• PTXGI-1224 UVPhotoMax photo catalyst module.

• Four self tapping mounting screws P/N HD-PP-0104

• Two lamp mounting screws P/N HD-PP-0005

• One 10” non ozone UVGI lamp P/N AS-1013-1

• One 6 ft 2 conductor power cord P/N AS-IH-0005

• One Y cable for splitting power P/N EL-OH-0080

• One 24 VAC multi tap step down transformer P/N 94-041

• Two Wire nuts (Orange)P/N EL-PP-0012

• One duct board mounting plate P/N SM-IH-0018

• UVC warning label

• Replacement lamp log

sheet

• Warranty card

• Duct board sealing tape

• Product gasket

• Cotton glove

• Warning labels

Package Contents:

Safety Precautions:

It is recommended that this unit be installed and maintained by a trained technician.

WARNING: UV Hazard. Always protect eyes from ultraviolet light. NEVER look at UV lamps in opera-

tion. Unplug or disconnect power before lamp replacement or servicing.

WARNING: Severe eye damage or temporary blindness may occur.

WARNING: DO NOT operate outside of air handler.

WARNING: No openings should be allowed which would give direct line-of-sight to the UV light.

Note: In the event of accidental breakage or replacement of the ultraviolet lamp, please ensure that

the lamp is disposed of in accordance with local and state environmental laws regarding uorescent

lamps containing mercury.

Notice: All wiring inside of the air handler in direct line of site of the UV lamp must be shielded with

aluminum foil tape or equivalent non-combustible material. When installing this unit, select a mount-

ing location that prevents ultraviolet light exposure to synthetic or other plastic components with

unknown resistance to ultraviolet light. Ultraviolet light may cause color shift or structural degrada-

tion of plastic internal components.

Also Included:

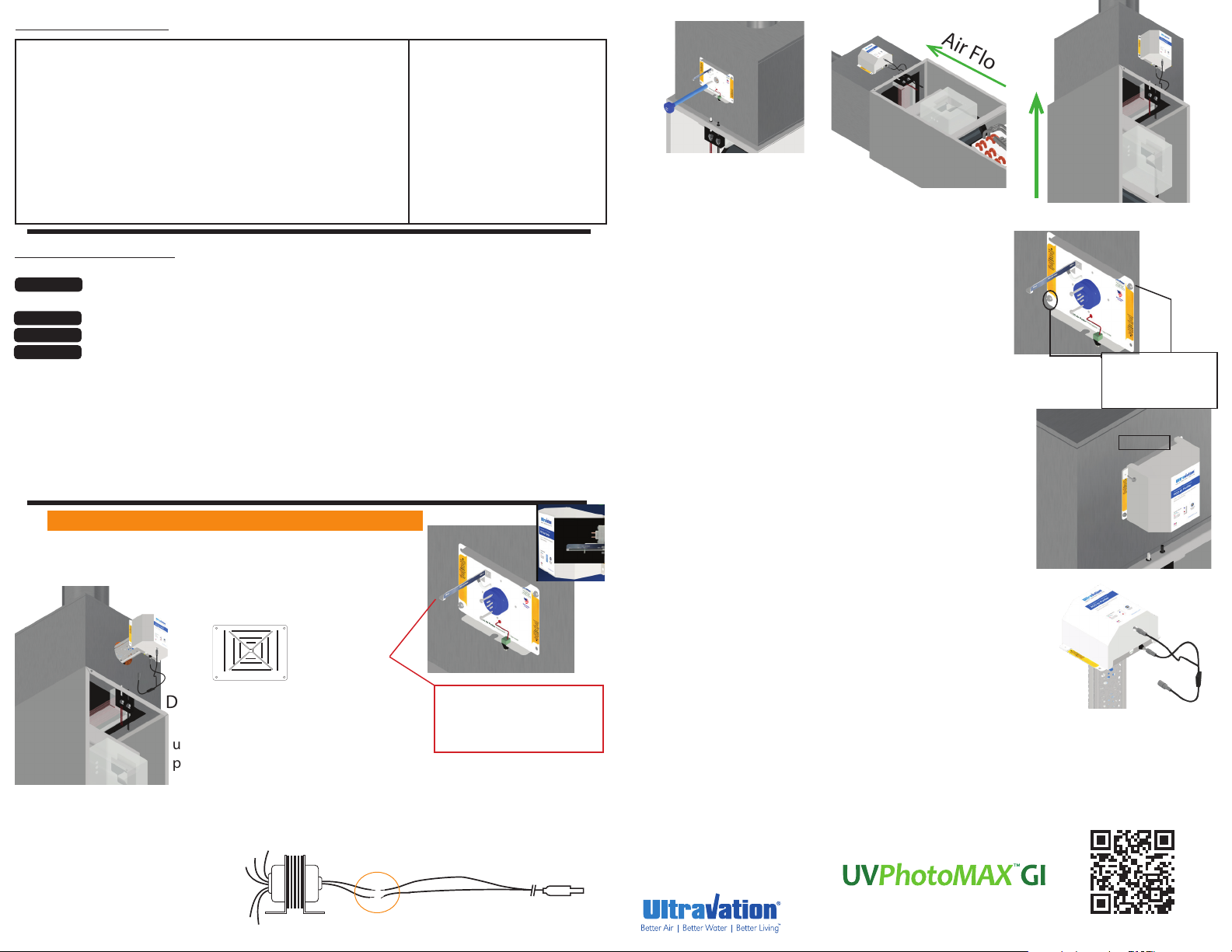

Installation:

Locate a section of duct that

will allow for the installation of

the purier.

Typically this would be the

supply “exit” side plenum.

Metal tabs fold in,

use the at as a tem-

plate. Cut a rectangle

4-3/4”W x 4-1/4” H.

Duct board plate Important!

Adjust the purier for the air

ow of the environment.

Disconnect power while performing installation

Air Flow

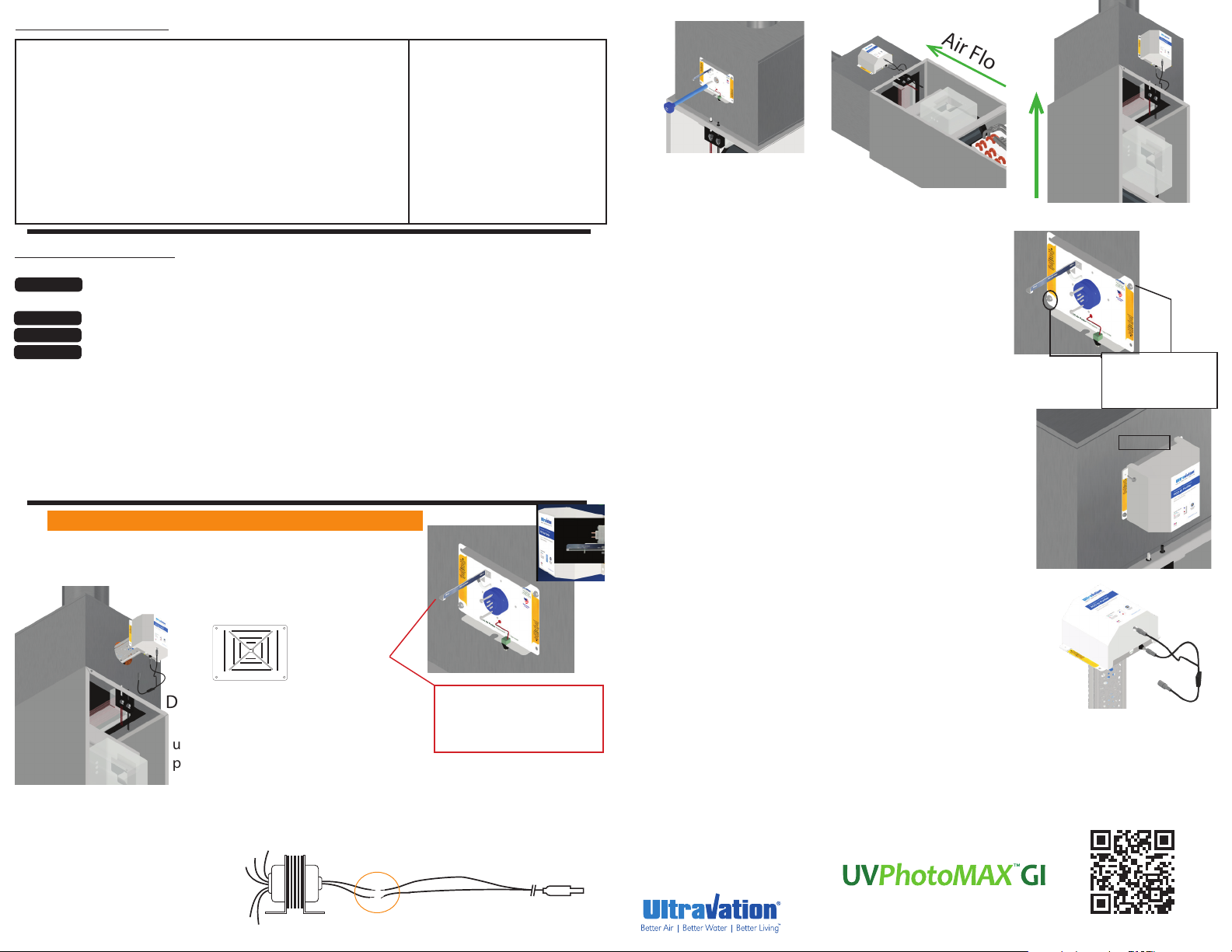

120

240

24 VA C

Common

Install transformer per local code. Typically

in the electronics area of the HVAC system.

Choose the proper incoming voltage. cap

any unused wires.

Route wires connect with

supplied wire nuts

Horizontal Install

Vertical Install

Steps:

1. Mechanically mount the product using 2 of

the 4 hex screws. Note the white cover has two

mount tabs do not use those yet.

2. Install the lamp using supplied 2 screws. Hand

tighten only. Use cotton glove to remove and

nger prints or debris.

3. Make sure the adjustment lever is set to the

appropriate coverage area.

4. Install the white electronics enclose using the

remaining 2 hex screws.

5. Connect the 6 foot cord to the Y connector.

6. Plug each Y into the ports on the purier.

7. One is on the white power head one is on the

metal base attached to the plenum.

2 X hex screws

diagonal, secures

base.

This product is designed to be powered on constantly. The service life for

the UVC lamp is 18,000 hours or approximately 2 years. The ionization

component does require maintenance and has an eective life of up

to 10 years. It is recommended that all installation and service be per-

formed by a licensed HVAC professional.

Metal Plenum:

Cut a 4”diameter circle.

Duct board:

Use supplied metal plate

Air Flow

Install base rst

Then the lamp.

Step 4