IV ULVAC CRYOGENICS INCORPORATED

Figures

Figure 1-1 Compressor Front Panel........................................................................... 7

Figure 1-2 Refrigerant Circuit Diagram...................................................................... 9

Figure 1-3 SW112-C Components inside................................................................. 10

Figure 1-4 SW112-C Control Components (Exterior components)......................... 12

Figure 1-5 SW112-C Control Components (Inside)................................................. 13

Figure 1-6 Remote connector pin locations............................................................. 14

Figure 1-7 Signal connector pin configuration......................................................... 14

Figure 1-8 Refrigerator connector pin locations ...................................................... 15

Figure 2-1 Maintenance space (unit: mm)............................................................... 17

Figure 2-2 Cooling water flow and inlet temperature............................................... 21

Figure 6-1 Electrical wiring....................................................................................... 29

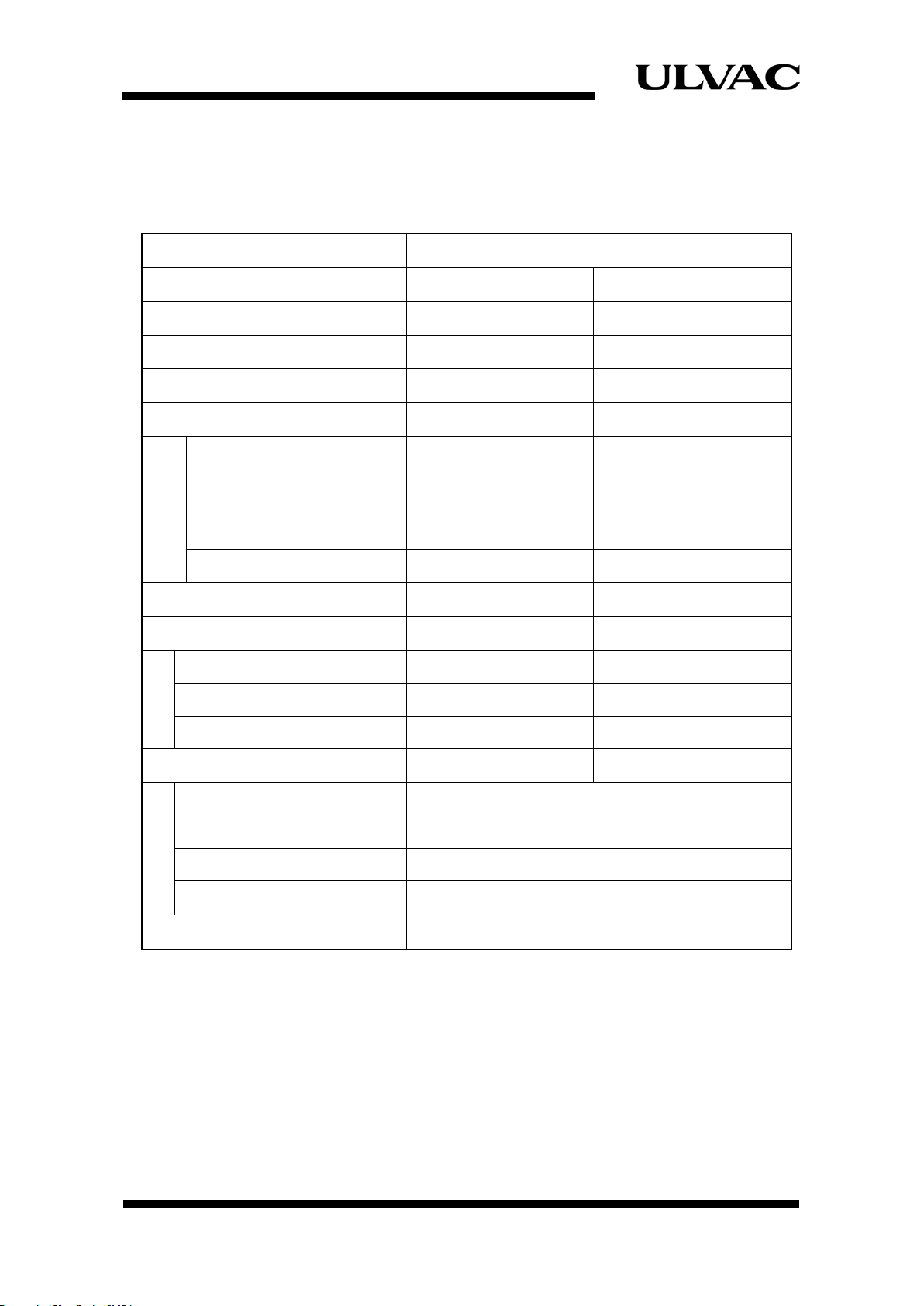

Tables

Table 1-1 Compressor Unit SW112-C Specifications............................................... 4

Table 1-2 Control and connection of the compressor unit....................................... 5

Table 1-3 Components and function......................................................................... 8

Table 1-4 List of control components.......................................................................11

Table 1-5 Remote sequence................................................................................... 14

Table 1-6 Remote connectors................................................................................. 14

Table 1-7 Monitor sequence ................................................................................... 14

Table 1-8 Applied connector for remote ................................................................. 14

Table 1-9 Refrigerator connector specifications..................................................... 15

Table 1-10 Connectors for the refrigerator ............................................................... 15

Table 1-11 Safeguards.............................................................................................. 15

Table 2-1 Electric wiring capacity ........................................................................... 19

Table 4-1 Fuse List (Spare fuses are attached to the product).............................. 25