3

Tabl e of Contents

Welcome ............................................................................................................................................................................4

General Product Information.........................................................................................................................................4

Ultra UV2 System Sizing ...............................................................................................................................................4

Pond Sizing Considerations..........................................................................................................................................4

Pond Sizing Chart ............................................................................................................................................................5

Pool, Spa, Fountain, Water Feature and Water Fall Sizing Chart .....................................................................5

First Step In Starting Your Installation........................................................................................................................5

Locating The Ultra UV2 Unit.........................................................................................................................................6

Installing Inlet/Outlet Unions.........................................................................................................................................6

Mounting The UV Unit On A Solid Base...................................................................................................................6

Plumbing The Ultra UV2 Unit........................................................................................................................................6

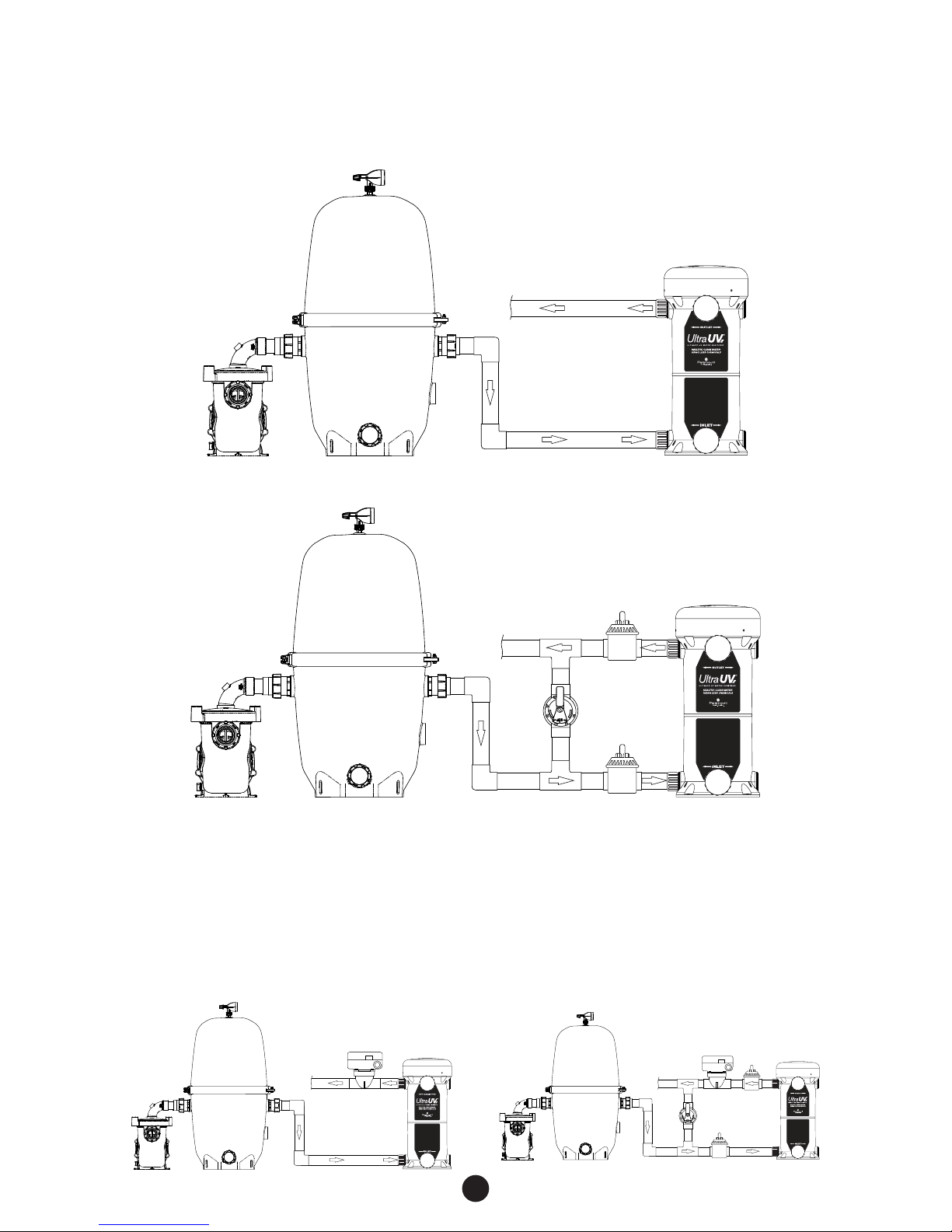

Typi cal Plumbing Without and with b ypass ............................................................................................................7

Parallel Plumbing Without and with bypass ..........................................................................................................8

Multiple port Plumbing FOR 3 LAMP UNITS Without and with bypass .....................................................9

Gluing Piping To The UV Unit....................................................................................................................................10

Providing Electrical Power To The Ultra UV2 Unit...............................................................................................10

Electrical Bonding (Grounding)................................................................................................................................10

System Start-Up ........................................................................................................................................................... 11

Connecting Pressure Switch.....................................................................................................................................11

Water Chemical Balance ............................................................................................................................................11

Upgrading The Output Of The

Ultra UV2 Unit.................................................................................................................................................................11

Consumer Operating Instructions............................................................................................................................12

Quartz Tube Maintenance...........................................................................................................................................12

Scheduled UV Lamp(s) Replacement....................................................................................................................14

Lamp Replacement Procedure.................................................................................................................................14

Normal Operation .........................................................................................................................................................15

Bypass Operation ........................................................................................................................................................15

Winterization Of Your Ultra UV2 Unit .....................................................................................................................15

Troubleshooting .............................................................................................................................................................16

Ultra UV2 Part Numbers .............................................................................................................................................18