4

INDEX

1. WARNINGS ......................................................................................................................................... 2

2. PRECAUTIONS FOR USE ...................................................................................................................3

3. NOTES CONCERNING THIS MANUAL .............................................................................................. 3

4. INTRODUCTION .................................................................................................................................. 5

5. DESCRIPTION OF CONNECTIONS AND CONTROLS ..................................................................... 6

6. DISPLAY UNIT ..................................................................................................................................... 7

7. POWER SUPPLY ................................................................................................................................ 7

7.1. Battery life ........................................................................................................................................ 7

7.2. Charging the batteries.......................................................................................................................7

7.3. Mains power supply unit .................................................................................................................. 7

8. ON/OFF SWITCH ................................................................................................................................ 7

9. IMPORTANT NOTE FOR USE ............................................................................................................ 8

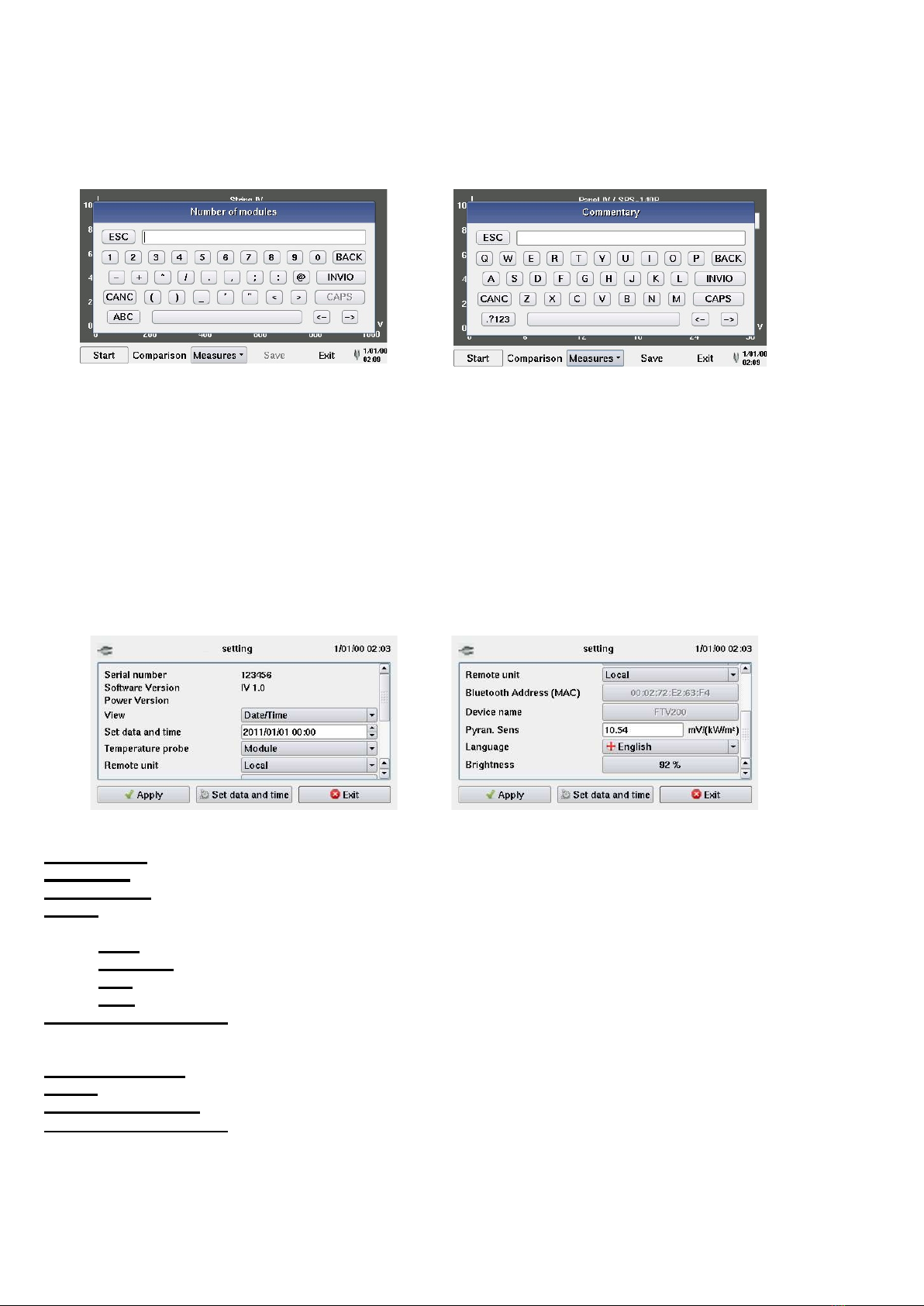

10. DESCRIPTION OF THE MENUS ........................................................................................................ 8

10.1. System ............................................................................................................................................. 8

10.2. Module Archive ................................................................................................................................ 9

10.3. Company Archive ...........................................................................................................................10

10.4. Measurements Archive ................................................................................................................... 11

10.5. Installations Archive ........................................................................................................................ 11

10.6. USB............................................................................................................................................... 12

10.6.1. USB-Bluetooth adapter ......................................................................................................... 12

10.6.2. USB pen drive ....................................................................................................................... 12

11. MAKING MEASUREMENTS .............................................................................................................. 14

11.1. Electrical connections: .................................................................................................................... 14

11.2. Remote Unit ................................................................................................................................... 15

11.3. Module or String..............................................................................................................................15

11.3.1. Interpreting the measurement results………………………………………………………….. 21

11.4. Other functions ............................................................................................................................... 22

11.4.1. "FS" (full scale) function ........................................................................................................ 22

11.4.2. Zoom Function ...................................................................................................................... 22

12. TECHNICAL CHARACTERISTICS ..................................................................................................... 24

12.1. Reference conditions ...................................................................................................................... 24

12.2. Specifications ................................................................................................................................. 24

12.3. Environmental conditions ............................................................................................................... 24

12.4. Construction specifications ............................................................................................................ 25

12.5. Electromagnetic compatibility ........................................................................................................ 25

12.6. Mechanical protection .................................................................................................................... 25

13. I-V Tracer 935 PC SOFTWARE ............................................................................................................ 26

13.1 General information ........................................................................................................................ 26

13.2 Installation ...................................................................................................................................... 26

13.3 Using the program .......................................................................................................................... 27

13. MAINTENANCE ................................................................................................................................. 36

13.1. Cleaning ......................................................................................................................................... 36

13.2. Metrological check .......................................................................................................................... 36

13.3. Repair ............................................................................................................................................ 36

14. WARRANTY ....................................................................................................................................... 37

15. TO ORDER ........................................................................................................................................ 38

15.1. Optional accessories ...................................................................................................................... 38

15.2. Spare parts .................................................................................................................................... 38

16. LIST OF POP-UP DISPLAY MESSAGES ..........................................................................................39