards the top of the vessel.

3. Tighten the gray PVC ring onto the nipple. This

will compress down onto the top of bracket.

4. Attach the smaller bracket to the bottom of the

vessel. The bracket has a clip type fastener that

attaches to the bottom rim of the vessel. The end

of the bracket with the three holes should be

facing down towards the bottom of the vessel.

5. Secure the top bracket to a wall by using three

appropriate screws or fasteners (not provided).

Be sure to leave plenty of clearance above

vessel for servicing the quartz tube and

germicidal lamp.

6. Secure the bottom bracket to the wall by using

three screws or fasteners (not provided).

7. Use quality unions and ball valves on the inlet and

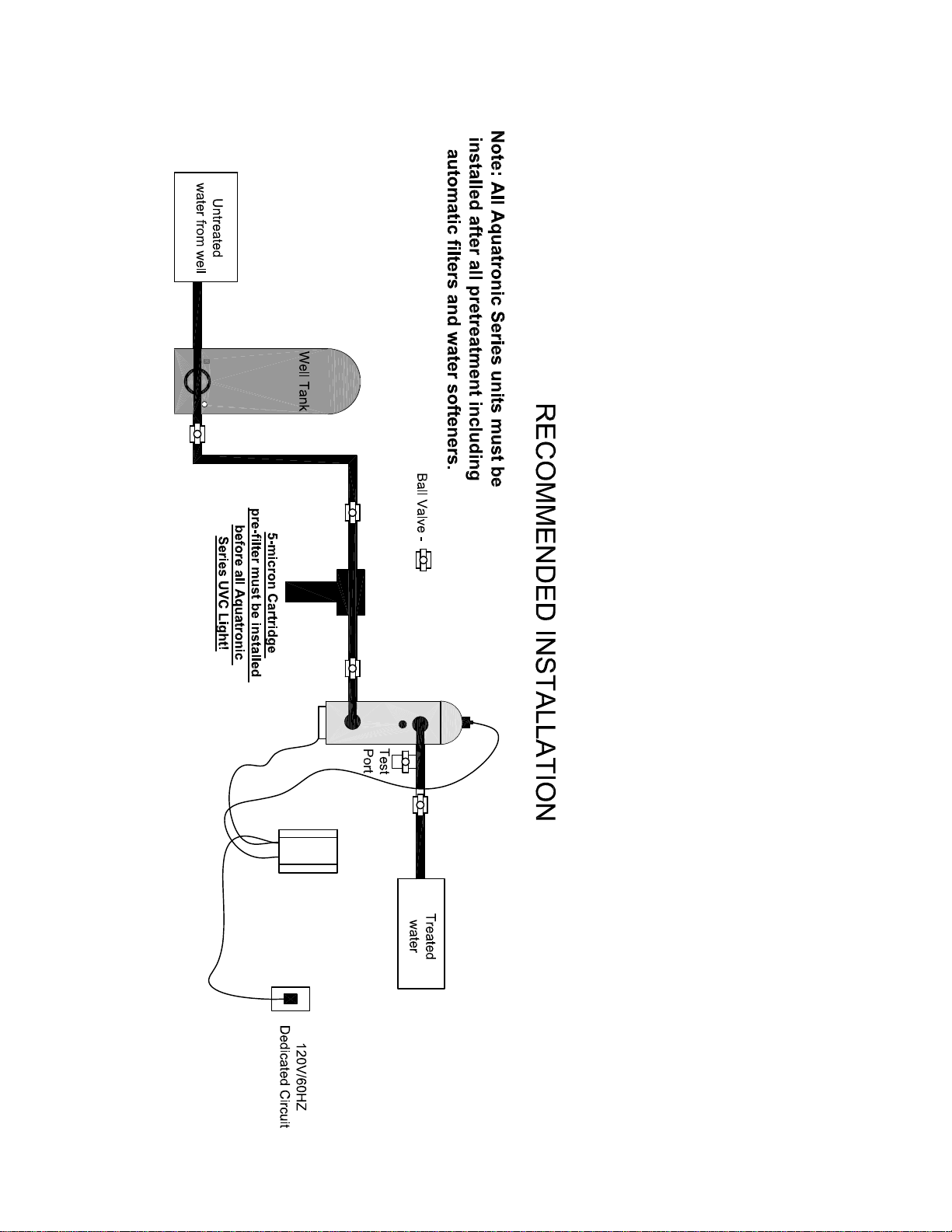

outlet for servicing the unit. See Page 7 for a

typical installation piping layout. If sweat fittings

are used, be sure soldering is done in such a

manner as not to allow heat to reach the UV

vessel. If Schedule 80 PVC or CPVC is used,

make sure to follow the proper primer and solvent

instructions.

8. Pipe the inlet into the bottom nipple and the

outlet into the top nipple on the UV vessel. There

is an internal flow restrictor in the outlet nipple of

all units. It is recommended you install a boiler

drain on the outlet piping of the unit for

bacteria testing.